Single-side aluminum substrate for LED lamp and manufacturing process of single-side aluminum substrate

A technology of LED lamp and manufacturing process, which is applied in the direction of circuit substrate materials, printed circuits connected with non-printed electrical components, printed circuits, etc., which can solve the inconvenience, the inability to mount electronic components, and the long pins of electronic components and other problems, to achieve the effect of convenient welding, improved bonding strength, and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

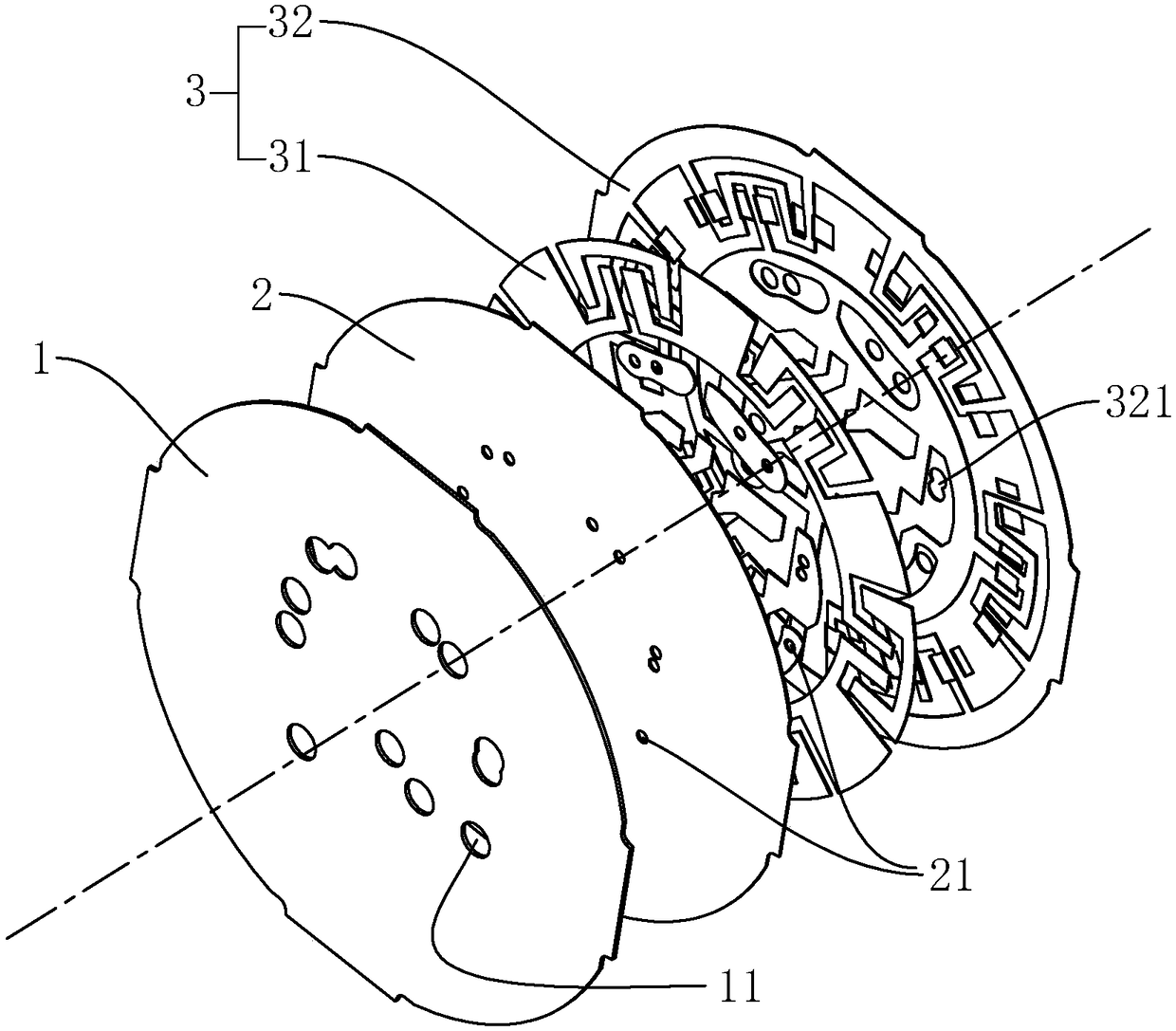

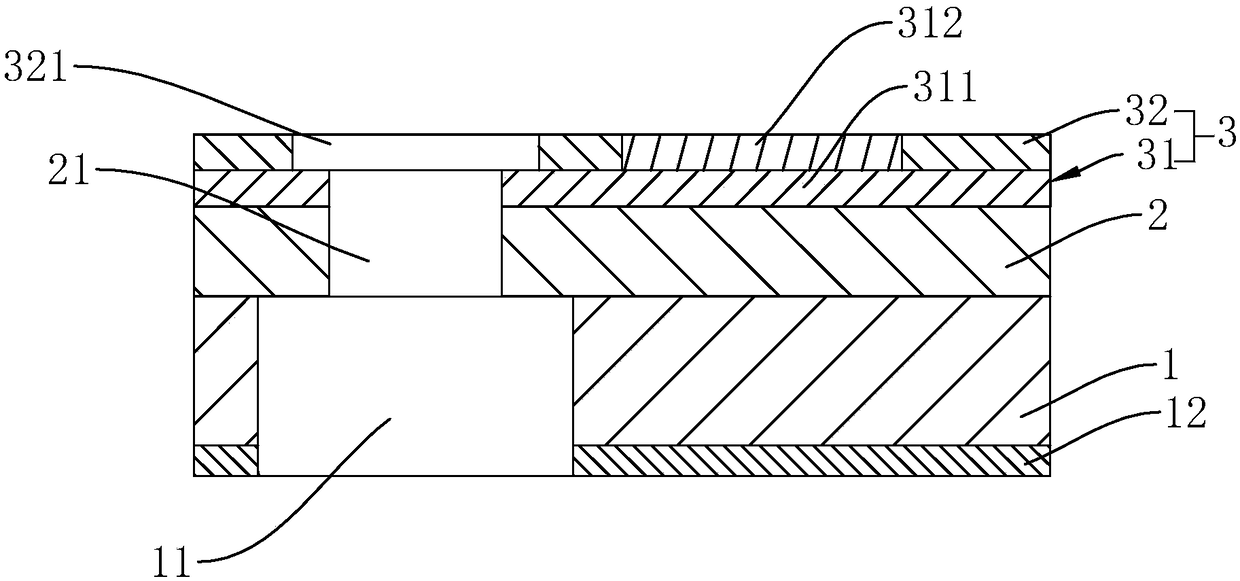

[0056] see figure 2 , a manufacturing process of a single-sided aluminum substrate for an LED lamp, comprising the following steps:

[0057] Step1, drill some first straight holes 11 on the surface of the light aluminum plate 1 according to the drawings;

[0058] Step2, polish the initial oxide layer on the surface of the light aluminum plate 1;

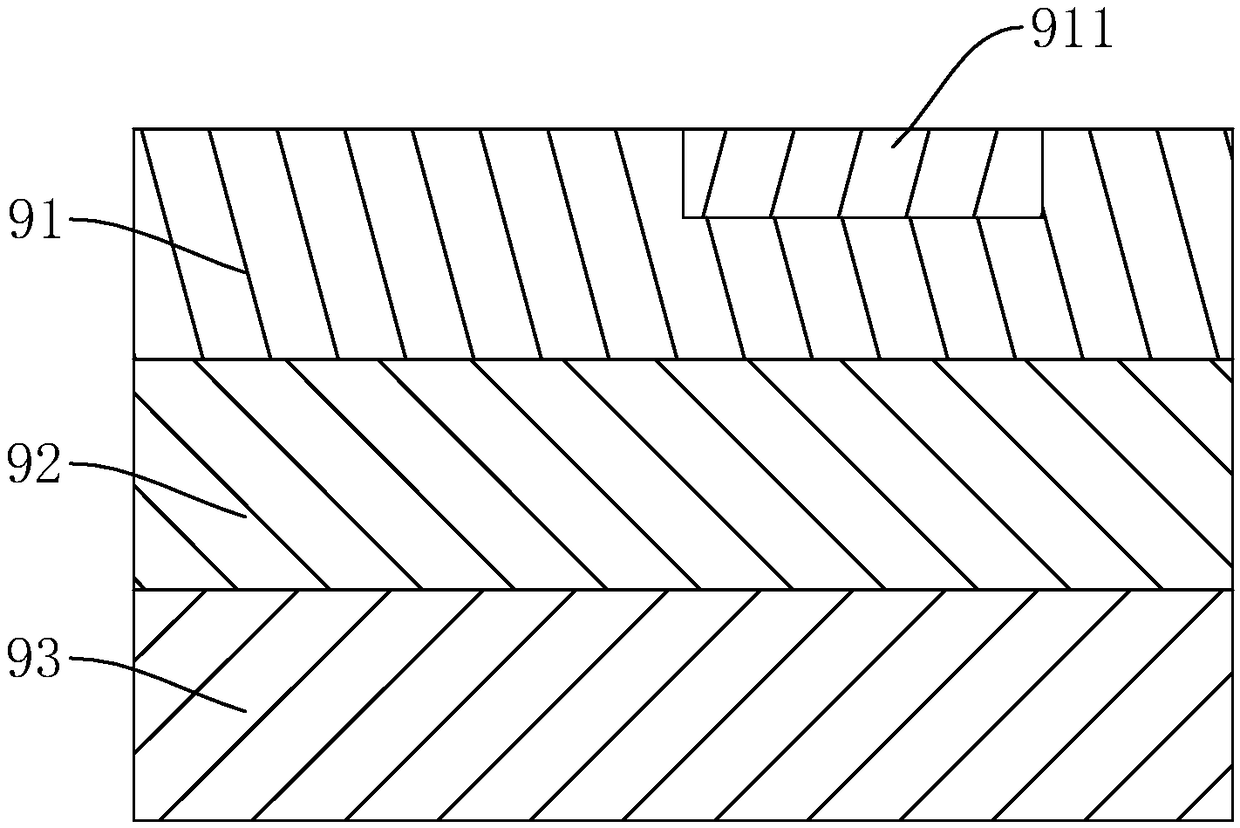

[0059] Step3, after the surface of the bare aluminum plate 1 is oxidized, hot pressing is followed by cold pressing to press the light aluminum plate 1, the resin insulating layer 2 and the copper foil wiring layer 31, wherein the pressure of the hot pressing is set to 100kg, and the temperature is set to 250°C; the pressure of cold pressing is set to 30kg, and the temperature is set to 30°C to obtain the initial substrate;

[0060] Step4, cutting the initial substrate according to the drawings to obtain the initial small plate, and drilling small holes to obtain the second straight hole 21 through the initial small plate;

[006...

Embodiment 1b

[0089] The difference between embodiment 1b and embodiment 1a is that, Step2.1, pour the thermosetting epoxy resin glue into the first straight hole 11 through the glue filling machine, bake at 170°C for 0.5h, until the curing degree reaches 80% , forming the resin protector 13 .

Embodiment 1c

[0091] The difference between embodiment 1b and embodiment 1a is that, Step2.1, pour the thermosetting epoxy resin glue into the first straight hole 11 through the glue filling machine, bake at 150°C for 1.5h, until the curing reaches 60%, The resin protector 13 is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com