Heatsink and cooling apparatus

A heat-absorbing device and heat-generating body technology, applied in lighting devices, cooling/heating devices of lighting devices, cooling/ventilation/heating transformation, etc., can solve problems such as noise, inability to cool LED lighting appliances with forced convection cooling devices, etc. To achieve the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

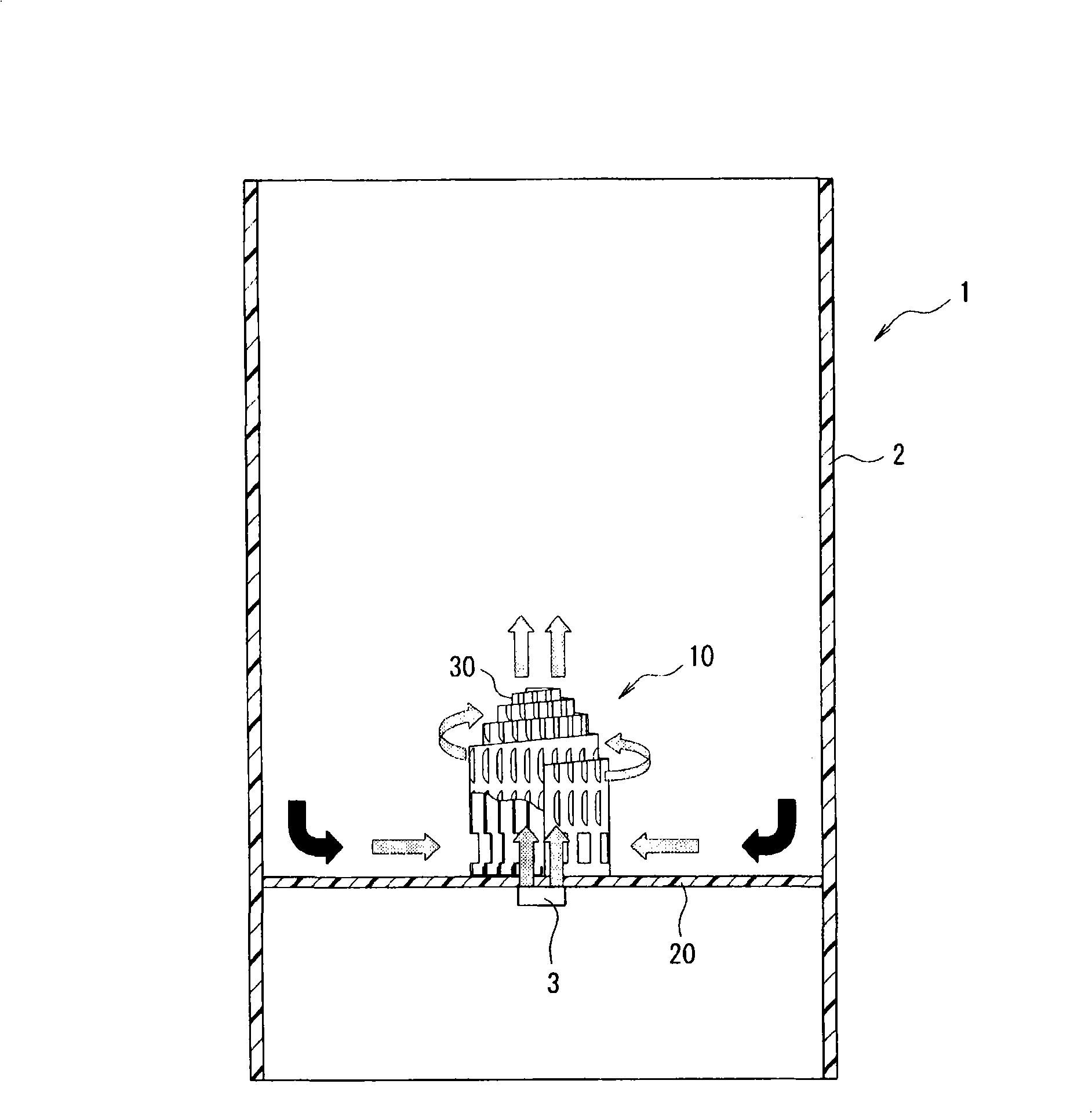

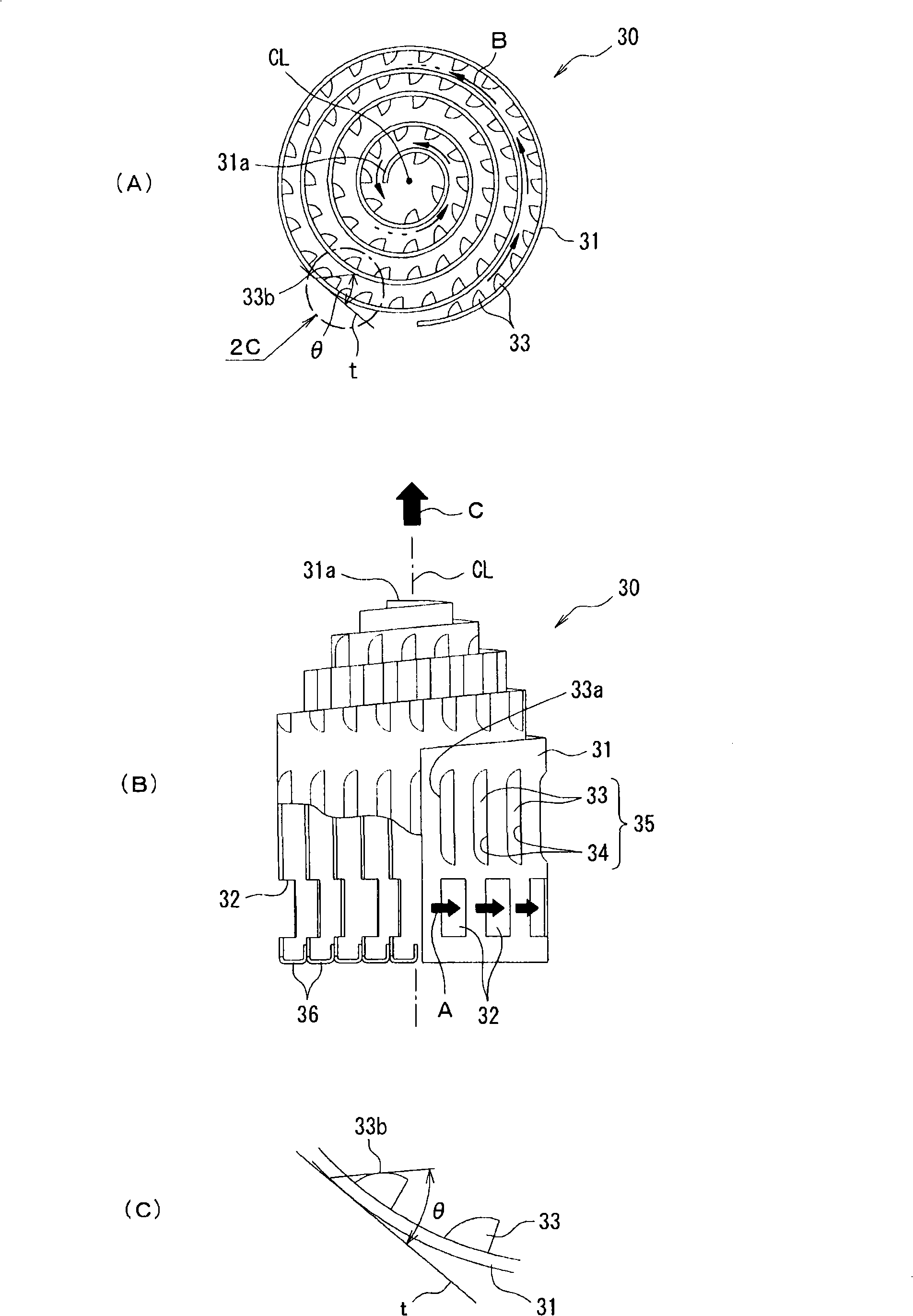

