Patents

Literature

117results about How to "Meet drawing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant for drawing spring steel wire

ActiveCN103897787AConsistent colorSignificant change in softening pointLubricant compositionSide effectBorax

The invention provides a lubricant for drawing a spring steel wire. The lubricant for drawing the spring steel wire comprises the following components in percentage by weight: 40-60% of calcium stearate, 35-55% of softening point regulator and 5%-8% of extreme pressure additive, wherein the softening point regulator is one or more selected from calcium hydroxide, titanium dioxide, zinc oxide, sodium carbonate, sodium silicate, borax and paraffin. The lubricant is characterized in that the softening point of the lubricant changes obviously in a drawing process, and in the viscosity-temperature change of the lubricant, the lubricant is brought into a mold during drawing, and therefore, the requirements of the drawing process can be met. The lubricant has the advantages that the protection capacity of the lubricant on the surface of the steel wire is further improved, the subsequent heat treatment is not affected after drawing, no toxic or side effects are produced, a stable lubricating film can be formed on the surface of the steel wire under severe wire drawing conditions, and the wire drawing process is stabilized and the surface of the steel wire is protected against scratch.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

Finite element compensation method for deformation of numerical control processed part

InactiveCN102354161AMeet drawing requirementsProgramme controlComputer controlNumerical controlElement model

The invention relates to a finite element compensation method for the deformation of a numerical control processed part, which comprises the following steps: saving the part as a digital model by using modeling software, converting the digital model to finite element analysis software, establishing a finite element model, defining a unit, a section and a material, completing the division of a unit grid, adding load and constraint according to a working condition, and performing calculation on the deformation of the part, which is caused by a clamping force borne by the part; outputting the deformation of all nodes on a plane or a line which needs to be processed, and drawing out the shape of the part under the clamping force according to the deformation by using the modeling software; according to the shape of the part under the clamping force, performing numerical control programming; and after processing is ended, loosening clamping to return the elasticity of the part to be normal. In the finite element compensation method for the deformation of the numerical control processed part, computer finite element analysis software and computer-aided design / computer-aided manufacturing (CAD / CAM) software are utilized, and a special fixture or special equipment does not need to be designed or manufactured, thereby, the processing cost is saved, the production efficiency is improved, and the processing quality is ensured.

Owner:SHANGHAI DIANJI UNIV

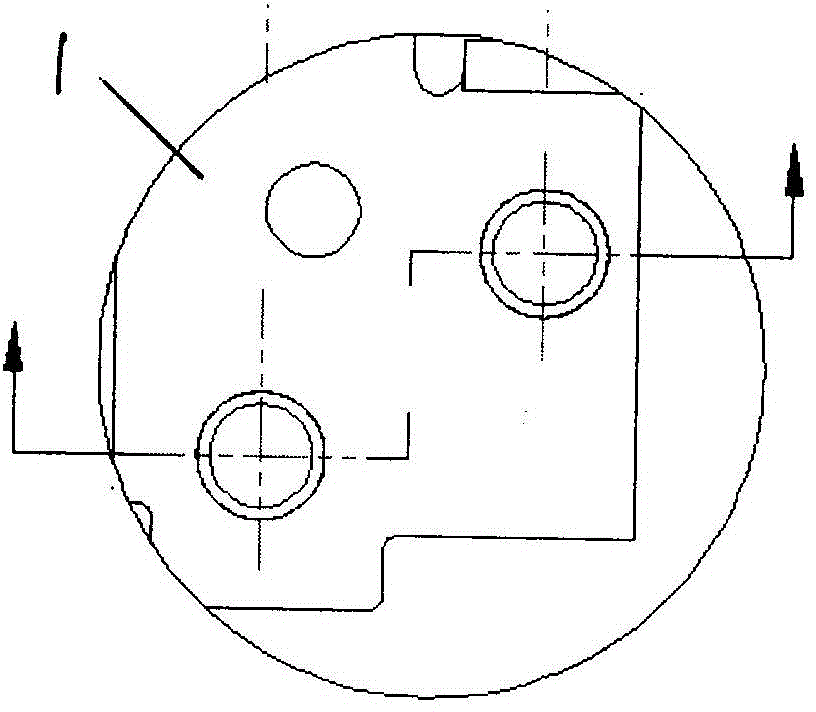

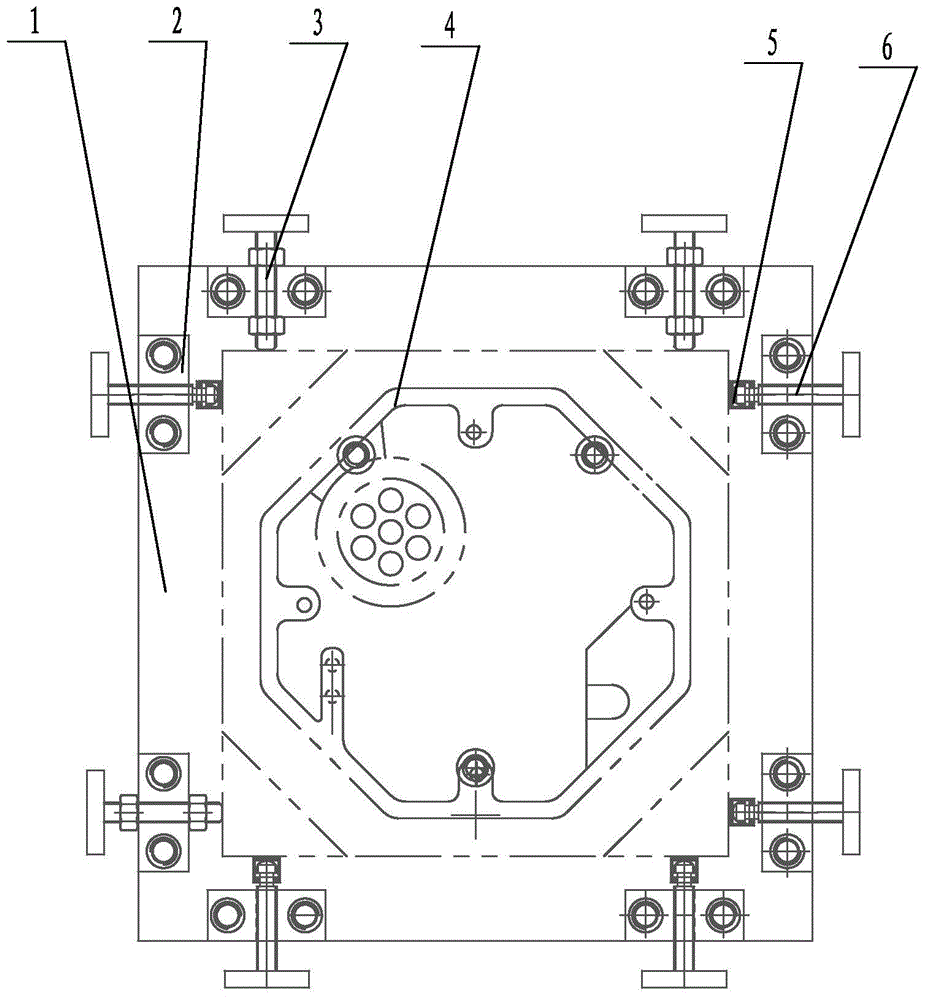

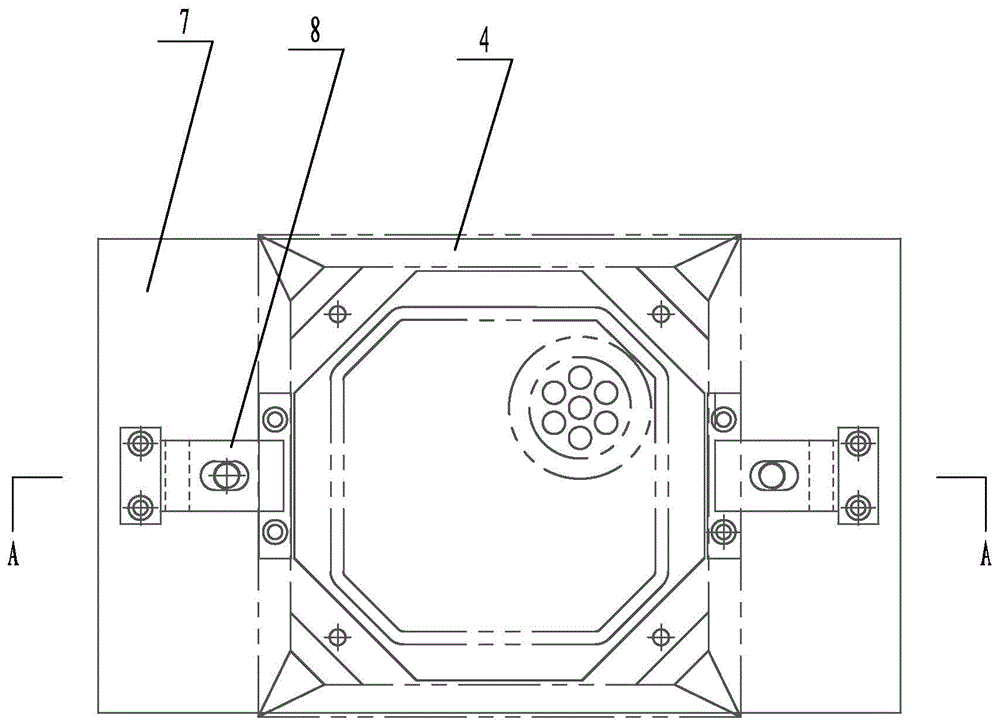

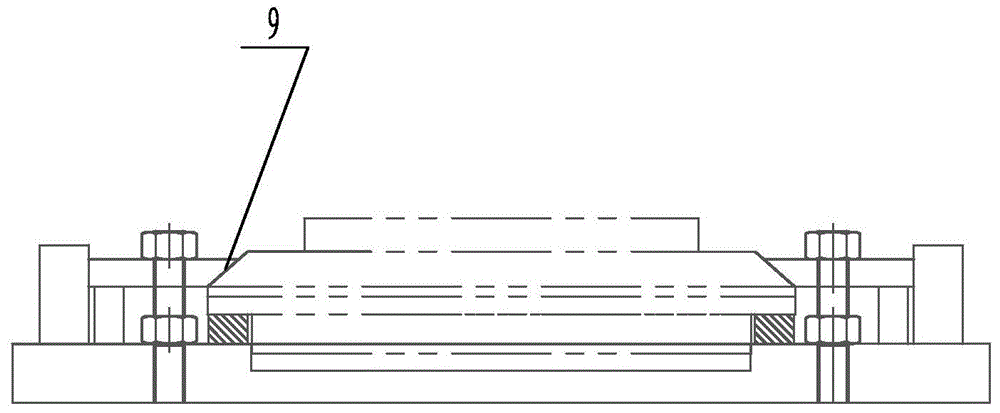

Hydraulic combination clamping device for cylinder body

InactiveCN102328230AEasy to installPrecise positioningPositioning apparatusMetal-working holdersEngineeringCylinder block

Owner:TIANJIN BAOLAI PRECISION MACHINERY

H-shaped beam fitting up device and fitting up method

InactiveCN101628367AHigh precisionMeet drawing requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses an H-shaped beam fitting up device and a fitting up method. The body of the device comprises a work bench; both sides of one end of the work bench are respectively provided with a support; the upper part of the support is connected with a pin shaft in a penetrating way; the pin shaft is pivoted with a bearing which is fixedly connected with a round tube; the end part of the round tube is connected with two positioning plates arranged in parallel and provided with laser openings by an end plate; the upper part of the end plate is articulated with one end of an actuating arm; and the other end of the actuating arm is connected with a threaded rod provided with a hand wheel on the top part in a penetrating way. When fitting up, a rib plate is vertically inserted into the laser opening of the positioning plate, and an H-shaped steel is levelly laid on the rid plate, the actuating arm is erected straightly, the H-shaped steel is tightly compressed and fixed by screwing off the threaded rod by screwing the hand wheel; and finally, point welding is completed by converting the device by screwing a handle. The invention can better ensure product accuracy, meanwhile, is convenient for workers to carry out fitting up and welding, thereby improving the working efficiency and providing strong guarantee for enterprises to carry out volume production of H-shaped beams with different types and line production.

Owner:天津豪钢机械工程有限公司

Stable heat processing method of titanium alloy part

ActiveCN104004982AGuaranteed structural sizeGuaranteed product performanceTitanium alloyHeat processing

The invention provides a stable heat processing method of a titanium alloy part. A stable heat processing clamp is used for processing the titanium alloy part, the problems that residual stress and a structure are not even in the processing process of the titanium alloy part are effectively resolved, and therefore the structural size and the product performance of the titanium alloy part are guaranteed.

Owner:吉林航空维修有限责任公司

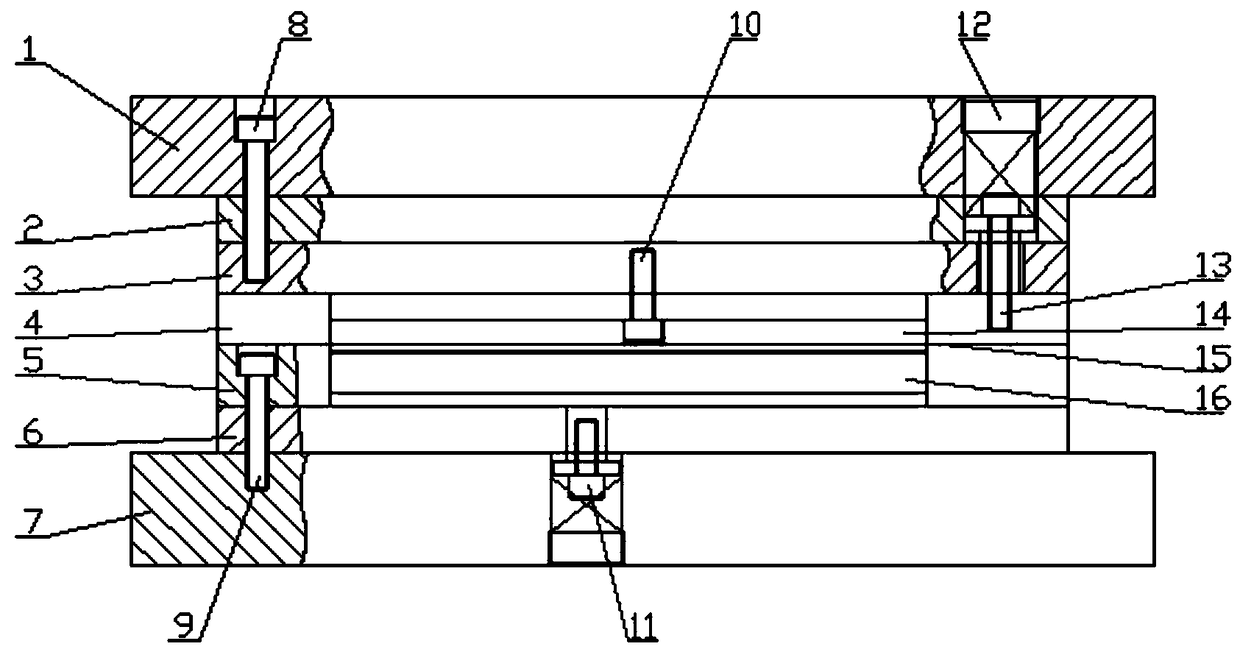

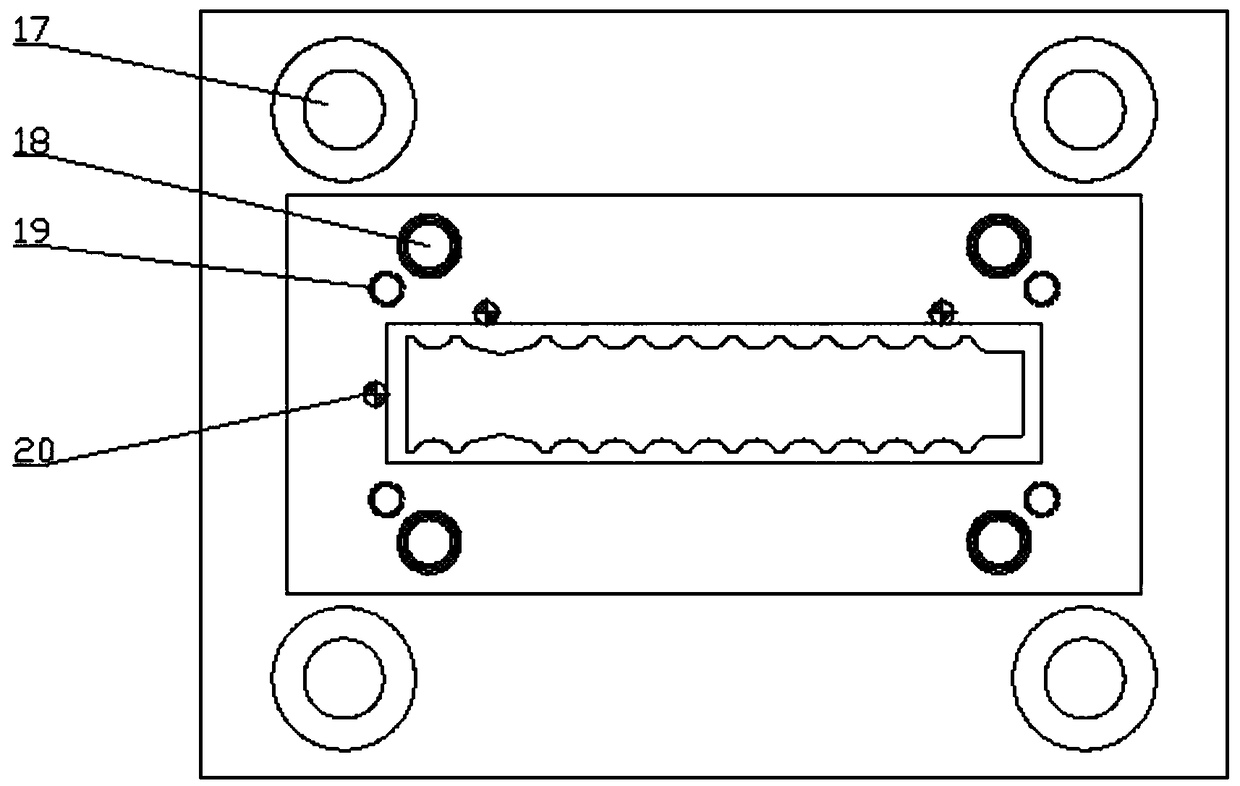

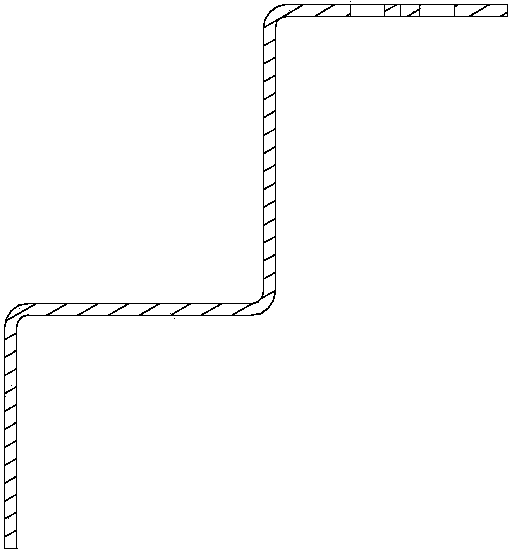

Coining die for outer strip of nuclear fuel assembly positioning grid frame

InactiveCN109500253AMeet drawing requirementsMeet the technical requirementsShaping toolsPunchingEngineering

The invention discloses a single-station die applied to the machining of an outer strip of a fuel assembly positioning grid frame. The single-station die applied to the machining of the outer strip ofthe fuel assembly positioning grid frame aims to meet the machining mode of the outer strip of the fuel assembly positioning grid frame and enable the outer strip of the positioning grid frame to meet the drawing and technical requirements, so that the smooth production of products is ensured. An overall shape punching die, an outer strip end bending and chamfering die and a right-angle bending and overlapping bending die are included.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

