Preparation method of aluminum oxide ceramic guide rail

An alumina ceramic and alumina technology, which is applied in the field of ceramic guide rail preparation, can solve the problems of low machining accuracy, performance degradation of ceramic guide rails, wear, etc., and achieve the effects of improving grinding processing efficiency, reducing molding difficulty and uniform density of blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of alumina ceramic guide rail, comprising the following steps:

[0040] (1) Ball milling: First, 99.5Kg of alumina and 0.5Kg of raw materials are loaded into the ball mill, and then 50kg of water, 2Kg of ammonium polyacrylate and 0.3Kg of polyvinyl alcohol are added to perform ball milling to obtain the desired slurry.

[0041] (2) granulation: the slurry obtained in step (1) is spray-dried to obtain granulated powder, which is set aside for use; granulation is carried out in a spray granulation tower, the inlet air temperature is set to 500°C, and the outlet air temperature is set to 300°C; the particle size of the granulated powder obtained after spray granulation is 120 μm.

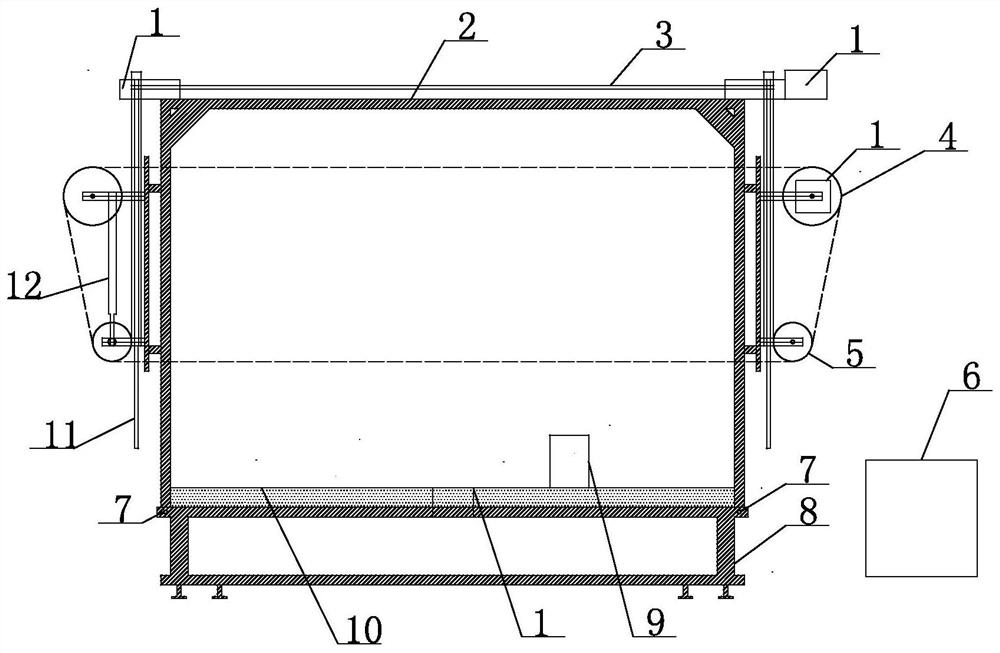

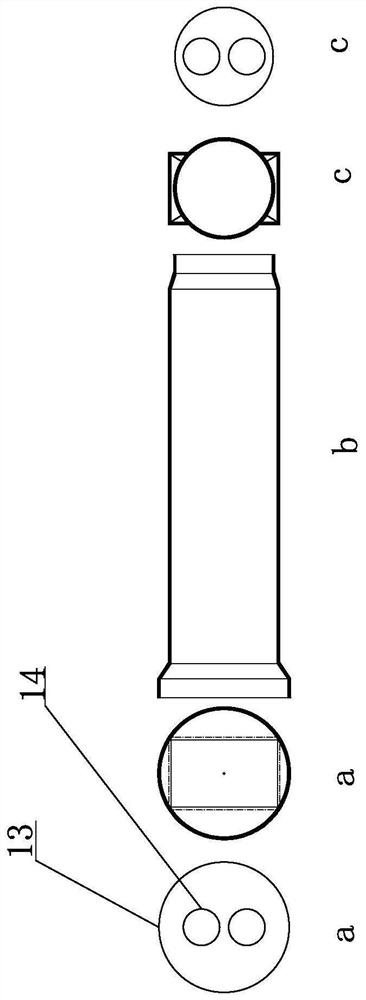

[0042] (3) Forming: take the granulated powder for ups and downs in step (2) and put it into a mold, and the mold kit used includes a rubber mold (rubber sleeve 13 and two upper and lower solid rubber stoppers 14), a polymer material with holes Positioning plate, 2 cylindri...

Embodiment 2

[0055] A method for preparing an alumina ceramic guide rail, comprising the following steps:

[0056] (1) Ball milling: first put 99.5Kg of alumina and 0.5Kg of raw materials into a ball mill, then add 50kg of water, 2Kg of ammonium polyacrylate and 0.3Kg of polyvinyl alcohol for ball milling to obtain the required slurry.

[0057] (2) Granulation: The slurry obtained in step (1) is spray-dried to obtain granulated powder for use; the granulation is carried out in a spray granulation tower, the inlet air temperature is set to 500°C, and the air outlet temperature is set to 300°C; the particle size of the granulated powder obtained after spray granulation is 120 μm.

[0058] (3) Molding: get the granulated powder stand-by ups and downs in the step (2) and pack into the mould, and the mold kit used comprises rubber mould (rubber sleeve 13 and two solid rubber stoppers 14 up and down), the band hole of macromolecular material Positioning plate, 3 cylindrical stainless steel mand...

Embodiment 3

[0066] A method for preparing an alumina ceramic guide rail, comprising the following steps:

[0067] 1) Ball milling: first put 99.5Kg of alumina and 0.5Kg of raw materials into a ball mill, then add 50kg of water, 2Kg of ammonium polyacrylate and 0.3Kg of polyvinyl alcohol for ball milling to obtain the required slurry.

[0068] (2) Granulation: The slurry obtained in step (1) is spray-dried to obtain granulated powder for use; the granulation is carried out in a spray granulation tower, the inlet air temperature is set to 500°C, and the air outlet temperature is set to 300°C; the particle size of the granulated powder obtained after spray granulation is 120 μm.

[0069] (3) Molding: get the granulated powder stand-by ups and downs in the step (2) and pack into the mould, and the mold kit used comprises rubber mould (rubber sleeve 13 and two solid rubber stoppers 14 up and down), the band hole of macromolecular material Positioning plate, 4 cylindrical stainless steel mandr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com