Patents

Literature

45results about How to "Avoid craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

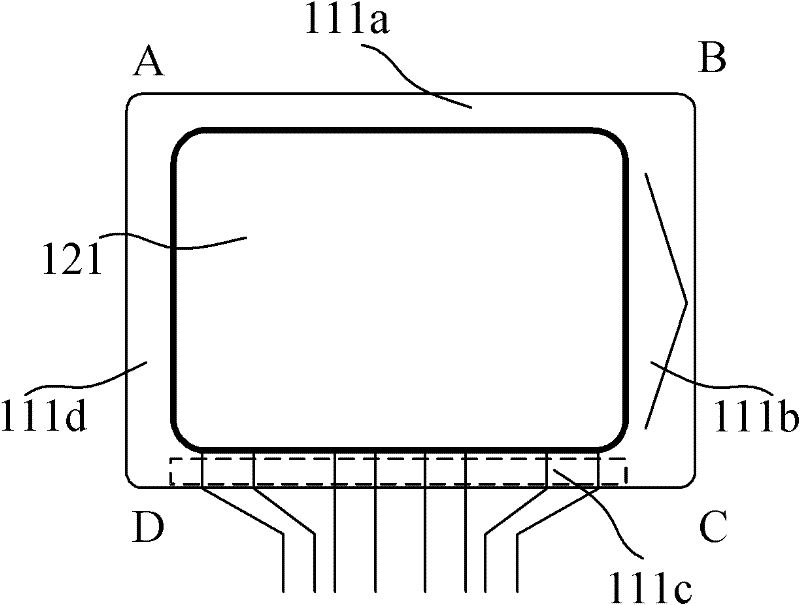

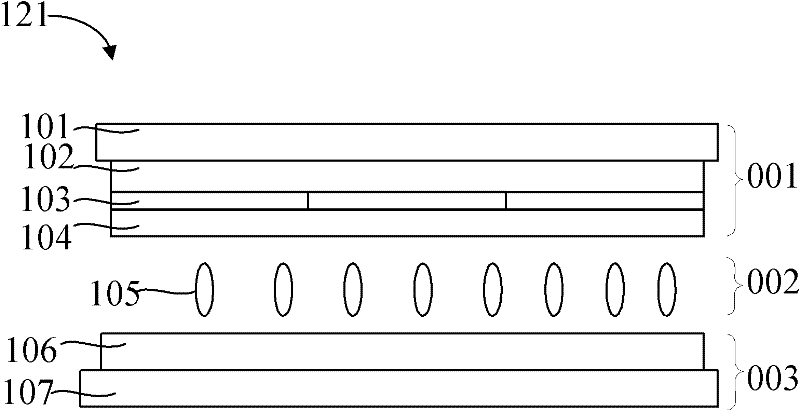

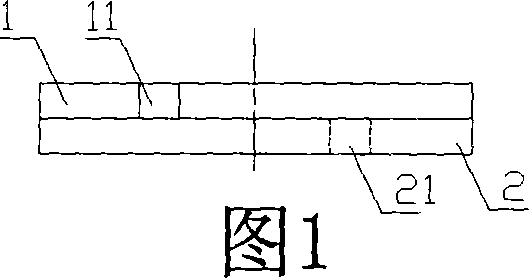

Touch display device and manufacturing method thereof

ActiveCN102541334AImprove signal-to-noise ratioAvoid craftStatic indicating devicesNon-linear opticsSignal-to-noise ratio (imaging)Pixel array

The invention discloses a touch display device and a manufacturing method thereof. The touch display device includes a touch screen base plate and a pixel array base plate, and further includes a first shielding layer and a second shielding layer. The touch screen base plate includes a touch control structure layer and output leads of the touch control structure layer (including drive electrode leads and induction electrode leads); the pixel array base plate is provided with a pixel array and peripheral leads of the pixel array; the output leads of the touch control structure layer and the peripheral leads of the pixel array are overlapped in the light transmitting direction; the first shielding layer is arranged between the drive electrode leads and the peripheral leads of the pixel array; and the second shielding layer is arranged between the induction electrode leads and the peripheral leads of the pixel array. The shielding layers reduce the parasitic capacitance between the peripheral leads of the pixel array base plate and the output leads of the touch control screen base plate, avoid the condition that drive electrodes and induction electrodes of the touch screen are coupled through the parasitic capacitance, and further improve the SNR (Signal to Noise Ratio).

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

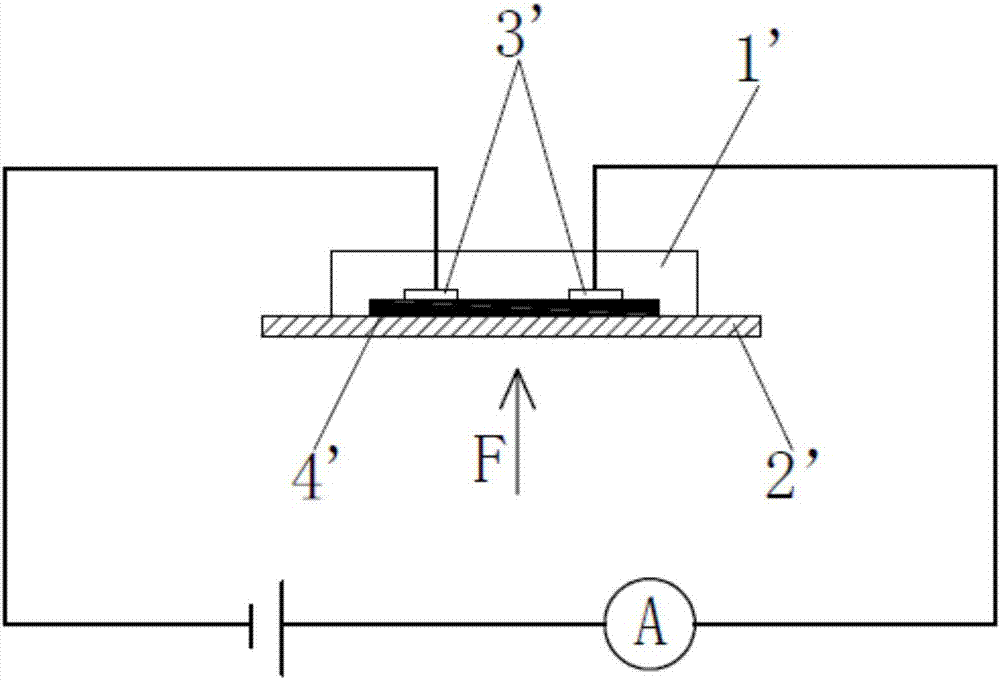

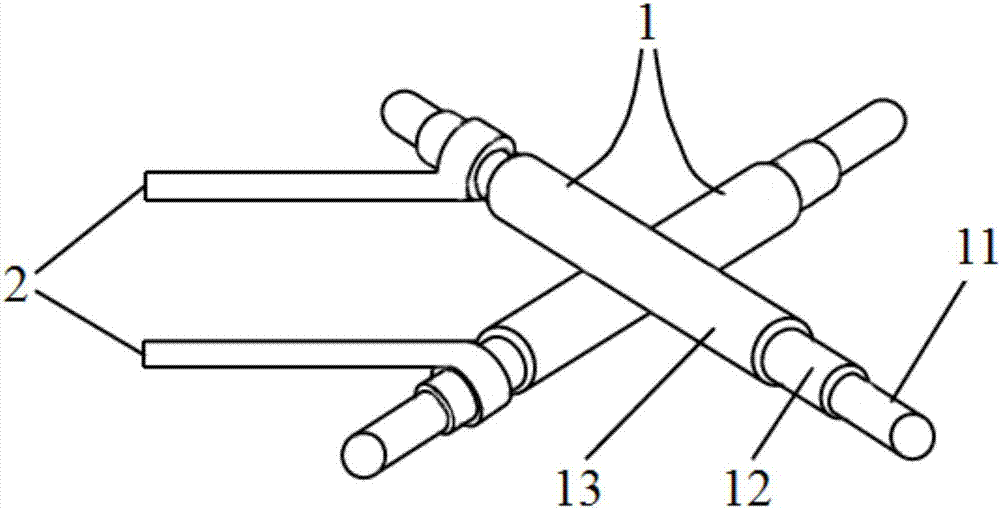

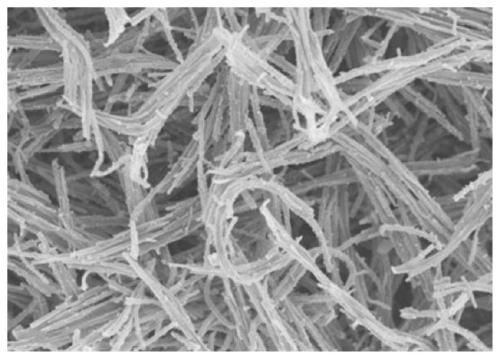

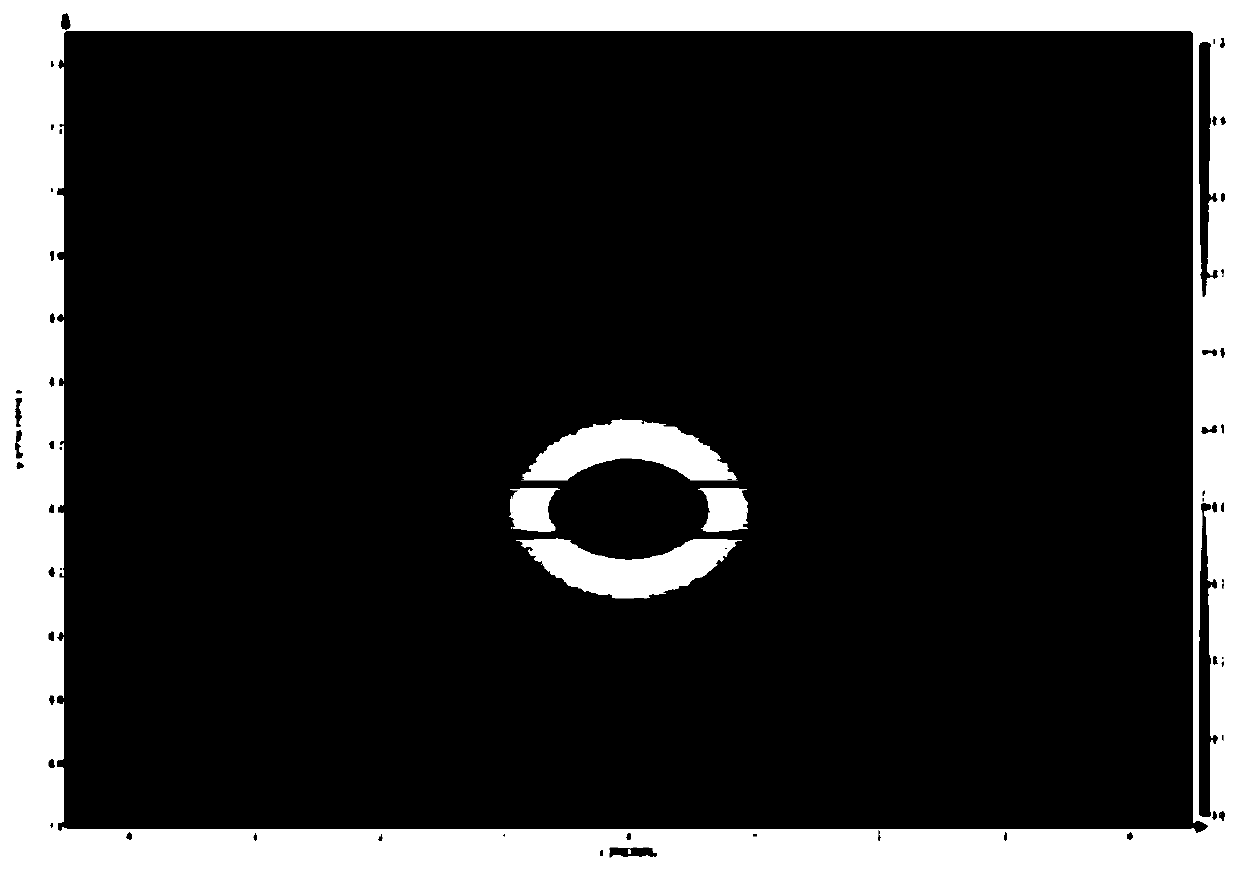

Flexible stress sensor and preparation method thereof

InactiveCN107271084ASmall sizeSolve the problem of difficult miniaturizationMaterial nanotechnologyForce measurementSemiconductor materialsMiniaturization

