Mounting machine and mounting process for clamp, rubber tube and joint

A technology for installing machines and hoses, applied in the field of machinery and equipment, can solve the problems of high labor intensity of workers, the output cannot meet the requirements, and the errors are large, and achieve the effect of saving labor costs, improving production efficiency, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] like Figure 2-3 As shown, a clamp-hose-joint installation machine of the present invention includes a workbench 1, a shelf 2, a bottom cabinet 3, a Foma wheel 4, a fan 5, and a lamp 6.

[0061] The bottom cabinet 3 is a cuboid cabinet. The door leaf of the cabinet is Q235 after plastic spraying treatment. Fuma wheels 4 are installed at the bottom four corners of the bottom cabinet 3. The workbench 1 is installed on the top of the bottom cabinet 3. The back of the bottom cabinet 3 Install the shelf 2, the shelf 2 is made of lapped profiles, the height of the shelf 2 is higher than the workbench 1, the shelf 2 forms an inverted L-shaped structure, and the operation instructions for the installation of the clamp and the hose are pasted on the vertical part, extending horizontally A fan 5 and a lamp tube 6 are installed on the section for providing heat dissipation and lighting when operating on the workbench 1 .

[0062] like Figure 4 As shown, workbench 1 is equipped ...

Embodiment 5

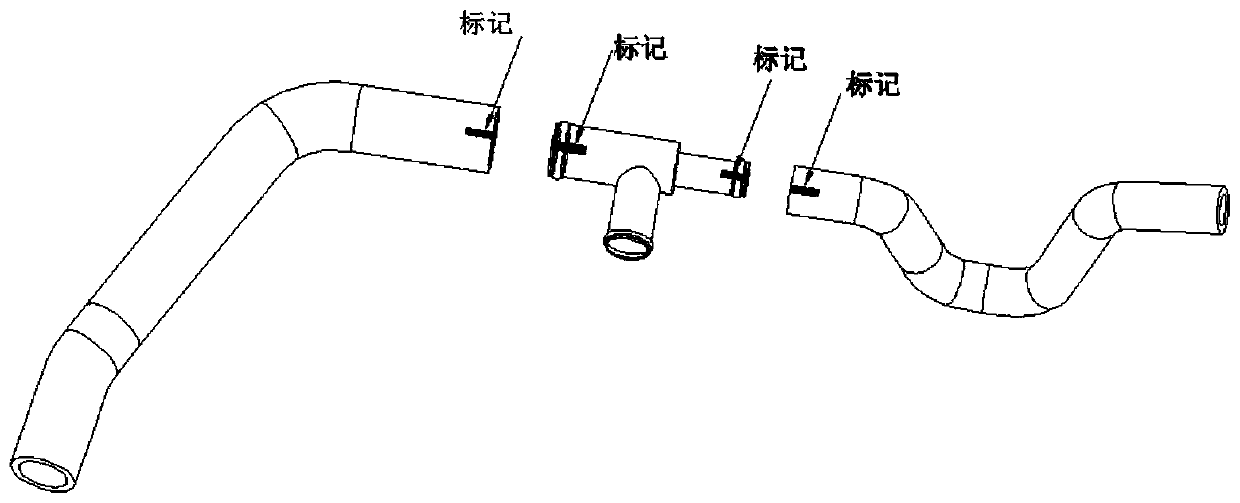

[0082] like Figure 7-13 As shown, a clamp-hose-joint installation process includes the following steps:

[0083] Step 1. Put clamp A9 into the profiling groove of clamp angle positioning mold A119, put clamp B10 into the profiling groove of clamp angle positioning mold B120, start clamp angle positioning mold A119 and Position the mold B120 at the clamp angle, and spread the clamp A9 and the clamp B10 apart.

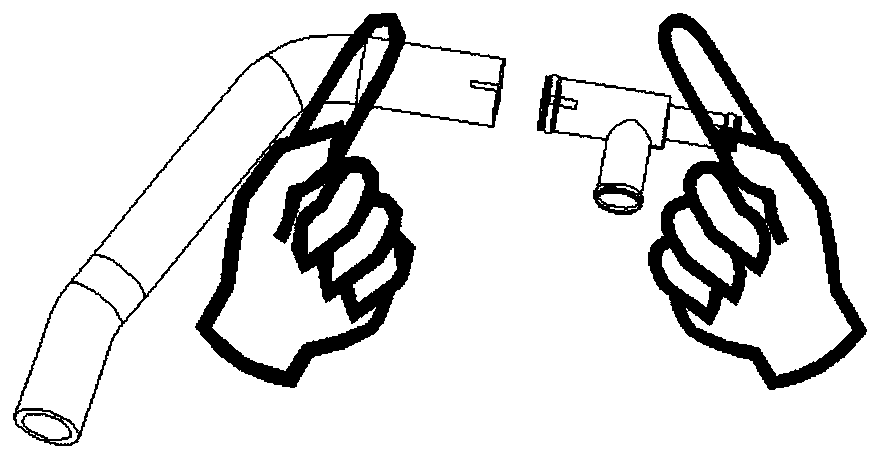

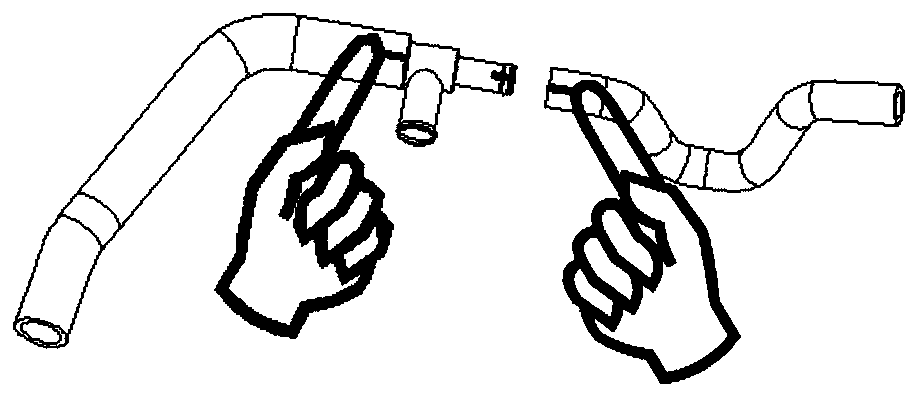

[0084]Step 2. Workers manually separate the hose angle positioning upper mold A110 from the hose angle positioning lower mold A113, separate the joint angle positioning upper mold 112 from the joint angle positioning lower mold 115, and separate the hose angle positioning upper mold B111 from the hose angle positioning lower mold Die B114 separates.

[0085] Step 3. Put the hose A11 into the profiling groove of the mold A113 under the angle positioning of the hose, put the joint 13 into the profiling groove of the mold 115 under the angle positioning of the joint, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com