Dense deep hole electric spark hole making method for annular part

A technology of ring parts and EDM, which is applied in the field of dense deep hole EDM drilling of ring parts, can solve the problems of reduced export processing speed, increased labor intensity, and no consideration of mismatching problems, so as to meet production needs and improve processing Effects on Quality and Process Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the diameter of the deep hole 8 is 0.7mm, and the depth is 7mm.

[0043] A method for forming dense deep-hole electric discharge holes for annular parts, comprising the following steps:

[0044] Step 1: Preparation Phase

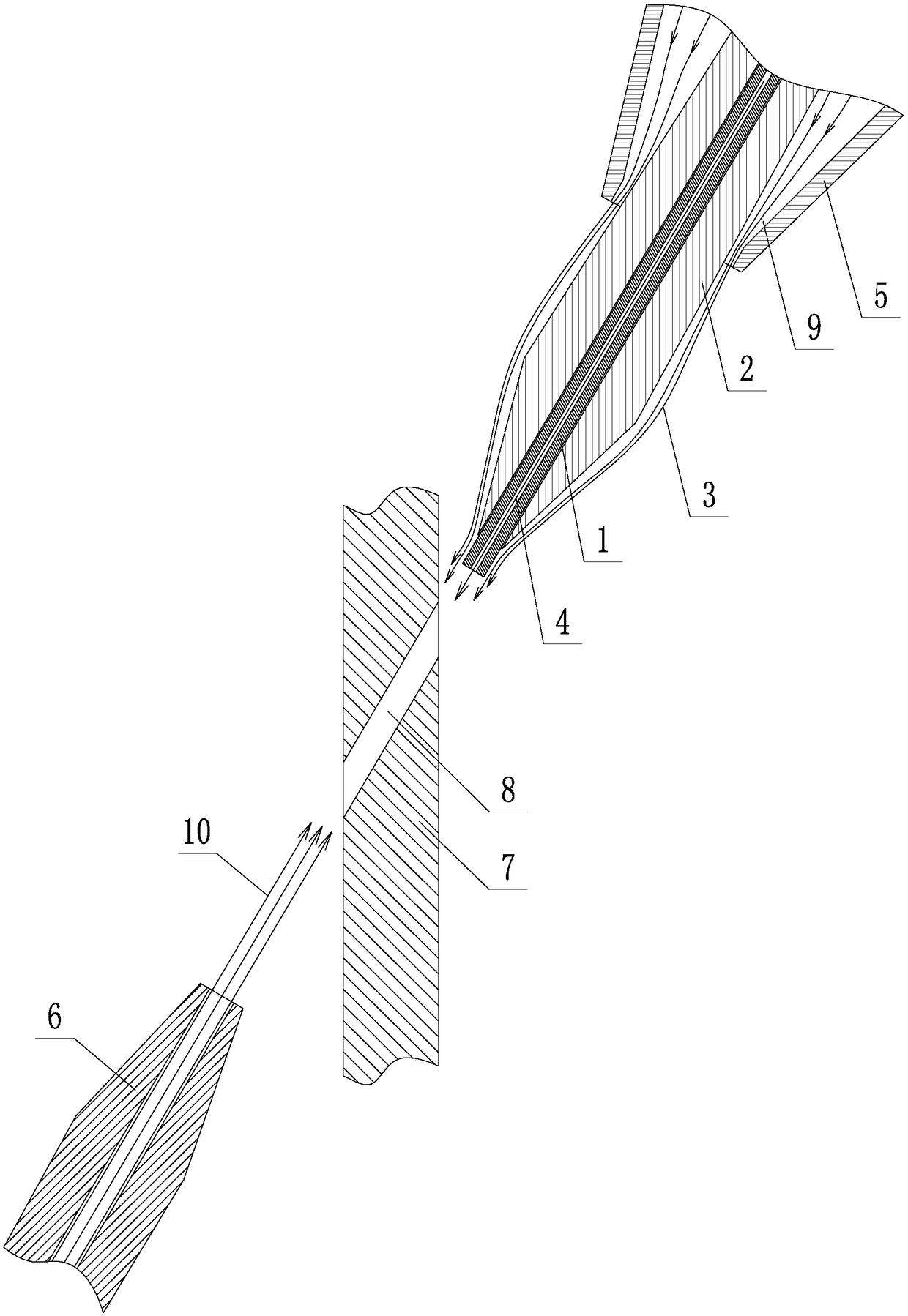

[0045] ①. Transform the electrode catheter 2, and process the end of the electrode catheter 2 into a conical structure;

[0046] ②. Prepare an inlet outer flushing conduit 5, set the inlet outer flushing conduit 5 on the outside of the electrode catheter 2, and form an annular liquid outlet gap 9 between the inlet outer flushing conduit 5 and the electrode catheter 2, and form a ring The liquid outlet gap 9 outputs the inlet flushing liquid 4, and the inlet flushing liquid 4 will flow along the outer surface of the electrode catheter 2 to the surface of the electrode tube 1;

[0047] ③. Prepare an outlet flushing nozzle 6, and connect the outlet flushing nozzle 6 with the bed of the EDM machine through a multi-degree-of-freedom b...

Embodiment 2

[0071] In the present embodiment, the aperture of the deep hole 8 is 0.85mm, and the hole depth is 8mm; the steps of the hole making method refer to embodiment one, and the difference is the processing parameters set in the preparation stage step 6. In the present embodiment, the hole making process The processing parameters of each stage are as follows:

[0072] The processing parameters in the clearing stage are: gap voltage is 60V, servo feed speed is 1mm / min, breakdown voltage is 140V, peak current is 2A, pulse width is 0.5us, and pulse gap is 27us;

[0073] The processing parameters in the rework stage are: the stroke distance is 1.5mm, the gap voltage is 40V, the servo feed speed is 1mm / min, the breakdown voltage is 140V, the peak current is 10A, the pulse width is 10us, and the pulse gap is 8us;

[0074] The processing parameters at the entrance stage are: stroke distance 1.3mm, gap voltage 30V, servo feed speed 1mm / min, breakdown voltage 140V, peak current 13A, pulse w...

Embodiment 3

[0078] In the present embodiment, the diameter of the deep hole 8 is 1 mm, and the depth of the hole is 9 mm; the steps of the hole-making method are with reference to Embodiment 1, and the difference is the processing parameters set in the preparatory stage step 6. In the present embodiment, in the hole-making process The processing parameters of each stage are as follows:

[0079] The processing parameters in the clearing stage are: gap voltage is 60V, servo feed speed is 1mm / min, breakdown voltage is 150V, peak current is 2A, pulse width is 0.5us, and pulse gap is 27us;

[0080] The processing parameters in the rework stage are: the stroke distance is 2mm, the gap voltage is 40V, the servo feed speed is 1mm / min, the breakdown voltage is 150V, the peak current is 10A, the pulse width is 10us, and the pulse gap is 8us;

[0081] The processing parameters at the entrance stage are: stroke distance 1.5mm, gap voltage 30V, servo feed speed 1mm / min, breakdown voltage 150V, peak cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com