The present invention relates to a flexible stress sensor. The flexible stress sensor comprises two sensing assemblies; each sensing assembly includes a flexible fiber wire and a nanostructured film coating the flexible fiber wire; the flexible fiber wire is made of a conductive material or the surface of the flexible fiber wire is provided with a conductive layer; the nanostructured film is made of a conductive material or a semiconductor material; the two sensing assemblies are cross-stacked; and the nanostructured films of the two sensing assemblies contact with each other at the intersection of the two sensing assemblies. The present invention also relates to a preparation method of the flexible stress sensor. The flexible stress sensor of the invention has the advantages of small size, high resolution, high sensitivity and simple preparation, is suitable for being applied to miniaturized and integrated equipment and can be used for making wearable equipment for detecting human health.

Owner:WUYI UNIV

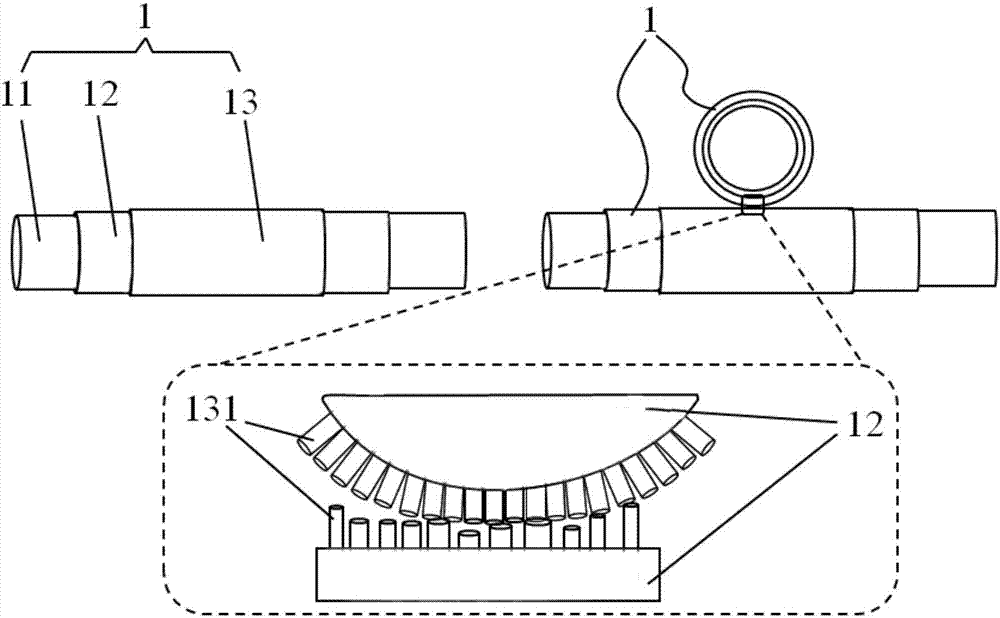

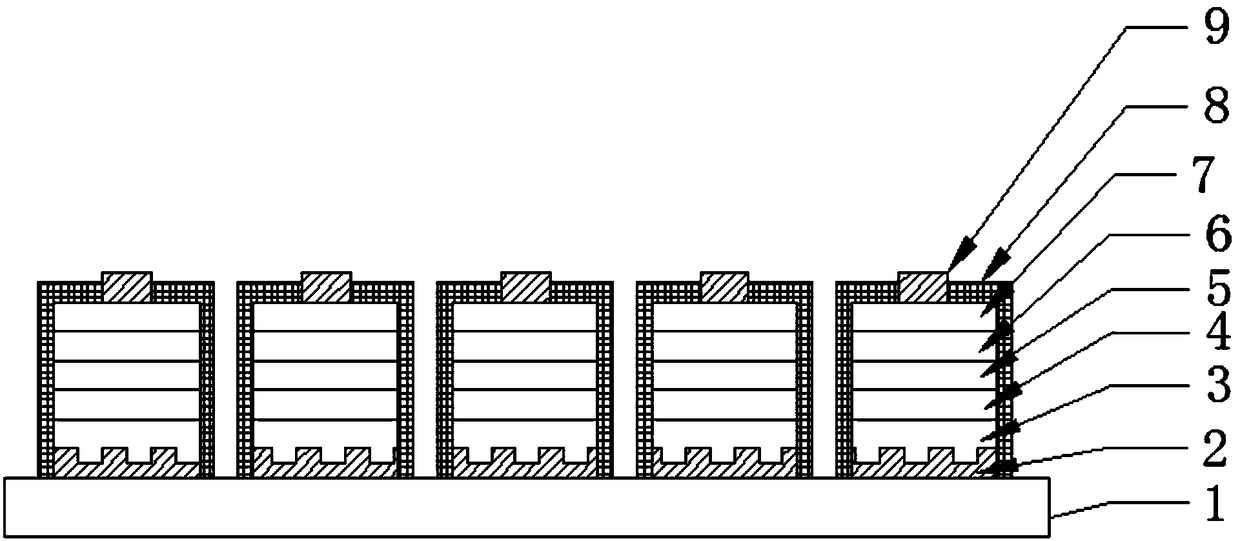

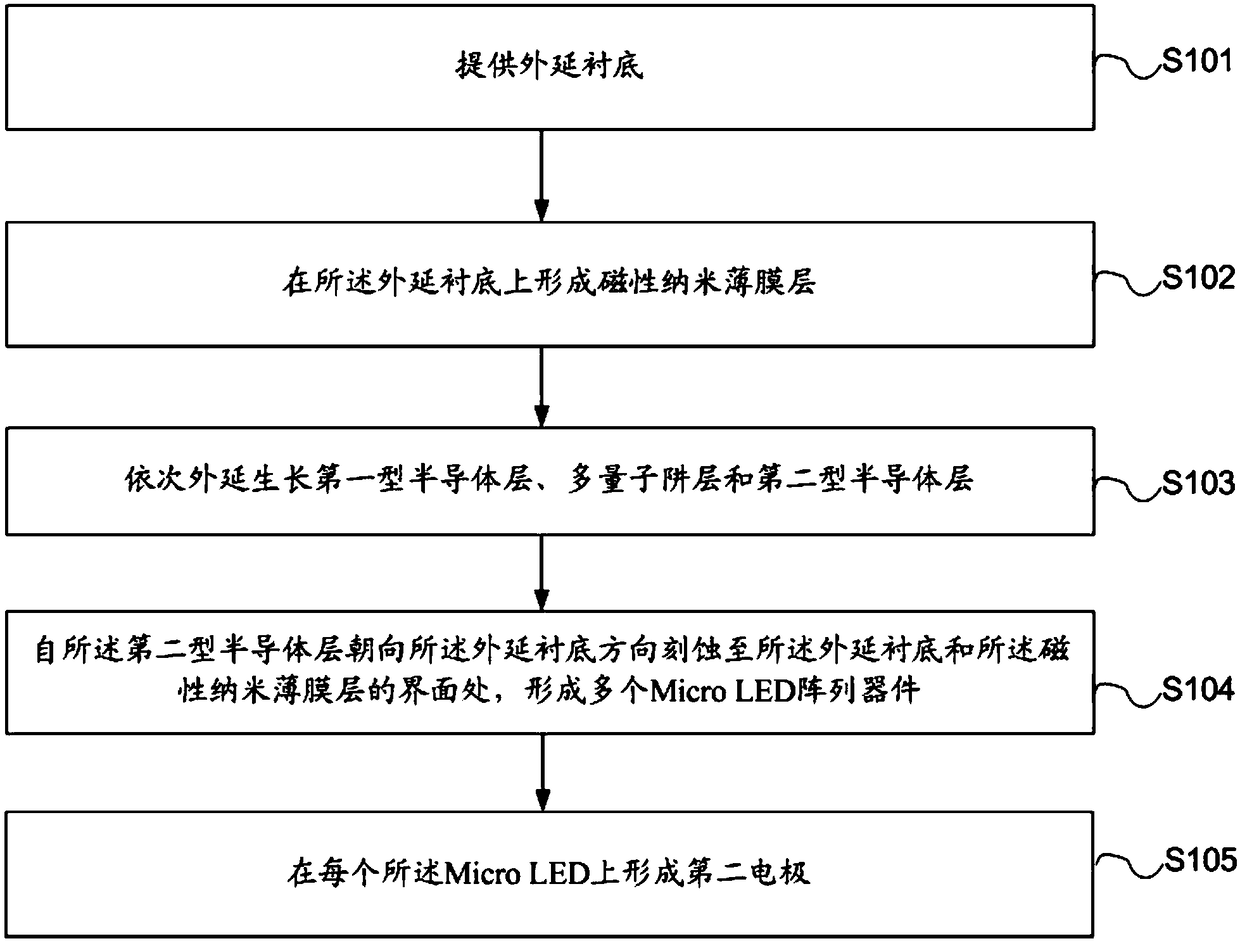

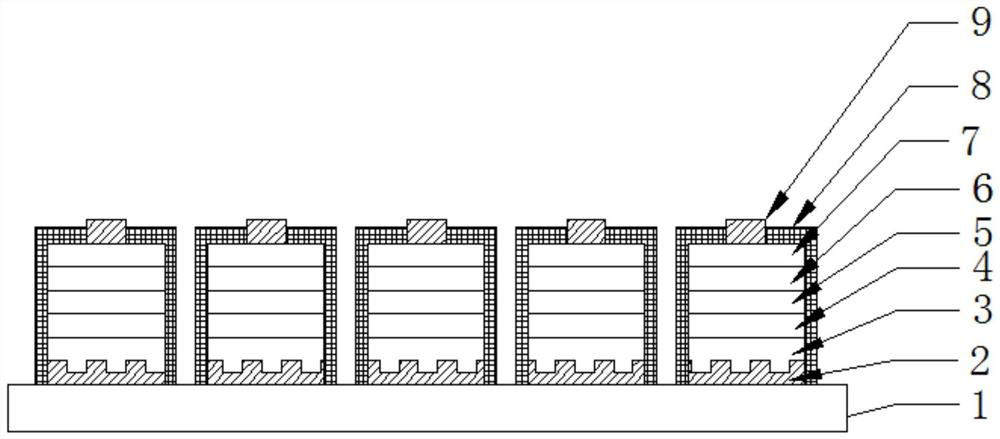

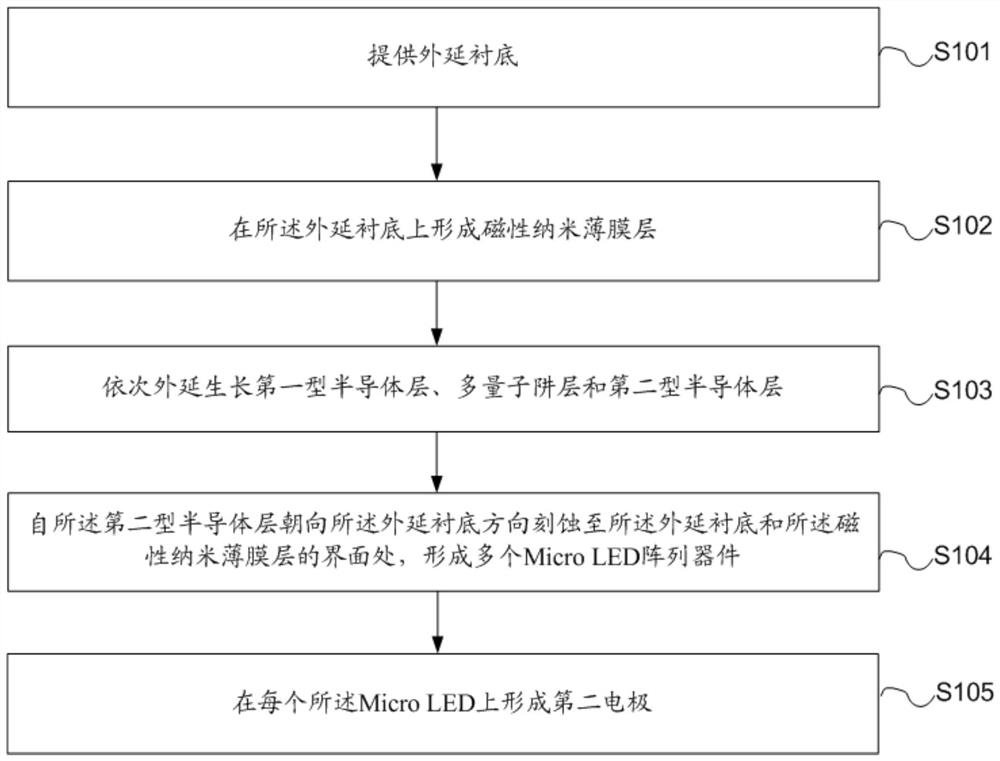

Micro LED array device, mass transfer device and related method

ActiveCN109216400AProcesses to avoid making and removingSimplified transfer methodSolid-state devicesSemiconductor devicesMagnetic layerEngineering

