Mounting structure of torsion spring capable of reverse rotation and rotary gear

A technology of torsion springs and rotating gears, applied to springs, springs, springs/shock absorbers made of plastic materials, etc., can solve problems such as manufacturing difficulties, manufacturing difficulties, and cost reduction without significant contribution, achieving simple fixation and easy The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

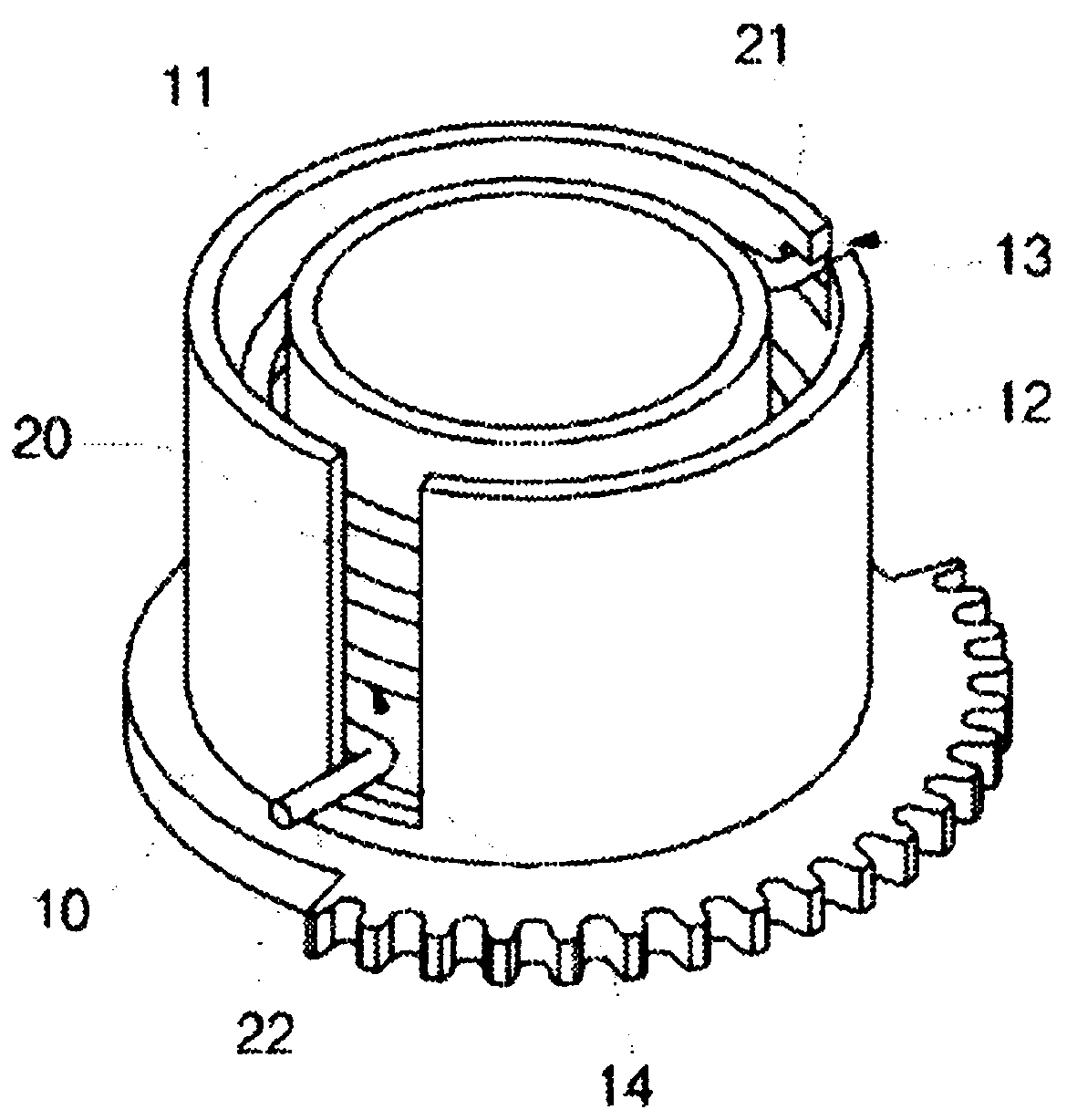

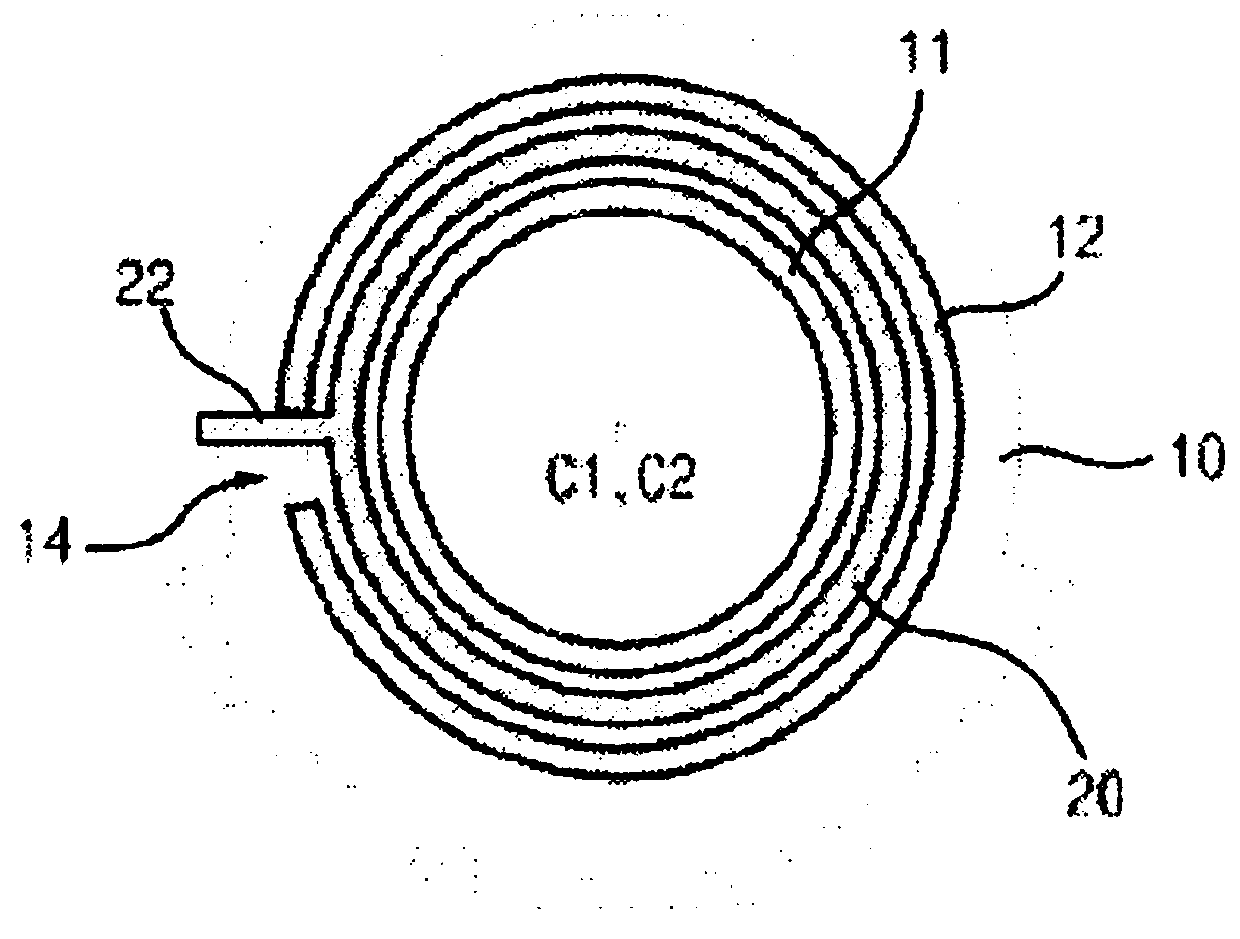

