Waste liquid pool aeration tube for sewage treatment, and sewage treatment water purifying agent

A technology for sewage treatment and aeration pipes, which is used in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc. The effect of aeration dispersibility, good dispersion effect and structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

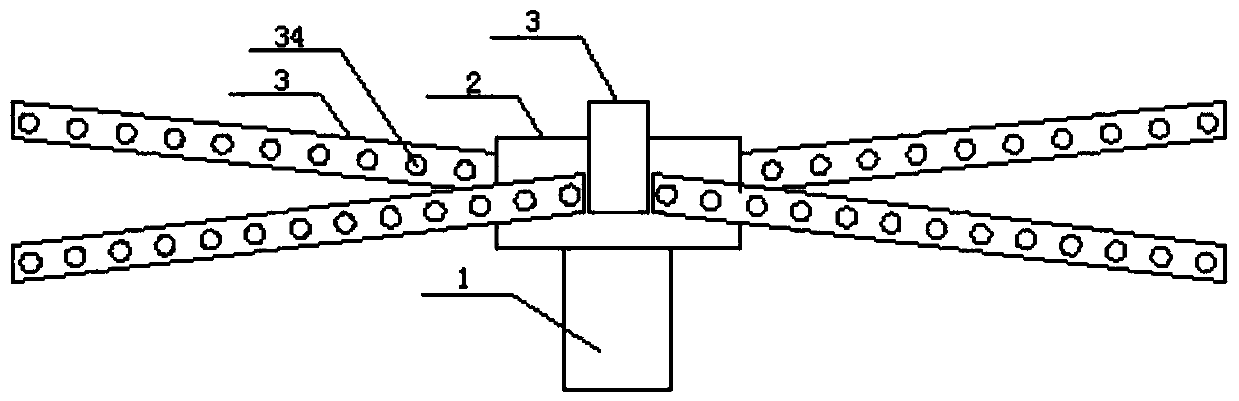

[0032] An aeration pipe for a waste liquid pool for sewage treatment, comprising an air inlet pipe 1 and a hollow cylindrical connection chamber 2, the bottom of the connection chamber 2 is provided with an installation port, and the installation port is adapted to the outer wall of the air inlet pipe 1, and the air inlet pipe 1 The through installation port is plugged into the connection chamber 2 and the upper port of the air intake pipe 1 is located in the connection chamber 2, and the air intake pipe 1 and the installation port are rotationally connected by a sealed bearing; specifically, the air intake pipe is fixedly extended from the bottom of the waste liquid pool, and connected The cavity is then rotatably installed with the upper part of the intake pipe.

[0033] The side wall of the connection chamber 2 is annularly provided with several connection ports 21, and the connection ports 21 are detachably connected with the aeration pipe 3. For example, the connection por...