The invention provides a Micro LED array device and a manufacturing method thereof, A mass transfer device and a transfer method, by forming a magnetic nano-film layer on an epitaxial substrate of a Micro LED array device, As one electrode of that Micro LED array device, As a result, the Micro LED array device can be directly adsorbed by the magnetic force without adding an additional magnetic layer, the manufacturing and removing process of the magnetic layer are avoided, the transfer method of the Micro LED array device can be simplified, and the efficiency of the Micro LED mass transfer isfurther improved.

Owner:XIAMEN CHANGELIGHT CO LTD

Polymer SPR chip and method for making same

InactiveCN101398377ALow costAvoid craftPhase-affecting property measurementsScattering properties measurementsSurface plasmonPrism

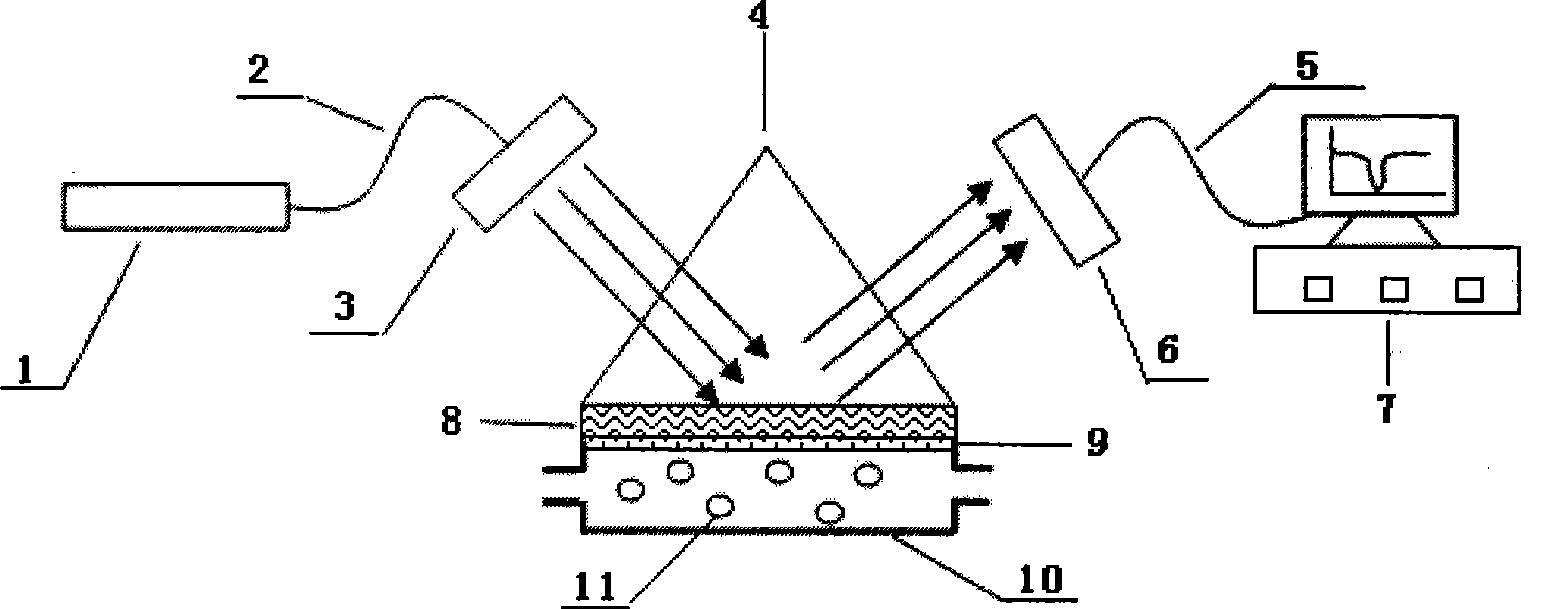

The invention provides a Surface Plasmon Resonance (SPR) chip and a preparation method thereof, belonging to the field of Micro-electro-mechanical-system (MEMS) technique; the SPR chip comprises a reflecting prism, a metal film and a sample channel structure; the prism is a polymer optical prim or a polymer optical prism array; the metal film is arranged on the back surface of the polymer optical prim or the polymer optical prism array; one or a plurality of sample channel structures corresponding to the polymer optical prism or the polymer optical prism are made of polymer material; and the sample channel structure is thermally pressed and bonded together with the polymer optical prism or the polymer optical prism. The SPR chip and the preparation method thereof prepare the polymer optical prism or polymer optical prism array and the sample channel structure by the MEMS micro-processing method, and can realize batch production. The SPR chip has low cost, and is convenient for carrying along and suitable for real-time detection and disposable usage.

