Pendulum-type concave-convex shear blade

A scissor blade and knife body technology, applied in the field of pendulum concave-convex scissors, can solve the problems of inability to guarantee the straightness and parallelism of the shearing surface of the sheet to be sheared, low cutting efficiency of the blade, and short service life, etc. The cutting effect is good, the deformation is small, and the service life is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

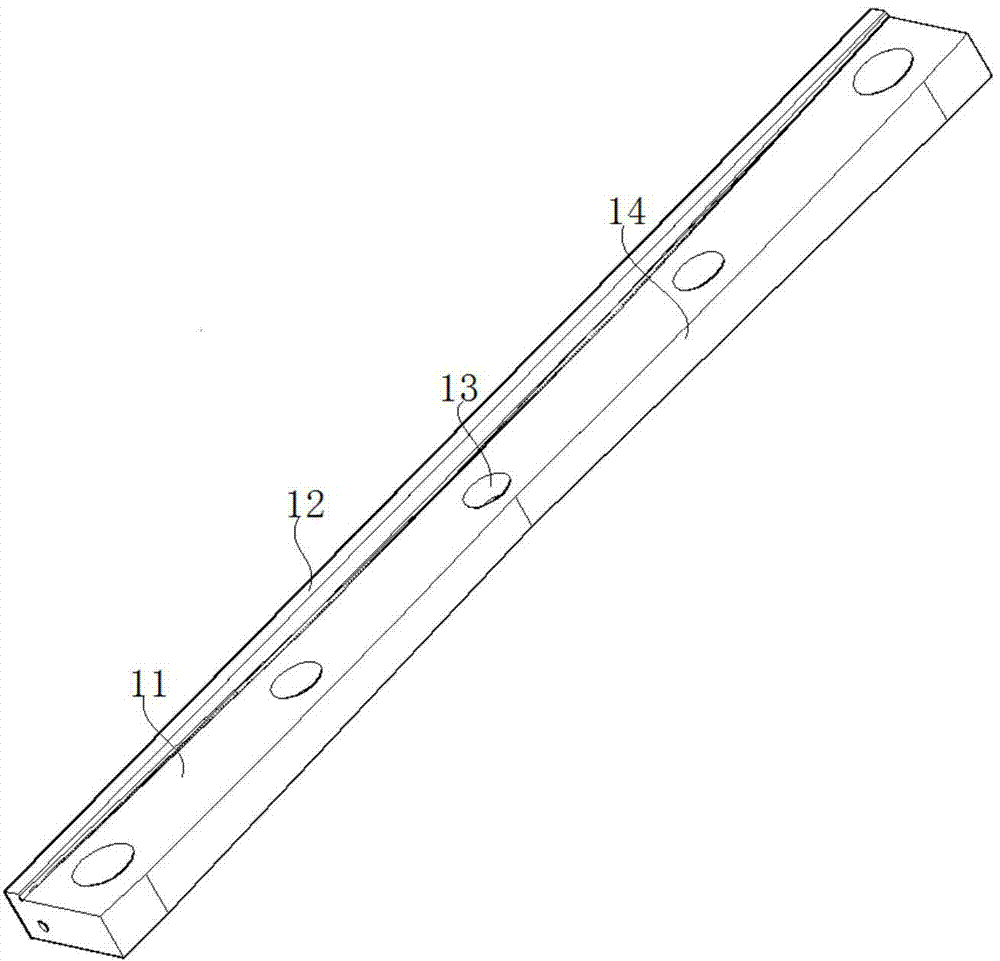

[0054] With reference to the accompanying drawings, a pendulum-type concave-convex scissor blade in this embodiment includes an upper knife and a lower knife. The upper knife (combined with image 3 ) includes an upper knife body and an upper knife back 12, the upper knife body is a strip structure, and this upper knife body includes an upper knife edge surface 11, an upper knife mounting hole 13 and an upper knife edge surface 14. The upper knife back 12 is located on the side of the upper knife body, and the upper knife back 12 protrudes from the upper knife edge surface 11 . The upper knife edge surface 11 is an inwardly concave arc surface, the upper knife edge surface 14 is an inwardly concave V-shaped structure, and the upper knife mounting hole 13 is uniform along the length direction of the upper knife body. set up.

[0055] The lower knife (combined with Figure 4 ) includes a lower knife body and a lower knife back 22, and the lower knife body is also a strip stru...

Embodiment 2

[0084] A pendulum-type concave-convex scissor blade in this embodiment is basically the same as in Embodiment 1, except that the upper knife and the lower knife are made of forged blanks, and the component weight percentages of the forged blanks in this embodiment are: C: 0.38%, Si: 1.0%, Mn: 0.35%, S: 0.030%, P: 0.030%, Cr: 5.1%, Ni: 0.25%, Cu: 0.30%, V: 1.0%, Mo: 1.4%, The balance is Fe.

[0085] A kind of manufacturing method of pendulum concave-convex scissor blade of the present embodiment, its steps are:

[0086] Step 1. Preparation of raw materials: The composition of the forging blank used in the pendulum concave-convex scissors of this embodiment is calculated by weight percentage: C: 0.38%, Si: 1.0%, Mn: 0.35%, S: 0.030%, P: 0.030%, Cr: 5.1%, Ni: 0.25%, Cu: 0.30%, V: 1.0%, Mo: 1.4%, and the balance is Fe.

[0087] Step 2, annealing treatment of forging blank:

[0088] The forged blank in step 1 is annealed in an annealing furnace to reduce the hardness of the forg...

Embodiment 3

[0111] A pendulum-type concave-convex scissor blade in this embodiment is basically the same as in Embodiment 1, except that the upper knife and the lower knife are made of forged blanks, and the component weight percentages of the forged blanks in this embodiment are: C: 0.45%, Si: 1.20%, Mn: 0.50%, S: 0.028%, P: 0.028%, Cr: 5.50%, Ni: 0.24%, Cu: 0.28%, V: 1.20%, Mo: 1.75%, The balance is Fe.

[0112] A kind of manufacturing method of pendulum concave-convex scissor blade of the present embodiment, its steps are:

[0113] Step 1. Preparation of raw materials: The composition of the forged blank used in the pendulum concave-convex scissors of this embodiment is calculated by weight percentage: C: 0.45%, Si: 1.20%, Mn: 0.50%, S: 0.028%, P: 0.028%, Cr: 5.50%, Ni: 0.24%, Cu: 0.28%, V: 1.20%, Mo: 1.75%, and the balance is Fe.

[0114] Step 2, annealing treatment of forging blank:

[0115] The forged blank in step 1 is annealed in an annealing furnace to reduce the hardness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com