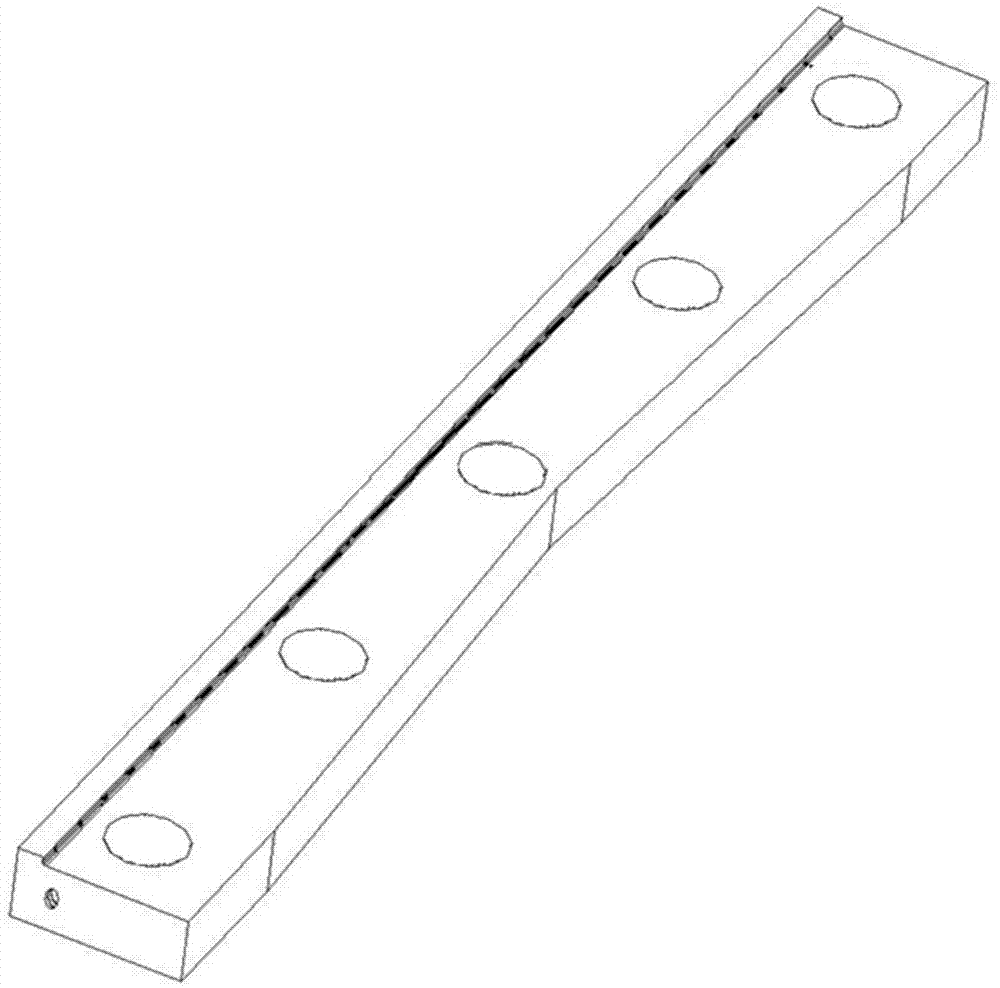

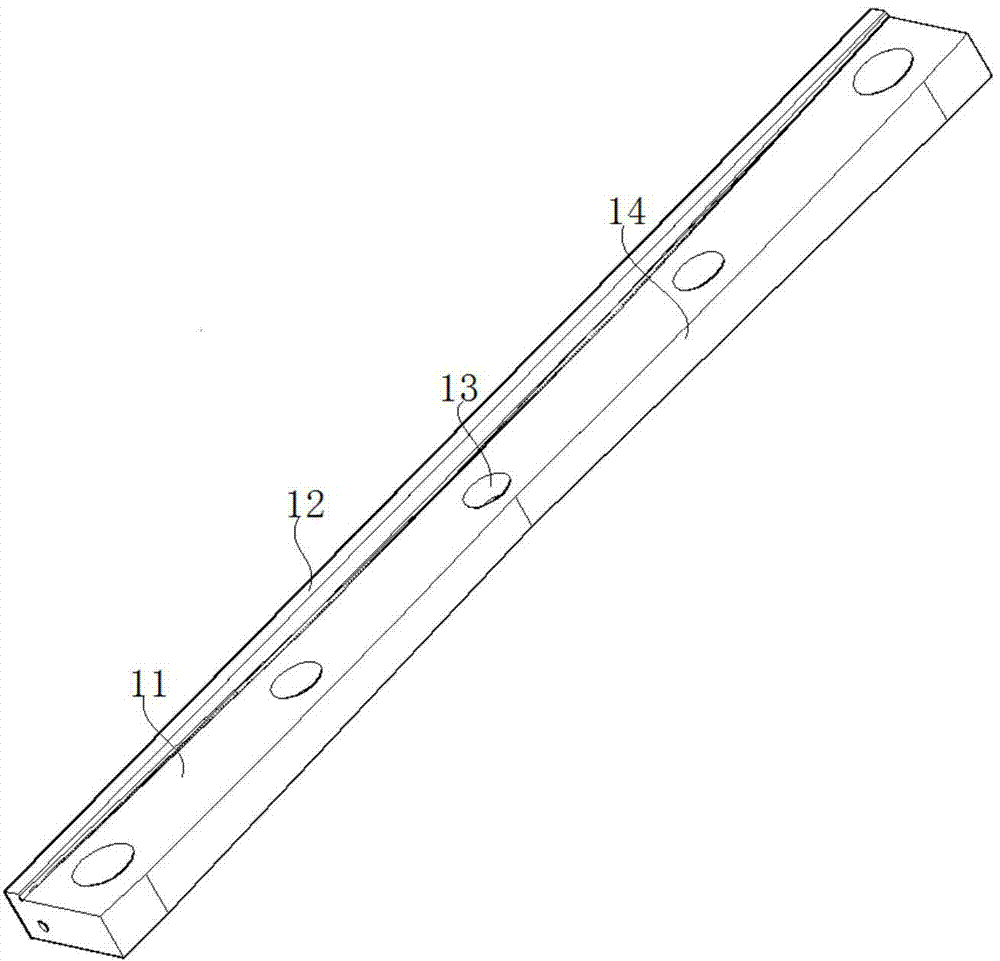

Preparation method of aluminum oxide ceramic guide rail

The invention relates to a preparation method of an aluminum oxide ceramic guide rail and belongs to the technical field of ceramic guide rail preparation. The preparation method comprises the following steps of: (1) mixing aluminum oxide and a sintering aid, mixing the mixture, water, a dispersing agent and a binder, and carrying out ball milling to obtain required slurry; (2) spray-drying the slurry to obtain granulation powder for later use; (3) performing a cold isostatic pressing process on the granulation powder to obtain a biscuit; (4) performing inner hole cutting on the biscuit by using fretsaw equipment to obtain a square hole ceramic guide rail biscuit; (5) sintering the green body to obtain a blank, milling the blank, and carrying out sintering to obtain a crude product; and (6) carrying out accurate grinding and polishing on the crude product to obtain the aluminum oxide ceramic guide rail. The preparation method is scientific and reasonable in design, and the prepared ceramic guide rail has the advantages of low volume density, high hardness, large elastic modulus, low thermal expansion coefficient, high hardness and high wear resistance.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

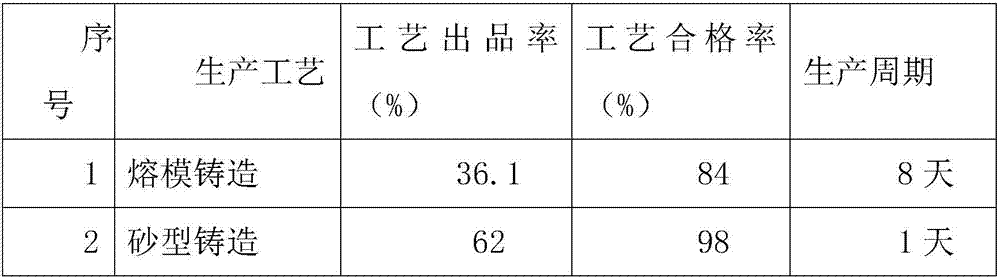

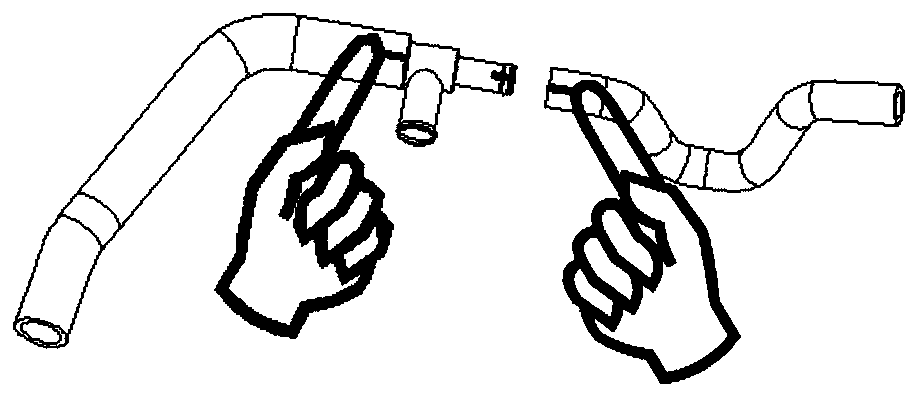

Sand mold casting process for heat-resisting alloy steel thin-wall pipe fitting

InactiveCN107385282AImprove yieldIncrease productivityFoundry mouldsFoundry coresInvestment castingPipe fitting

The invention discloses a sand mold casting process for a heat-resisting alloy steel thin-wall pipe fitting. The heat-resisting alloy steel thin-wall pipe fitting comprises the following raw materials of, by weight, 0.35%-0.55% of C, 1%-2% of Si, 0-1.5% of Mn,0-0.04% of P, 0-0.03% of S, 27%-30% of Cr, 47%-50% of Ni, 0-0.5% of Mo, 4%-5.5% of W, and the balance Fe. According to the sand mold casting process, through improvement of the traditional process for a thin-wall M-shaped elbow casting, investment casting is changed to be sand mold casting, the casting yield and production efficiency are improved greatly, the casting size meets the requirement of a drawing, the process yield is increased to 56%, the casting pass rate is increased to 98%, and very good economic benefits are achieved.

Owner:烟台市中拓合金钢有限责任公司

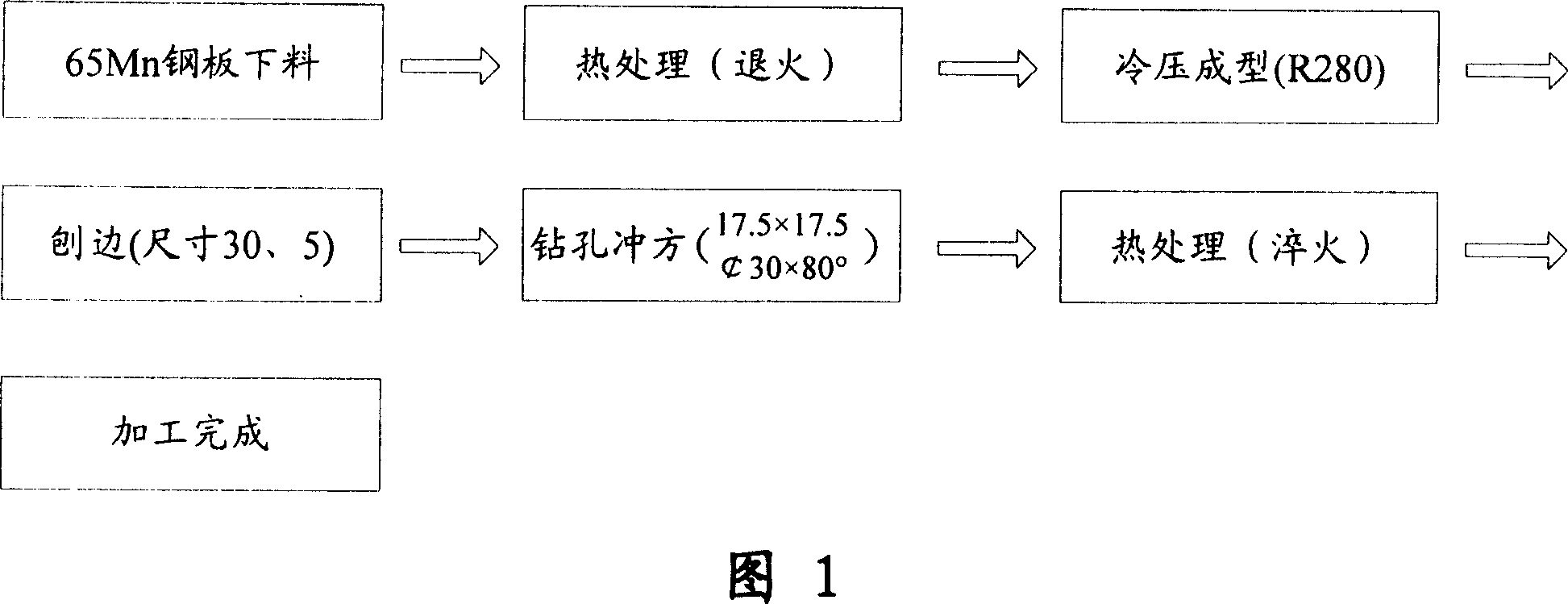

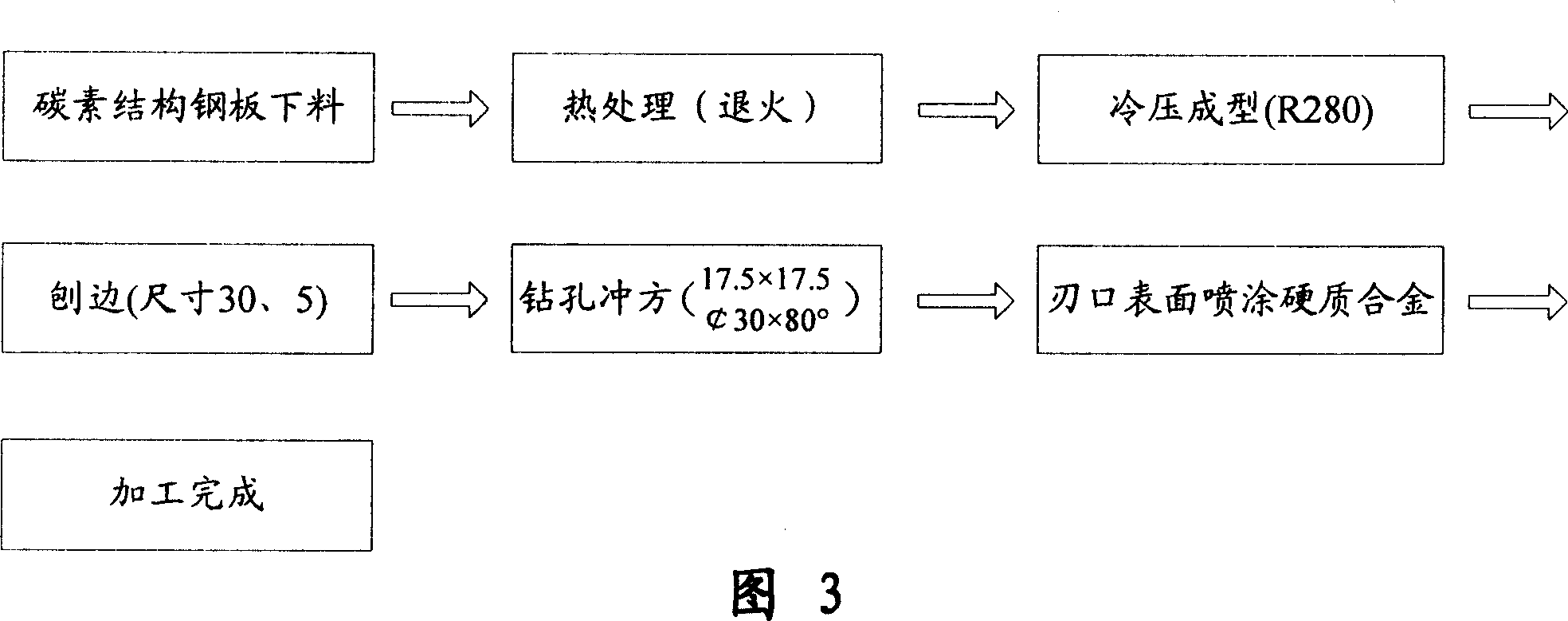

Pendulum-type concave-convex shear blade

Owner:MAANSHAN HENGLIDA MACHINE BLADE

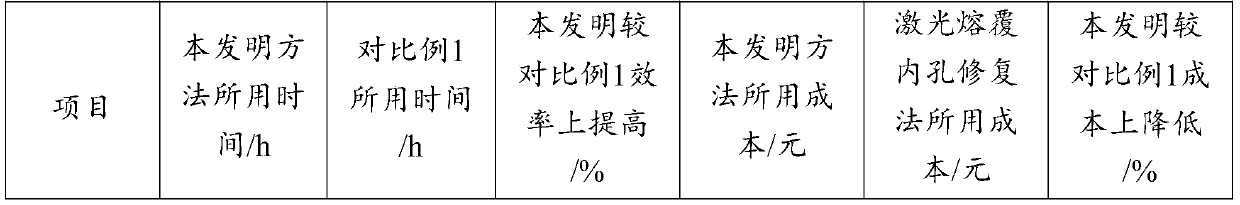

Hydraulic support oil cylinder refabrication method based on CMT (Cold Metal Transition)

The invention provides a hydraulic support oil cylinder refabrication method based on CMT and belongs to the technical field of metal surface engineering. The hydraulic support oil cylinder refabrication method comprises the steps that mechanical machining and cleaning are firstly performed on the oil cylinder inner wall to be repaired in sequence, then CMT welding is performed on the hydraulic support oil cylinder inner wall, finally, the mechanical machining is performed on a CMT weld layer, and a refabricated hydraulic support oil cylinder is obtained. According to the hydraulic support oilcylinder refabrication method based on the CMT, the cold metal transition welding technology is utilized to weld the hydraulic support oil cylinder inner wall, heat input and spatter are less in thewelding peocess, the fact that the refabricated oil cylinder will not lose efficacy due to heat deformation can be guaranteed, and the service life of the oil cylinder is prolonged; by means of the manner that the mechanical machining is performed on the oil cylinder inner wall before and after the welding, the surface smoothness, the size and the tolerance of the oil cylinder all can be guaranteed to meet the drawing requirements; and meanwhile, the refabrication method provided by the invention is low in cost and high in efficiency, and full-automatic production can be realized.

