Folded plate membrane assembly for retarding membrane pollution in membrane bioreactor

A membrane bioreactor and membrane fouling technology, applied in the field of environmental engineering, can solve the problems of occupying a large space and reducing the packing density of membrane modules, so as to reduce operating costs, reduce concentration polarization, and enhance turbulence and disturbance effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

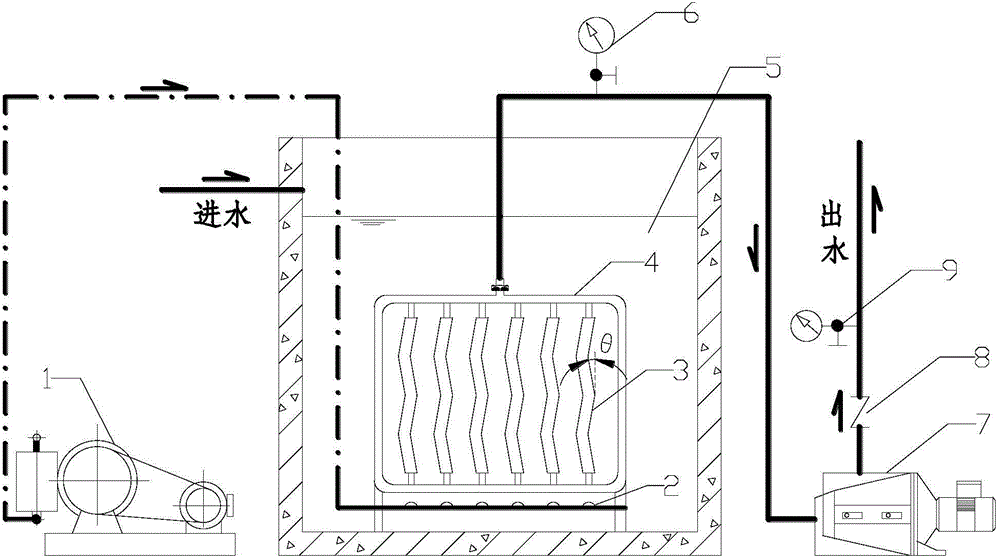

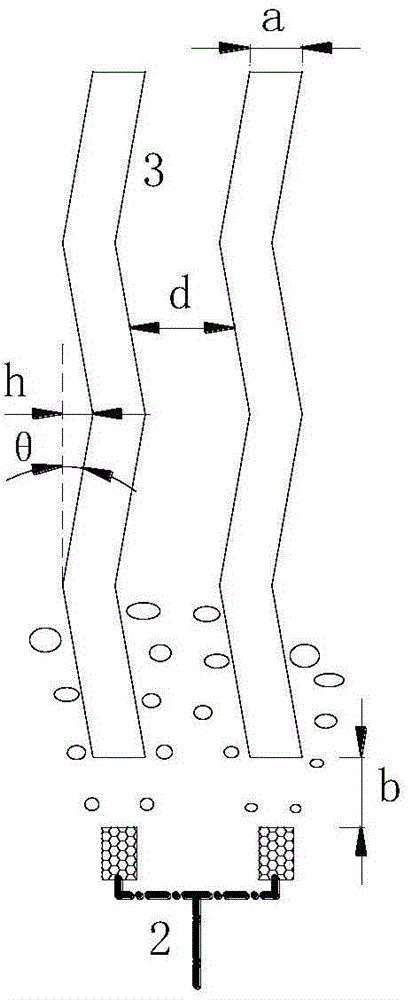

[0019] The amount of domestic sewage treated is 10.8m 3 / d, the COD concentration is 400mg / L. The flux of the folded plate membrane module 3 is maintained at 25L / (h·m 2 ), the effective filter area is 3m 2 , with a single-sided area of 1.5m 2 , a single folded plate membrane module contains 2 complete waveforms, the specific dimensions are: thickness a = 15mm, membrane surface height 1500mm, membrane surface width 1000mm, vertical inclination angle θ = 15°, and the wave height of each complete waveform h = 100mm, then It is calculated that a total of 6 appealing folded plate membrane modules are required. Six folded plate membrane modules 3 are installed in the membrane frame 4 in parallel, the horizontal distance between the membrane modules is d=30mm, the water outlet pipe at the upper end of the folded plate membrane module 3 is connected with the water collecting pipe above the membrane frame 4, and the membrane frame 4 is The slideway is put into the bioreactor 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com