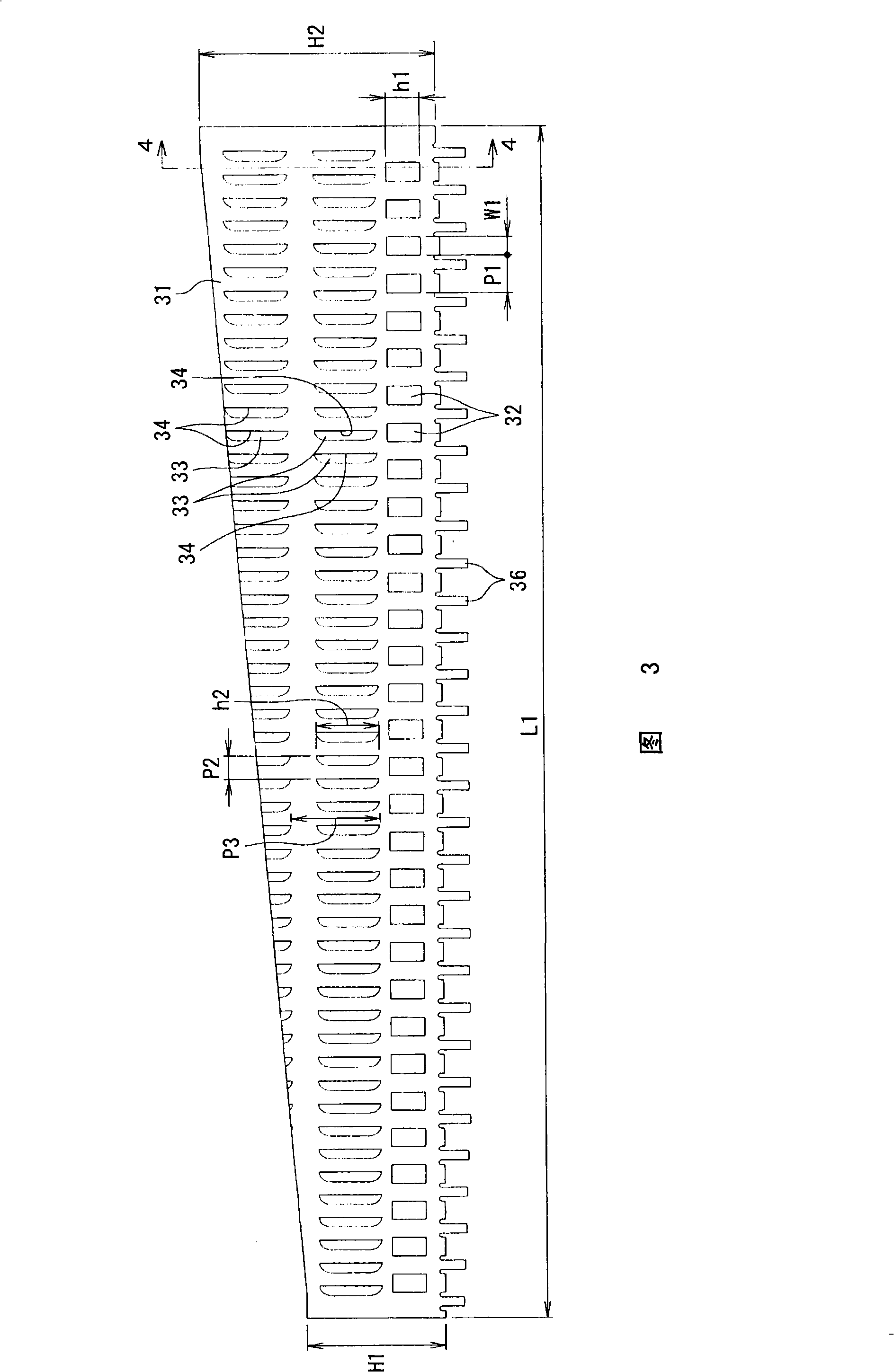

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic cross-sectional view showing a state in which the heat absorbing device according to the first embodiment of the present invention is attached to a lighting fixture. figure 2 express figure 1 (A) is a top view, (B) is a front view with a part cut off, and (C) is an enlarged view of a part indicated by an arrow 2C in (A). Figure 3 is to constitute the figure 2 A top view of the expanded state of the metal sheet of the heat sink. Figure 4 It is a cross-sectional view taken along line 4-4 in FIG. 3 .

[0045] figure 1 Among them, a printed wiring board 20 with LEDs (heating elements) 3 mounted on the lower surface is mounted in a housing 2 of a lighting fixture 1 . And the heat sink 30 for cooling the LED3 which generate|occur|produces heat is attached to the upper surface of the printed wiring board 20. As shown in FIG. The printed wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com