Owner:PEKING UNIV

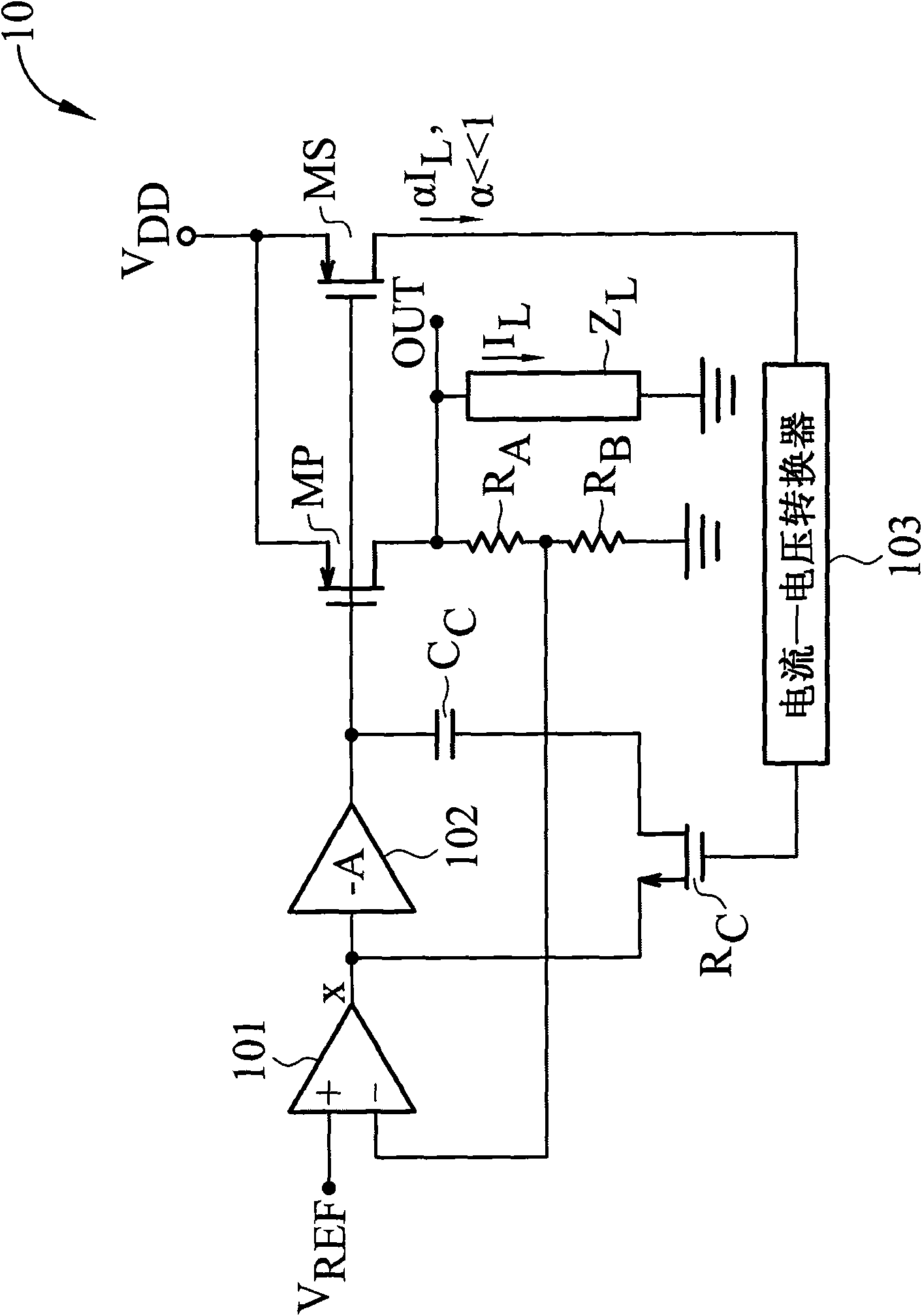

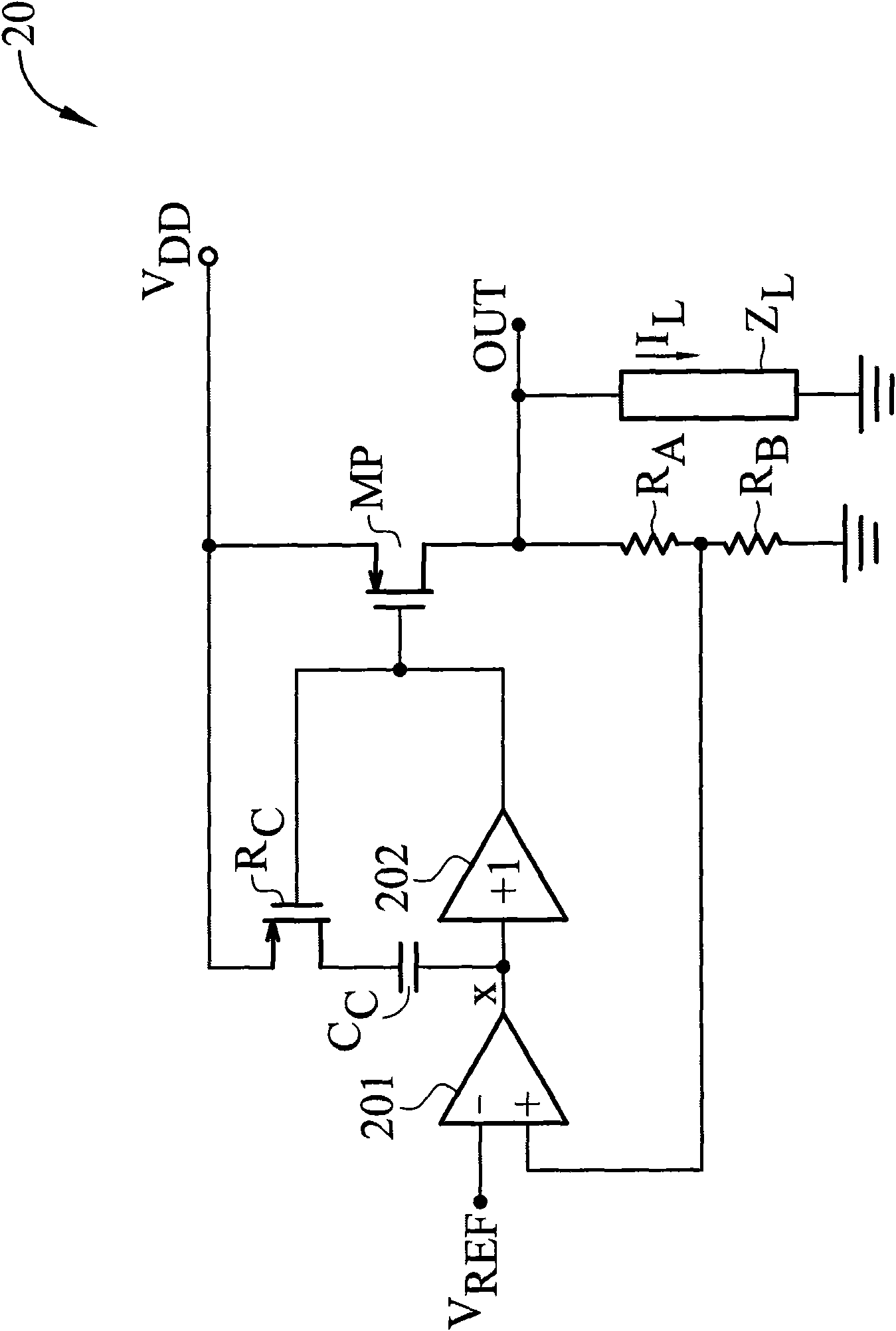

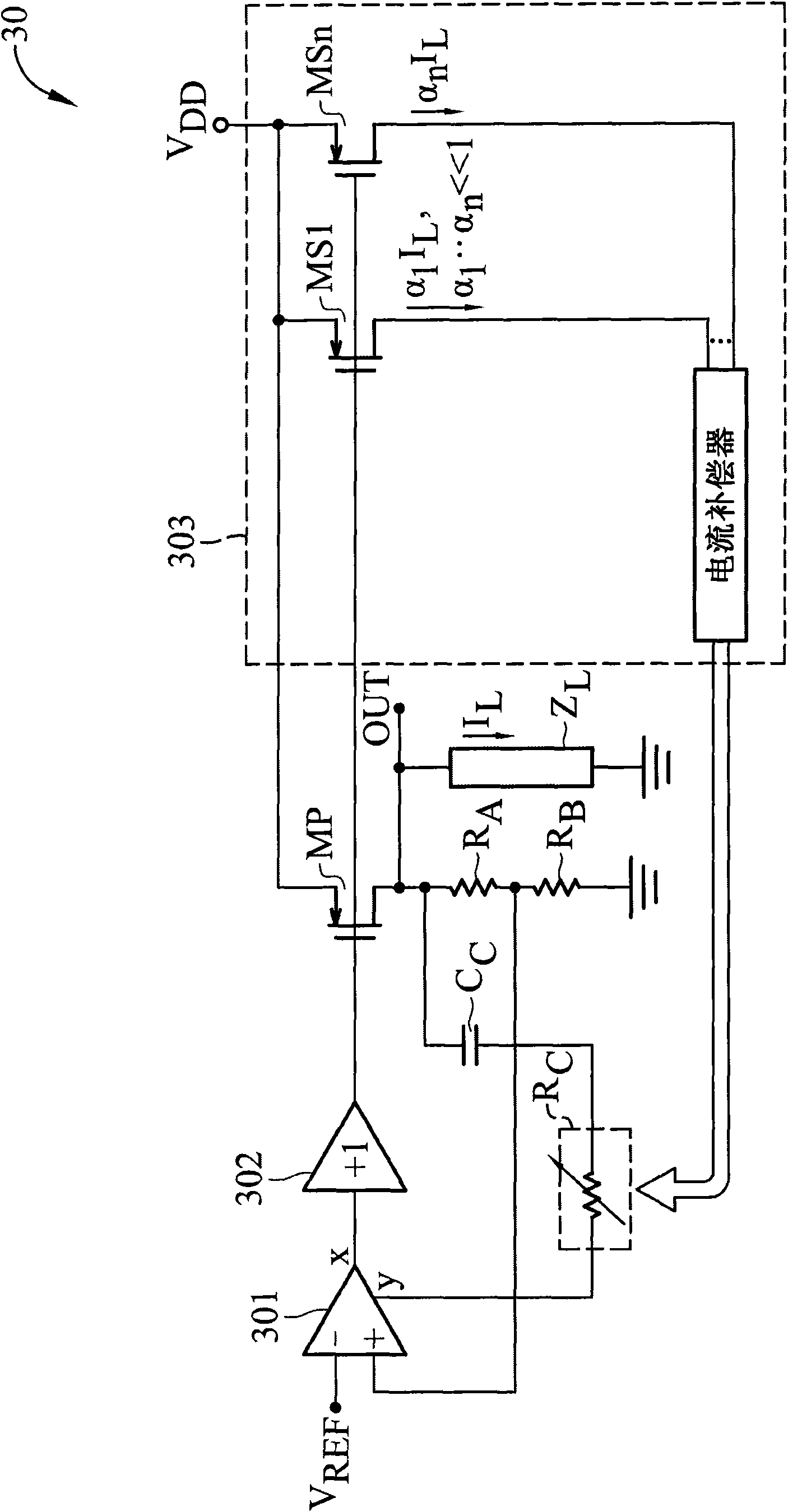

Low dropout regulator

InactiveCN101676829AGood frequency compensationAvoid craftElectric variable regulationCapacitanceManufacturing technology

The invention provides adequate compensation for a wide range of output loads, a low dropout (LDO) regulator has an amplifier, a pass transistor, a voltage divider, a compensation network, and a control circuit. The amplifier outputs a comparison result according to a reference signal and a feedback signal. The pass transistor generates an output current based on the comparison result of the amplifier. The voltage divider generates the feedback signal according to the output current. The compensation network couples the output of the pass transistor to a low-impedance node of the amplifier, and has a compensation capacitor and a variable resistor coupled to the compensation capacitor. The control circuit is coupled to the input of the pass transistor and to the variable resistor for controlling resistance of the variable resistor according to the output current of the pass transistor. The low dropout regulator provides better frequency compensation and more stable resolution and prevents the compensation effect influenced by manufacture technology and temperature.

