Sand mold casting process for heat-resisting alloy steel thin-wall pipe fitting

A technology of sand casting and alloy steel, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of non-conformity to circular requirements, long production cycle, shrinkage porosity, etc., and improve the casting yield and production efficiency , good economic benefit, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

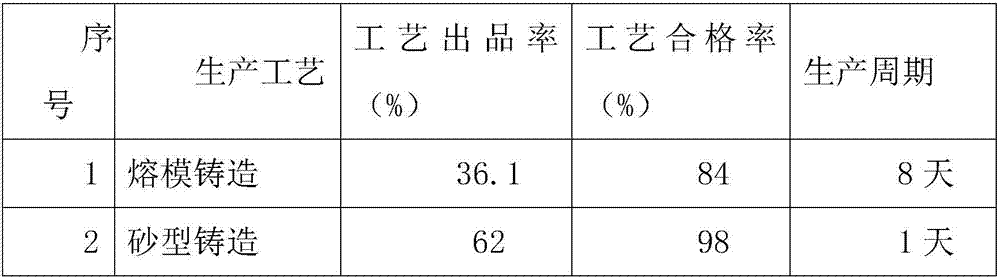

[0029] The example form is as follows:

[0030] Statistical Table of Product Qualification Rate

[0031]

[0032] Working principle: It needs to be explained that this invention improves the traditional process of thin-walled M-shaped elbow castings, changing from investment casting to sand casting, which greatly improves the casting yield and production efficiency. The casting size meets the drawing requirements and the process yield rate It has increased to 56%, and the qualified rate of castings has increased to 98%, which has achieved good economic benefits. In the continuous annealing furnace of the metallurgical industry, there are many thin-walled heat-resistant steel alloy pipe fittings, which can be improved according to this process, and can also be applied to petrochemical In the industrial cracking furnace, there are many pipe fittings in the cracking furnace, such as Y-shaped pipe, palm-shaped pipe, 90° elbow, 180° elbow and other heat-resistant steel alloy cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com