Air-cooled heat-dissipation axial flow cooling fan for electronic equipment

A technology for electronic equipment and cooling fans, which is applied to structural components of electrical equipment, cooling/ventilation/heating transformation, mechanical equipment, etc. It can solve the problems of large air volume, high noise, and high back pressure, and achieve large air volume and reduce aerodynamic noise , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

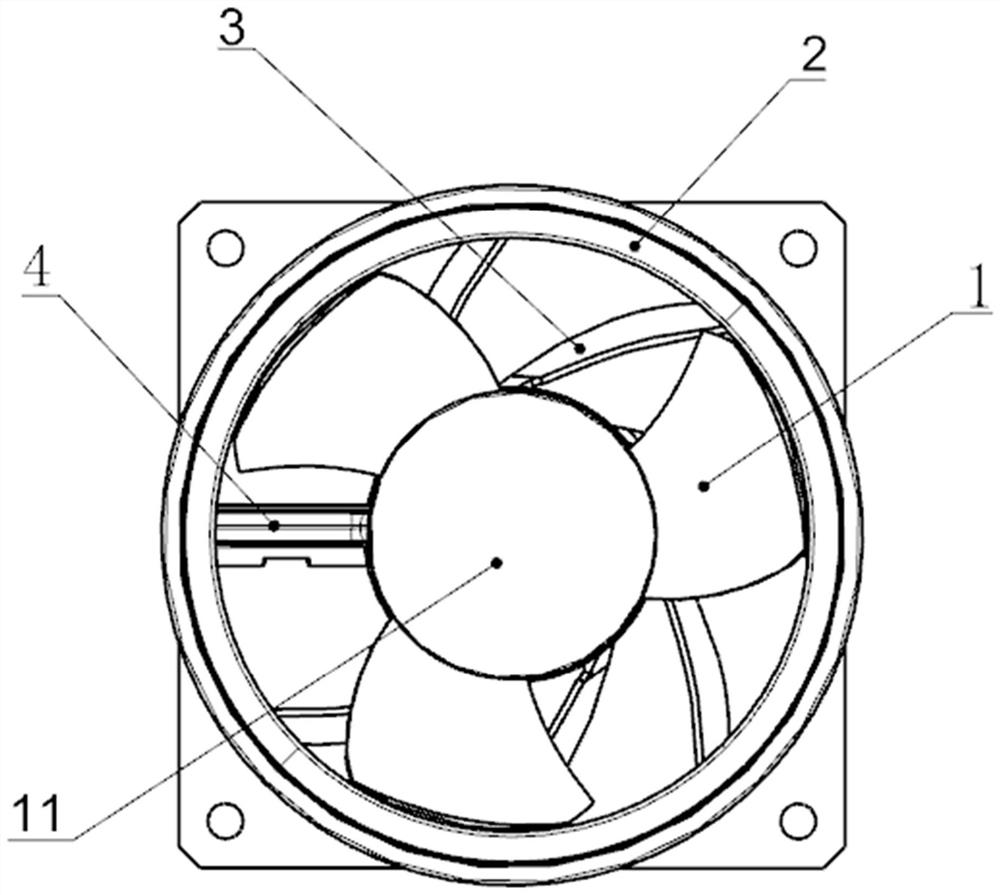

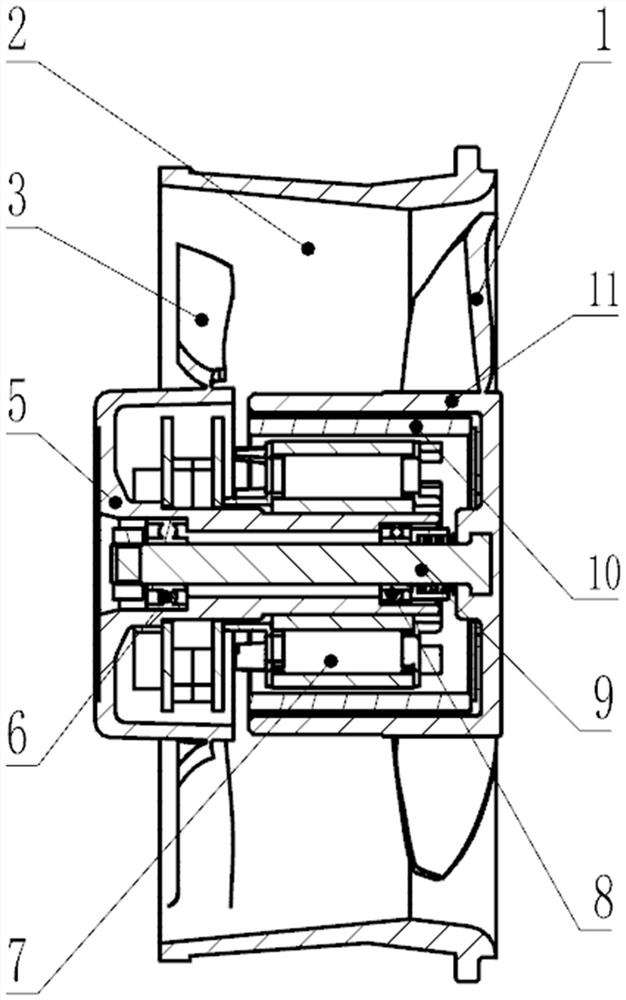

[0019] refer to figure 1 , figure 2. In the preferred embodiment described below: an air-cooled heat dissipation axial cooling fan for electronic equipment, including: a motor located in the casing 2 connected through a cable channel 4, an impeller fixed in the pipe of the casing 2 and connected to the hub of the motor And the blade 1 is characterized in that: the casing is a double-funnel-shaped inclined-angle air-channel casing with a wide front end, a narrow middle, and a wide rear, with an inclined inner wall and the middle cross-sections change according to a linear law. Adopt the installation angle of at least 27.4°, the forward bending angle of the blade is at least 30.6°, the suction surface with an upward inclination of at least -14° and the pressure surface with a downward inclination of at least -11° constitute an axial flow sweeping blade, and the rear end of the flow channel is set There is a spiral guide vane 3 with an installation angle of at least 65° at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com