Owner:MEDIATEK SINGAPORE PTE LTD SINGAPORE

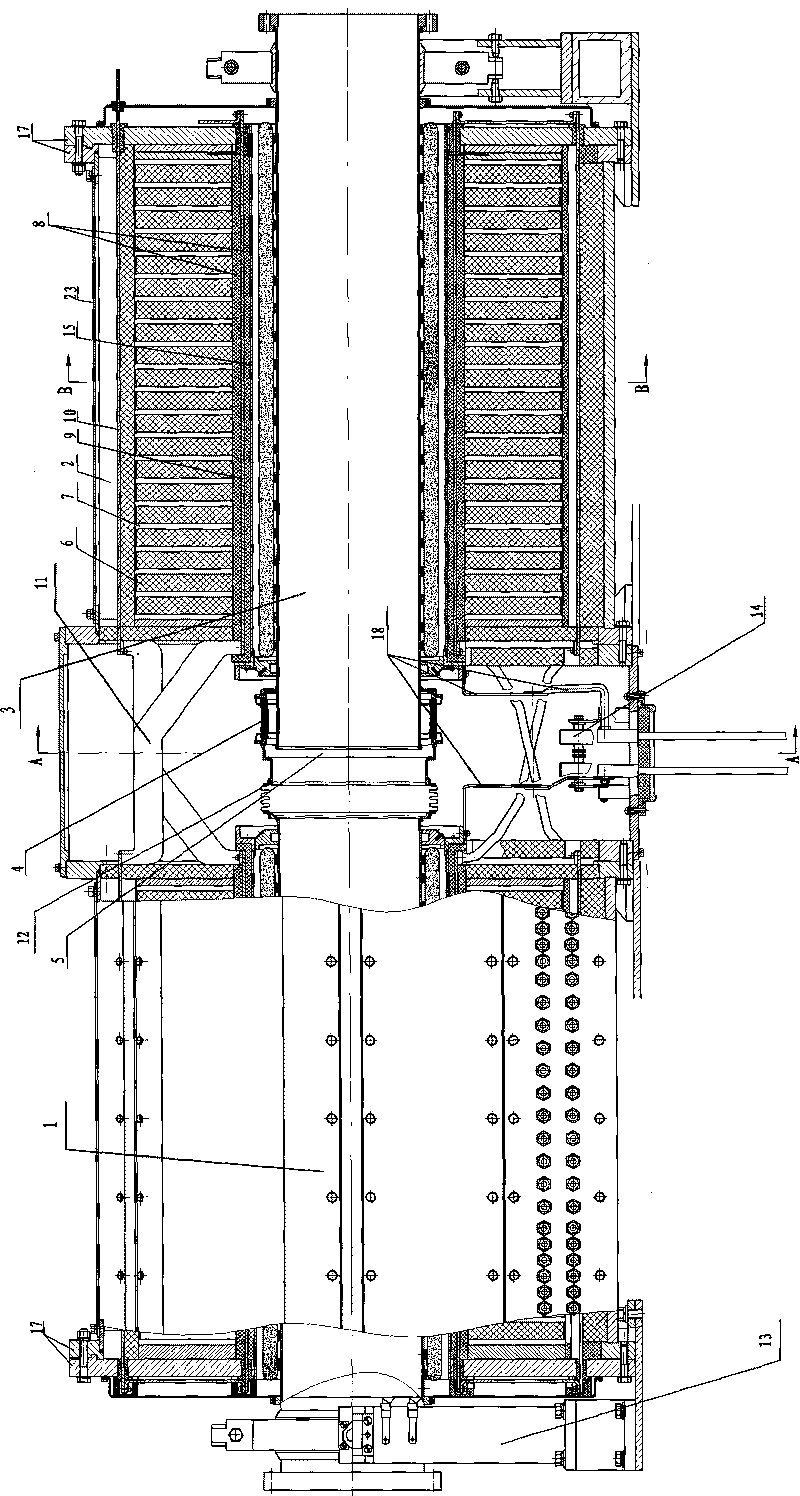

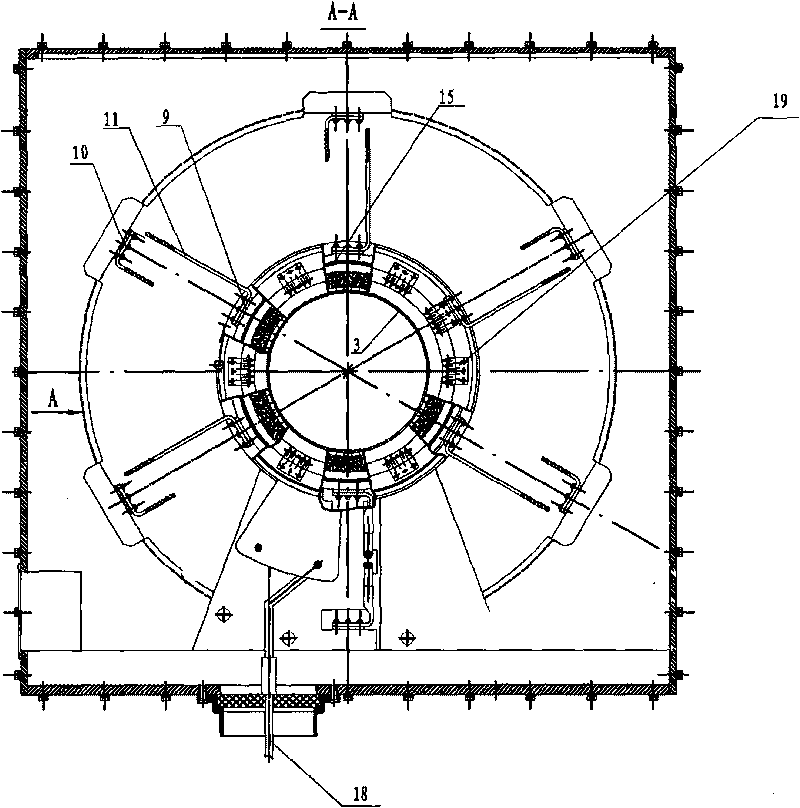

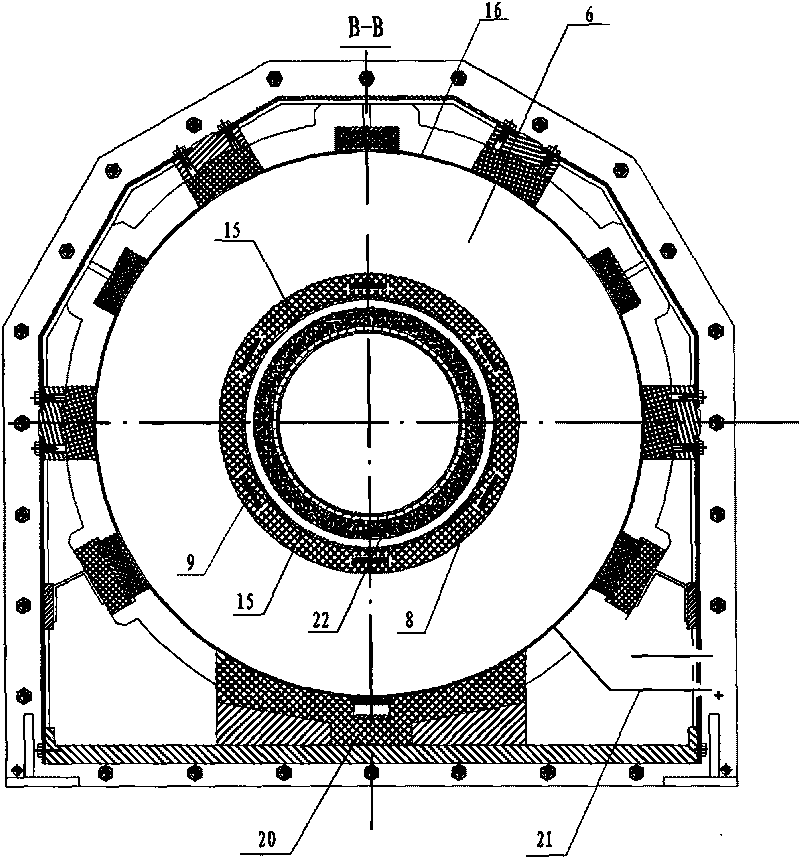

Loading and frequency conversion tuning cavity of large power ferrite

InactiveCN101715272AAvoid craftMeet the requirements of dual mode workMagnetic resonance acceleratorsPhysicsRadio frequency

The invention mainly relates to a loading and frequency conversion tuning cavity of a large power ferrite. The tuning cavity comprises a left resonant cavity (1) and a right resonant cavity (2) which are coaxially and oppositely arranged; a plurality of cavity loaded ferrite magnetic rings (6) are filled between an inner conductor (15) and an outer conductor (16) of the right resonant cavity (2); an insulating tetrafluoride medium (8) is filled between the inner diameters of the ferrite magnetic rings (6) and the inner conductor (15); a first field bias coil conductor (9) is arranged in the insulating tetrafluoride medium (8); a second field bias coil conductor (10) is installed at the outer part of the ferrite magnetic ring (6); a vacuum chamber (3) is arranged in the center of the inner conductor (15) of the right resonant cavity (2); a corrosion resistant casing (23) is installed at the outer part of the right resonant cavity (2); and a supporting corrosion resistant plate (17) is arranged on the side of the right resonant cavity (2). The tuning cavity can not only be operated in frequency sweep impulse modulation mode, but also be operated in radio frequency continuous wave mode within the frequency range of 0.5 MHz to 2 MHz, and meets the requirement of double mode operation of a CSR experimental ring high frequency system.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

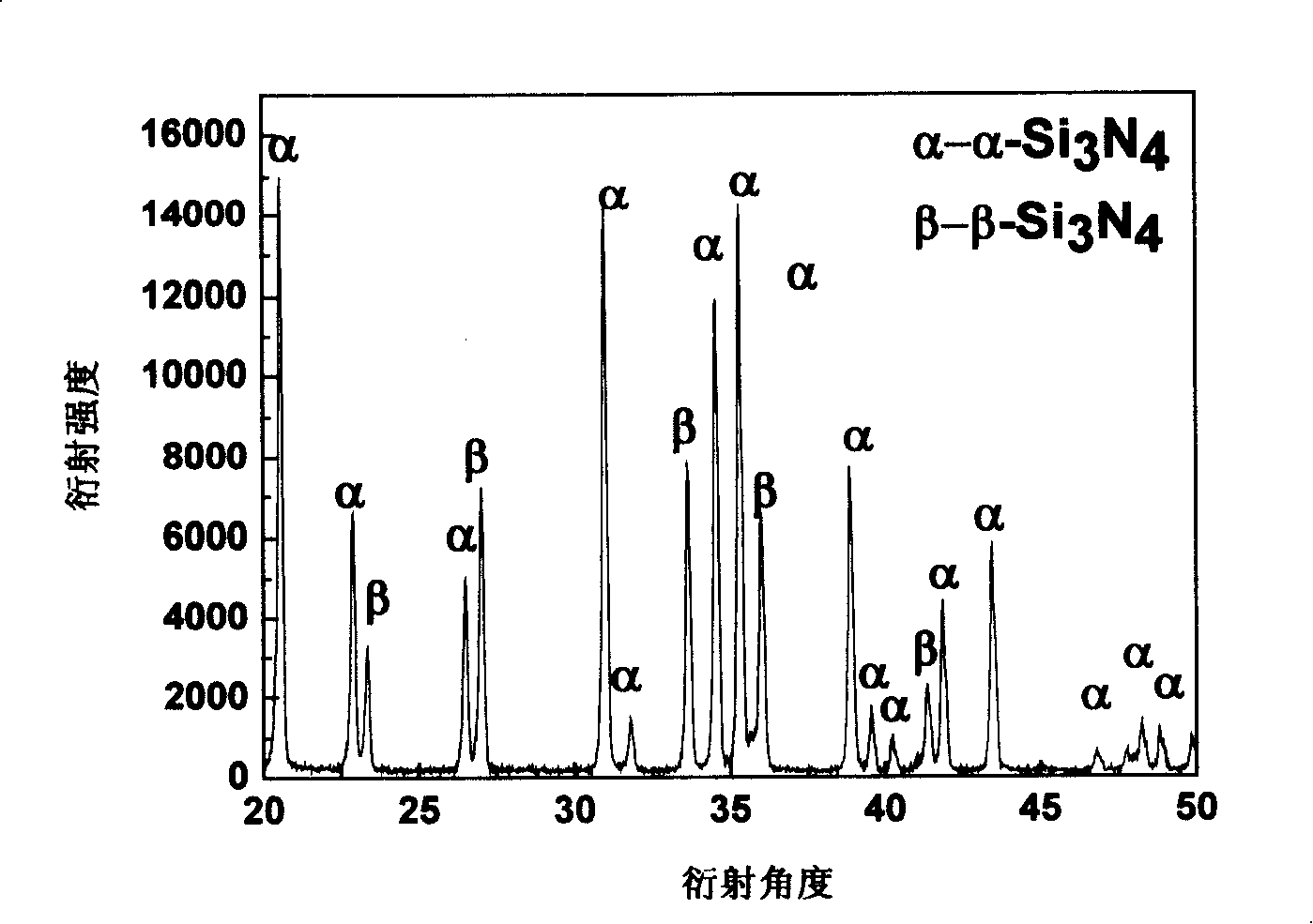

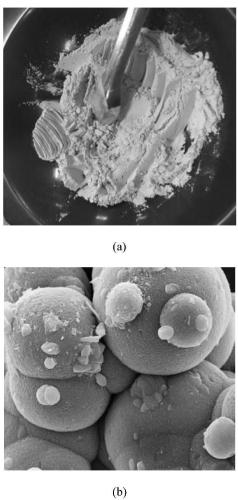

Method for combustion synthesis of silicon nitride powder by using polytetrafluoroethylene as additive

InactiveCN101229916ALow impurity contentFine and uniform particlesNitrogen compoundsSilica fumeSilicon nitride

The invention belong s to the preparation technical filed of silicon nitride ultrafine powder of non-oxide, in particular relating to a method in which when non-silicon nitride is taken as diluents, polytetrafluoroethylene is taken as addictive to combust and synthesize silicon nitride powder. Silicon powder, ammonium salt or nitrogen compound and polytetrafluoroethylene are taken as the raw material, the reaction mixture is prepared according to different component ratio; the mixture after ground and mixed for a while is put into an airtight vessel of high temperature resistance with apparent density of 0.8-2.0g / cm<3>; nitrogen and ammonia and so on are filled into the device after a reaction device is vacuumized. The gas pressure of the reaction device for combusting and synthesizing is controlled within 5MPa; products are processed by fine grinding to obtain the homogenous silicon nitride powder and the content of Alpha phase is 60 to 80 percent. The invention realizes that the silicon power is combusted and synthesized to be the silicon nitride under the condition that non-silicon nitride is taken as diluents and break through the limitation that the traditional combusting and synthesizing process of the silicon nitride must be added with a large amount of silicon nitride diluents. The method of the invention improves the net yield and reduces the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Preparation method of high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material