Owner:YANSHAN UNIV

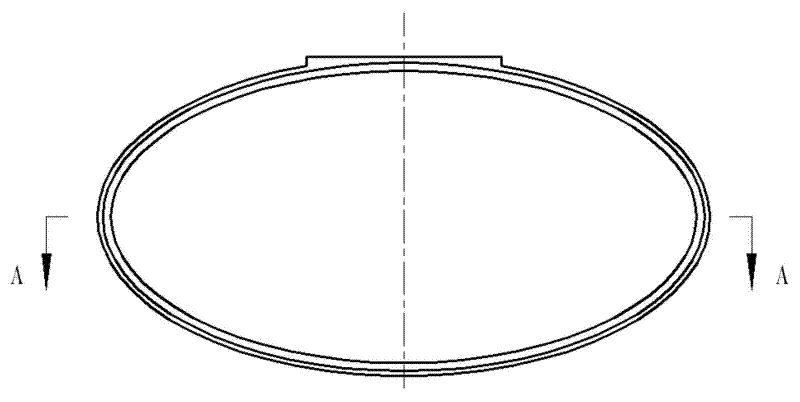

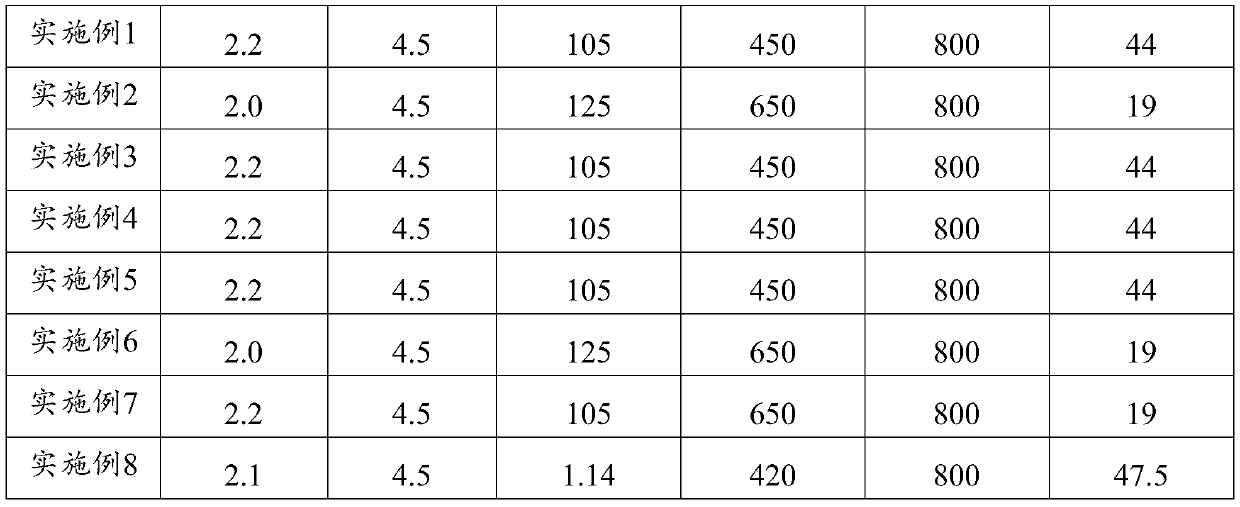

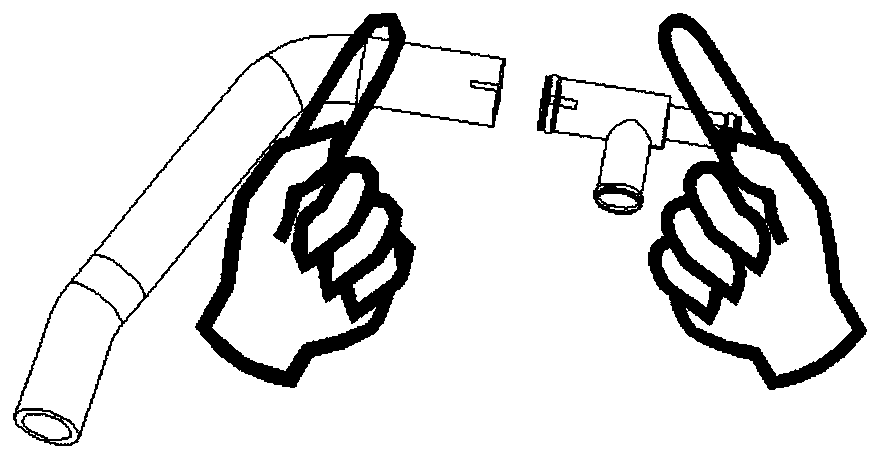

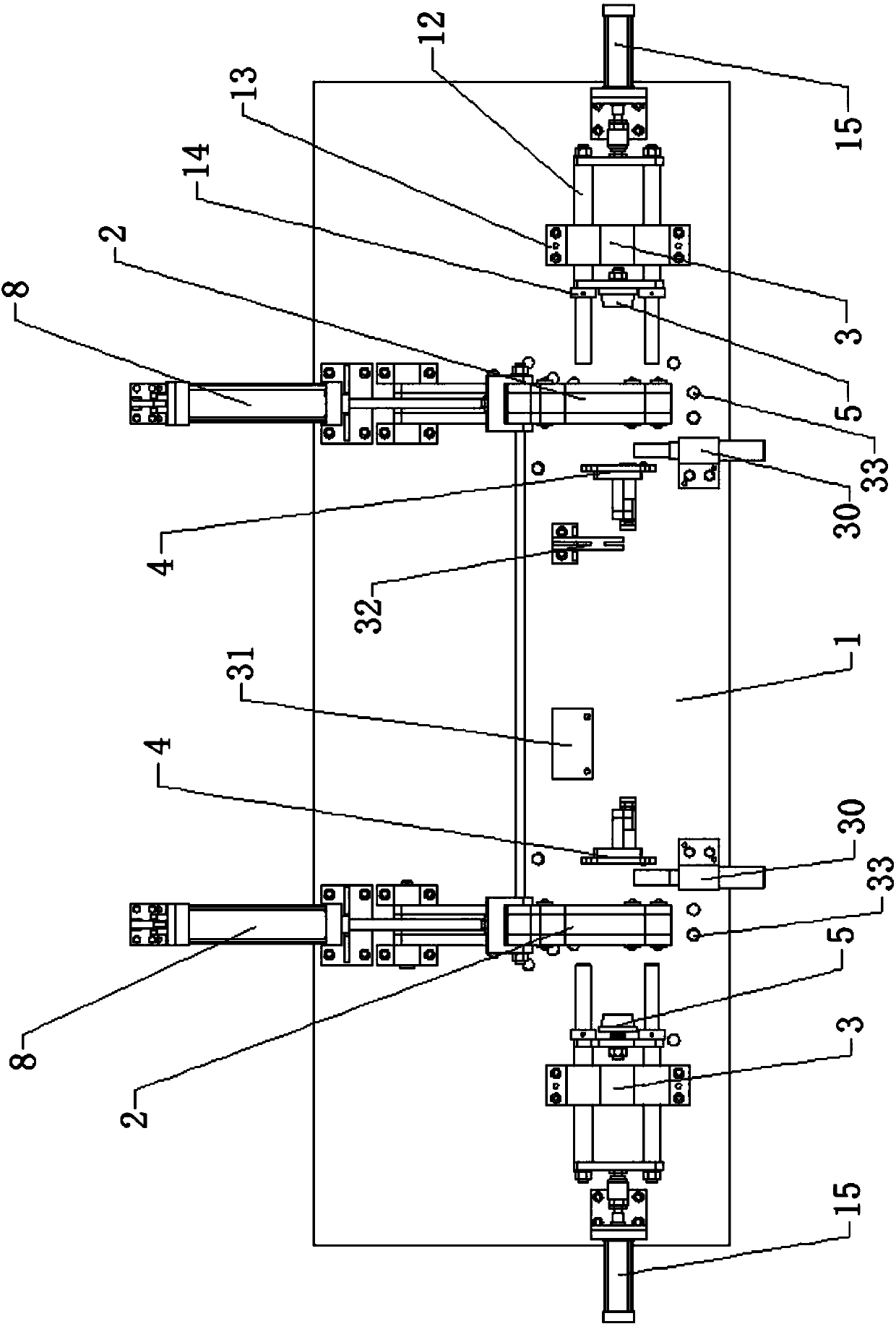

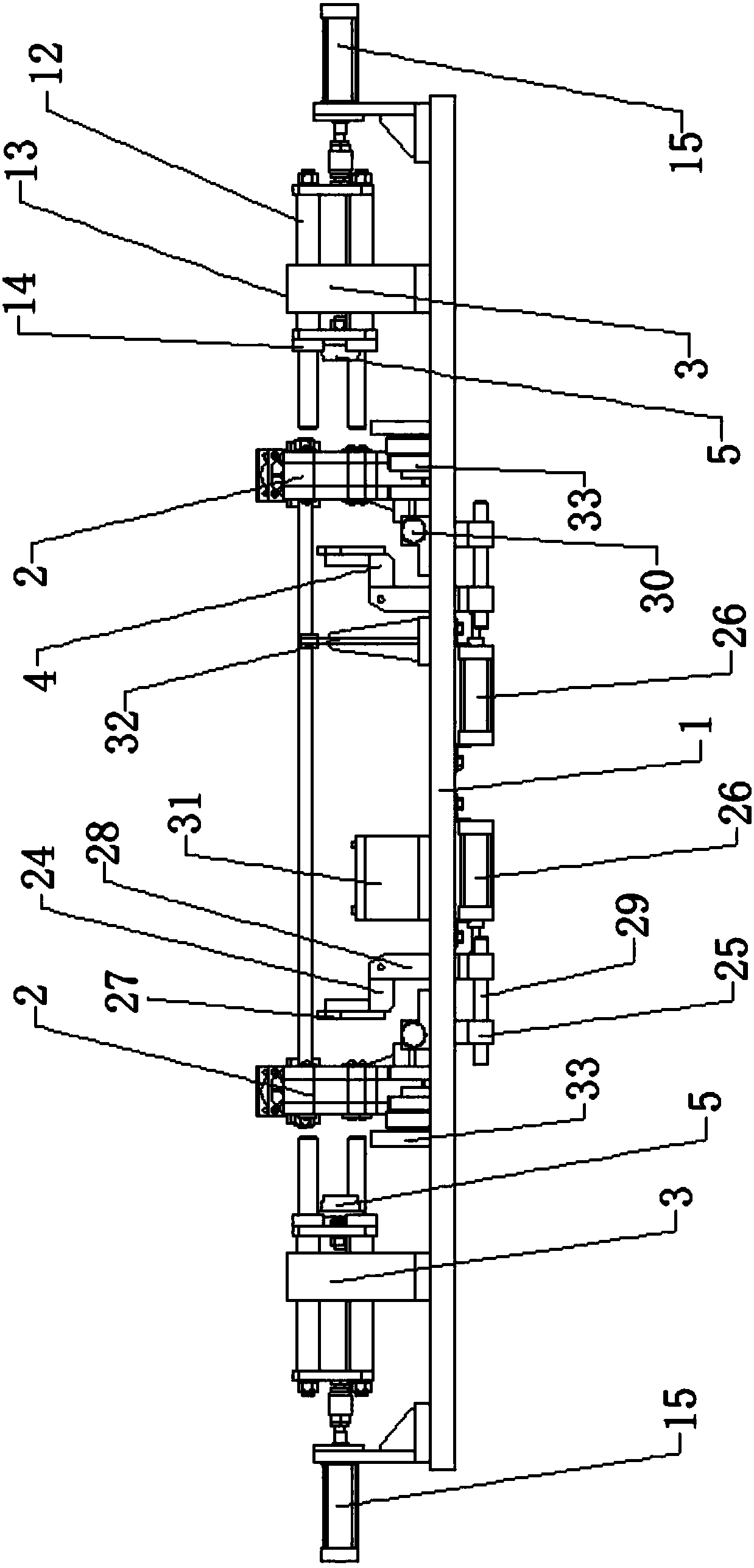

Mounting machine and mounting process for clamp, rubber tube and joint

PendingCN111300039AAdvantages of installation processIncrease productivityAssembly machinesEngineeringMachine

The invention provides a mounting machine and a mounting process for a clamp, a rubber tube and a joint. The mounting machine comprises a workbench and a bottom cabinet, wherein the workbench is mounted on the bottom cabinet, a joint angle positioning die, a rubber tube angle positioning die, a clamp angle positioning die and a slide rail are mounted on the workbench, the middle of the slide railis used for installing the joint angle positioning die, the two sides of the joint angle positioning die are provided with the rubber tube angle positioning die and the clamp angle positioning die correspondingly, all positioning die bottom plates are installed on the slide rail, and all the positioning dies are provided with profiling grooves used for installing the rubber tube, the joint and theclamp correspondingly. According to the machine and the process, the speed is high, one assembly can be completed within 10 s, the number of workers is small, only one worker is needed for completingthe assembly, the product accuracy is high, deviation is avoided, the drawing requirement can be met, operation is easy, full-automatic assembly is achieved, and the labor intensity of the worker isrelieved.

Owner:四川省胜顺鸿兴模具有限公司

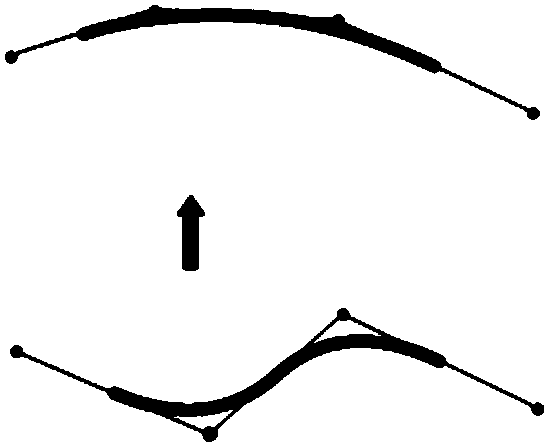

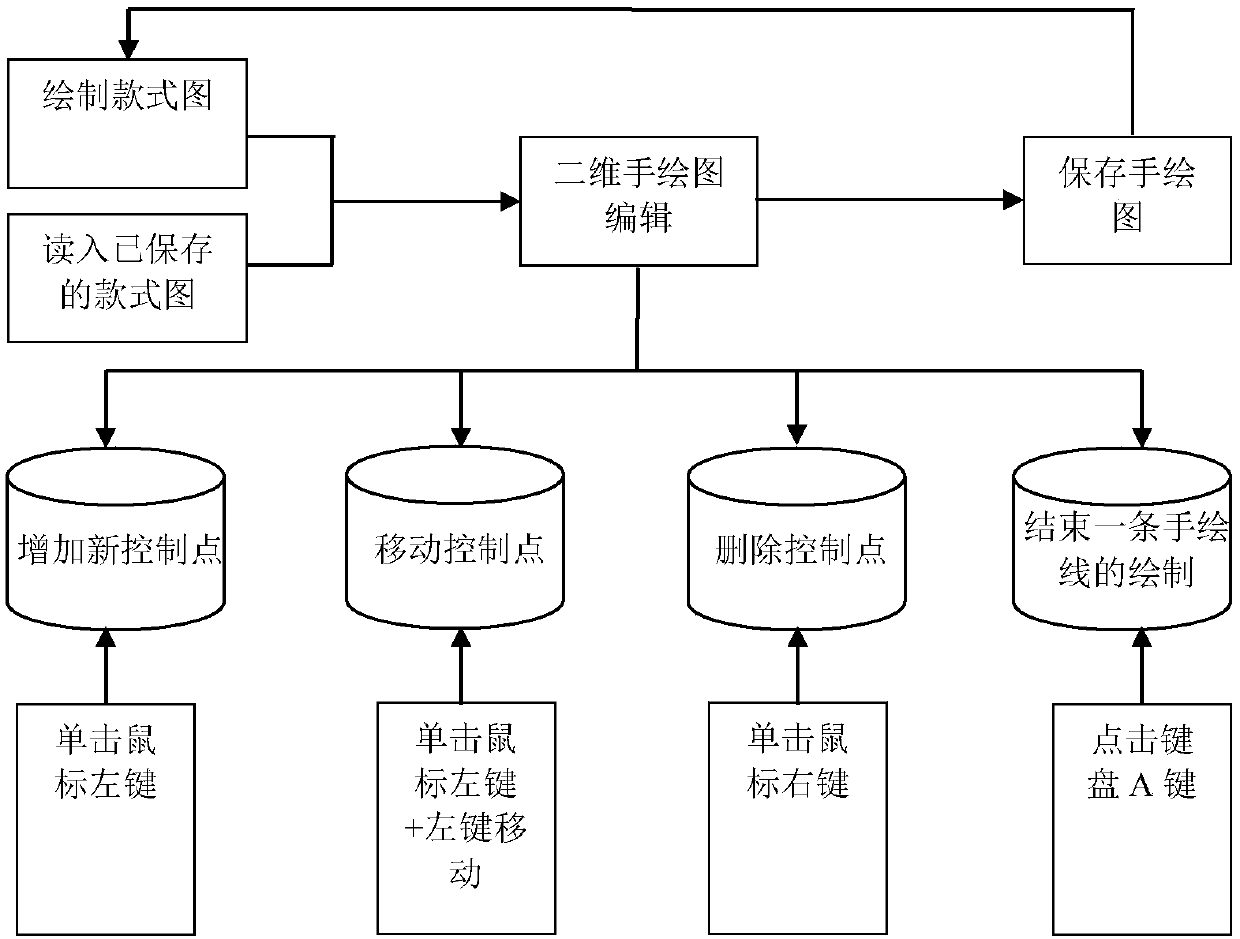

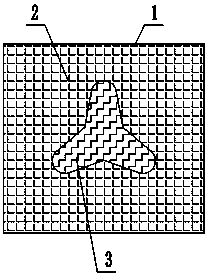

Two-dimensional digitalized clothes style drawing design system

InactiveCN107788600AGive continuityGuaranteed independenceSpecial data processing applicationsClothes making applicancesEngineeringDigitization

The invention brings forward a two-dimensional digitalized clothes style drawing design system, pertaining to the technical field of digitalized clothes design. A drawing process of a designer is integrated into the clothes style drawing design system. A two-dimensional clothes style drawing which is traditionally drawn by the clothes designer with paper and a pen is converted into a two-dimensional digitalized style drawing with coordinate information. The system comprises the following steps: utilizing B sample curves to fit style drawing lines drawn by the designer; drawing, altering and editing clothes style drawings in an interactive manner; performing reading operation with a data structure of a singly linked list and saving lines of style drawings. The system utilizes the data structure of the singly linked list to store data of hand-drawn line control points so that editing efficiency of hand-drawing is increased while hand drawings can be stored.

Owner:JINLING INST OF TECH

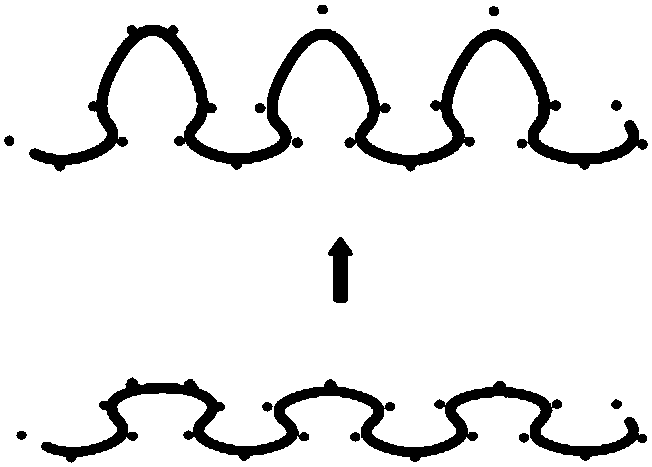

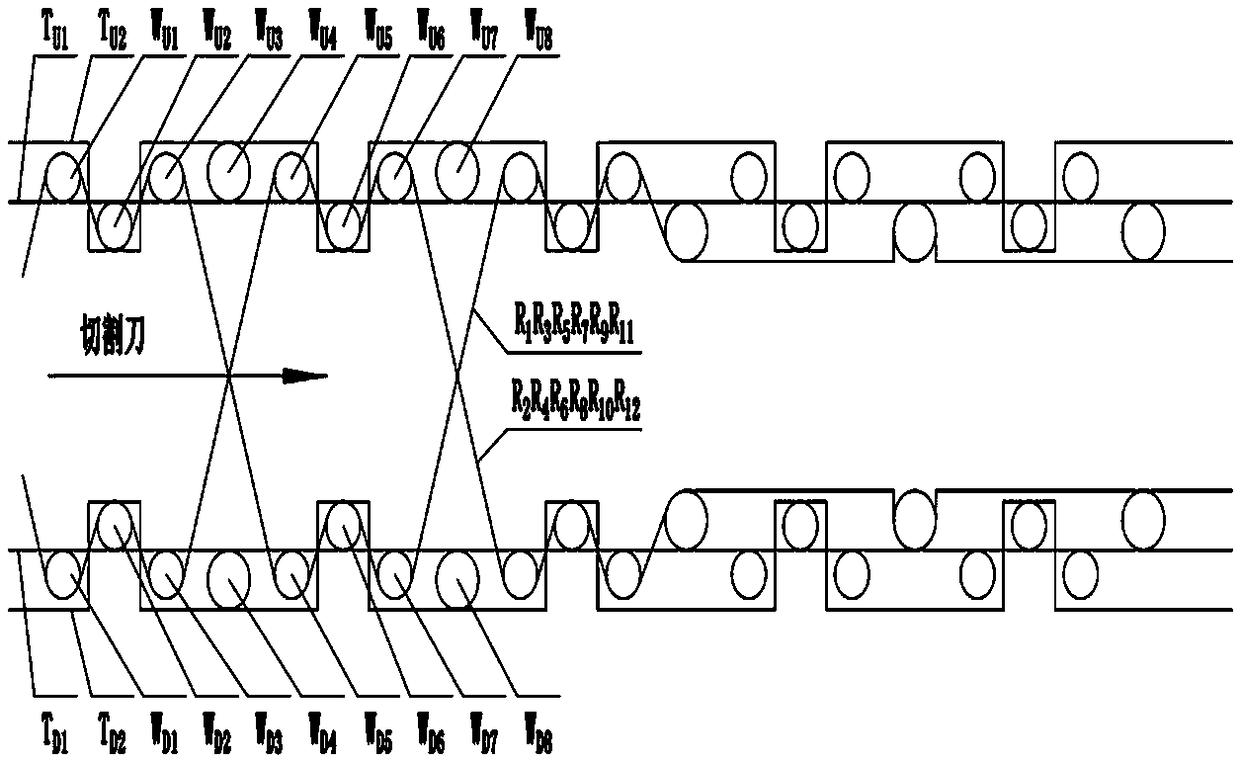

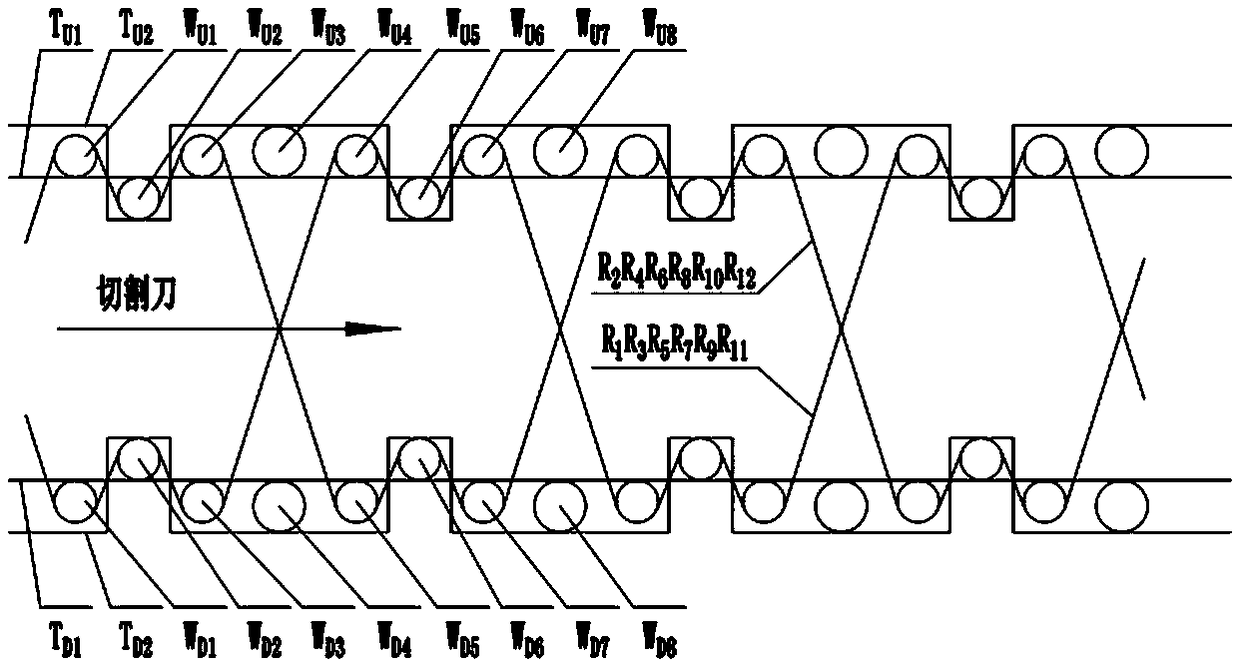

Silk borcade velvet with honeycomb cloth arranged at bare bottom of velvet and weaving method thereof

InactiveCN108239811AMeet yarn requirementsMeet drawing requirementsMulti-ply fabricsSwivel-woven fabricsHoneycombEngineering

The invention provides silk brocade velvet with honeycomb cloth arranged at bare bottom of the velvet and a weaving method thereof and belongs to the technical field of textile. The silk brocade velvet comprises an upper base cloth layer, a lower base cloth layer and a connecting line; a fourth weft yarn, an eighth weft yarn, a twelfth weft yarn, a sixteenth weft yarn, a twentieth weft yarn, a twenty fourth weft yarn, a twenty eighth weft yarn and a thirty second weft yarn of the upper layer are thick weft yarns, and the other weft yarns of the upper layer are thin weft yarns; a fourth weft yarn, an eighth weft yarn, a twelfth weft yarn, a sixteenth weft yarn, a twentieth weft yarn, a twenty fourth weft yarn, a twenty eighth weft yarn and a thirty second weft yarn of the lower layer are thick weft yarns, and the other weft yarns of the lower layer are thin weft yarns; the connecting line is interwoven and connected with the upper-layer thin weft yarns of the upper base cloth layer andthe lower-layer thin weft yarns of the lower base cloth layer at velvet parts; velvet piling is carried out to form piles of the velvet parts; one part, arranged above, of the connecting line is interwoven with the upper-layer thick weft yarns of the upper base cloth layer; one part, arranged below, of the connecting line is interwoven with the lower-layer thick weft yarns of the lower base clothlayer; and finally, upper-layer base cloth honeycomb cloth and lower-layer base cloth honeycomb cloth are formed. The silk brocade velvet provided by the invention is simple and easy to produce, operation is easy, and the product has the advantages that the velvet parts are dense due to the piles and honeycomb holes at the other parts are roughly concave and convex.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

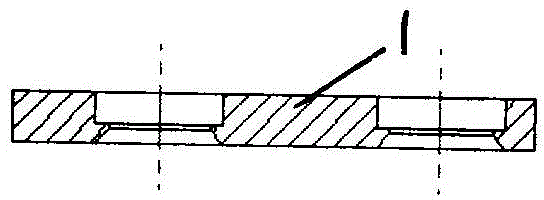

Blanking forming technical method for processing step holes by adopting smooth feeding mold

The invention provides a blanking forming technical method for processing step holes by adopting a smooth feeding mold. The mold adopts a double-guide structure, a guide nail is adopted between material belt process steps for precise positioning, and the positioning precision is + / -0.005mm. The method adopts the following six process steps for hole punching and forming: (1) hole pre-punching; (2) step forming; (3) hole punching; (3) chambering; (5) shaping; (6) fine hole trimming. An upper die punching head is adopted, and holes with the diameter being 2.1mm are finely trimmed. The method has the effects that the mold structure and the production process methods are adopted, the punching speed can reach higher than 100 times / minute, and the dimension precision and the position precision of the step holes meet drawing requirements.

Owner:TIANJIN JINRONG TIANYU PRECISION MACHINERY CO LTD

Processing method for machining main studs of large and medium-sized rotor spiders by utilizing rotating tire

InactiveCN103394735AVersatilityImprove versatilityLarge fixed membersMilling equipment detailsHigh pressureSpherical roller bearing

The invention relates to a processing method for machining main studs of large and medium-sized rotor spiders by utilizing a rotating tire. According to the processing method for machining main studs provided by the invention, a self-aligning thrust roller bearing is adopted for being connected with a rotating shaft and a bearing seat in a rotating tire tool, high-pressure oil is injected into an oil cylinder to jack up a rotor spider, in a pressure maintaining state, a workpiece is rotated, when a main stud needing to be machined faces to boring machine equipment, the oil pressure is released, and the rotor spider slowly falls on a cushion cylinder at the equal altitude of a base of the rotating tire along with the decrease of the oil pressure. The processing method can be used for solving the difficult problem that the main stud cannot be integrally machined as the weight and external diameter of the rotor spider are too large, and meanwhile the processing method is high in precision of machining quality, strong in bearing capacity, high in production efficiency, and applicable to the machining of the main studs of the large and medium-sized rotor spiders, and has very high popularization and application values.

