Honing full-floating tool

A full-floating and honing technology, used in honing machine tools, manufacturing tools, metal processing equipment, etc., can solve problems such as being unable to keep on the same axis, unable to meet production requirements, increasing production costs, and shortening auxiliary processing time. , the effect of improving processing efficiency and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

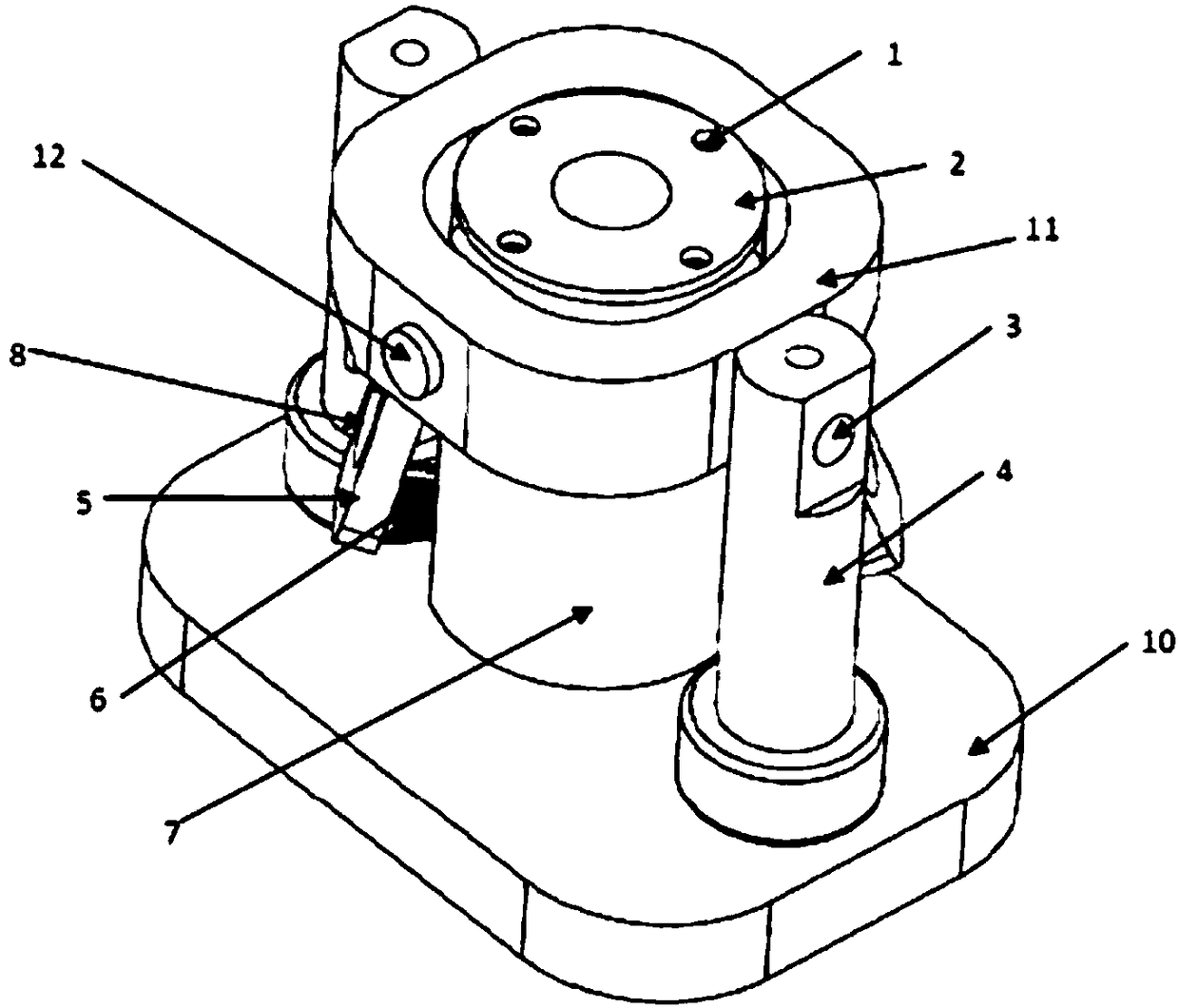

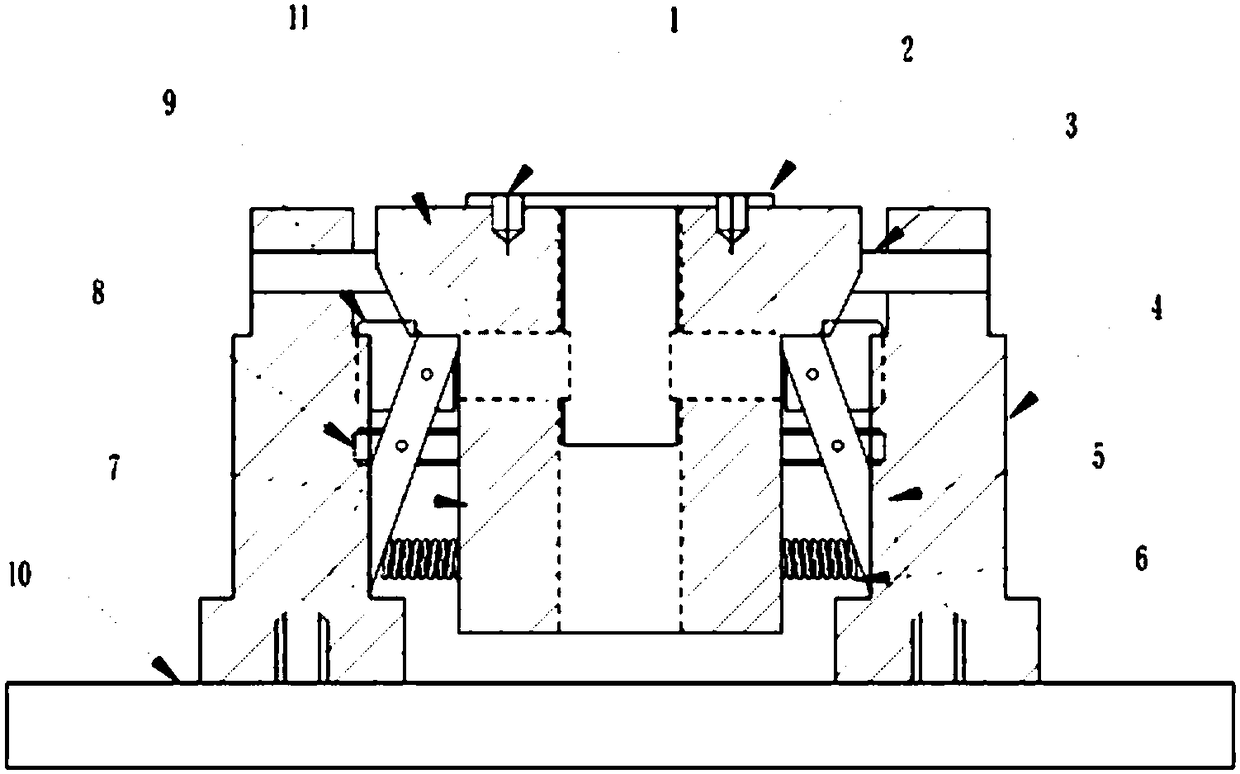

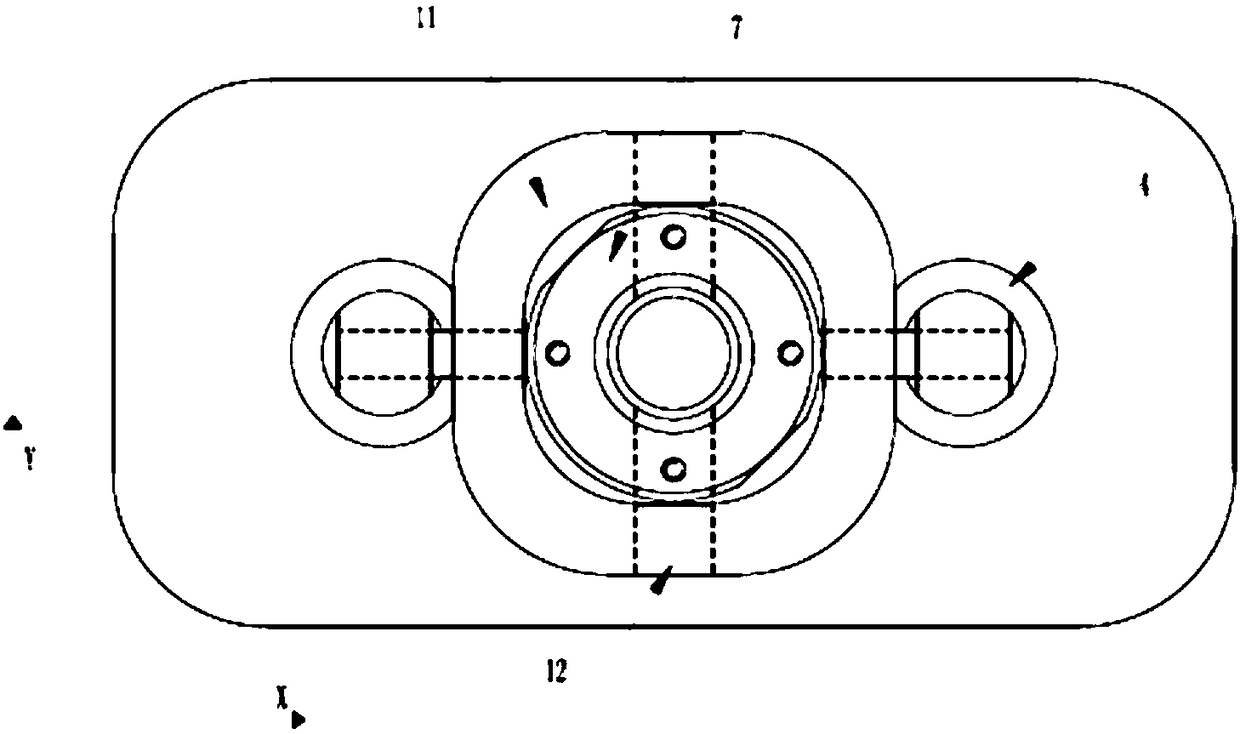

[0019] Such as Figure 1-3 A honing full-floating tool is shown, including positioning screw 1, reducing sleeve 2, center pin 3, honing support column 4, handle 5, spring 6, honing core sleeve 7, fixing screw 8, honing pin 9, base 10, honing floating sleeve 11 and shaft pin 12;

[0020] The honing support column 4 is fixed on the base 10 by screws;

[0021] The honing floating sleeve 11 is connected with the honing support column 4 through the central pin 3;

[0022] Connect the honing core sleeve 7 and the honing floating sleeve 11 through the shaft pin 12;

[0023] The reducing sleeve 2 is assembled into the honing floating sleeve 11 and fixed by the positioning screw 1;

[0024] The handle 5 is U-shaped, the upper end is a U-shaped mouth, and is provided with two pairs of symmetrical mounting holes, the lower end is a circular groove for placing the spring 6, and the handles 2 on both sides pass through the mounting holes at the upper end and are fixed on the honing pins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com