PendingCN113831103AImprove mechanical propertiesEnhanced skeleton structureCeramicwareFiberOxide composite

The invention discloses a preparation method of a high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material, wherein the preparation method comprises the following steps: (1) sufficiently dispersing and mixing nano aluminum oxide powder, micron aluminum oxide powder, an infrared opacifying agent and short fibers to obtain a mixture A; (2) performing compression molding on the mixture A to obtain an aluminum oxide composite material; (3) uniformly mixing a silicon source, ethanol and water to obtain silicon dioxide sol; (4) dipping the aluminum oxide composite material by adopting silicon dioxide sol; and (5) performing drying treatment to obtain the high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material. According to the preparation method disclosed by the invention, compounding of aluminum oxide and silicon oxide aerogel is realized through impregnation, a complex preparation process is avoided, the preparation period is shortened, the silicon oxide aerogel is fixed in the aluminum oxide composite material, the compactness of the aluminum oxide composite material is further increased, the composite material has relatively good mechanical properties, and great shrinkage of the aluminum oxide composite material at high temperature is avoided.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

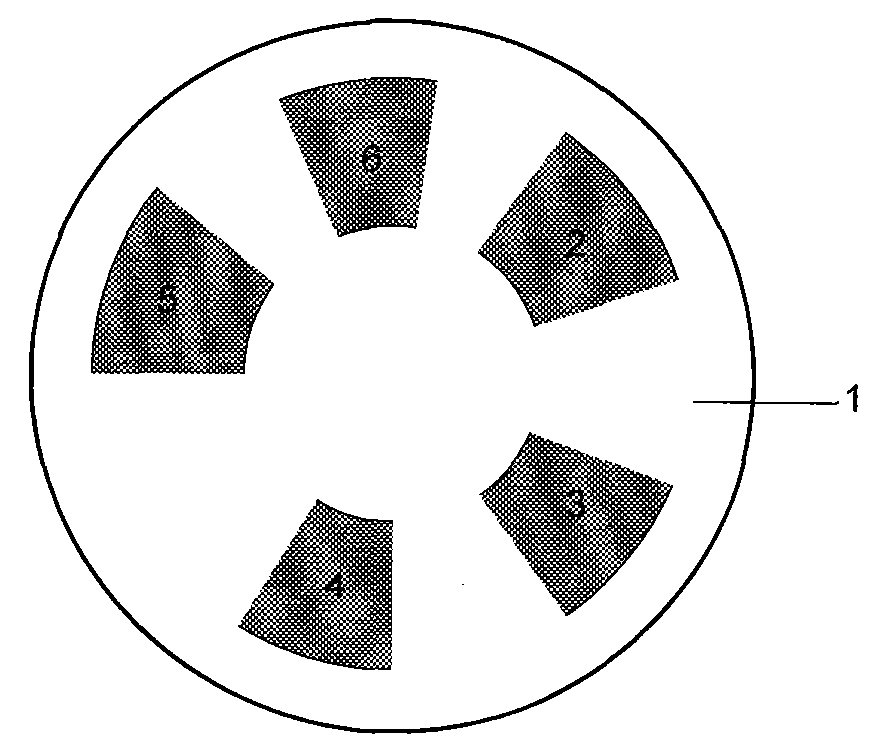

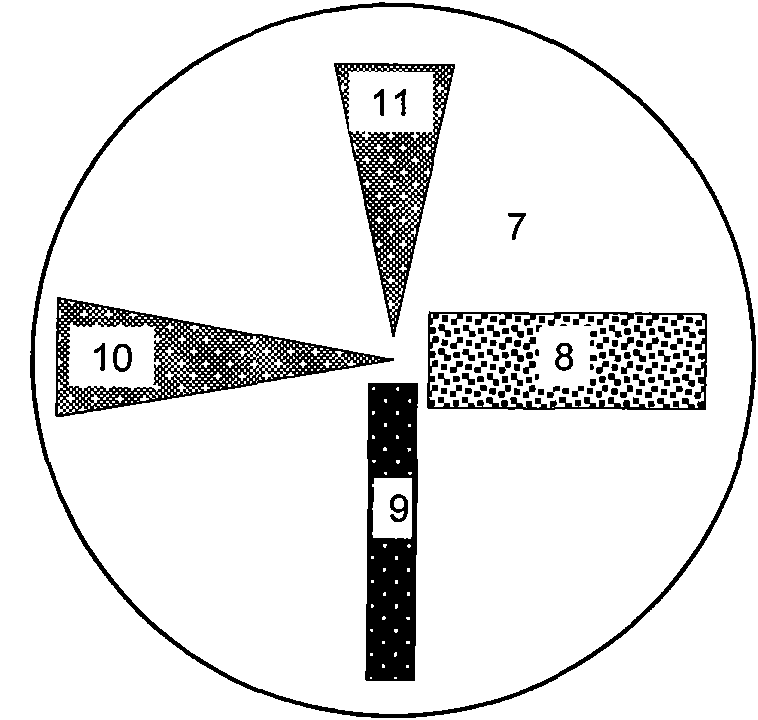

Assembling target material for preparing composite material, manufacturing method thereof, repair method thereof and modification method thereof

InactiveCN101892453AAvoid craftEasy to fixVacuum evaporation coatingSputtering coatingRepair methodMaterials science

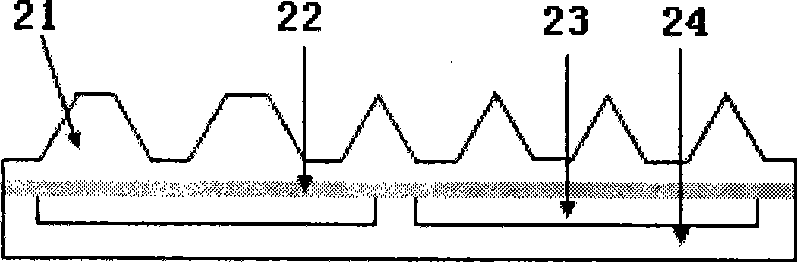

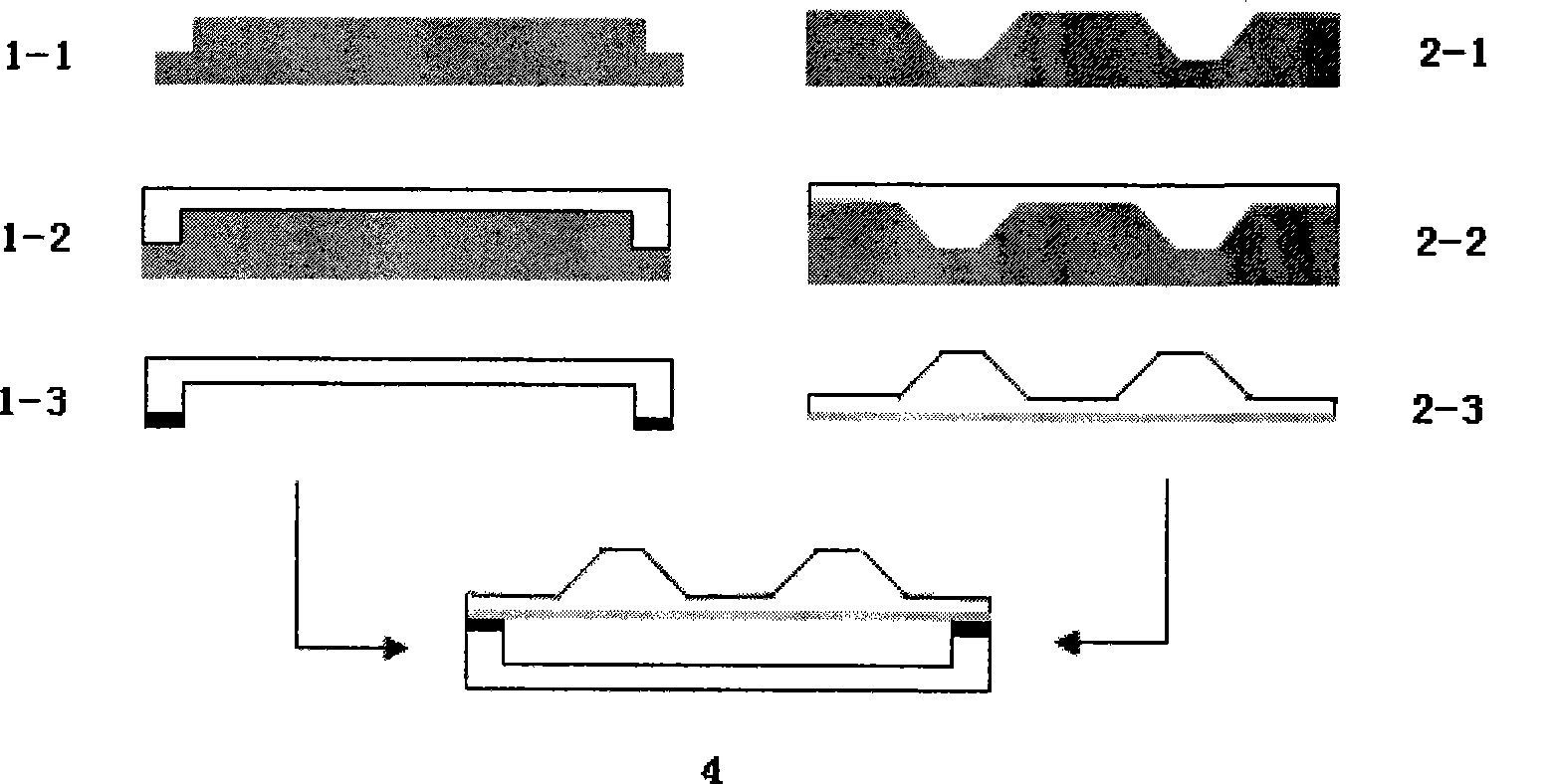

The invention discloses an assembling target material for preparing a composite material, which is characterized by comprising a first material substrate, wherein a plurality of grooves are formed on the substrate; and at least one material different from the first material is filled in the grooves. The target material is manufactured by the following steps: forming a groove structure on the first material substrate target material; filling the powder or melt of the at least one material different from the first material; sintering; cooling; and flattening to obtain the target material. After part of the target material is wear, the worn part of the target material is repaired to realize the recycling of the target material, and thus, the utilization rate is improved. When the assembling target material is used, composite material films can be prepared conveniently, the preparation cost of the films can be reduced, and the utilization rate of the target material is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

