Blanking forming technical method for processing step holes by adopting smooth feeding mold

A technology of mold processing and stepped holes, which is applied in the field of mechanical processing, punching and forming, and can solve problems such as the inability to realize automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

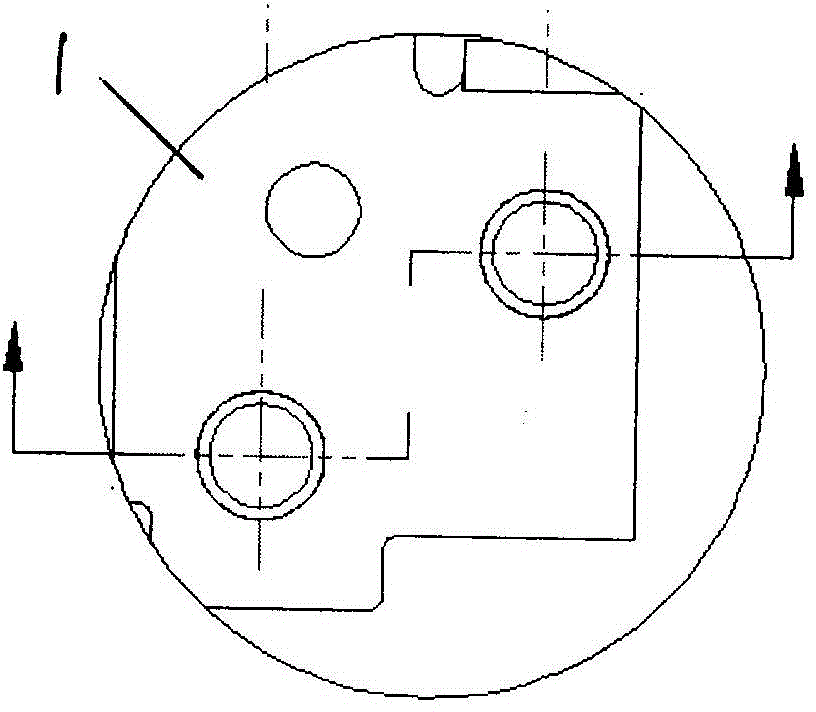

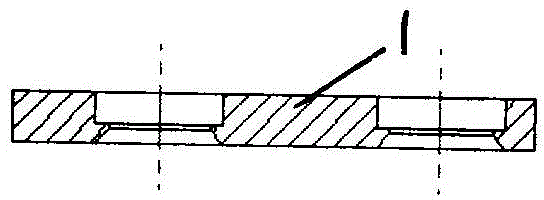

[0023] Such as Figure 1.1 , 1.2 One of the parts shown is the static contact in the circuit breaker product. The material of the part is pure copper and semi-hard; the thickness of the material is 1±0.03mm.

[0024] Due to assembly and functional requirements, there are two precision stepped holes in the part drawing. The diameter of the stepped hole is 2.6±0.03mm on the front, the depth is 0.65±0.03mm, and the depth on the back is 0.25±0.03mm*45 degrees. The diameter is 2.1±0.03mm, and the position accuracy of the two stepped holes in the X-axis direction and the Y-axis direction are both ±0.02mm.

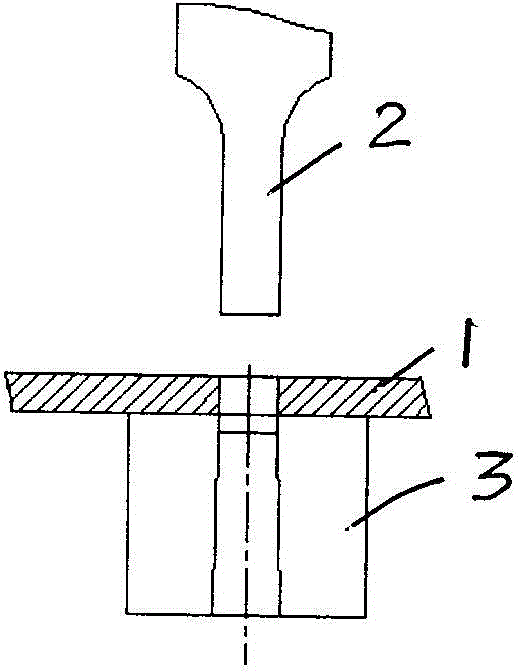

[0025] Adopt the overall structure requirements of the mold: in order to meet the shape and dimensional accuracy requirements of the step hole of the part, it is necessary to design a six-step forming structure. In order to ensure the position accuracy of each step of the forming structure and the position accuracy of the two step holes, the overall structure of the mold is devel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com