Owner:HARBIN ELECTRIC MASCH CO LTD

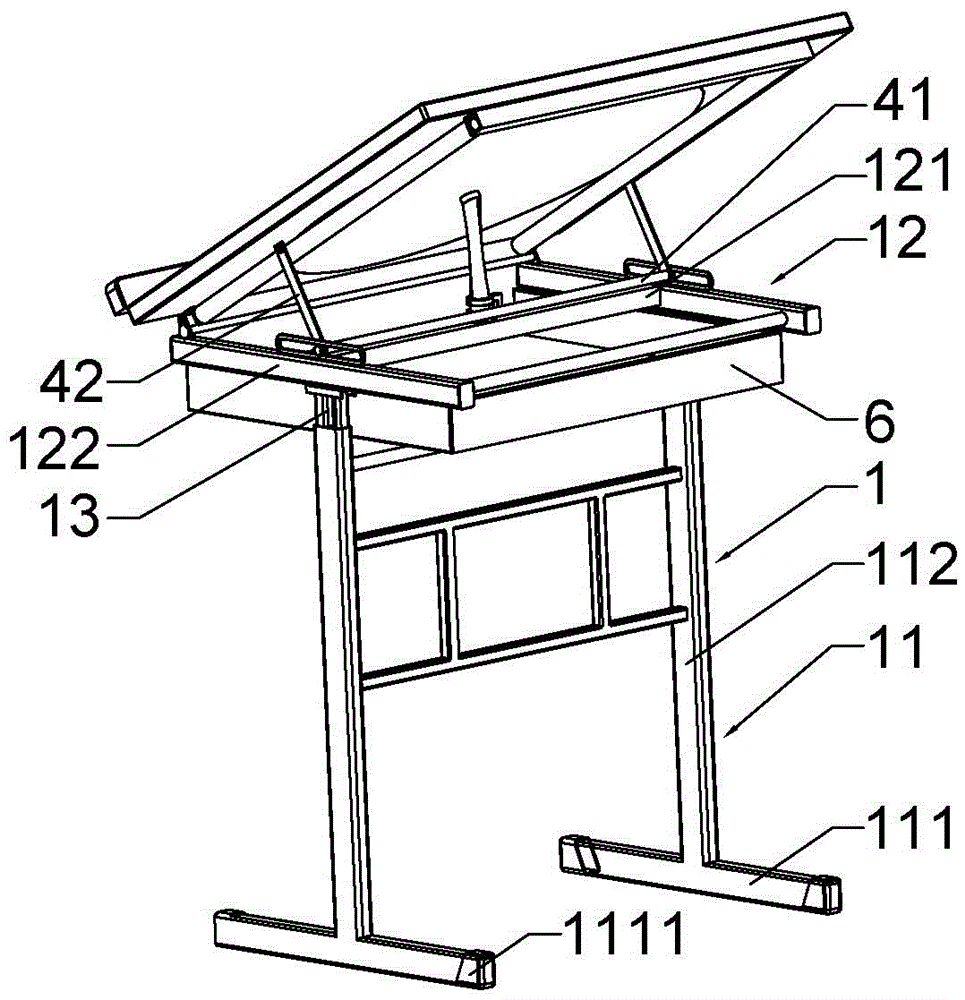

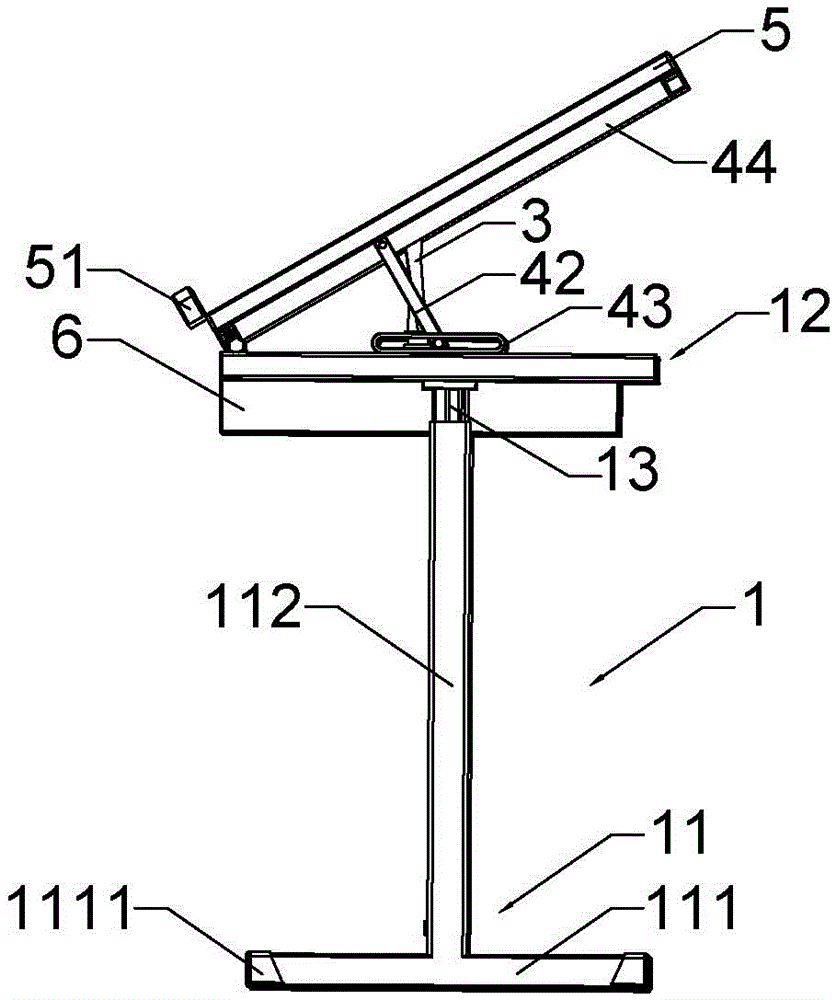

Multifunctional drawing table and using method thereof

InactiveCN106667040AImprove practicalityMeet drawing requirementsDrawing desksRound tableComputer science

The invention relates to the technical field of tables, in particular to a multifunctional drawing table and a using method thereof. The multifunctional drawing table comprises a frame, a round table top arranged at the top of the frame and a rotating mechanism for driving the round table top to rotate. The frame comprises a supporting frame, a lifting frame arranged at the top of the supporting frame and a lifting mechanism for driving the lifting frame to move up and down. According to the multifunctional drawing table, the round table top rotates through the rotating mechanism, the height adjustment of the table is performed through the lifting mechanism, the multifunctional drawing table is suitable for people having different heights, the inclination of the round table top is adjusted further through an inclination angle adjusting mechanism, drawing requirements are met in multiple aspects, and the multifunctional drawing table integrates multiple functions and is simple to operate, convenient to use and high in real-time performance.

Owner:东莞产权投资有限公司 +1

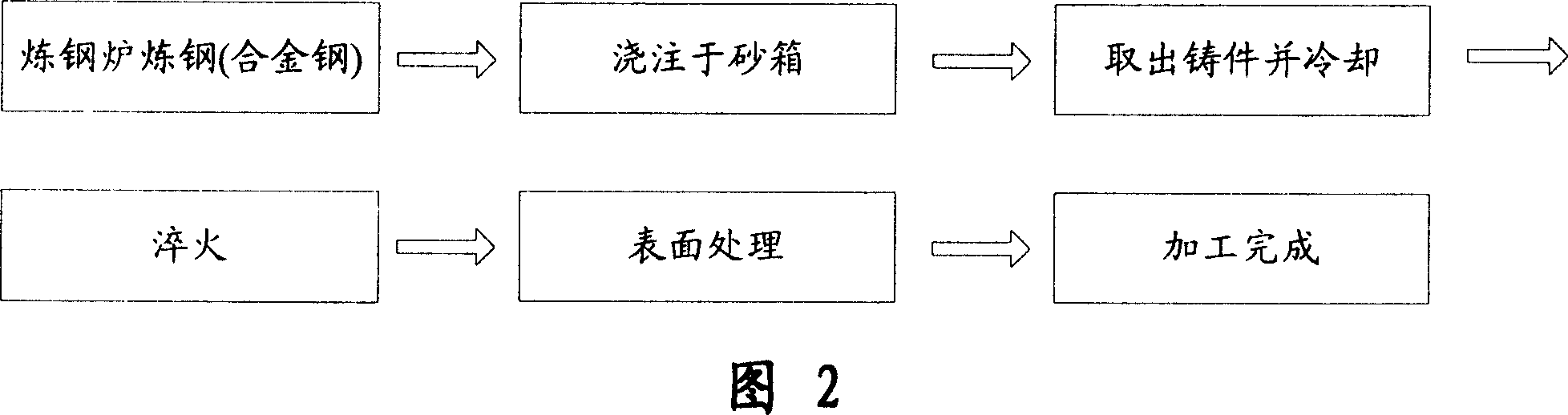

Method for manufacturing land leveler blade

InactiveCN1920187AExtended service lifeHigh hardnessSoil-shifting machines/dredgersLevelerMaterials science

The invention relates to a method for producing scraper of leveler, wherein it comprises: (1) smelting abrasion resistant steel in the steelsmelting furnace, and irrigating the steel water into the steel module; (2) the casting machine casts the steel module, to cool and shape the steel water stepped, to avoid loose and foam; (3) using transmitter to transmit the work piece to another device, fixing work piece, and punching the mounting hole, and cooling it naturally in the device; (4) when the work piece is cooled to anneal temperature, thermally treating the work piece, to improve the surface rigidity and internal flexibility; (5) when the work piece is cooled to the solidify temperature, transmitting it to the check area, and cooling it to the room temperature and finishing, storing. The invention can confirm the quality of scraper, simplify the process, and reduce the producing cost.

Owner:肖红路

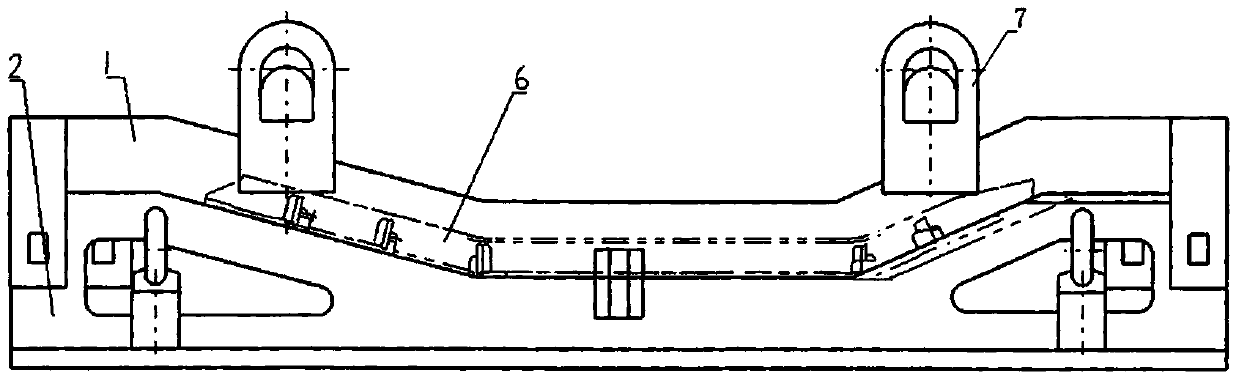

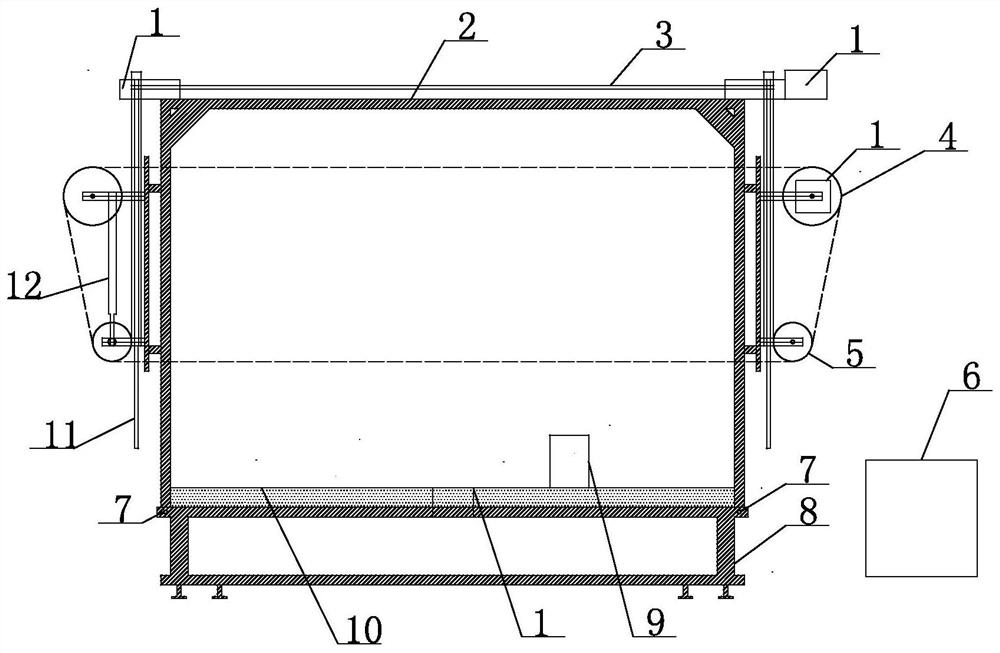

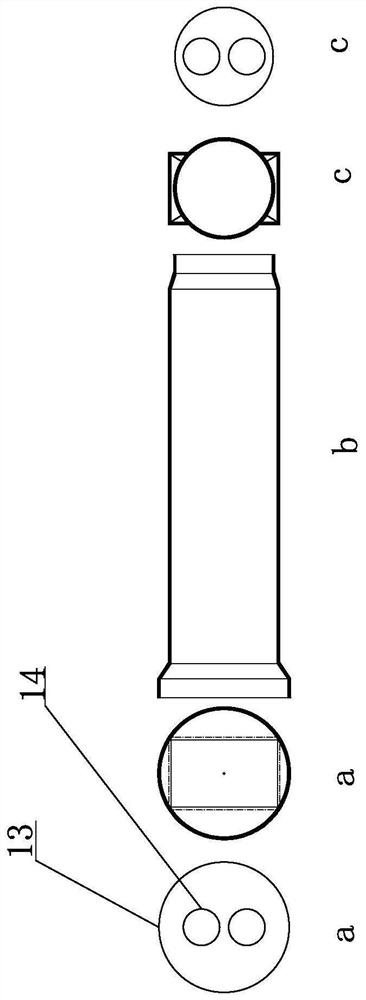

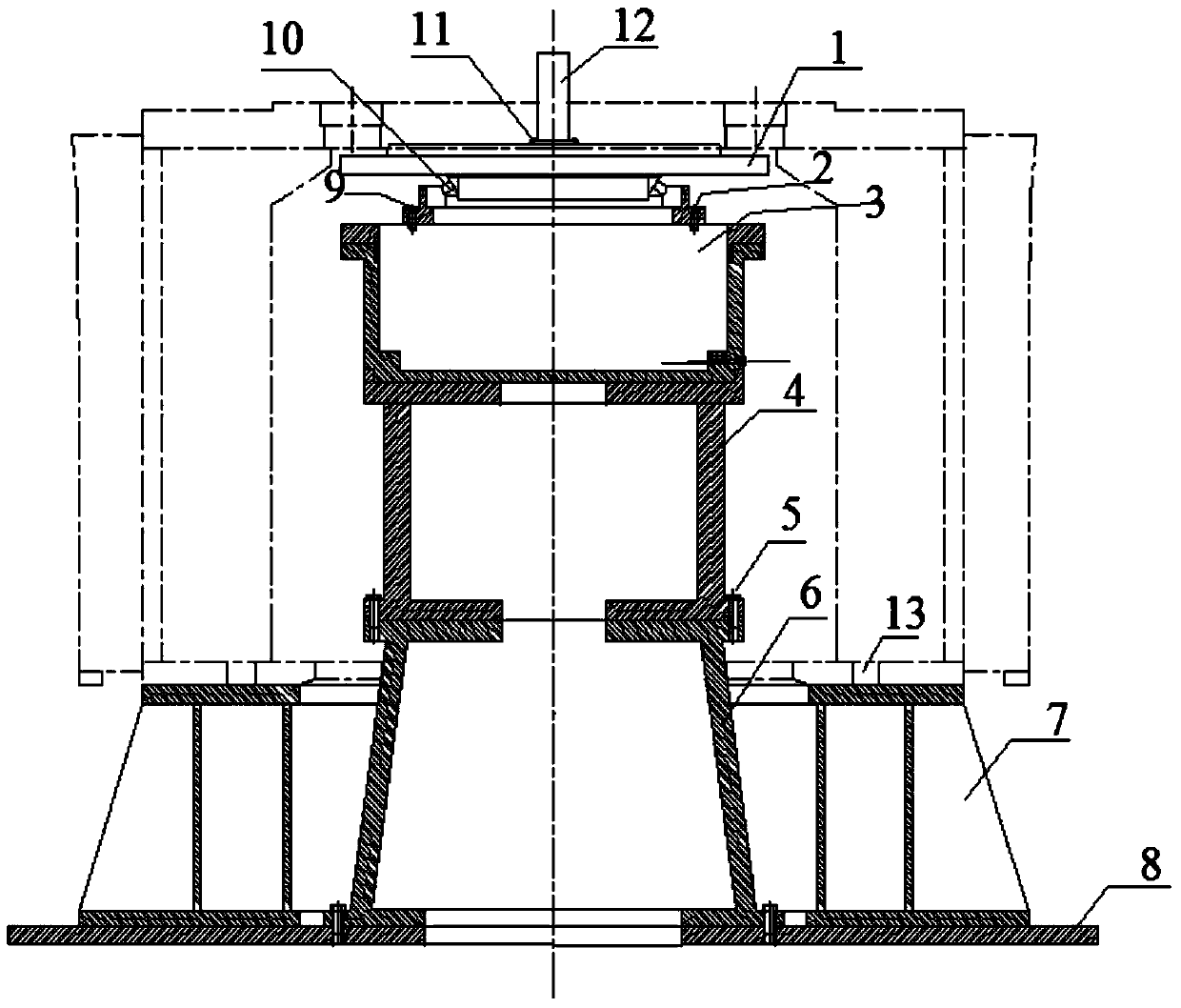

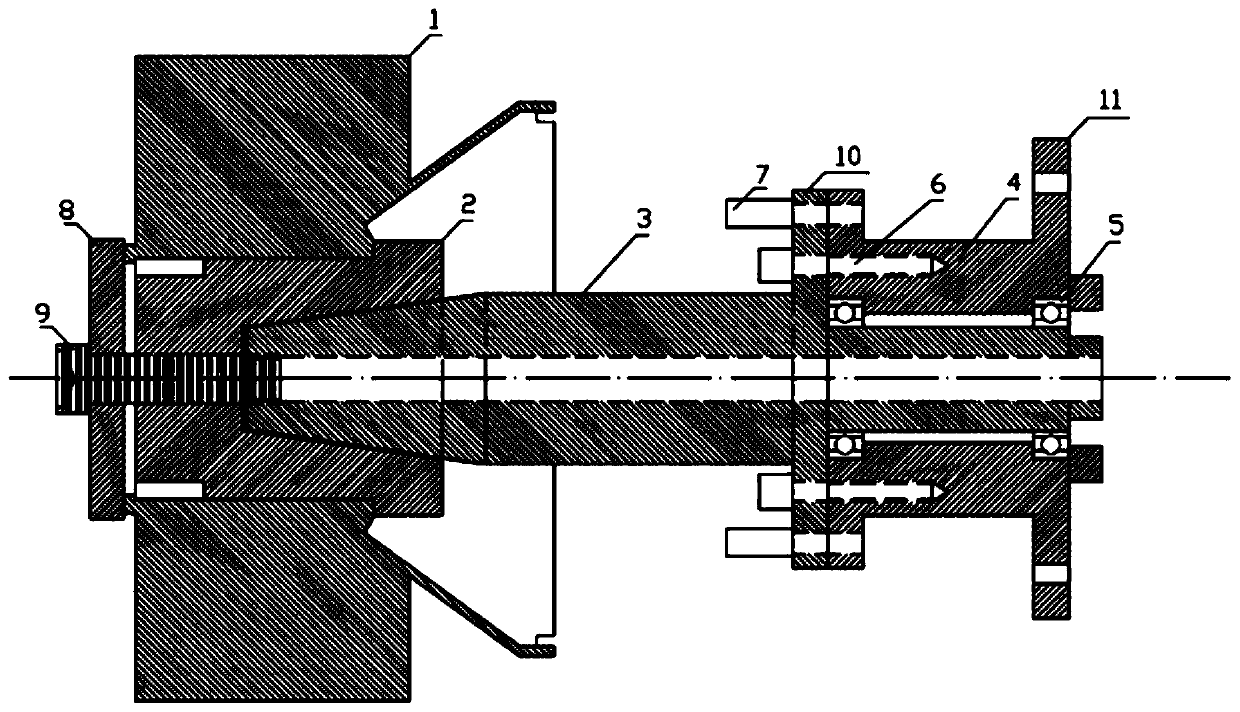

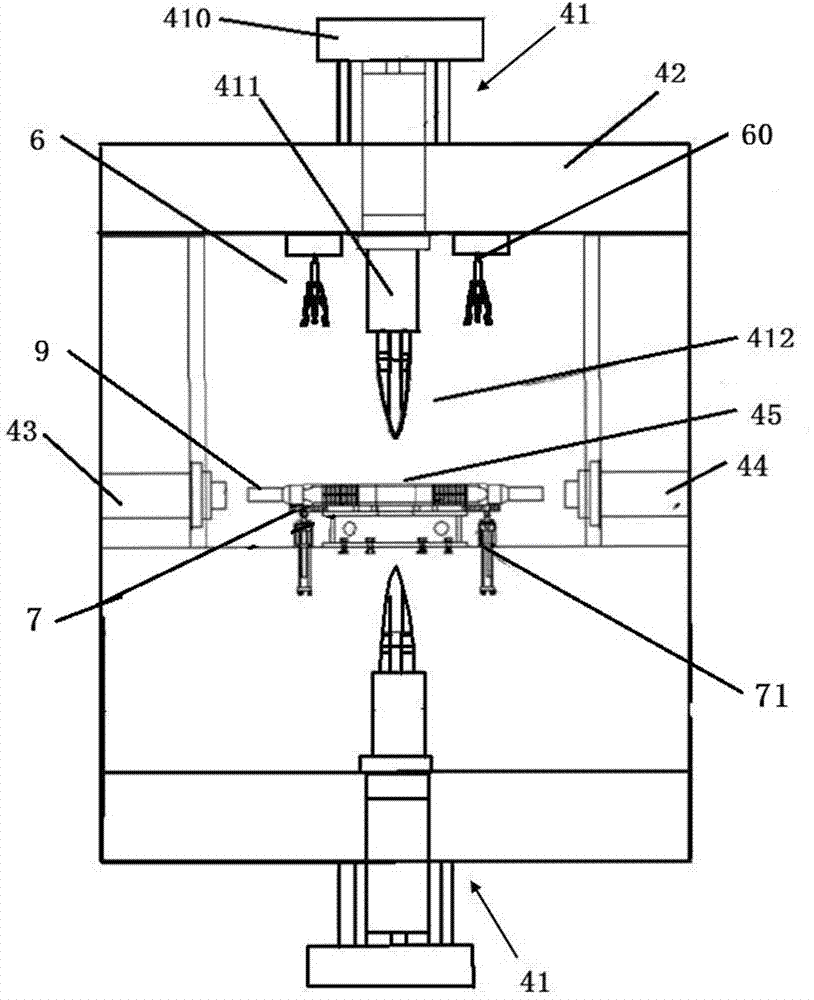

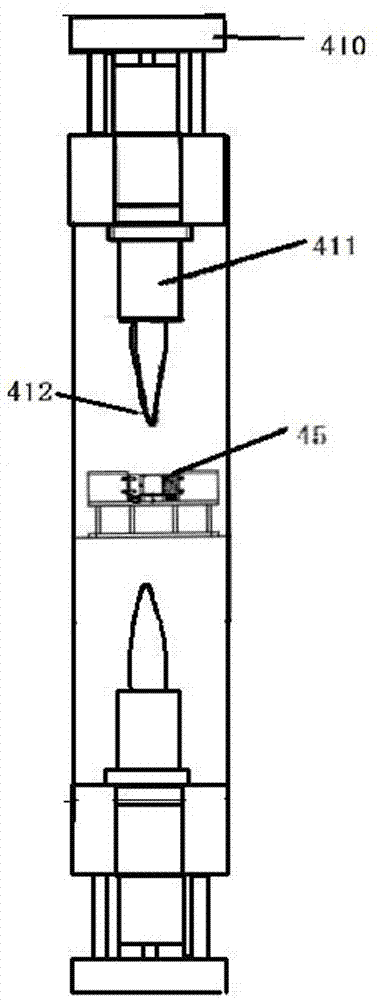

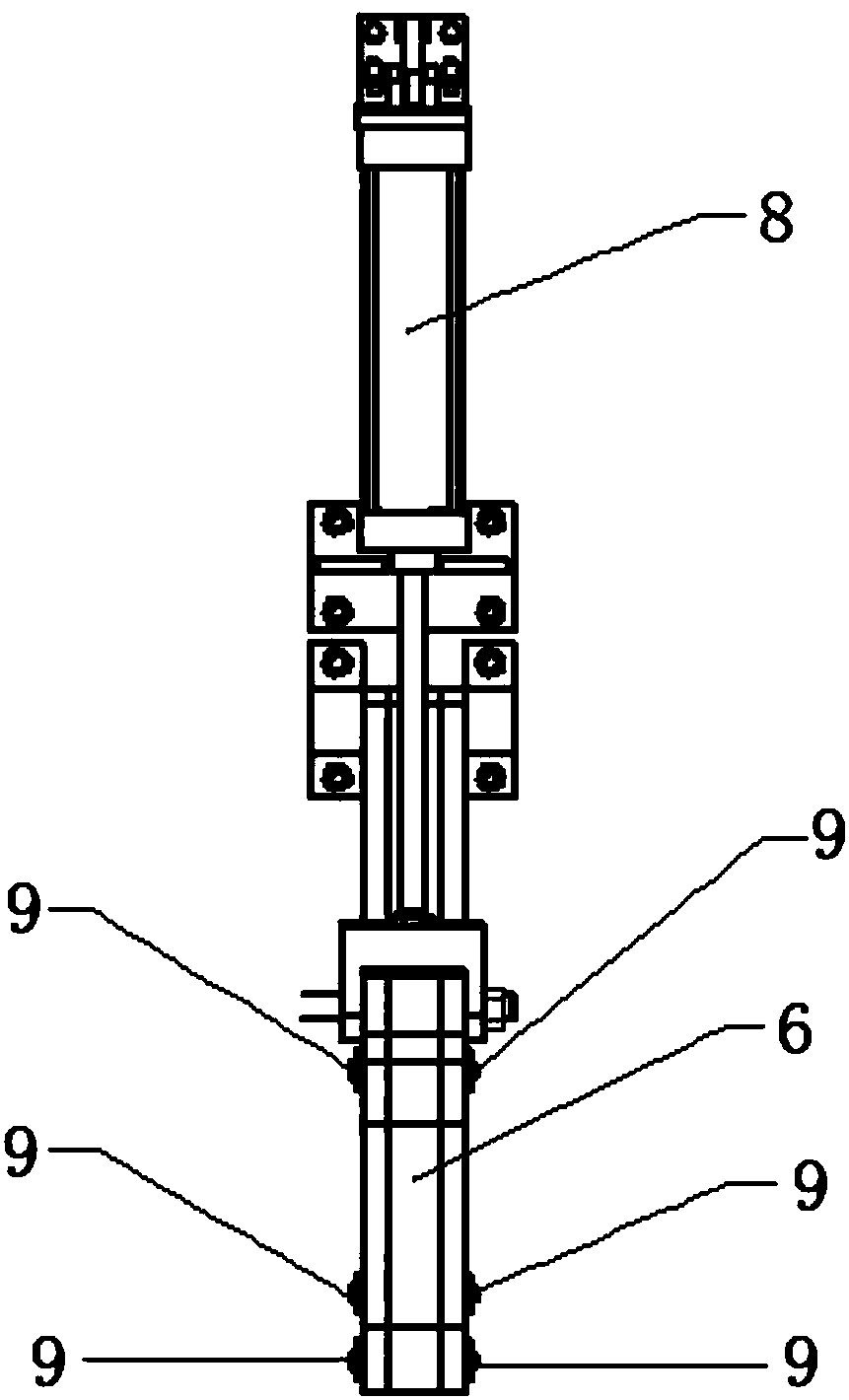

Laser shock processing device for blisk

InactiveCN110116270AReduce the amount of motion trajectory programmingSatisfy the requirements of laser oblique shot impact strengtheningWelding/cutting auxillary devicesAuxillary welding devicesProgramming complexityEngineering