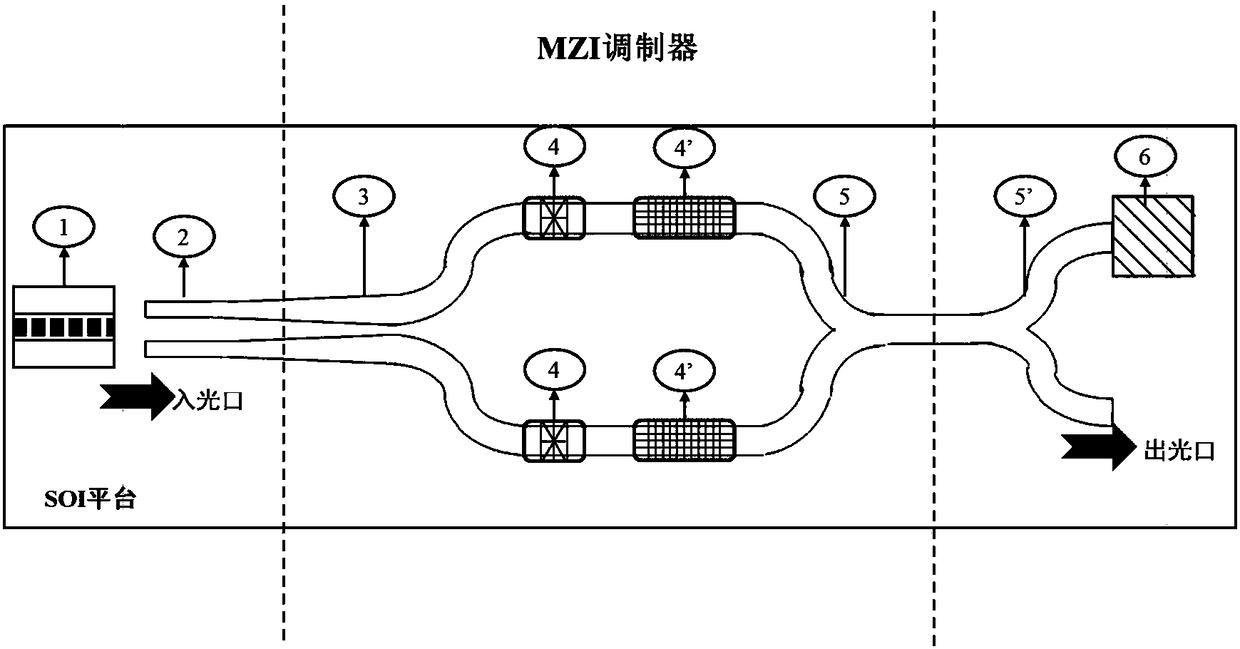

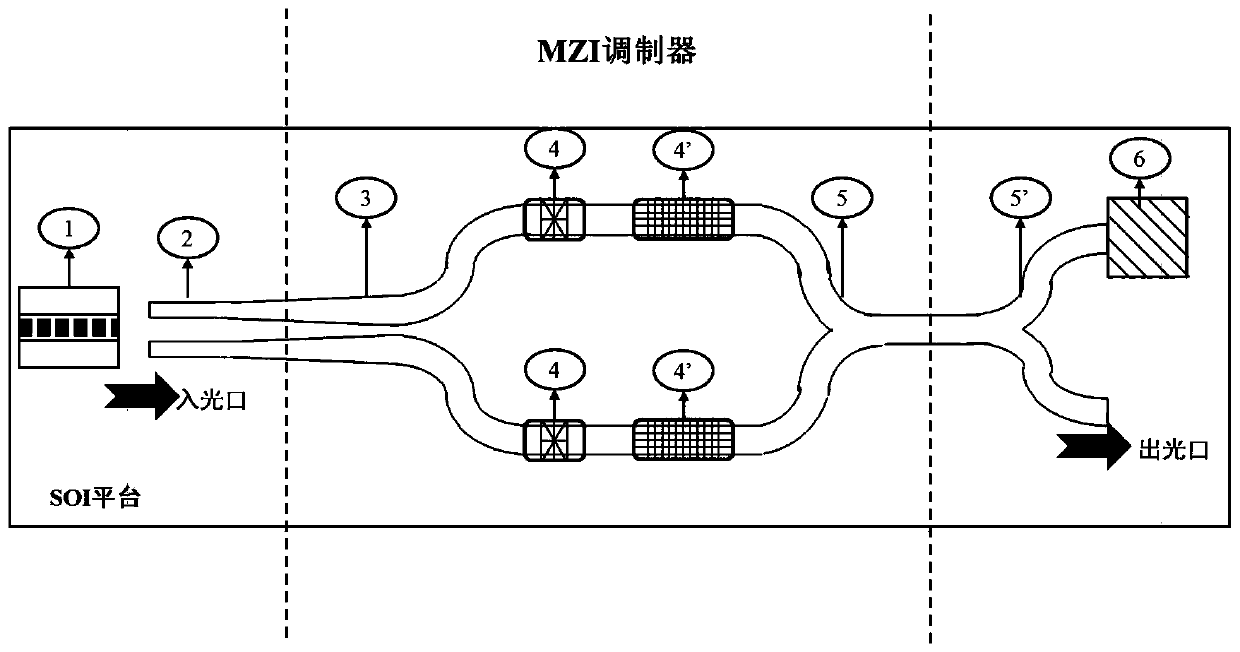

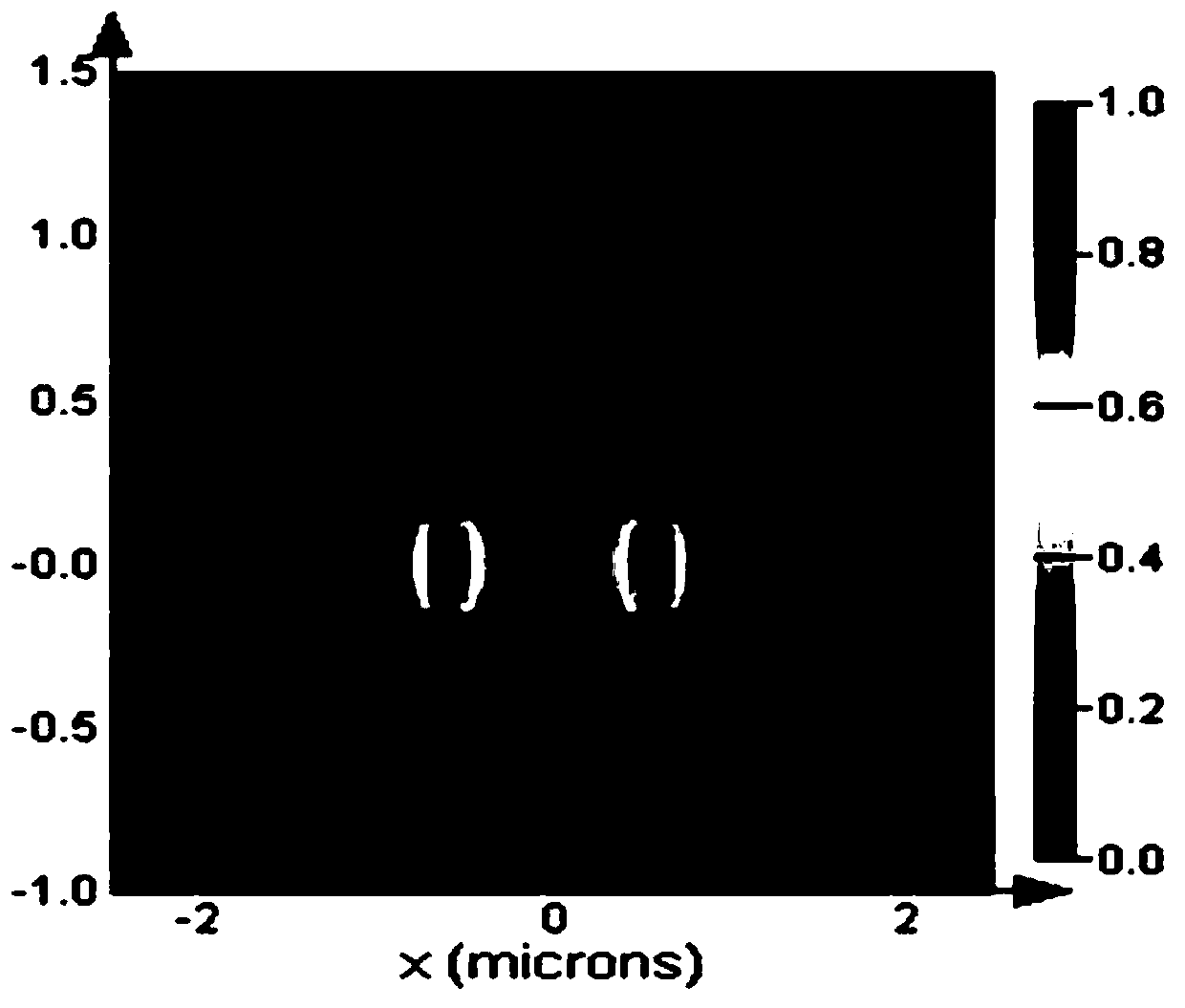

Monolithic silicon-based transmitter

ActiveCN108183390ARealize coupling integrationAvoid craftLaser detailsSemiconductor lasersBeam splitterPhotonics

The present invention discloses a monolithic silicon-based transmitter, and relates to the silicon photonic and photoelectron integration field. The emitter comprises a laser integrated to a silicon-based platform; a tip mode spot matcher formed on the end face of a silicon waveguide; a silicon waveguide biconical beam splitter used as the input end of an MZI modulator and connected with the tip mode spot matcher; two thermodes respectively formed on the two arms of the MZI modulator and / or two high-frequency electrodes respectively formed on the two arms of the MZI modulator; an MMI beam splitter formed behind the output end of the MZI modulator, wherein two output ports are split by the MMI beam splitter; and a backlight detector formed on the silicon-based platform and connected with one output port of the MMI beam splitter. The monolithic silicon-based transmitter not only realizes the monolithic integration of the laser and the modulator on the silicon-based platform, is low in manufacturing cost, simple in technology and high in integration degree, and facilitates the large-scale production.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

