Detection method for swirl holes in nozzle swirl plate of aircraft engine

An aero-engine and detection method technology, which is applied in the field of measurement, can solve the problems of scrapped nozzles, inability to measure, and affect the atomization performance indicators of nozzles, and achieve the effect of ensuring atomization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

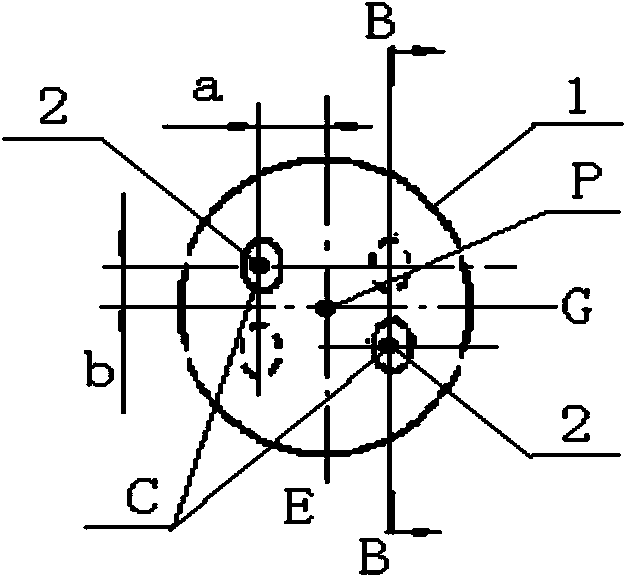

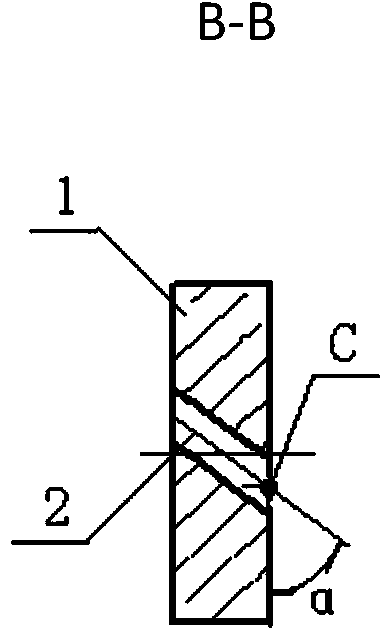

[0026] Drawings require dimension a=0.75±0.012mm, b=0.42±0.012mm, and the detection steps of dimension a and dimension b are as follows:

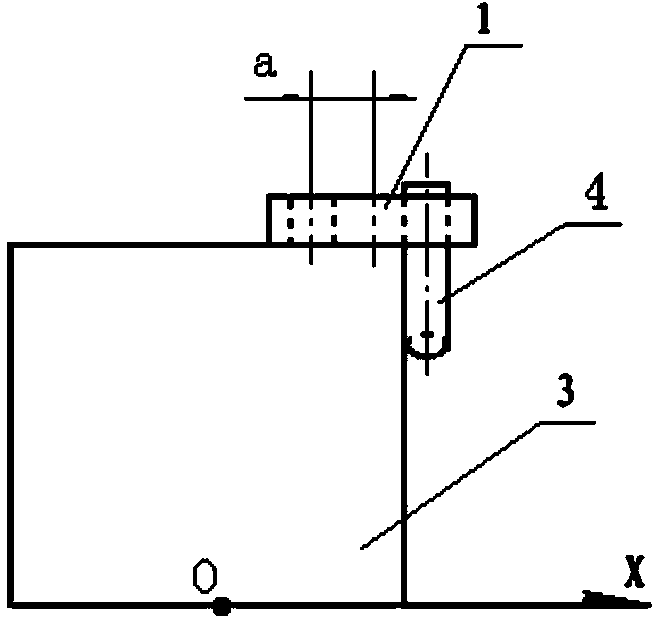

[0027] 1. Assemble the locating pin: Insert the upper end of the locating pin 4 into the vortex hole 2 from the lower port of the vortex hole 2 of the nozzle vortex sheet 1. The locating pin 4 is a cylindrical pin with an outer diameter of 0.518mm;

[0028] 2. Place the nozzle vortex sheet 1: place the nozzle vortex sheet 1 with the positioning pin 4 on the upper surface of the detection platform 3 to ensure that the lower surface of the nozzle vortex sheet 1 fits with the upper surface of the detection platform 3, and the position of the positioning pin 4 The outer circular surface is attached to the side of the detection platform 3, and the detection platform 3 is a cube; 502 glue is applied to the bonding seam between the lower surface of the nozzle vortex sheet 1 and the upper surface of the detection platform 3;

[0029] 3. Measure the...

Embodiment 2

[0035] Drawings require dimensions a=0.75±0.012mm, b=0.42±0.012mm, and the detection steps of a and b are as follows:

[0036] 1. Assemble the positioning pin: Insert the upper end of the positioning pin 4 into the vortex hole 2 from the lower port of the vortex hole 2 of the nozzle vortex sheet 1. The positioning pin 4 is a cylindrical pin with an outer diameter of 0.52mm;

[0037] 2. Place the nozzle vortex sheet 1: place the nozzle vortex sheet 1 with the positioning pin 4 on the upper surface of the detection platform 3 to ensure that the lower surface of the nozzle vortex sheet 1 fits with the upper surface of the detection platform 3, and the position of the positioning pin 4 The outer circular surface is attached to the side of the detection platform 3, and the detection platform 3 is a cube; 502 glue is applied to the bonding seam between the lower surface of the nozzle vortex sheet 1 and the upper surface of the detection platform 3;

[0038] 3. Measure the center coo...

Embodiment 3

[0044] Drawings require dimensions a=0.75±0.012mm, b=0.42±0.012mm, and the detection steps of a and b are as follows:

[0045] 1. Assemble the locating pin: Insert the upper end of the locating pin 4 into the vortex hole 2 from the lower port of the vortex hole 2 of the nozzle vortex sheet 1. The locating pin 4 is a cylindrical pin with an outer diameter of 0.515mm;

[0046] 2. Place the nozzle vortex sheet 1: place the nozzle vortex sheet 1 with the positioning pin 4 on the upper surface of the detection platform 3 to ensure that the lower surface of the nozzle vortex sheet 1 fits with the upper surface of the detection platform 3, and the position of the positioning pin 4 The outer circular surface is attached to the side of the detection platform 3, and the detection platform 3 is a cube; 502 glue is applied to the bonding seam between the lower surface of the nozzle vortex sheet 1 and the upper surface of the detection platform 3;

[0047] 3. Measure the center coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com