The invention discloses a laser shock processing device for a blisk. According to the device, the blisk 1 is fixed through a shaft sleeve 2, a cover plate 8 and a central screw 9 of the laser shock processing device; and through the location of a location pin 7 and the fixing of a screw 6, the central axis of the clamped blisk (1) is enabled to keep vertical to the end surface of a flange disc ofan industrial robot and keep coaxial with the flange disc of the industrial robot. In order to reduce the programming workload of the industrial robot, a second blade is rotated to the position of a first blade through the manner of rotating the flange disc 10 at the middle part, the industrial robot movement program of the first blade can be repeatedly called, and laser shock processing for the second blade and all the subsequent blades is realized, so that the workload is greatly reduced, and the program complexity is reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Lathe clamping machining and production process for motor end cover

ActiveCN105643194AEliminate mill chatterHigh precisionPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to a lathe clamping machining and production process for a motor end cover and belongs to the field of motor shell machining and manufacturing. The lathe clamping machining and production process comprises the steps that 1, the motor end cover is subjected to rough machining through a vertical lathe, and then the two end faces where middle bearing holes of the end cover are located are subjected to finish turning; 2, screw holes of the end cover are drilled and tapped through a drilling machine; 3, the vertical lathe is adopted, a special tool is placed on a workbench, positioning is conducted through the end cover upper end face subjected to finish turning, clamping is conducted by bolts through the screw holes, and auxiliary clamping is conducted on the large end face of the end cover through rubber; and 4, the large end face of the end cover is finally subjected to finish turning by 0.05-0.15 mm, an outer circle is subjected to finish turning by 0.05-0.15 mm, and the middle bearing holes are subjected to finish turning by 0.05-0.15 mm. The lathe clamping machining and production process for the motor end cover is high in finished product production efficiency.

