Aluminum foil oiling device and oiling method thereof

An oiling device and aluminum foil technology, applied in the direction of spray discharge device, liquid supply device, liquid spraying equipment, etc., can solve the problem of increasing the labor intensity and operation content of operators, affecting the stability of product quality, and the uneven randomness of manual coating Problems such as the amount of application, to achieve the effect of preventing the spread of oil mist, uniform charge, and uniform oil application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

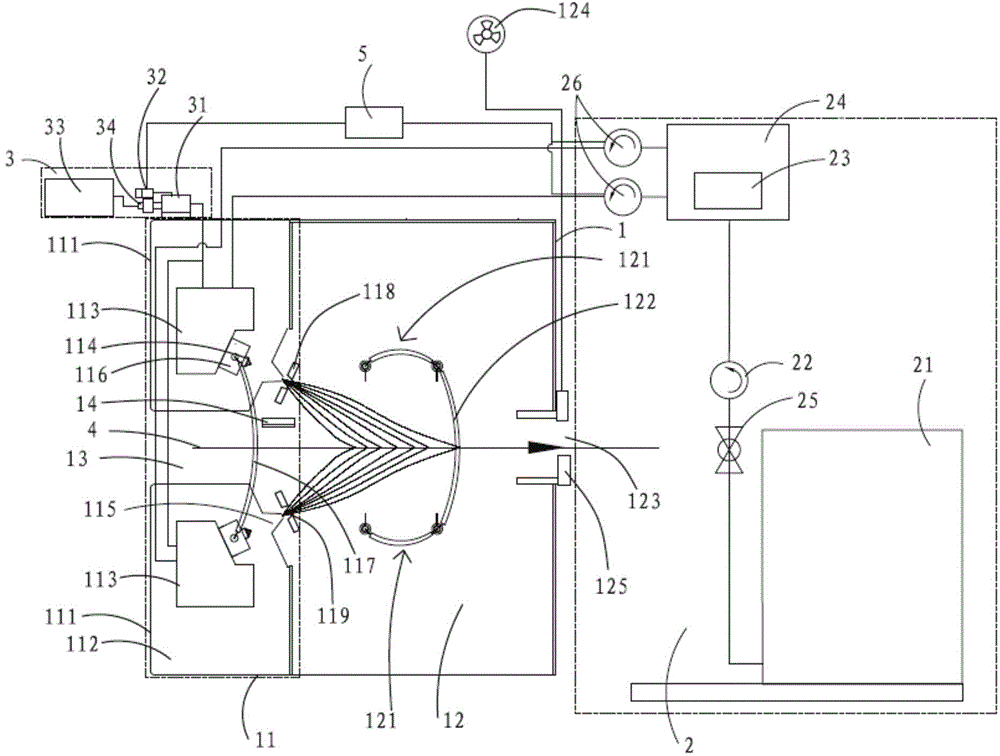

[0029] Attached below Figures 1 to 2 And the specific embodiment will further describe the aluminum foil oiling device of the present invention.

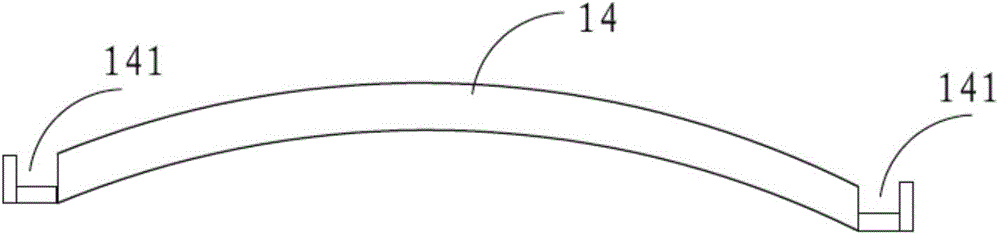

[0030] Such as figure 1 , figure 2 As shown, an aluminum foil oiling device is disclosed, including an oiling box 1, an oil supply unit 2 and an air supply unit 3, and the oiling box 1 is connected to the oil supply unit 2 and the air supply unit 3 respectively; wherein, the oiling box 1 includes an atomizing device 11 and an oiling chamber 12 that are closely connected to each other; the atomizing device 11 includes two groups of atomizing units 111, and there is a placement space 13 for placing the aluminum foil 4 to be oiled between the two groups of atomizing units 111, Two groups of atomizing units 111 are arranged symmetrically on the upper and lower sides of the placement space 13. The atomizing units 111 include an atomizing chamber 112 and a mixing box 113 located inside the atomizing chamber 112. The oil supply unit 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com