End corner post molding process of track vehicle

A rail vehicle and forming process technology, which is applied in the field of end corner column forming, can solve problems such as wrinkling and cracking at deformation points, and difficulty in overall forming, and achieve the effects of improving forming quality, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

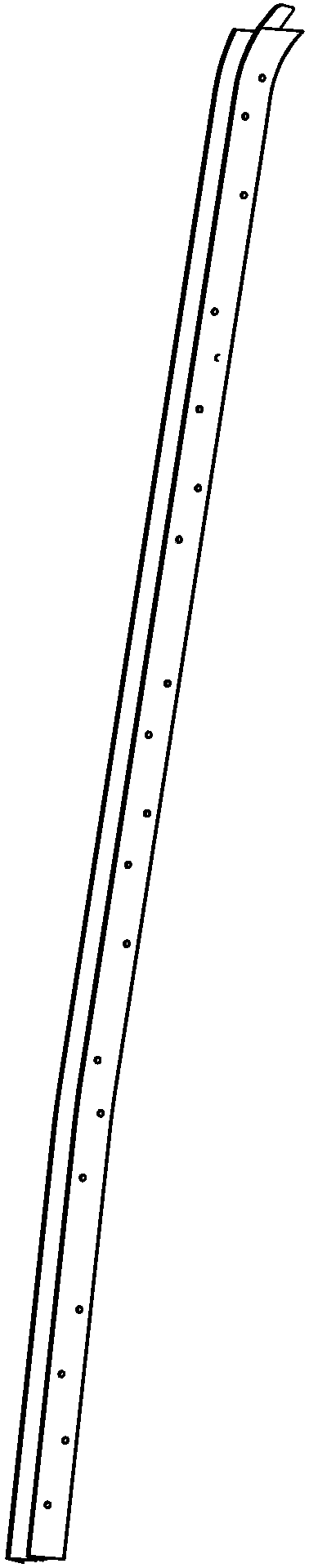

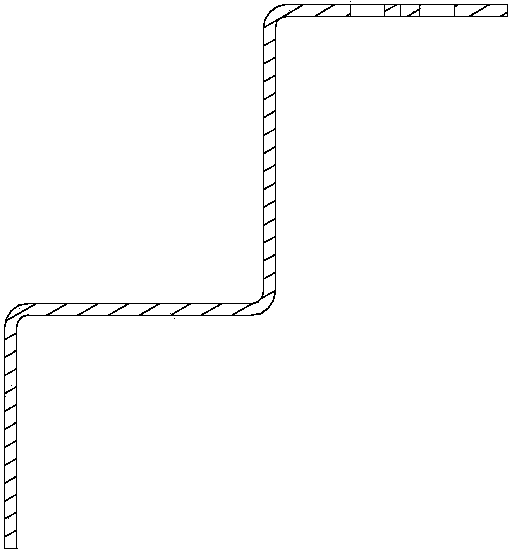

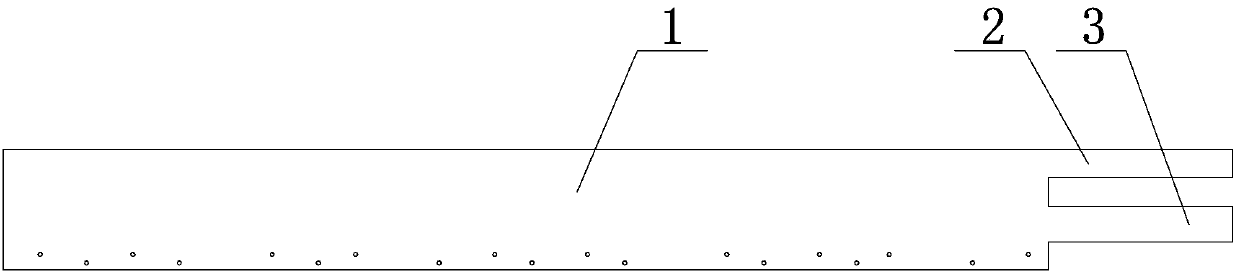

[0020] Such as figure 1 , figure 2 Shown is the end corner post involved in the present invention. image 3 It is a schematic diagram of the main material plate of the end corner column of the present invention. Figure 4 , Figure 5 It is a schematic diagram of the first and second plates of the end corner post of the present invention.

[0021] The forming process of the rail vehicle end corner post of the embodiment of the present invention includes the following steps:

[0022] The first step is to cut the material by a laser cutting machine to obtain the elongated main material plate 1, so that one end of the main material plate 1 after cutting has two rectangular first plates 2 and second plates 3 parallel to each other. The widths of the first plate 2 and the second plate 3 are the same as the widths of the two folded edges of the corner column W-shaped interval, and the distance between the first plate 2 and the second plate 3 is equal to the distance between the two folde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com