Fluid electromagnetic valve type metering ejector

A technology of solenoid valves and injectors, applied in fuel injection devices, machines/engines, exhaust gas treatment, etc., can solve problems such as insufficient atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

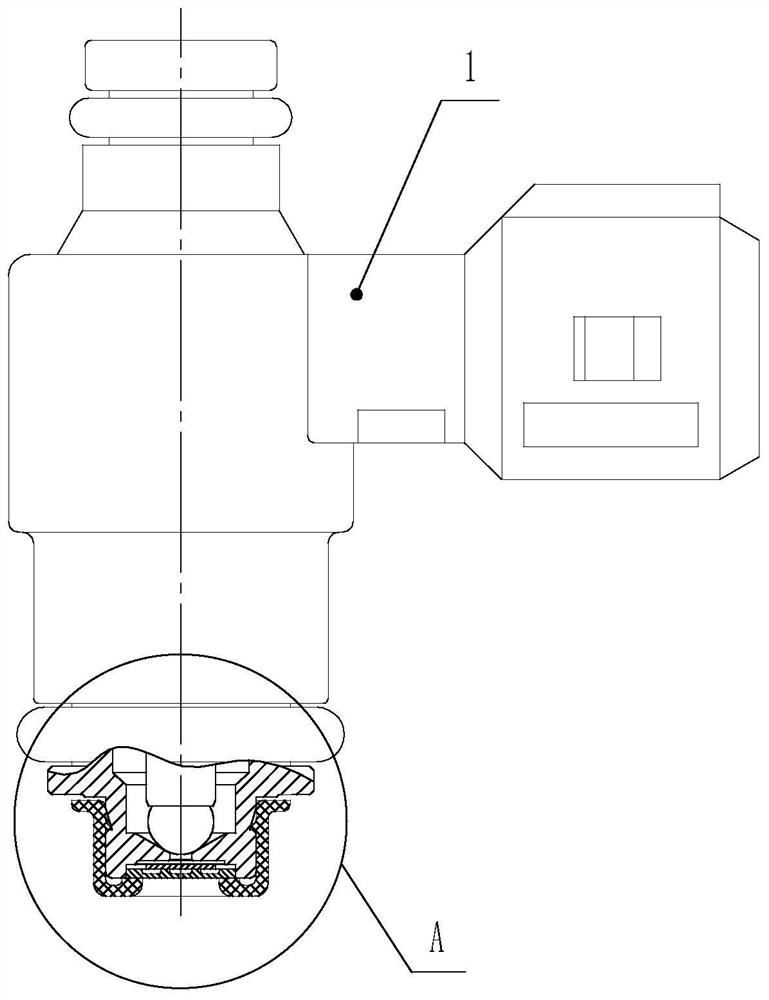

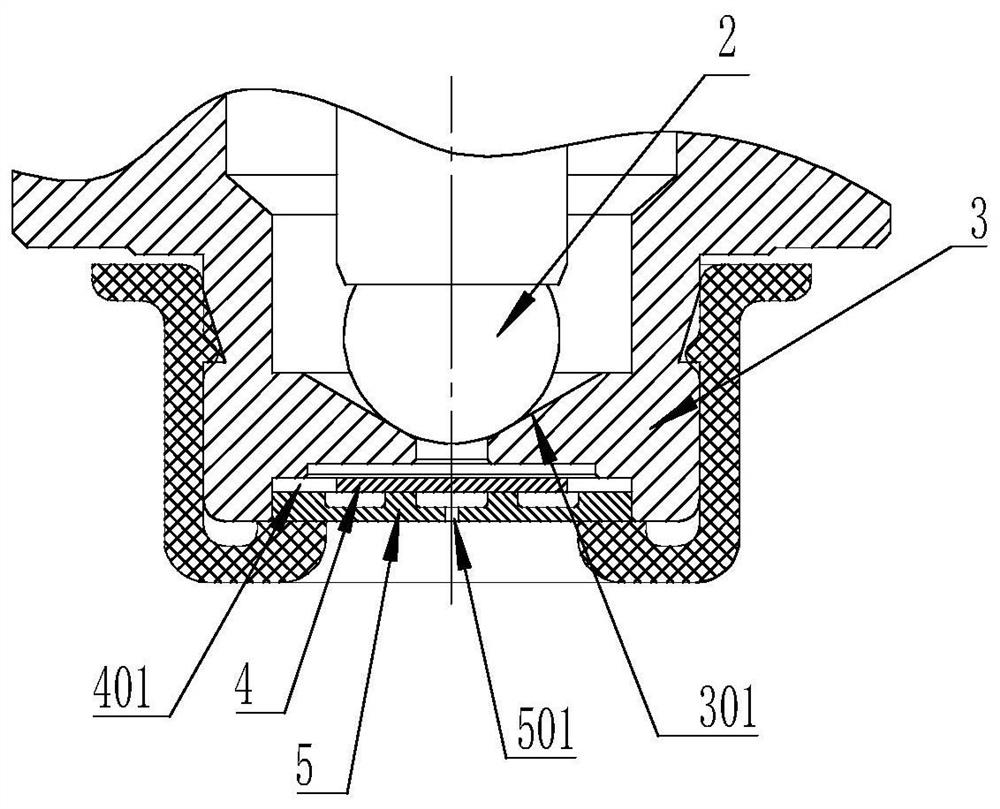

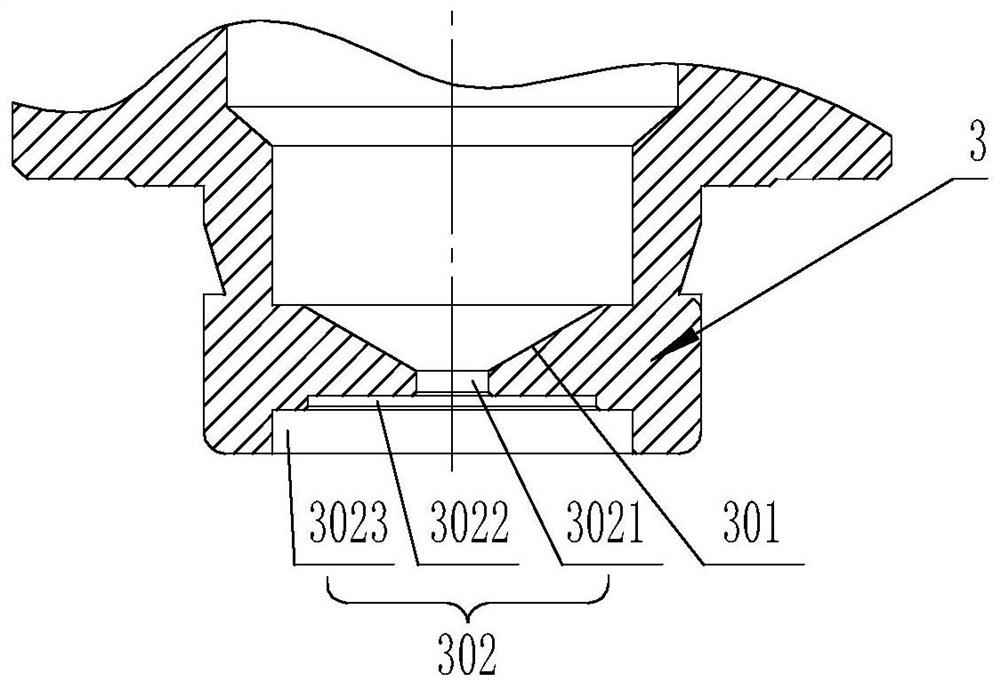

[0046] figure 1 Disclosed in is a fluid solenoid valve metering injector, which comprises a solenoid valve spray body 1 with a fluid input port, a nozzle with a spray hole, and the nozzle includes a valve seat 3 with a valve hole 301 1. The sealing steel ball 2 installed at the valve hole 301, the middle hole of the valve seat 3 positioned at the front end of the valve hole 301 is a stepped hole 302, and the stepped hole includes a first stepped hole 3021, a second stepped hole whose diameter gradually increases from inside to outside. Step hole 3022, third step hole 3023; wherein the first step hole 3021 is connected to the valve hole 301, and the third step hole 3023 is installed with a splitter 4 and a turbulent nozzle orifice plate 5 sequentially from the inside to the outside, and the flow sheet 4 is along the diameter The center of the turbulent nozzle orifice plate 5 is coaxially provided with a circular turbulent flow chamber Q1 and the spray hole 501, and the circumfe...

Embodiment 2

[0049] Figure 5 Disclosed in is another fluid solenoid valve type metering injector, the structure of which is basically the same as that of Embodiment 1, the difference is that: the turbulent flow orifice plate 5 is a split structure, the turbulent The flow orifice plate 5 is composed of a turbulent flow plate 51 and an orifice plate 52, and the turbulent flow plate 51 and the orifice plate 52 are installed on the outside of the shunt plate 4 sequentially from the inside to the outside; the turbulent flow chamber Q1 and the centrifugal turbulent flow groove Q2 is set on the turbulence sheet 51 , and the spray hole 501 is set on the spray hole plate 52 .

[0050] The specific dimensions of the split flow tank 401 , the turbulent flow chamber Q1 , the centrifugal turbulent flow tank Q2 , and the spray hole 501 are all different.

[0051] The specific structure of the fluid electromagnetic valve type metering injector described in the second embodiment is as follows:

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com