Owner:SHANDONG YUANTONG MASCH CO LTD

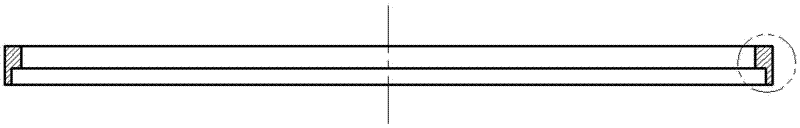

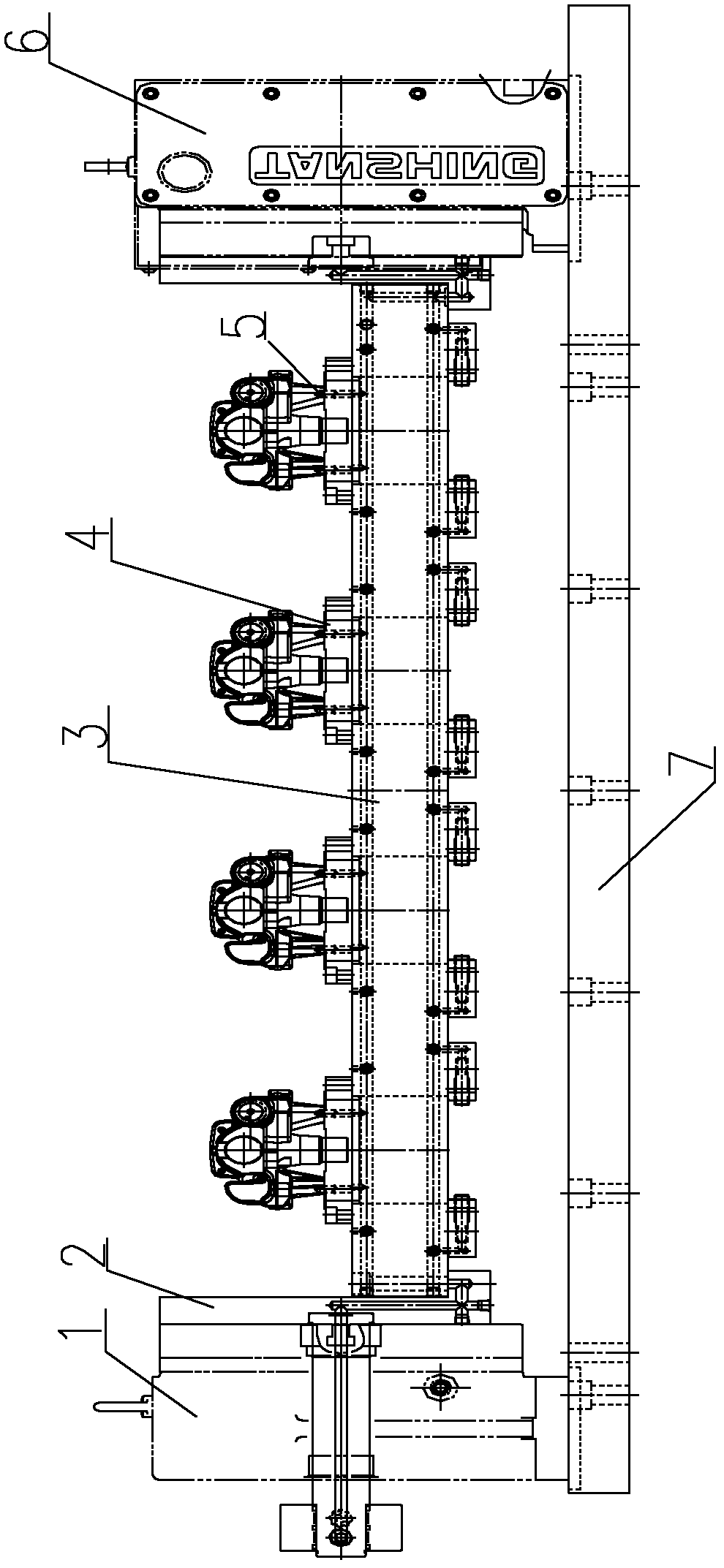

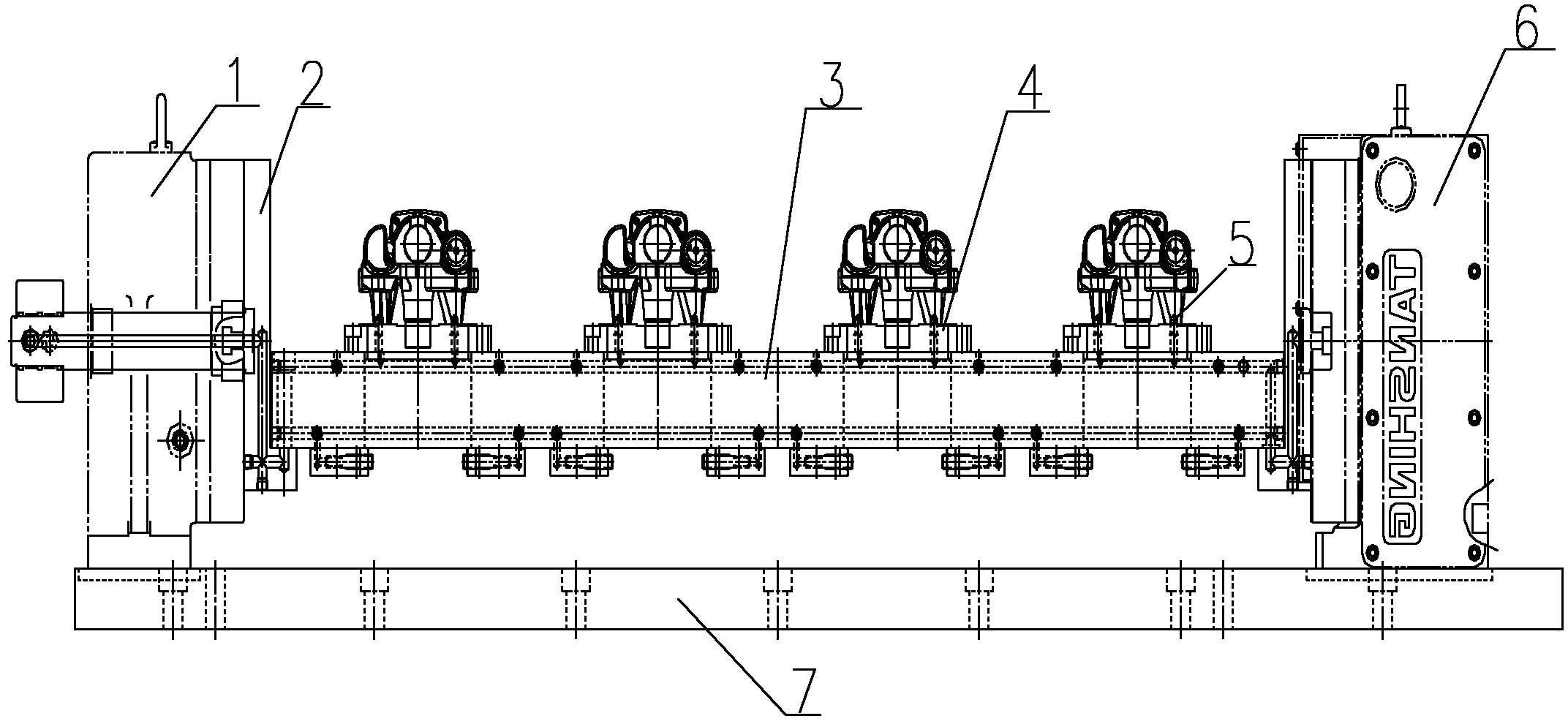

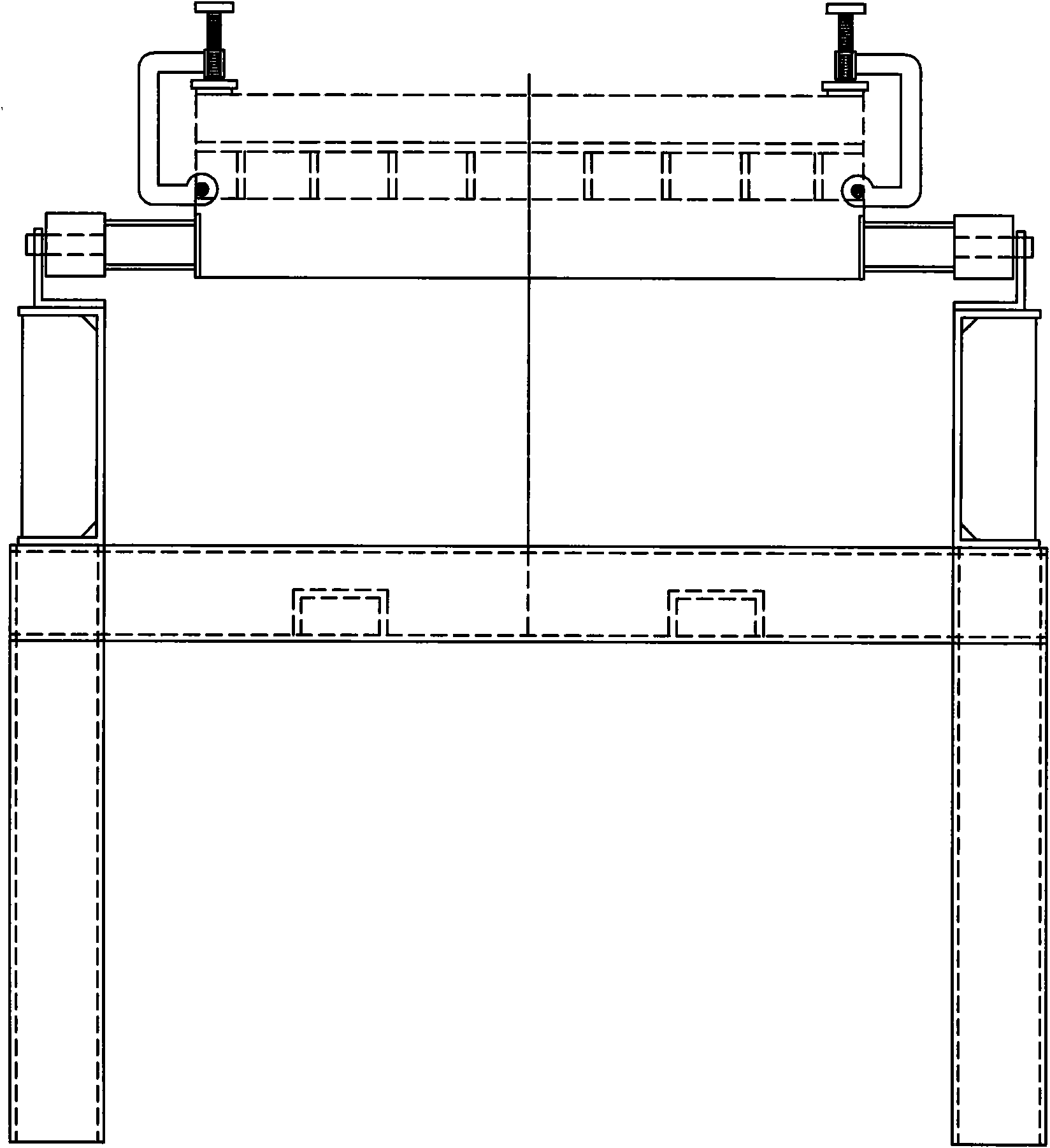

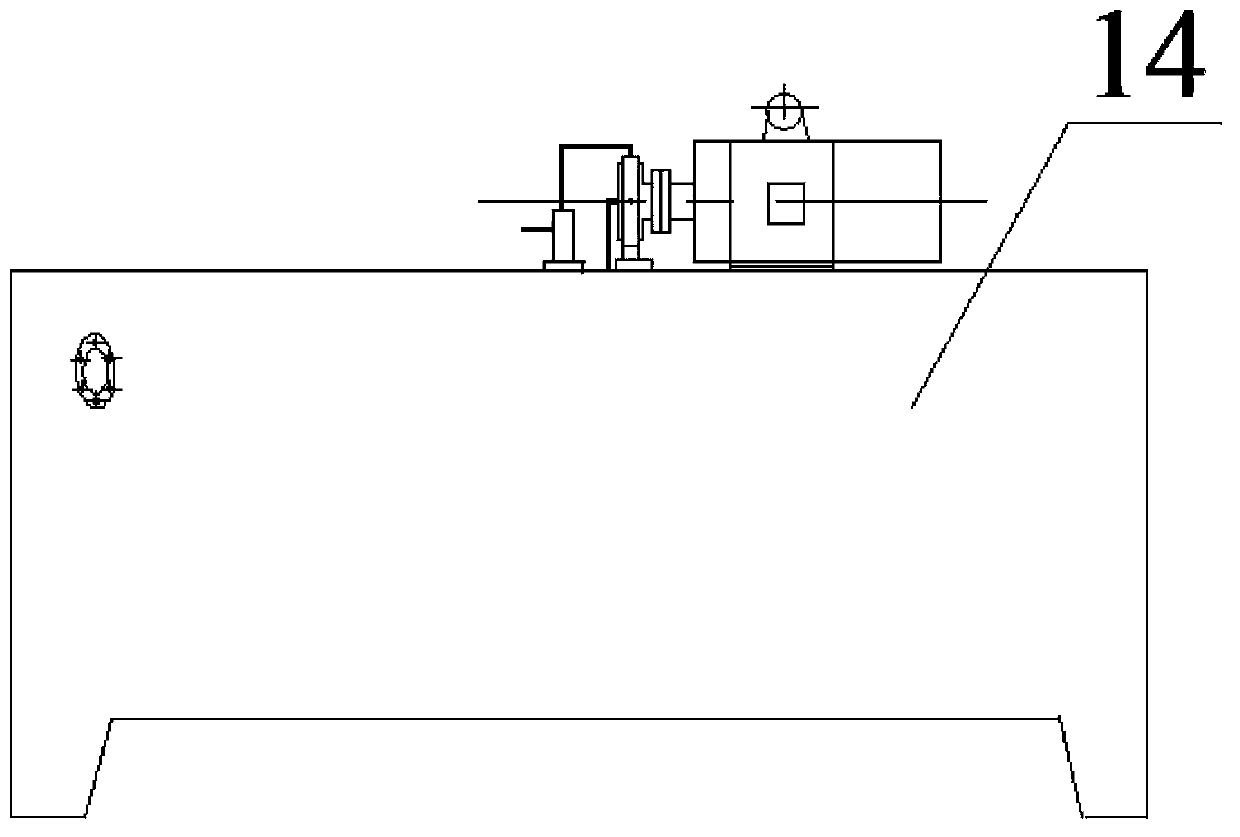

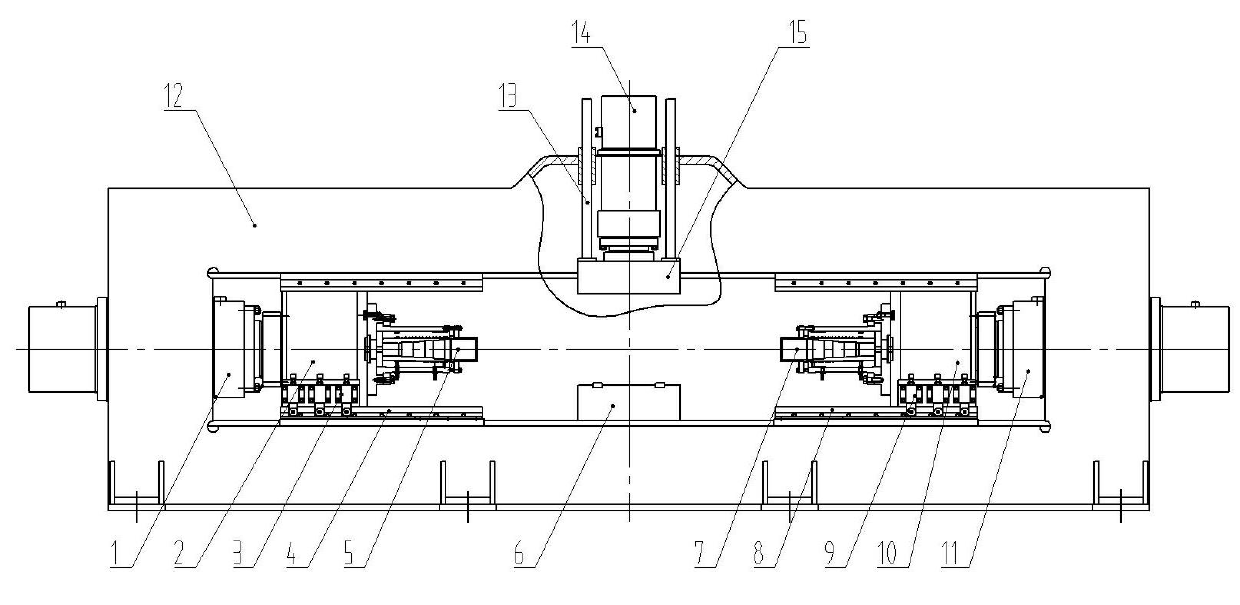

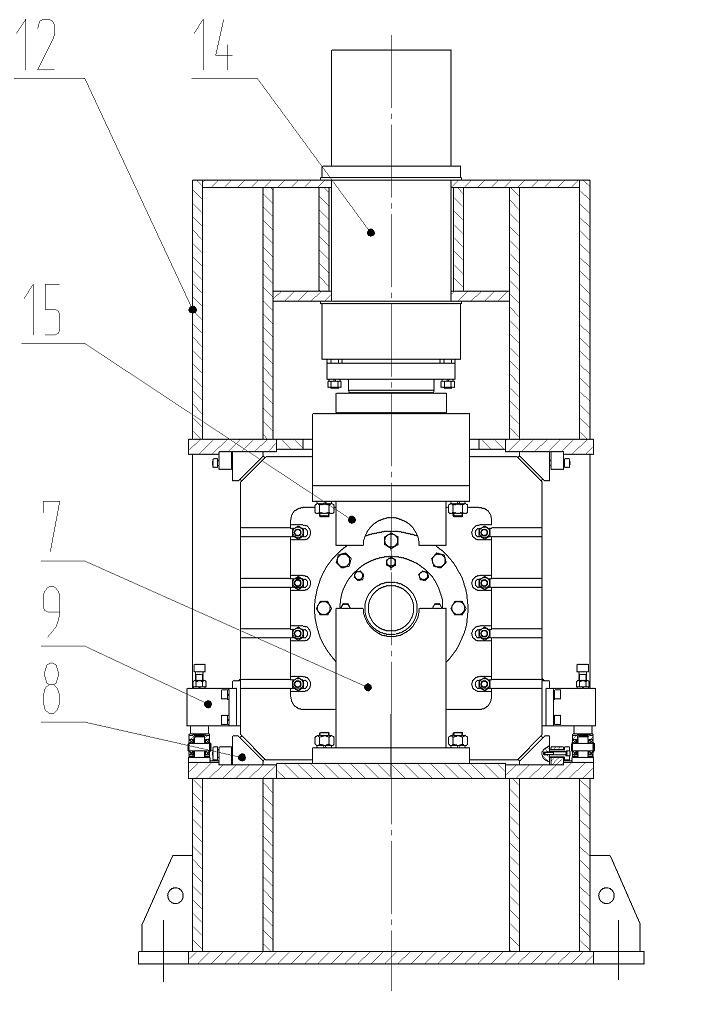

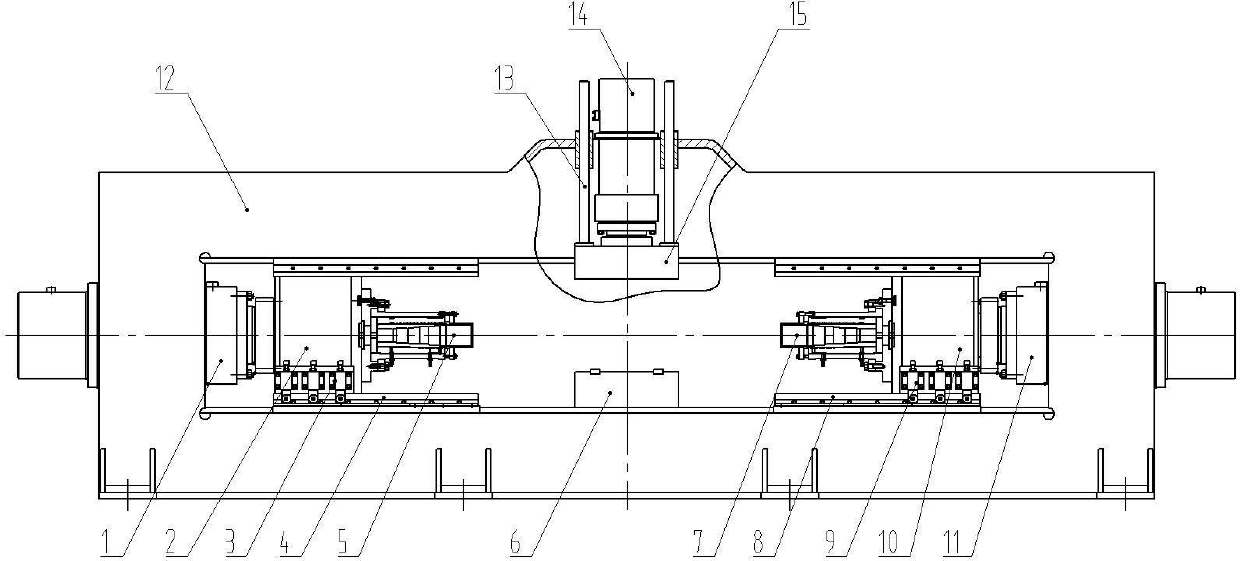

Once-forming extruding machine for tubular axle blank of heavy truck

The invention discloses a once-forming extruding machine for a tubular axle blank of a heavy truck and belongs to the field of equipment manufacturing. The machine comprises a rack, left and right horizontal thrust oil cylinders, left and right extrusion forming dies, a clamping oil cylinder and upper and lower clamping dies. The rack is of a T-shaped steel-structure framework; the left and right horizontal thrust oil cylinders are mounted at the left and right ends of the rack respectively; and the left and right extrusion forming dies are connected with piston rods of the left and right horizontal thrust oil cylinders respectively. The clamping oil cylinder is vertically mounted at the upper end of the middle part of the rack; the upper clamping die is connected with the piston rod of the clamping oil cylinder; and the upper clamping die is connected with the rack through a guide sleeve of a guide rod. The lower clamping die is mounted at the lower part of the rack. Sliders are arranged between the horizontal thrust oil cylinders and the extrusion forming dies; and the sliders are connected with the rack through a sliding guide rail and a wheel-type guide rail. The once-forming extruding machine disclosed by the invention has the advantages that the axle blank has high strength, the manufacturing processes of the axle blank are reduced, the production rate is improved, the blank material is easily prepared and can adopt a round pipe, and the material is saved.

Owner:XUZHOU DAYI METALFORMING EQUIP

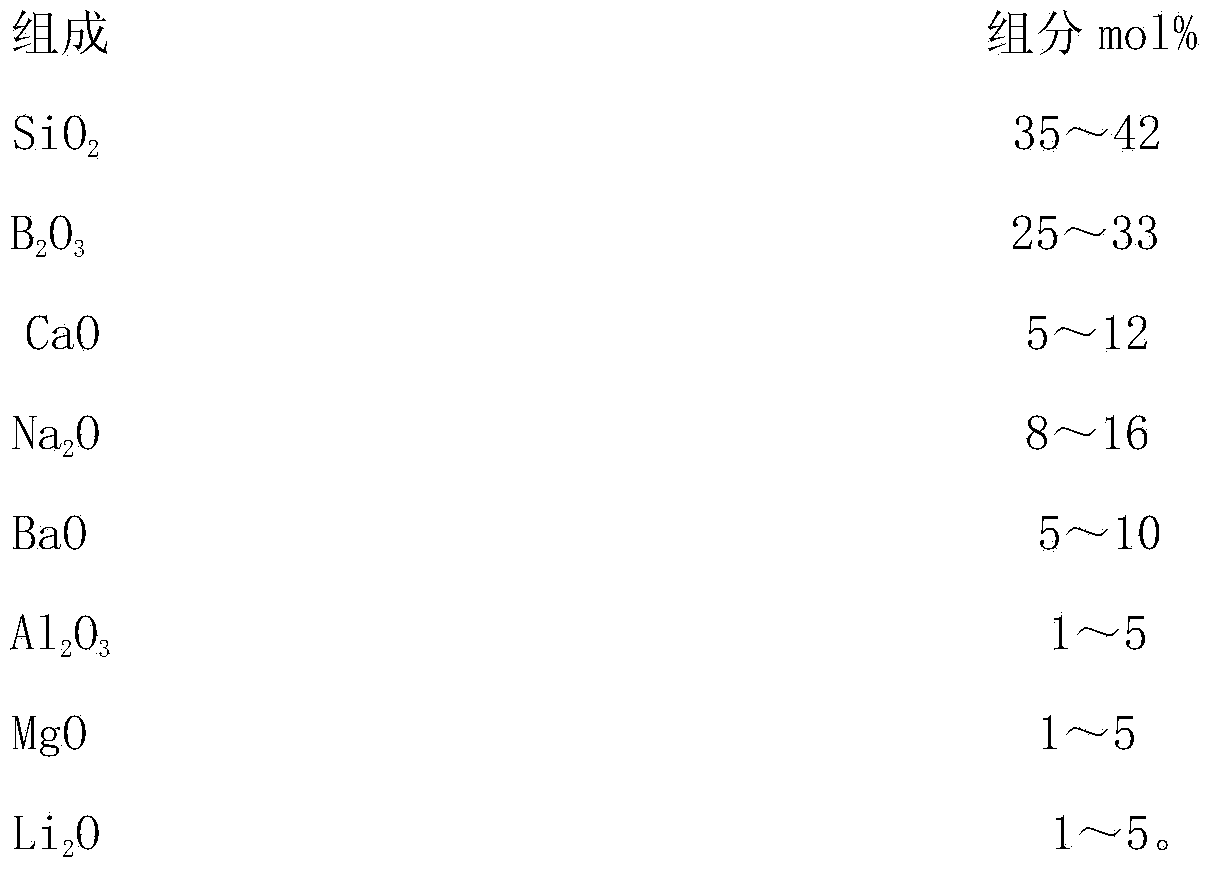

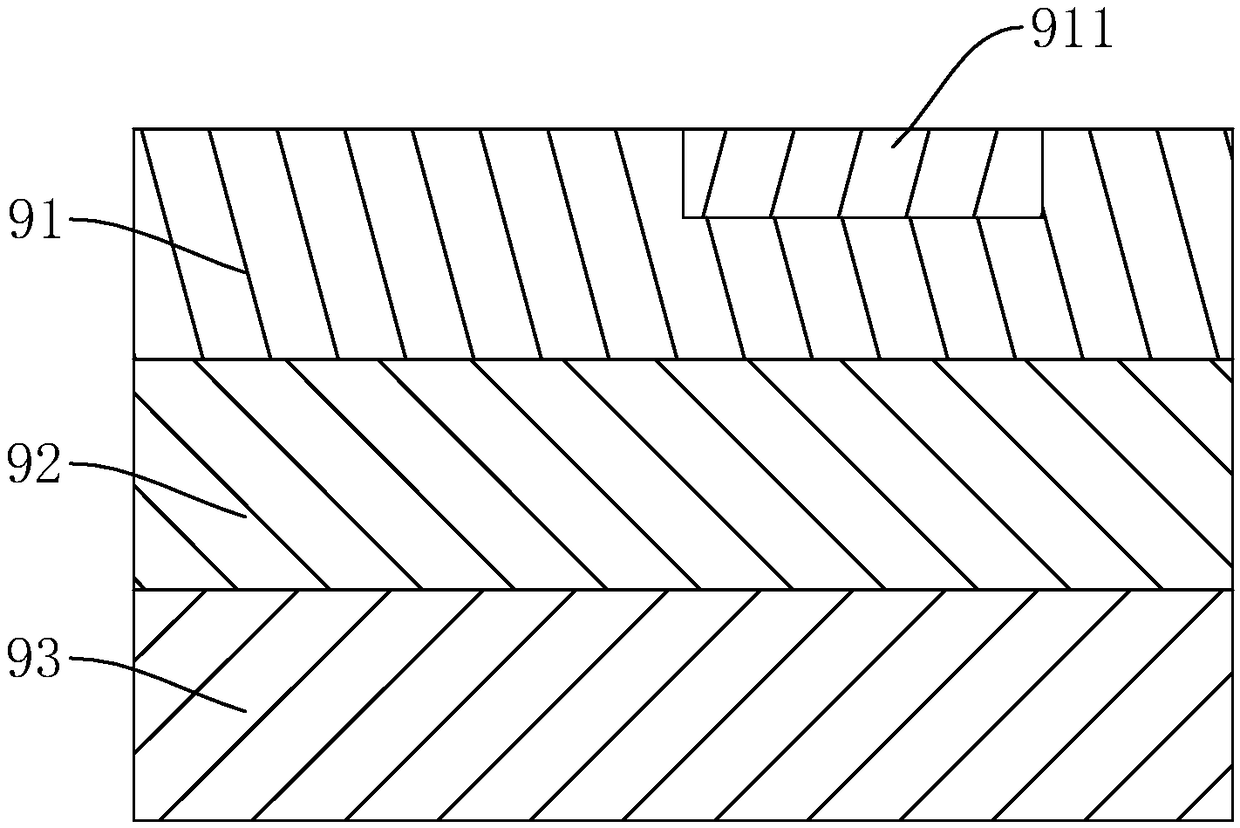

Cladding glass for flexible optical fiber image bundles with high resolution ratio, and preparation method thereof

InactiveCN103553329AGood chemical stabilityNot easy to corrodeGlass making apparatusDevitrificationVitreous Humors

The invention proposes cladding glass for flexible optical fiber image bundles with high resolution ratio, and a preparation method thereof. The method comprises the following steps: calculating and weighing raw materials according to the constituents of the glass and the mole percent; evenly stirring and mixing after fully grinding, and sealing a mixture by using a plastic sealed bag for use; adding the mixture to a crucible for a plurality of times; putting the crucible into a silicon carbide rod furnace at 1000-1400 DEG C; stirring once at an interval of 15 minutes after raw materials are completely melted until the raw materials are completely melted and settled; taking out vitreous humour, pouring the vitreous humour into a pre-heating die, cooling and molding; putting the poured cooled glass into a muffle furnace with a set temperature program and annealing; taking out the sample, namely the cladding glass for the flexible optical fiber image bundles with high resolution ratio after annealing is finished. The cladding glass has a good acid dissolving effect in an acid liquor; the prepared acid soluble glass has good chemical stability and good devitrification resistance, and is not easily corroded in air.

Owner:NANJING UNIV OF POSTS & TELECOMM

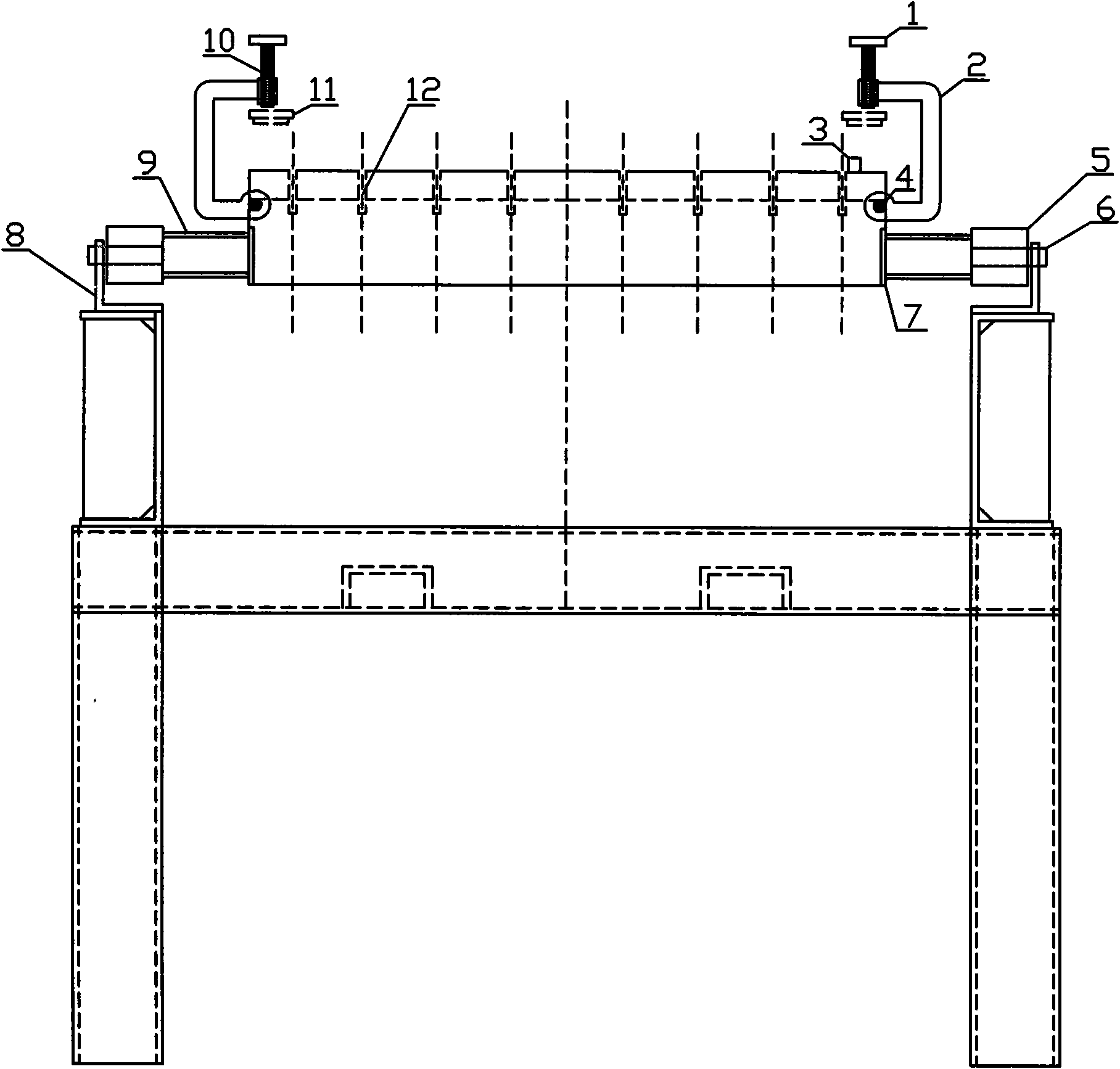

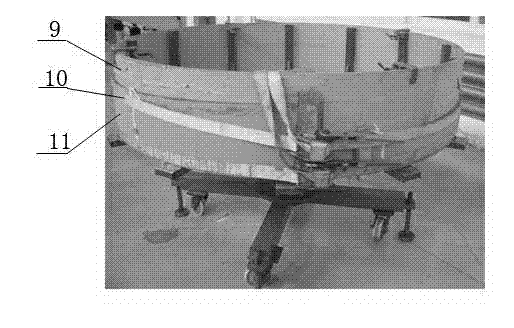

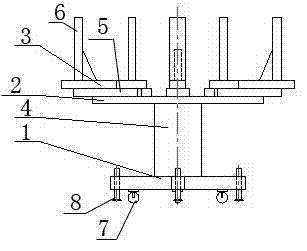

Locating welding tool for spiral guide rail

InactiveCN105345349AAdjust the lift angleGuaranteed weldingRailsWelding/cutting auxillary devicesButt weldingEngineering

The invention relates to a locating welding tool for a spiral guide rail. The locating welding tool comprises a tool rack. A plurality of tool plates are fixedly connected to the surface of the tool rack. A plurality of stand column mounting plates are fixedly connected to the surfaces of the tool plates. Each stand column mounting plate is connected with a longitudinally-arranged stand column. Shelves are movably arranged on the stand columns. The locating welding tool is simple in structure and convenient to use; the stand columns and the stand column mounting plates on the tool rack can shift in the linear direction, the shelves on the stand columns can vertically shift in the stand columns, and therefore the aim of adjusting the center distance of the guide rail and the lifting angle of the guide rail is achieved; the center distance between different guide rails is achieved; welding of gear racks and the guide rails is guaranteed; smooth butt welding of the left and right guide rails and the spiral guide rail is achieved; the requirements of drawings are met; and production efficiency is greatly improved.

Owner:SYMAX ELEVATOR CHINA

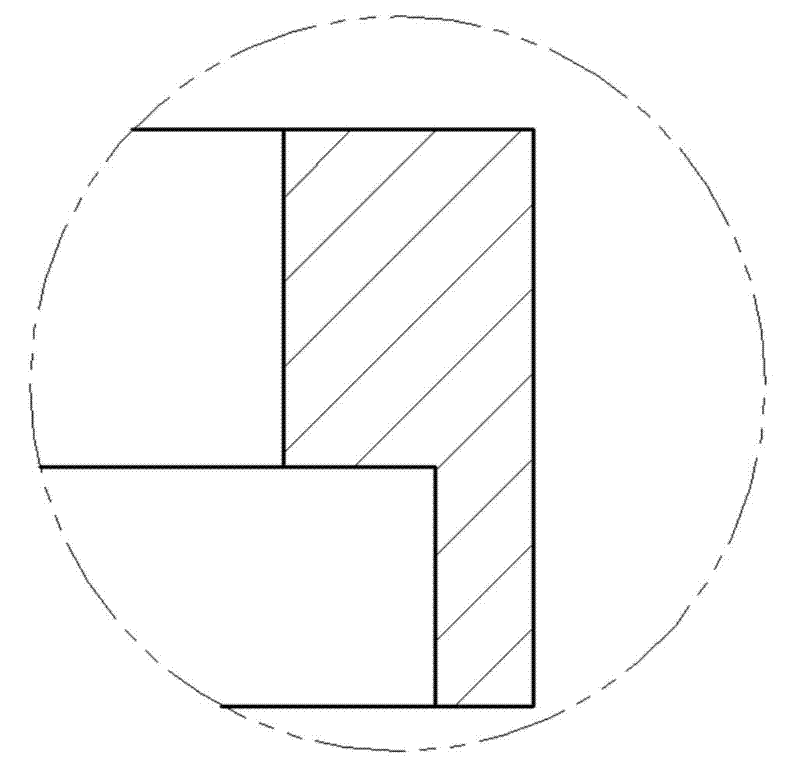

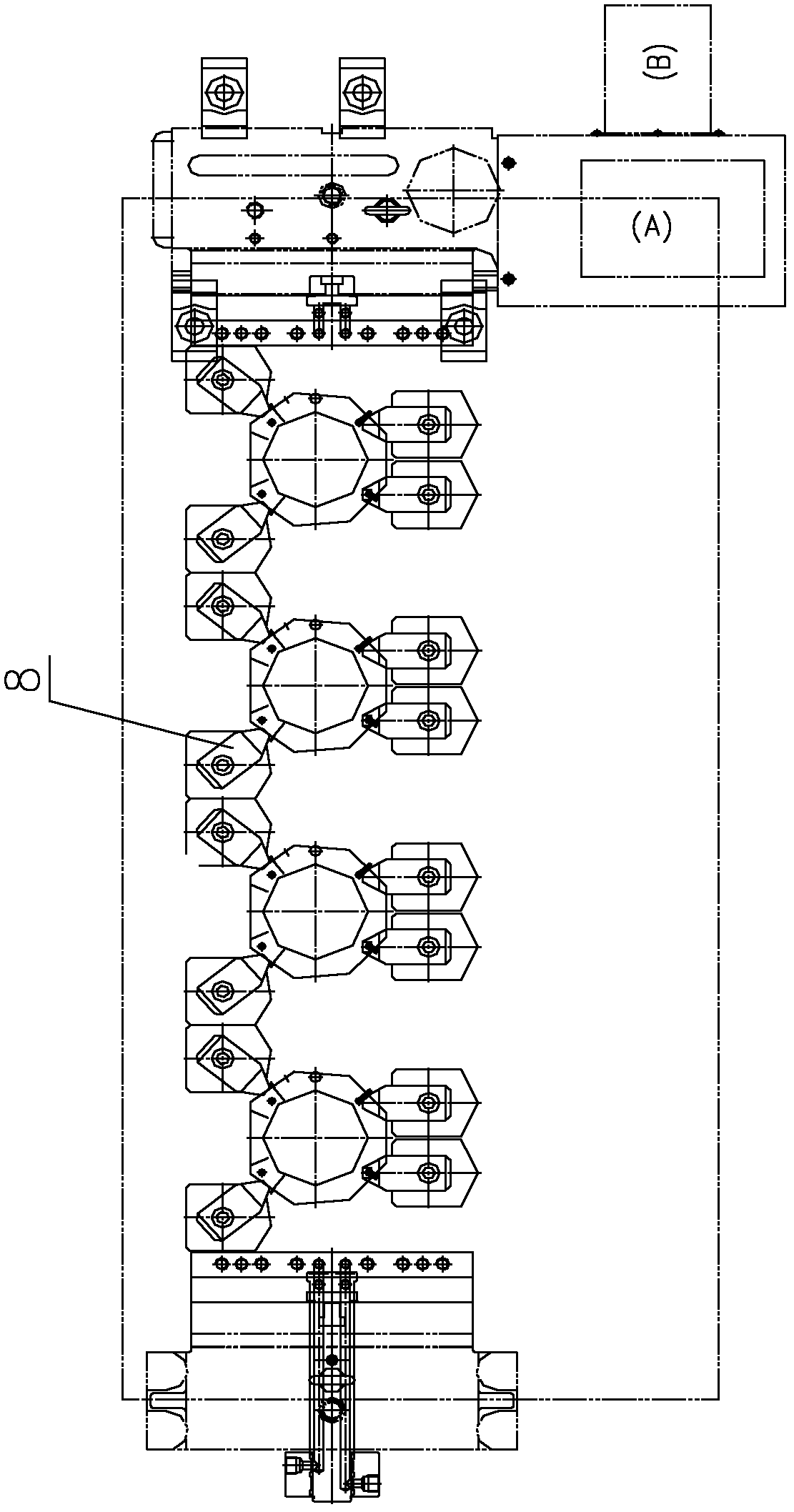

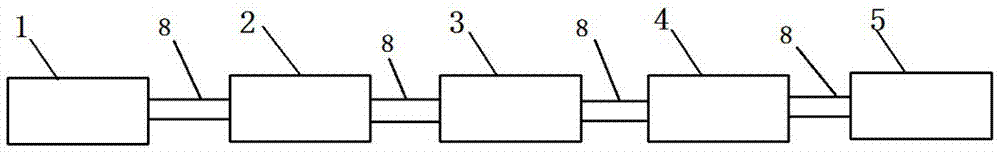

Drive axle housing integrated forming equipment

PendingCN107009147AHigh strengthAdd thickening processOther manufacturing equipments/toolsPunchingFlange

The invention relates to drive axle housing integrated forming equipment. The drive axle housing integrated forming equipment comprises an axle head forming device, a square pushing device for cold-rolling circular tubes into square tubes, a punching device, a flange hole forming device, a sizing device and a conveying belt which sequentially communicates with the axle head forming device, the square pushing device, the punching device, the flange hole forming device and the sizing device. A drive axle housing forming structure prepared by the equipment is reasonable, the material utilization ratio is high, the rejection rate is low, welding does not exist on the whole, welding stress and defects do not exist, and product performance is stable.