Embodiment 2

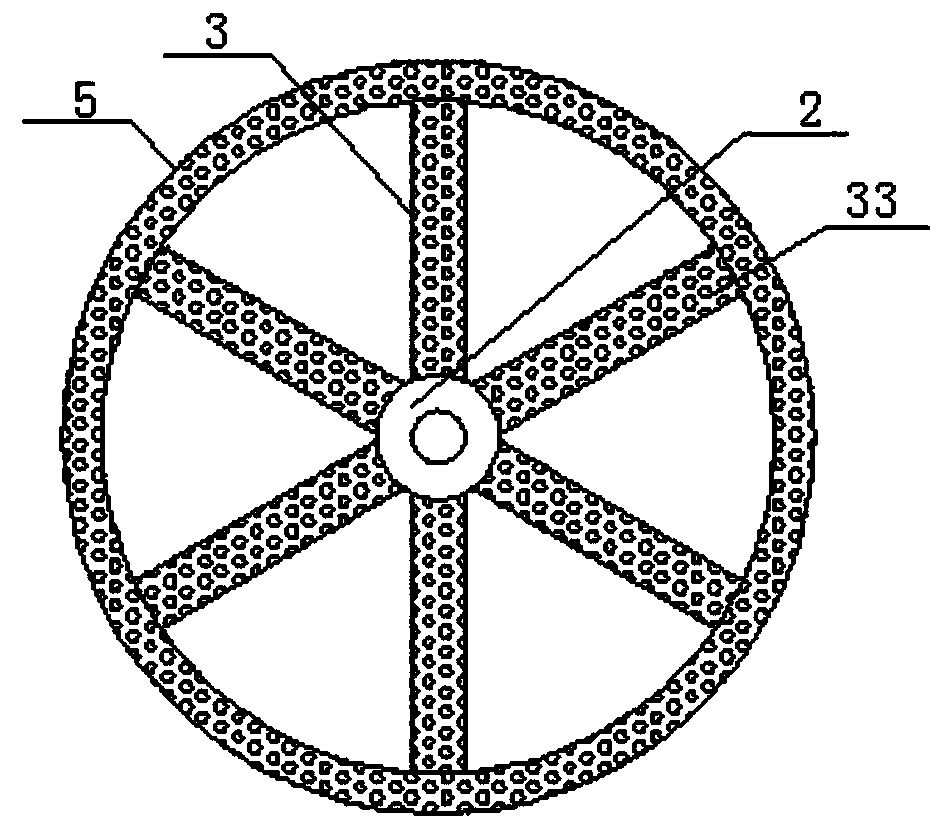

[0037] Based on the structure proposed in Example 1, the aeration tubes 3 are arranged obliquely, and the inclination directions of two adjacent aeration tubes 3 are opposite.

[0038] Further, it also includes an annular aeration tube 5, which is integrally communicated with the aeration tube 3 to improve the stability of the aeration tube 3; at least one annular aeration tube is connected between the aeration tubes 3 in the same inclined direction. Aeration pipe 5.

Embodiment 3

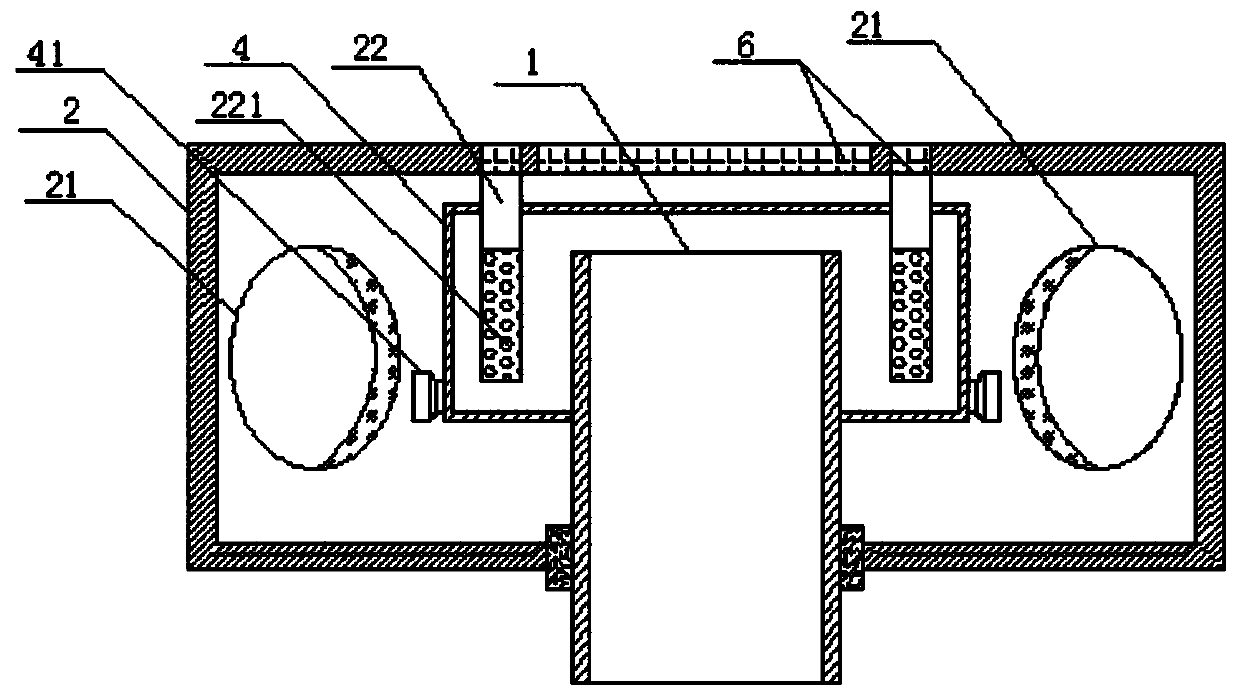

[0040] Based on the structure proposed in embodiment 1 or embodiment 2,

[0041] At least one stirring rod 22 is arranged on the top of the connecting chamber 2, and the lower end of the stirring rod 22 extends into the tank body 4 for stirring and mixing the water purifying agent.

[0042] Further, the stirring rod 22 is a hollow structure for containing solid water purifying agent, a number of communication holes 221 are opened on the side wall of the stirring rod 22 extending into the tank body 4 for mutual communication between the inside and outside, and the connecting cavity 2 The upper end face is hingedly equipped with a sealed chamber door 6, the sealed chamber door 6 is vertically corresponding to the tank body 4 and the stirring rod 22, and is used for putting in liquid water purifying agent and solid water purifying agent. The stirring rod 22 and the bottom surface of the tank body 4 are provided with Sewage outlet (not shown in the figure).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com