Flame denitration combustor device and flame denitration system

A denitrification burner and flame technology, which is applied in the field of nuclear engineering, can solve problems such as difficult to ensure stable reaction and less products, achieve stable combustion, improve stability, and ensure the effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

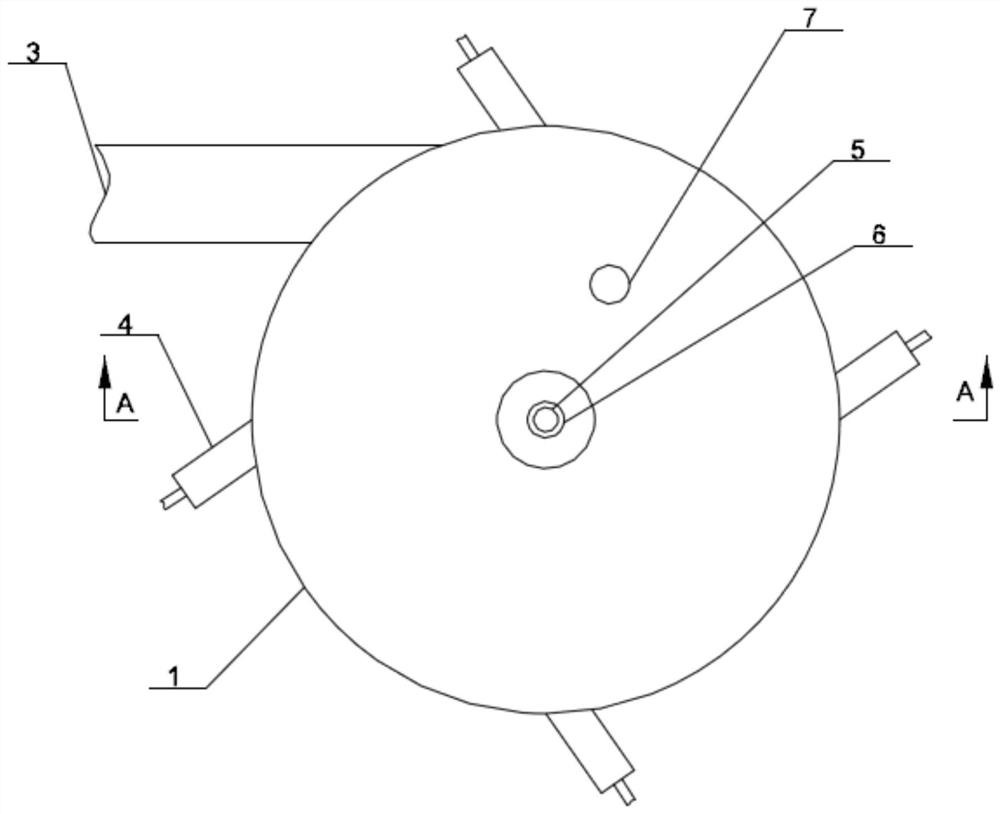

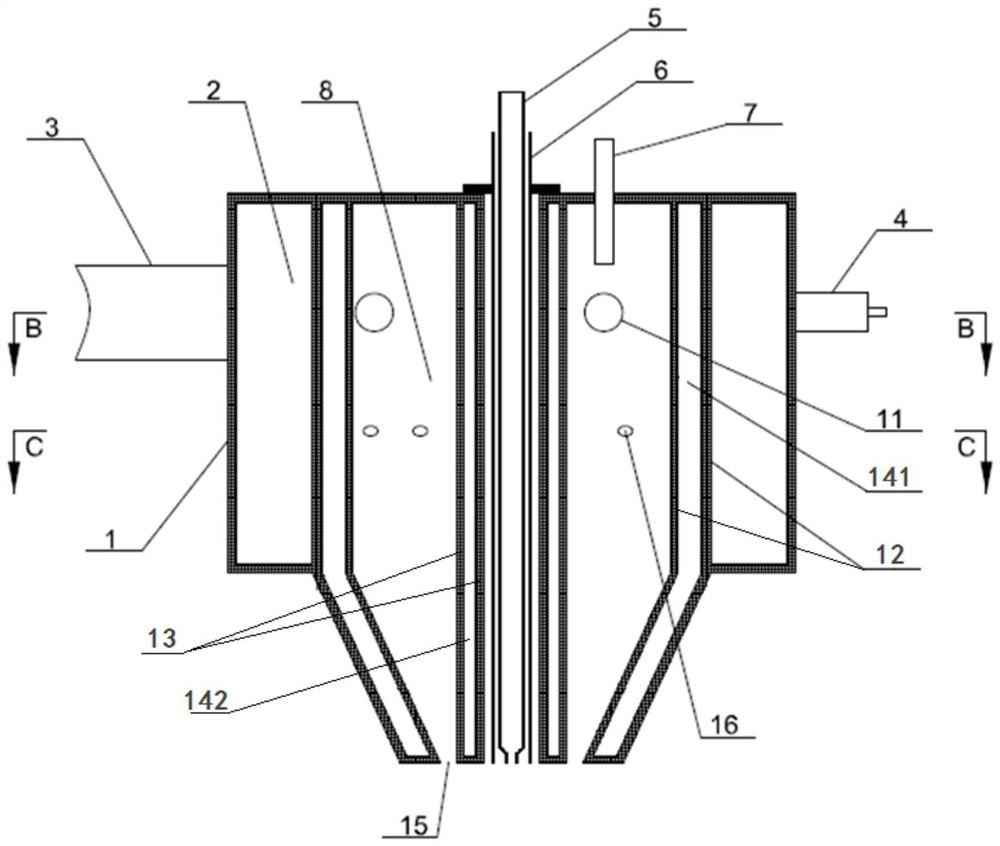

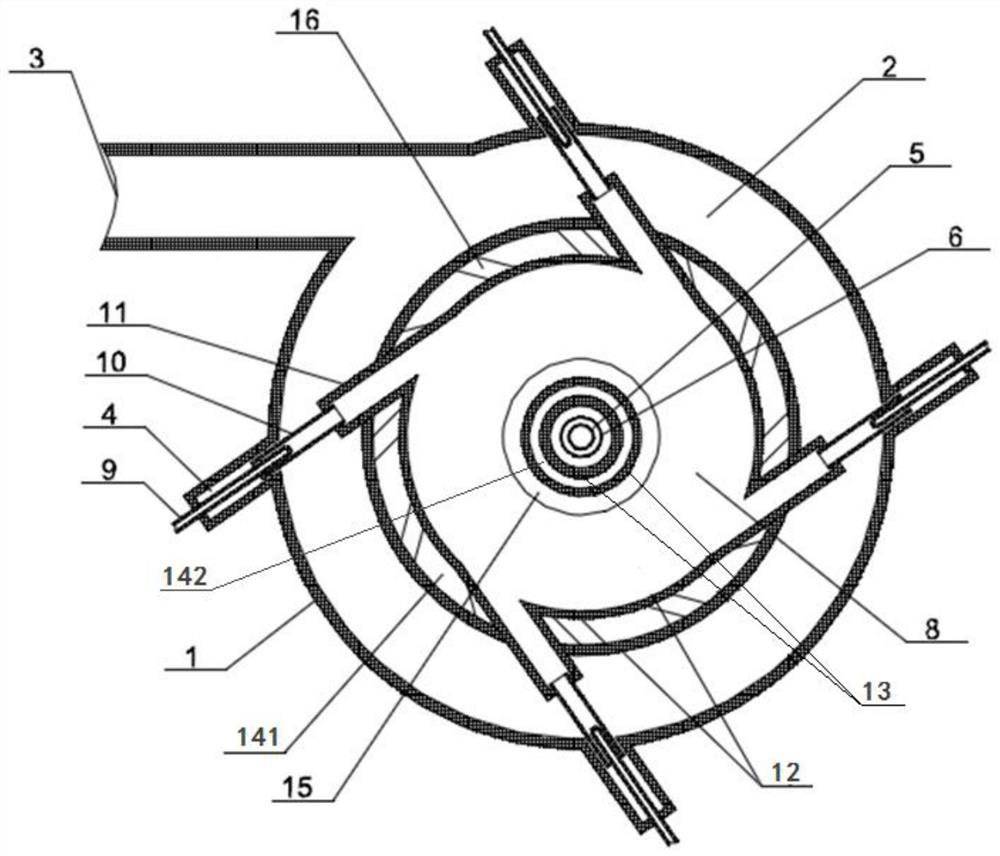

[0042] Such as Figure 1-Figure 5 As shown, this embodiment discloses a flame denitrification burner device, which includes a flame chamber 8, a combustion head 4, and a material nozzle 5, wherein: the combustion head 4 communicates with the flame chamber 8, and is used to pass into the flame chamber 8. A mixture of fuel and air; the mixture ignites the fuel in the flame chamber and generates high-temperature gas; the flame chamber 8 is provided with a combustion gas outlet 15, and the fuel gas outlet 15 is located at the end of the combustion head 4, and the center of the flame chamber 8 has Through the inner hole, the material nozzle 5 is arranged in the through inner hole of the flame chamber 8 and runs through the flame chamber 8, the material nozzle 5 is used to circulate uranyl nitrate, the outlet position of the material nozzle 5 and the position of the fuel gas outlet 15 are the flame chamber 8 The same end of the same end, so that the uranyl nitrate ejected from the m...

Embodiment 2

[0058] This embodiment discloses a flame denitration fuel device, which differs from the flame denitration burner device described in Embodiment 1 in that it also includes a pressurizing mechanism,

[0059] The pressurizing mechanism is used to pressurize the air before the air is passed into the air chamber 2, so that the air has a relatively high pressure. After the pressurized air enters the flame chamber 8, it will promote the gas in the flame chamber 8 to form a high-speed The rotating high-pressure and high-temperature gas, after contacting the uranyl nitrate ejected from the material nozzle 5, the high-pressure and high-temperature gas will not only heat the uranyl nitrate, but also atomize the uranyl nitrate.

[0060] Moreover, since the device is equipped with a pressurizing mechanism, the material nozzle 5 can be an ordinary material nozzle 5, that is, the material nozzle 5 does not have the function of atomizing uranyl nitrate, but only plays the role of transporting...

Embodiment 3

[0062] This embodiment discloses a flame denitration system, which includes the flame denitration burner device described in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com