Owner:山西奥帕斯智控车桥科技有限责任公司

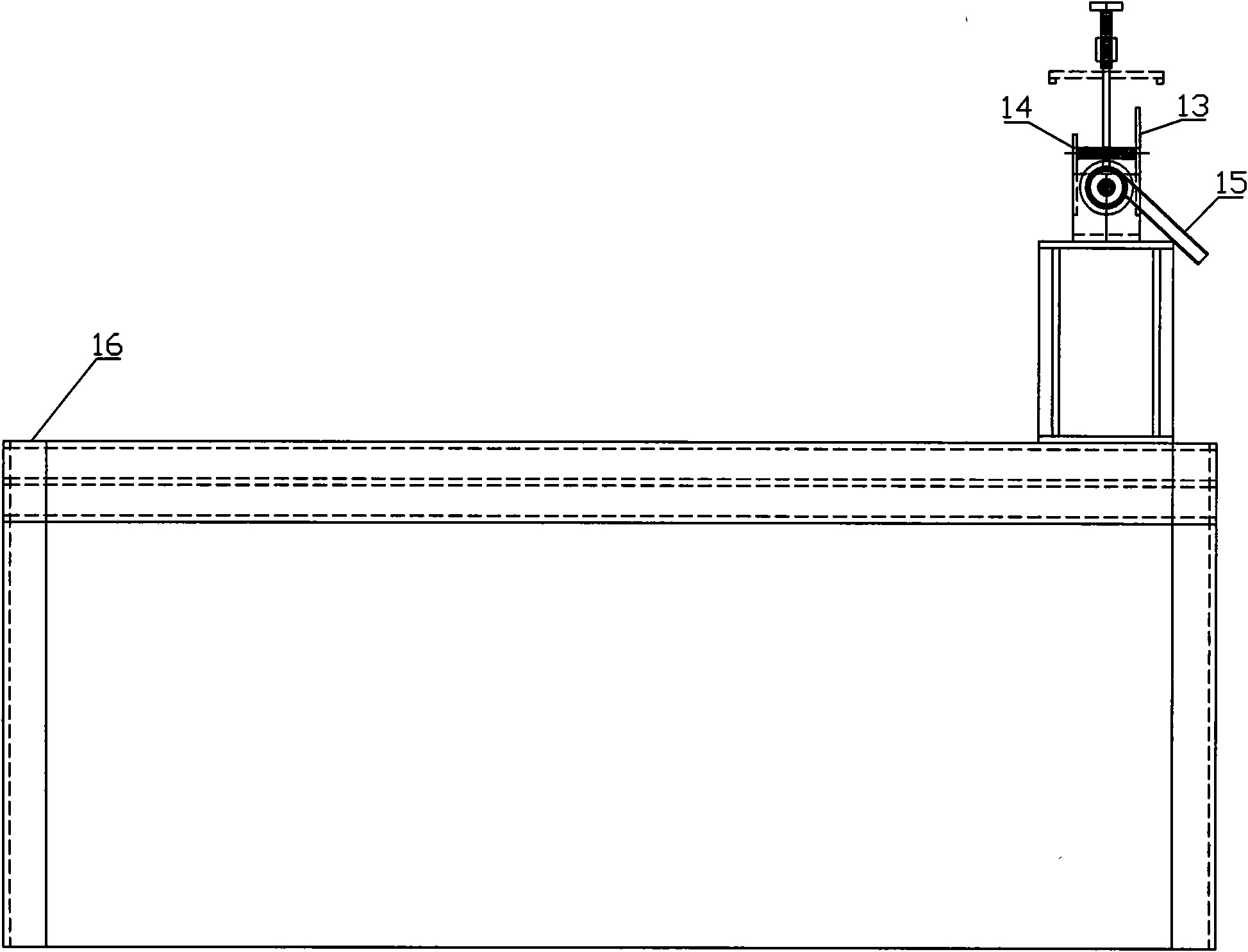

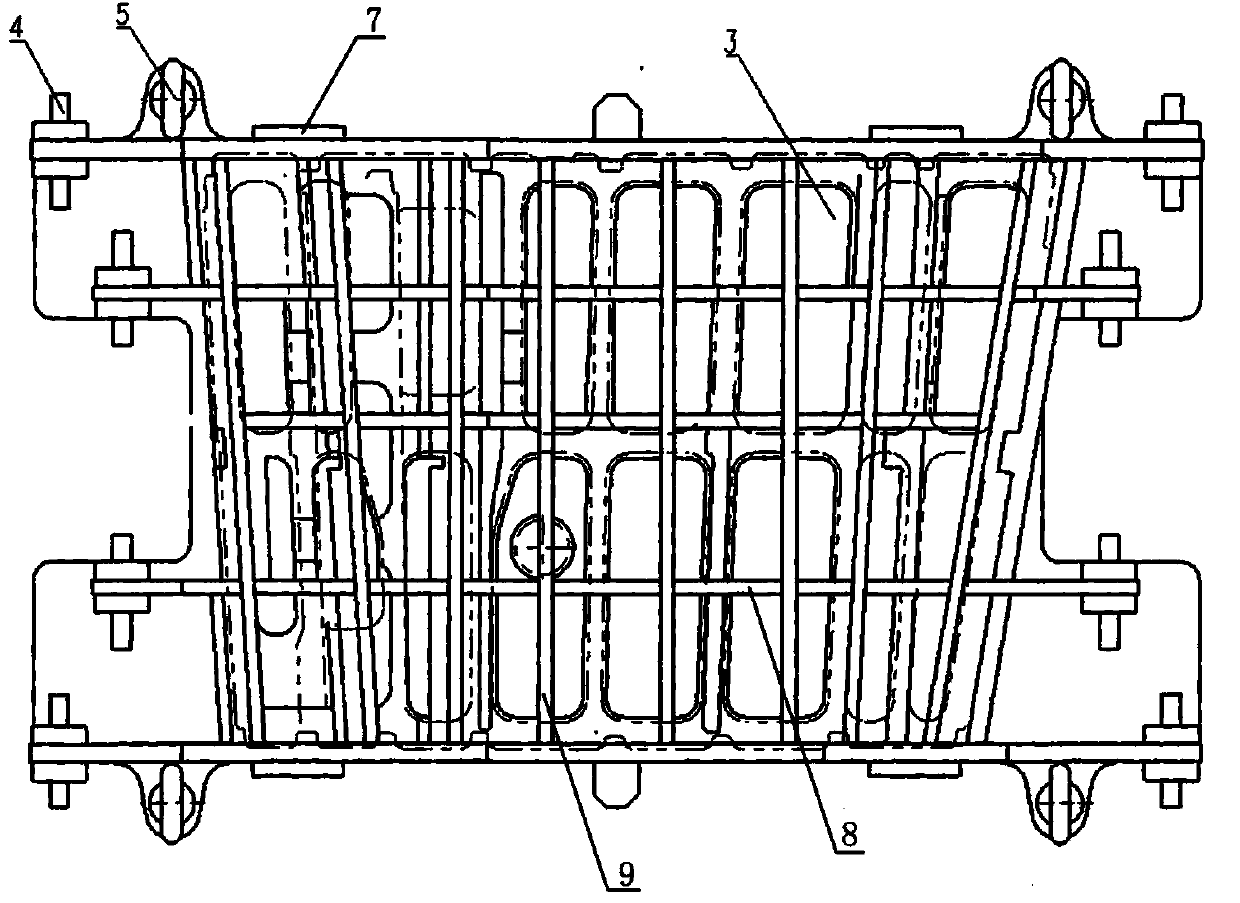

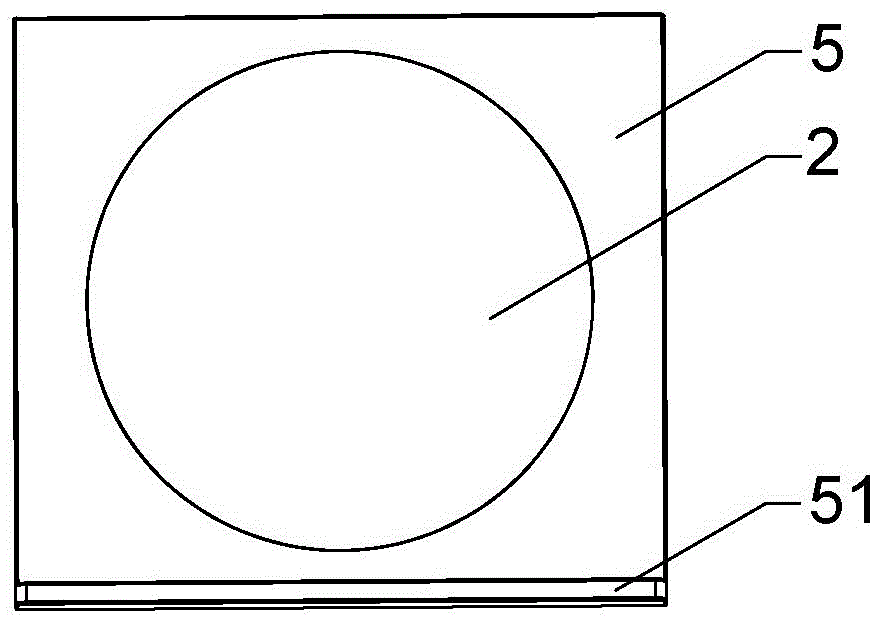

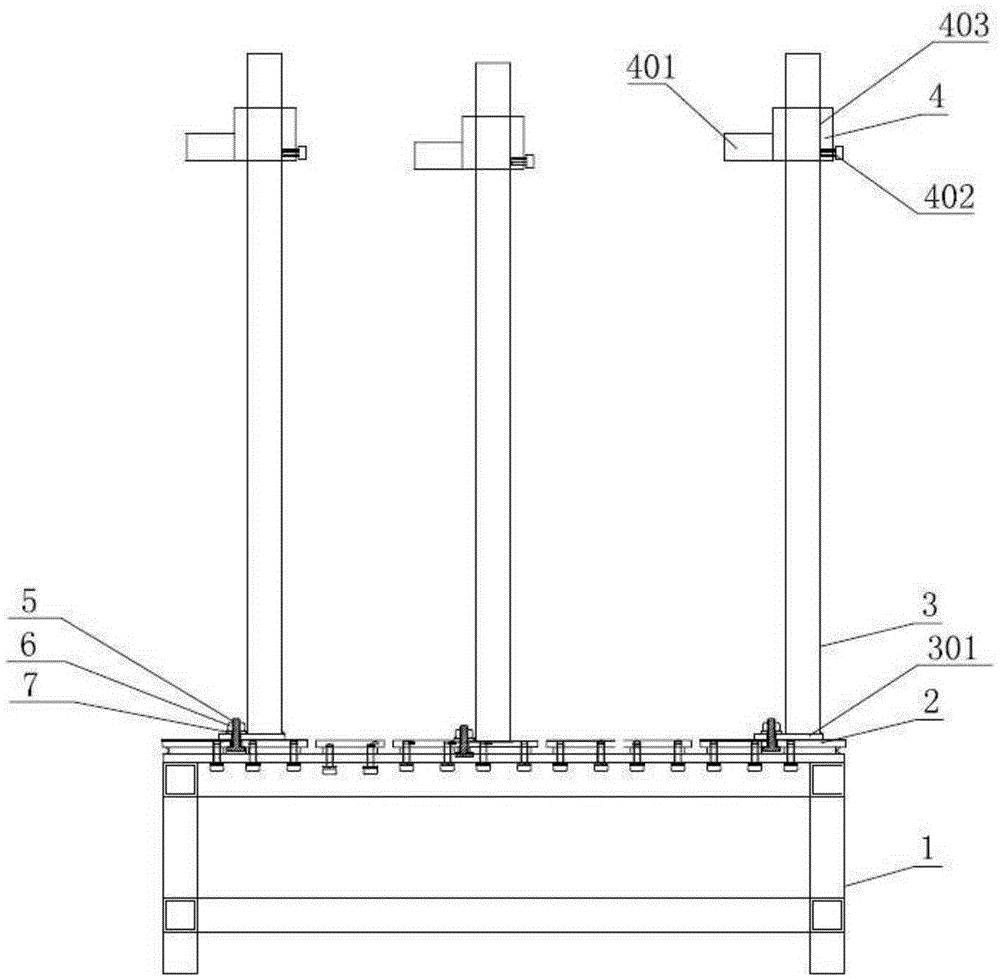

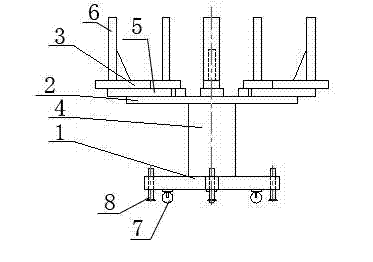

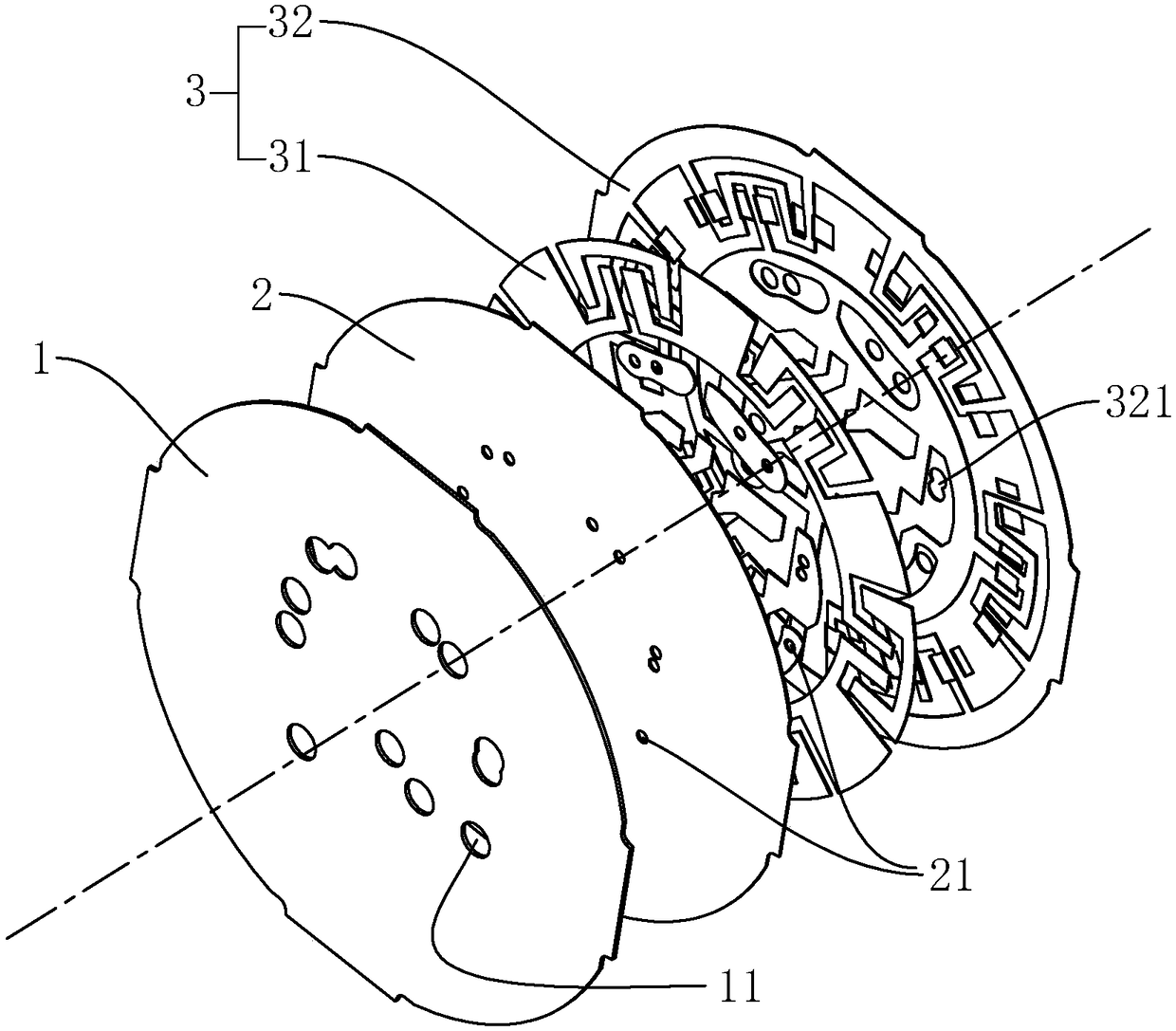

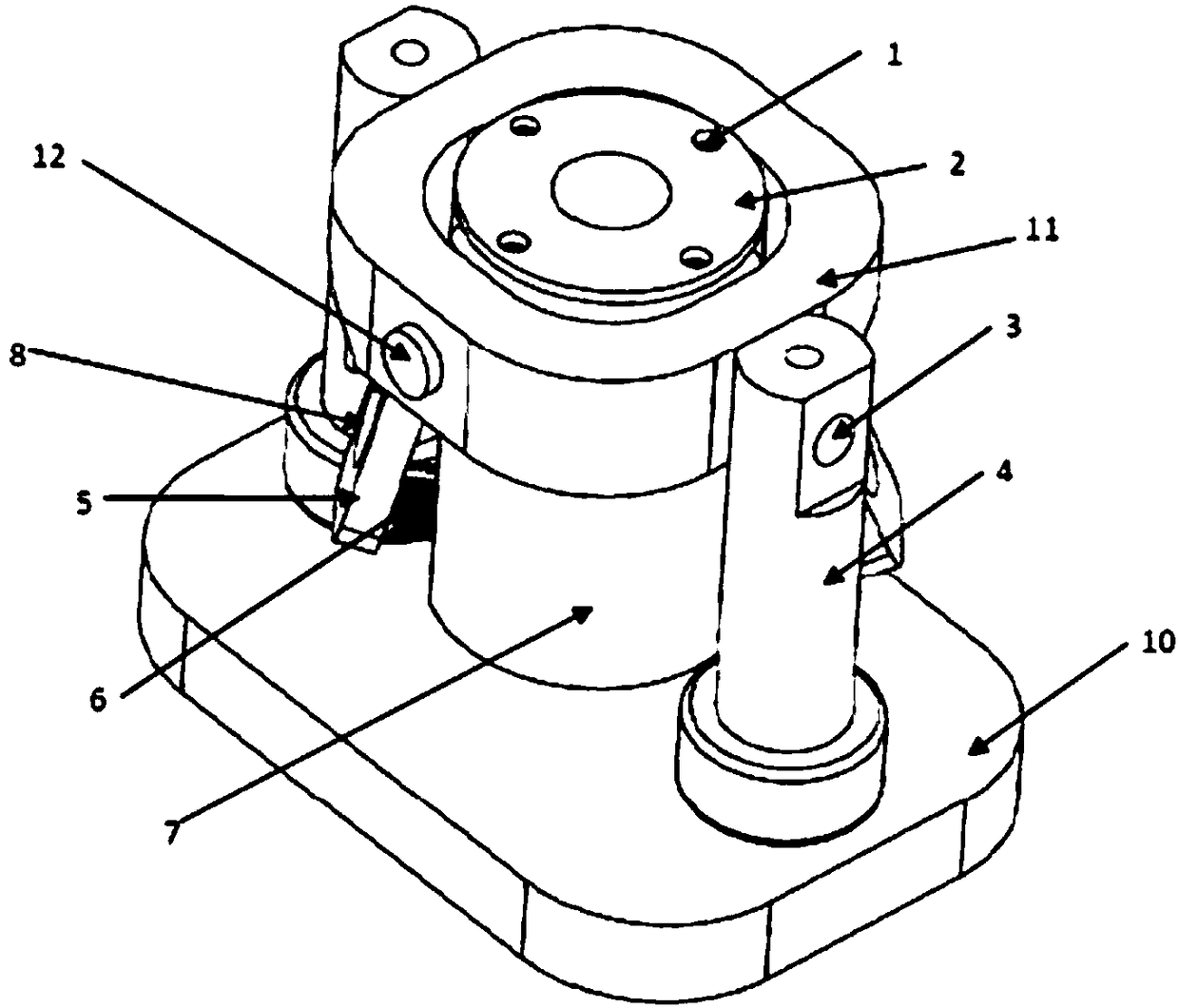

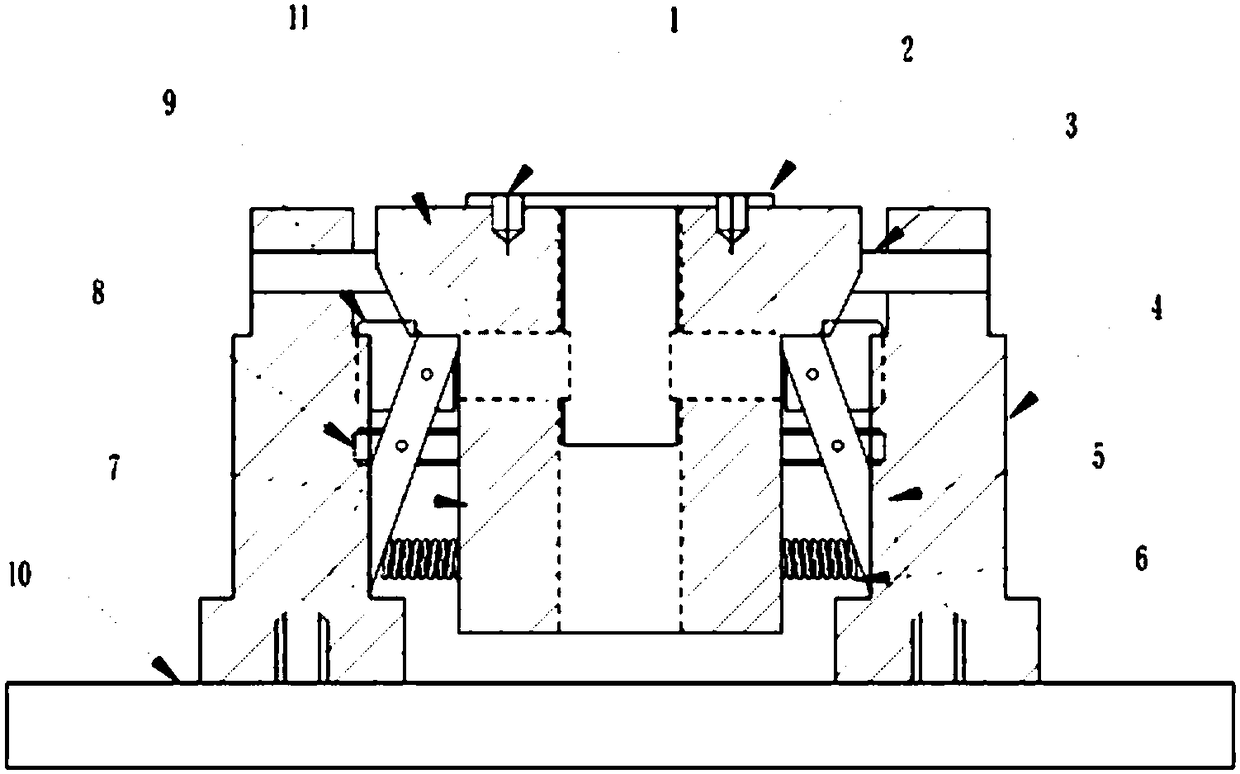

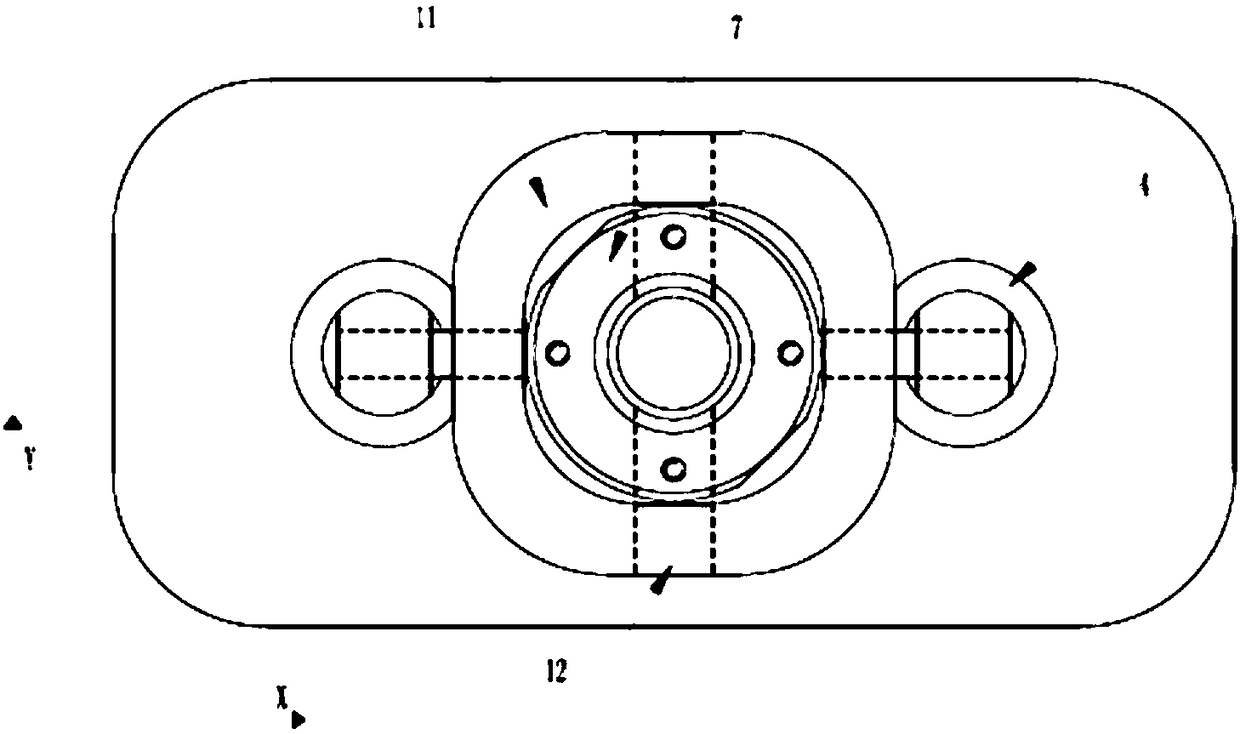

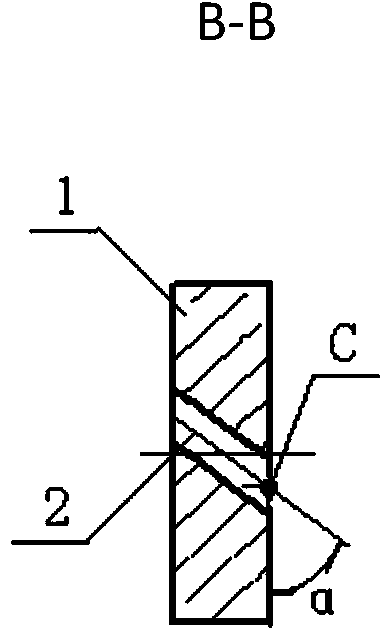

Moulding process of diagonal end ring of transformer and special mould

ActiveCN102368436AReduce frequency of useImprove operational safetyInductances/transformers/magnets manufactureDislocationOperations security

The invention relates to a moulding process of a diagonal end ring of a transformer and a special mould, belonging to the technical field of the transformers. The technical scheme provided by the invention is as follows: the special mould comprises a bracket (1), a round disk (2), an adjusting mechanism and a rotating mechanism (4); the adjusting mechanism is composed of fixing plates (5), telescopic plates (3), iron support strips (6) and calibrated scales; the telescopic plates are disposed on the fixing plates, the iron support strips are vertically disposed on the telescopic plates and the calibrated scales are disposed on the fixing plates; the round disk is disposed on the bracket via the rotating mechanism; a plurality of circular holes are formed in the round disk and equally separated into 24 groups along the circumferential direction; one fixing plate is fixed by means of each group of circular holes. The invention has the positive effects that a paper board is directly encircled on the special mould by an operator and then a packet tightener is mounted so that the dislocation of the packet tightener is very easy to find out, and the operation safety is effectively improved; the special mould can be further directly rotated when being used, so that the labour intensity of the operator can be relieved; the dimension of the special mould can be adjusted, and the manufactured diagonal end ring better meets the demand of graph paper.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

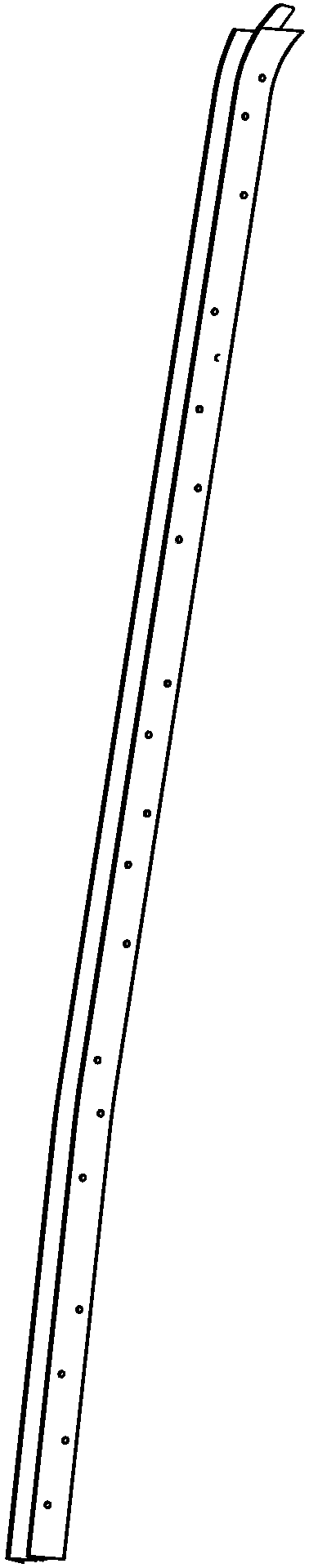

End corner post molding process of track vehicle

The invention relates to an end corner post molding process of a track vehicle. The process comprises the steps of obtaining a strip-shaped main material panel by utilizing a laser cutter for cutting and blanking; cutting a first supplement plate and a second supplement plate, with radian at side edges, by the laser cutter; bending the main material panel to form an end corner post with an W-shaped section by a bending machine; bending the middle lower part of the end corner post in a simmering mode to form a bending part consistent with a vehicle body drum shape in angle; bending a first plate and a second plate at the upper part of the end corner post to form the arc connected with a vehicle top; and welding the first and second supplement plates. The process analysis is performed according to design paper, the scheme combining the bending, the simmering and additionally welding the supplement plates is made; the end corner post quality is greatly improved by technological innovation, all sizes are controlled, the demands of paper and assembly are met, the quality and work efficiency are improved, the cost is reduced, the manufacturing process for forming a complicated workpiece is realized and the experience is accumulated for later forming of the complicated workpiece.

Owner:CRRC NANJING PUZHEN CO LTD

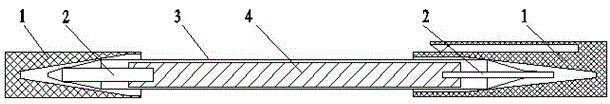

Marking liquid specially used for radiotherapy and marking pen applying marking liquid

ActiveCN104479455AClear and accurate positioningAdhesive and strongInksX-ray/gamma-ray/particle-irradiation therapyAlcoholTannic acid

The invention discloses a marking liquid specially used for radiotherapy and a marking pen applying the marking liquid and belongs to the technical field of medical devices. The marking liquid specially used for radiotherapy is composed of basic fuchsin, absolute ethyl alcohol, tannic acid, medical liquid paraffin and water. The marking pen applying the marking liquid specially used for radiotherapy comprises a pen body composed of a pen cap, a pen point and a pen holder, wherein an inner core is arranged in the pen holder, the pen point is inserted into the inner core, and the inner core is filled with the marking liquid specially used for radiotherapy. The marking pen applying the marking liquid specially used for radiotherapy can be used for accurately and clearly marking a radiotherapy line and (or) point on body surface of a patient receiving radiotherapy.

Owner:陈林

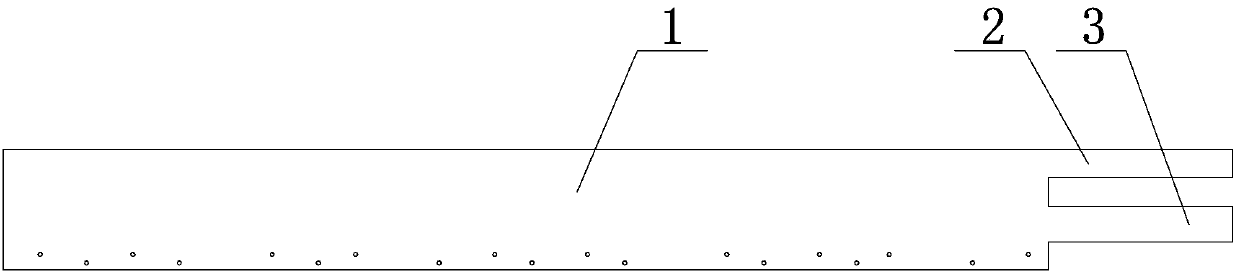

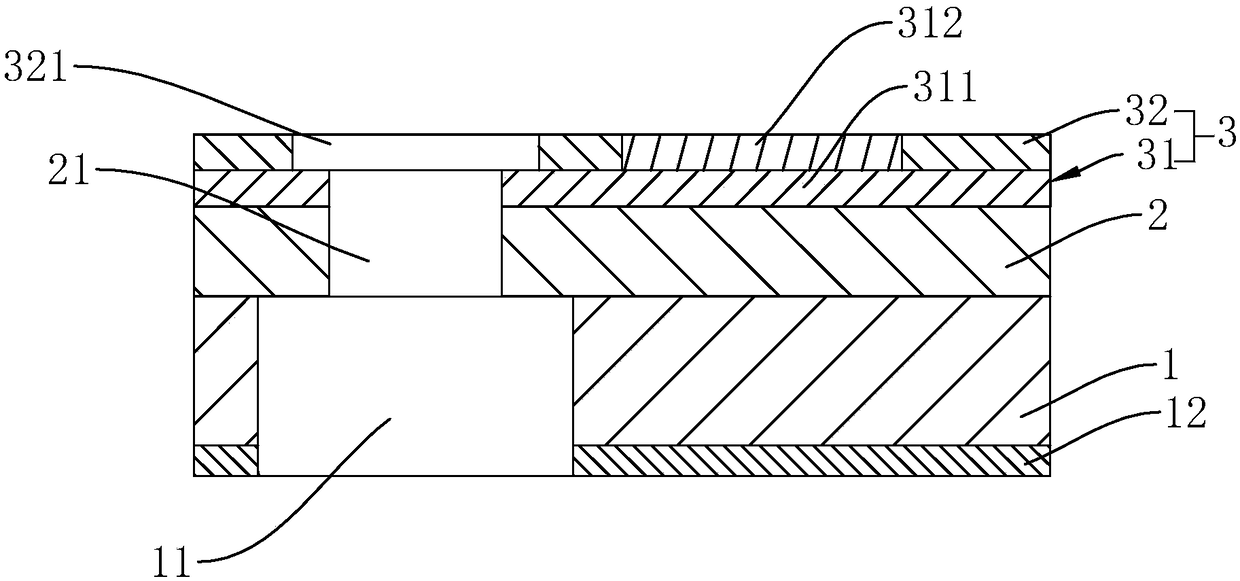

Single-side aluminum substrate for LED lamp and manufacturing process of single-side aluminum substrate

PendingCN108260274AEasy to weldAvoid short circuitPrinted circuit aspectsCircuit susbtrate materialsEngineeringAluminum substrate