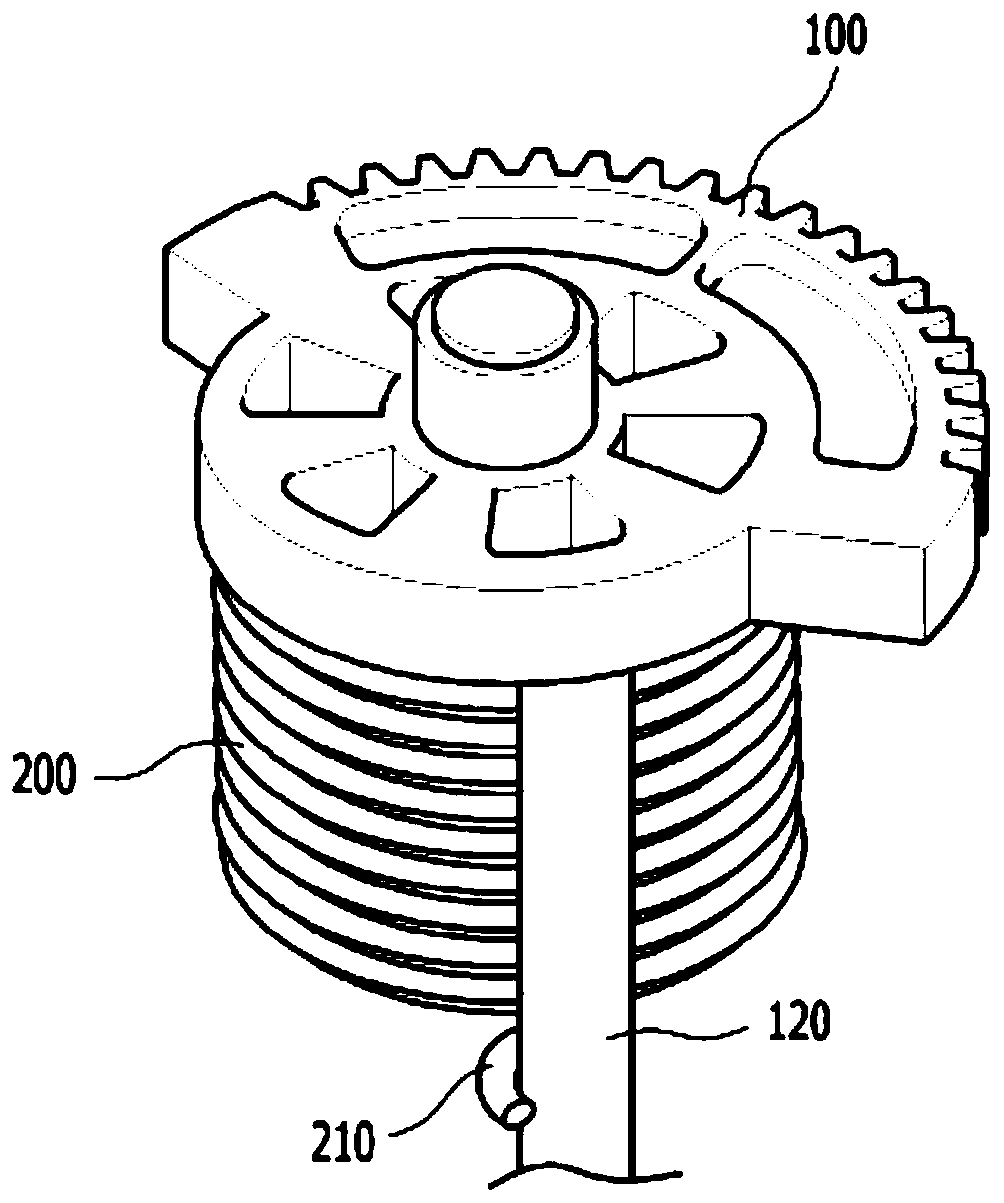

[0026] According to the first embodiment of the present invention, a reversible installation structure of a torsion spring and a rotating gear can be provided, which is characterized in that it includes: a torsion spring; Gear teeth are formed, extending downward from the center, and the torsion spring is installed on the outer peripheral surface of the rotating shaft; at least two or more guide rods are formed protruding downward from the outer upper surface of the rotating gear to limit The movement of one end and the other end of the torsion spring; and the fixed part, which is processed on the inner surface of the casing, and the casing covers the rotating gear to form the appearance of the EGR valve; the torsion spring includes a main body fixing ring, and the fixing A portion covers the main body fixing ring and prevents the main body fixing ring from rotating.

[0027] The embodiments described below are provided to enable practitioners to easily understand the technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com