The invention discloses a single-side aluminum substrate for an LED lamp and a manufacturing process of the single-side aluminum substrate and solves the problem that a manually-welded electronic component usually has long pins and cannot conveniently be welded to a soldering lug. According to the technical scheme, the single-side aluminum substrate is characterized in that an optical aluminum plate is provided with a plurality of first direct insertion holes allowing the pins of an electronic component to penetrate, a resin insulating layer and a circuit layer are provided with second directinsertion holes communicated with the first direct insertion holes, the first direct insertion holes and the second direct insertion holes form stepped holes, the first direct insertion holes are filled with resin protectors, one end faces, facing the resin insulating layer, of the resin protectors contacts with the resin insulating layer, and the resin protectors are provided with third direct insertion holes communicated with the second direct insertion holes. By the single-side aluminum substrate, short circuit between the direct insertion type electronic component and the aluminum substrate after direct insertion is avoided, and the welding between the direct insertion type electronic component and the aluminum substrate is facilitated.

Owner:宁波科杰电子科技有限公司

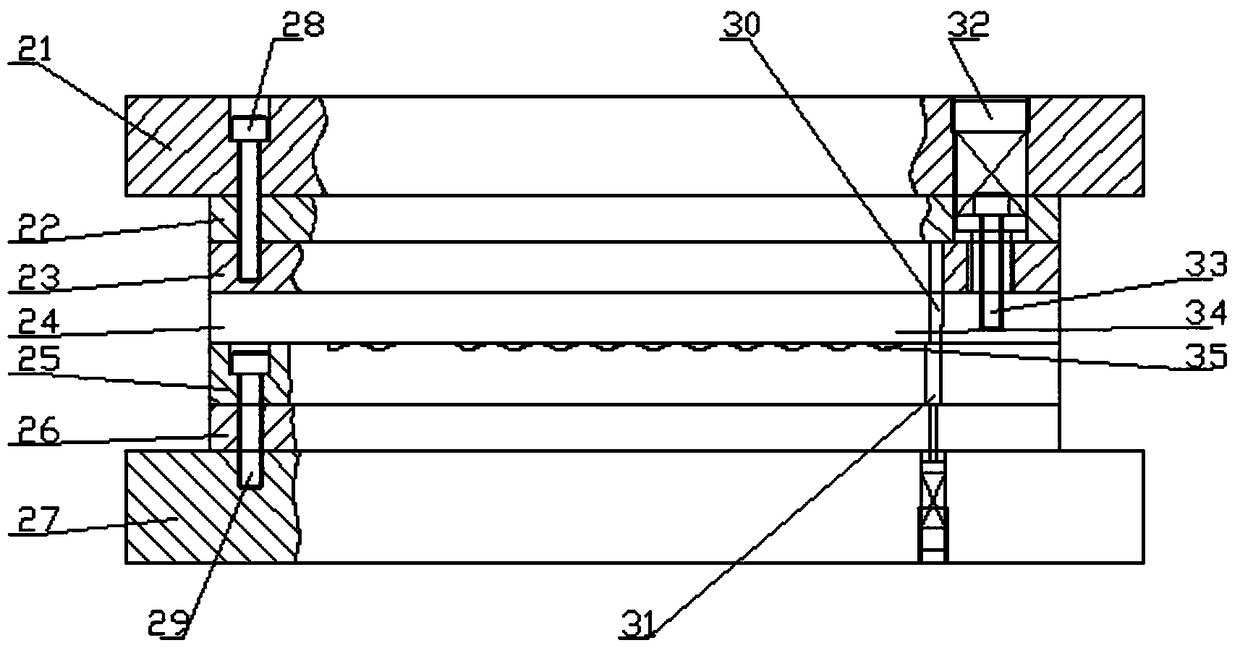

Tractor bracket welding tool

PendingCN107617837ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesTractorWelding

The invention discloses a tractor bracket welding tool which comprises a working table, two bottom plate hold-down devices and an outer side plate hold-down device arranged on the working table, and an inner side plate hold-down device, wherein the two bottom plate hold-down devices are symmetrically arranged in parallel and are fixedly connected through a straight pipe; the outer side plate hold-down device is perpendicularly arranged on the outer side of the bottom plate hold-down devices and is cooperated with the bottom plate hold-down devices to compress an outer side plate; the inner side plate hold-down device is perpendicularly arranged on the inner side of the bottom plate hold-down devices and is cooperated with the bottom plate hold-down devices to compress an inner side plate;and a circular pipe positioning device capable of compressing a hollow connecting circular pipe is further arranged on the outer side plate hold-down device. The tractor bracket welding tool can precisely combine all components of a tractor bracket, can install and weld all components of the connecting bracket at one time, is high in welding rate of finished products and is simple in structure andconvenient to operate.

Owner:浙江顺得机械有限公司

Honing full-floating tool

The invention discloses a honing full-floating tool. Honing support pillars are fixed onto a base through screws; a honing floating sleeve is connected with the honing support pillars through center pins; a honing core sleeve is connected with the honing floating sleeve through a rotary shaft pin; a reducing sleeve is assembled into the honing floating sleeve and is fixed through positioning screws; handles on two sides are fixed onto honing pins through a way of penetrating screws through installation holes in the upper end; fixed screws are clamped to the middle of a U-shaped port, are connected onto fixed screw caps through a way of penetrating screws through installation holes, and are connected onto the honing support pillars; springs are symmetrically arranged on the surface of the honing core sleeve; one ends of pin heads of the honing pins are inserted into the honing support pillars; the other ends of the pin heads of the honing pins penetrate through side holes of the honingcore sleeve and the reducing sleeve; and a component to be processed is fixed through pressing the surface of the component to be processed, and the honing core sleeve and the reducing sleeve are fixed on the same horizontal line. According to the honing full-floating tool provided by the invention, the dimensional accuracy and the behavior tolerance of the product can be ensured.

Owner:DADONG LINGANG IND PARK ZONE HEBEN PRECISION MACHINERY

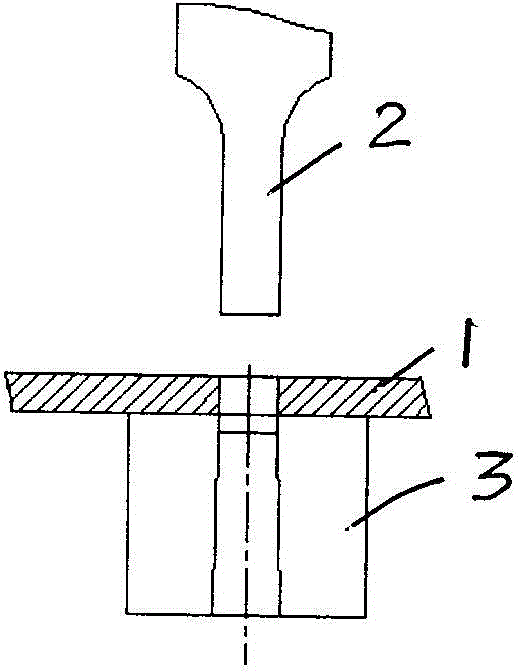

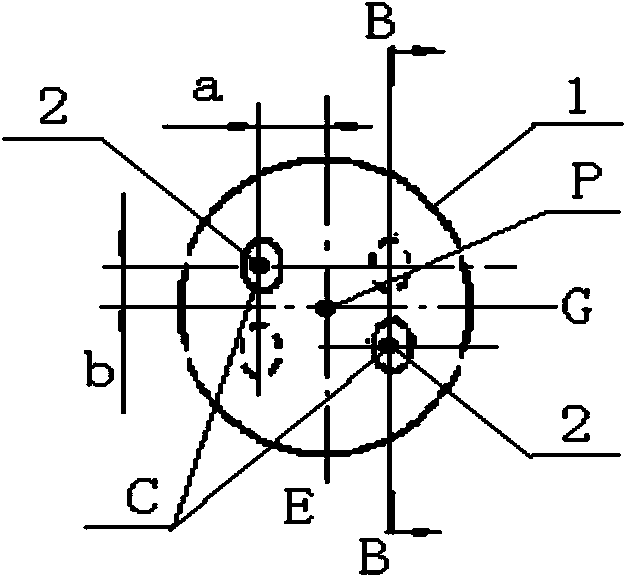

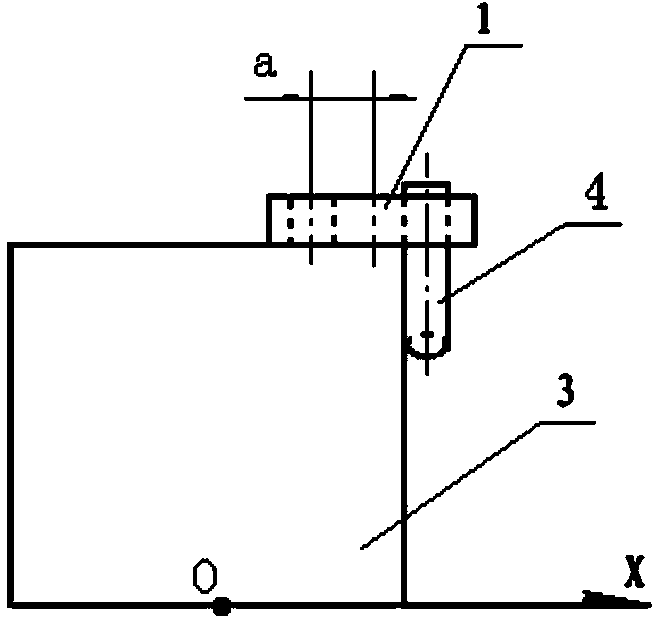

Detection method for swirl holes in nozzle swirl plate of aircraft engine

InactiveCN104279966AGuaranteed atomization effectAccurate measurementUsing optical meansAero engineAerospace engineering

The invention belongs to measuring technologies and relates to a detection method for swirl holes in a nozzle swirl plate of an aircraft engine. The method comprises the following detection steps of assembling positioning pins, placing the nozzle swirl plate (1), measuring central coordinate values of the nozzle swirl plate (1), detecting the size a and detecting the size b. According to the detection method for the swirl holes in the nozzle swirl plate of the aircraft engine, the size a and the size b can be measured accurately, it is guaranteed that the size a and the size b meet requirements of drawings, and the atomization performance of a nozzle is guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com