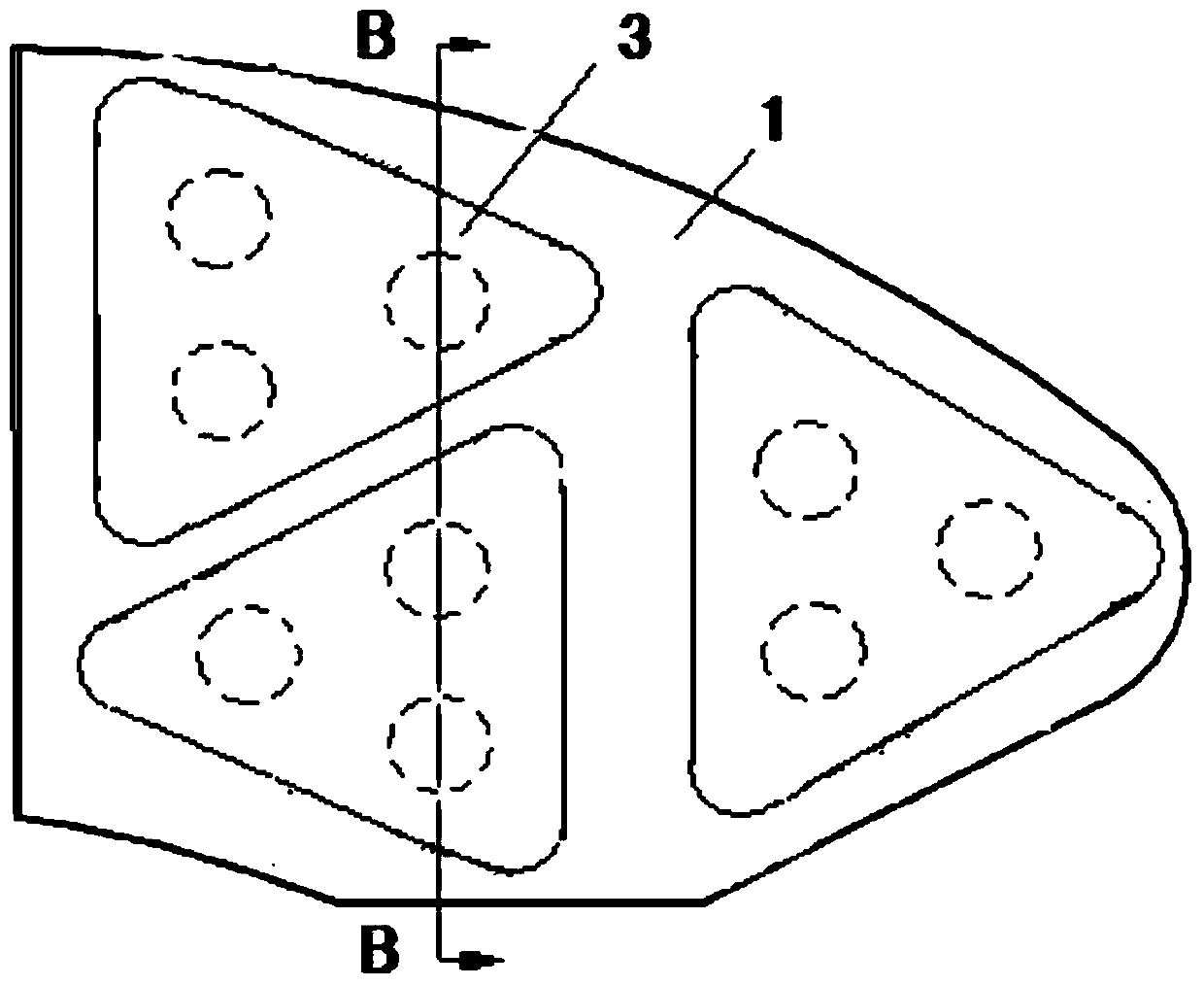

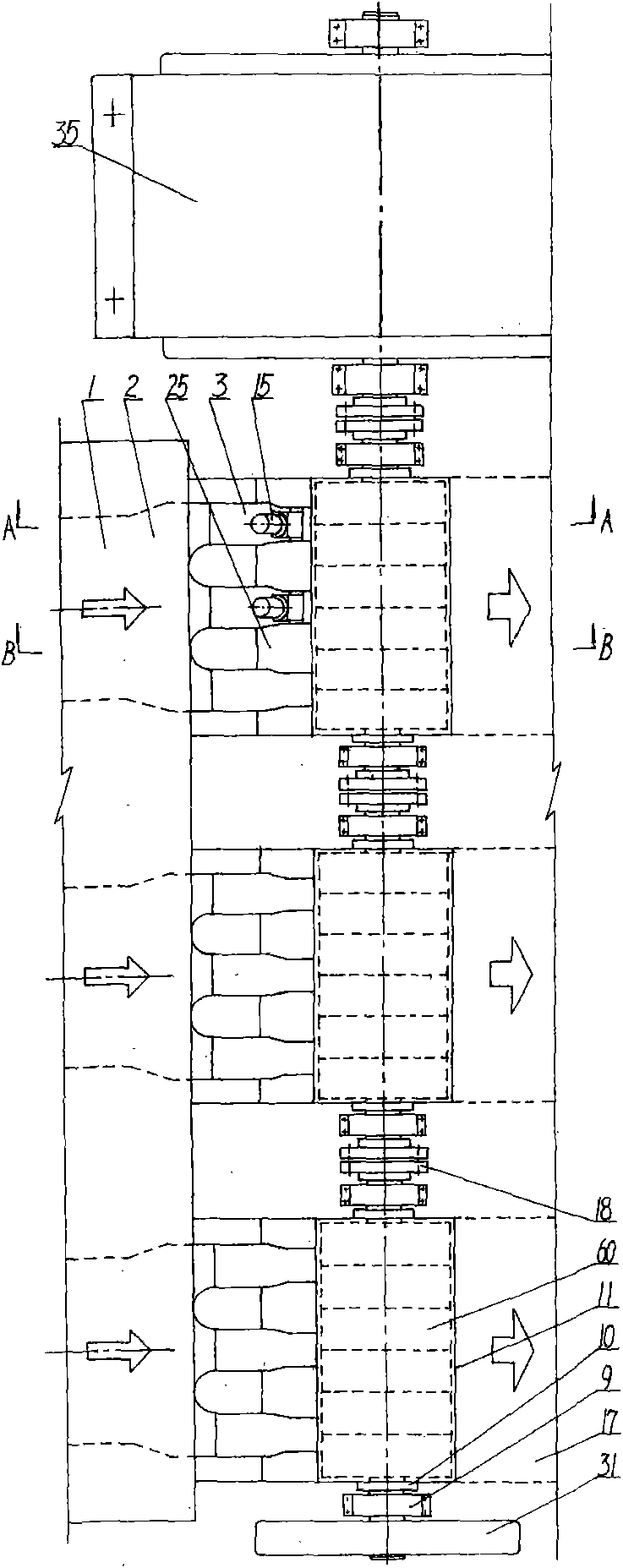

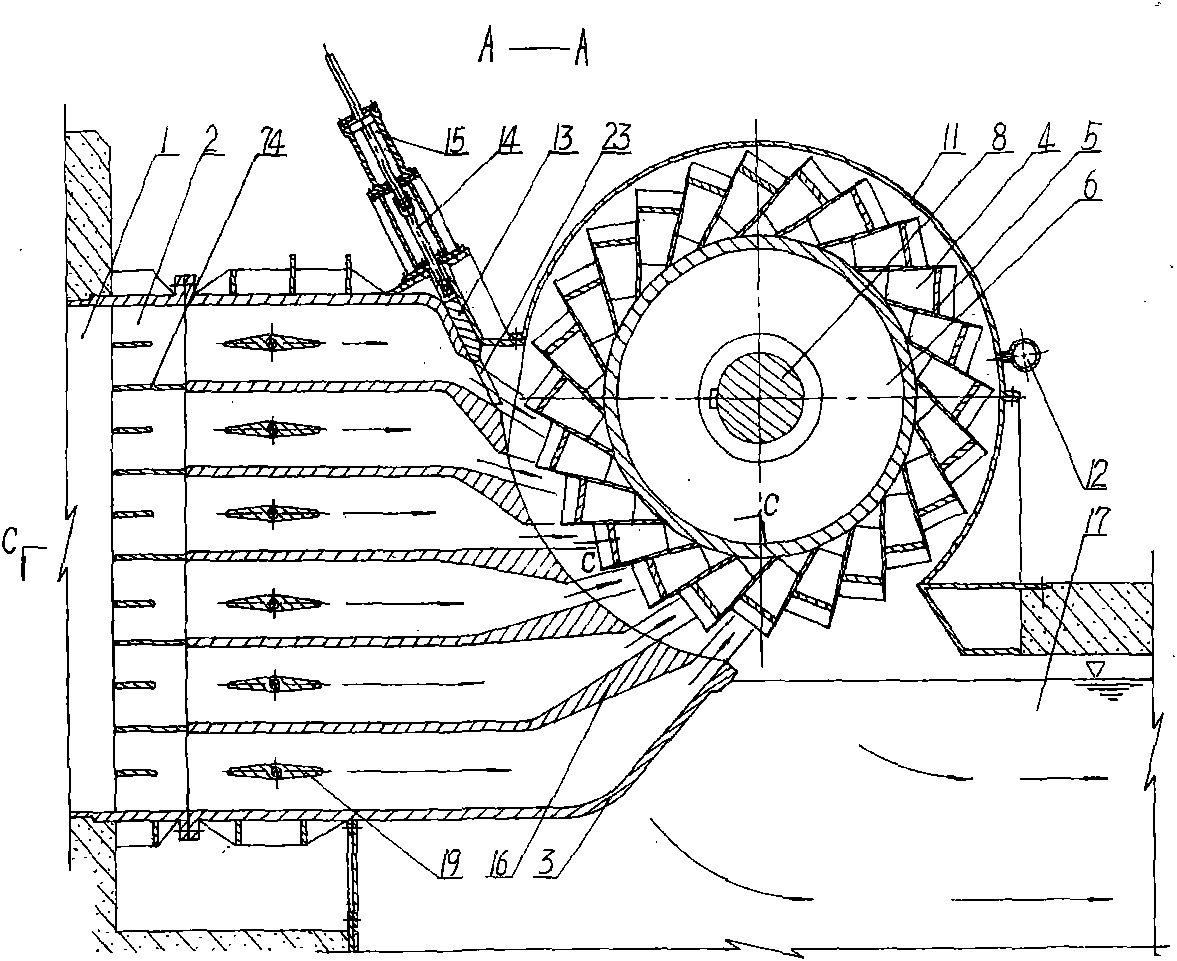

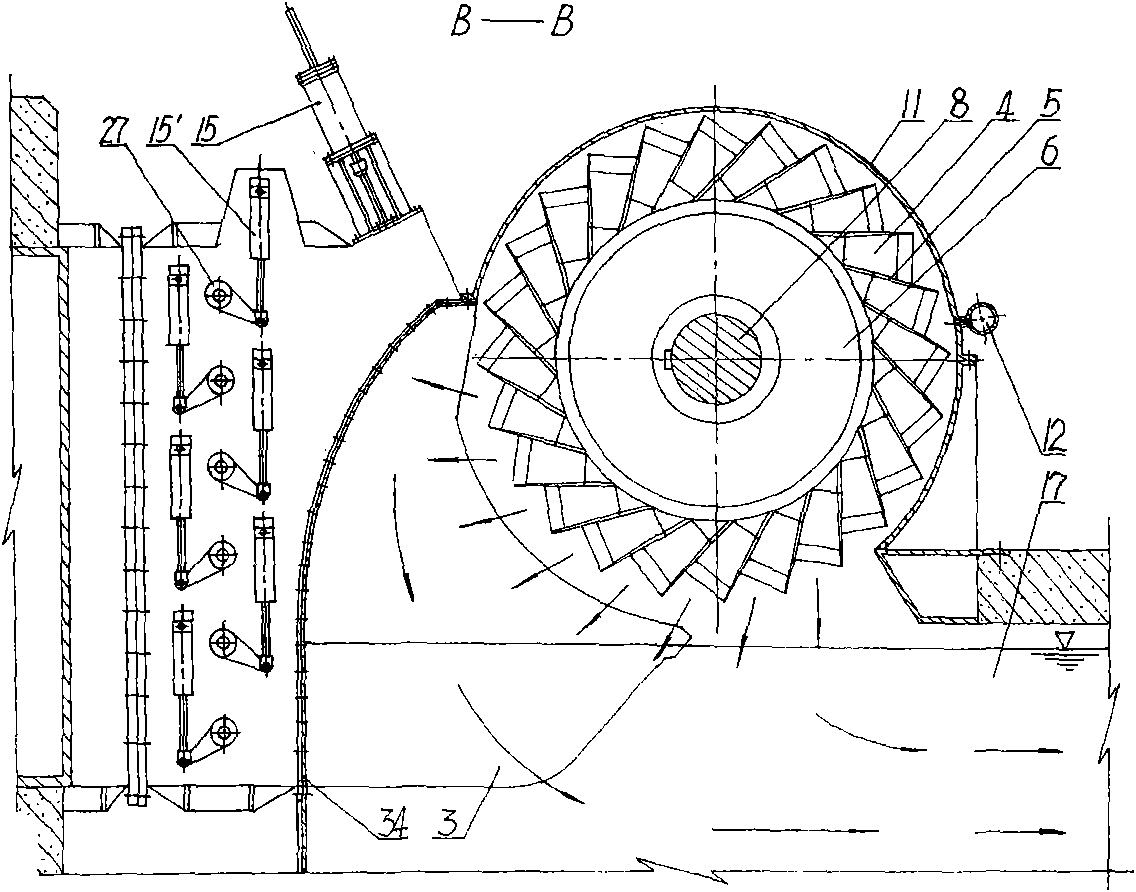

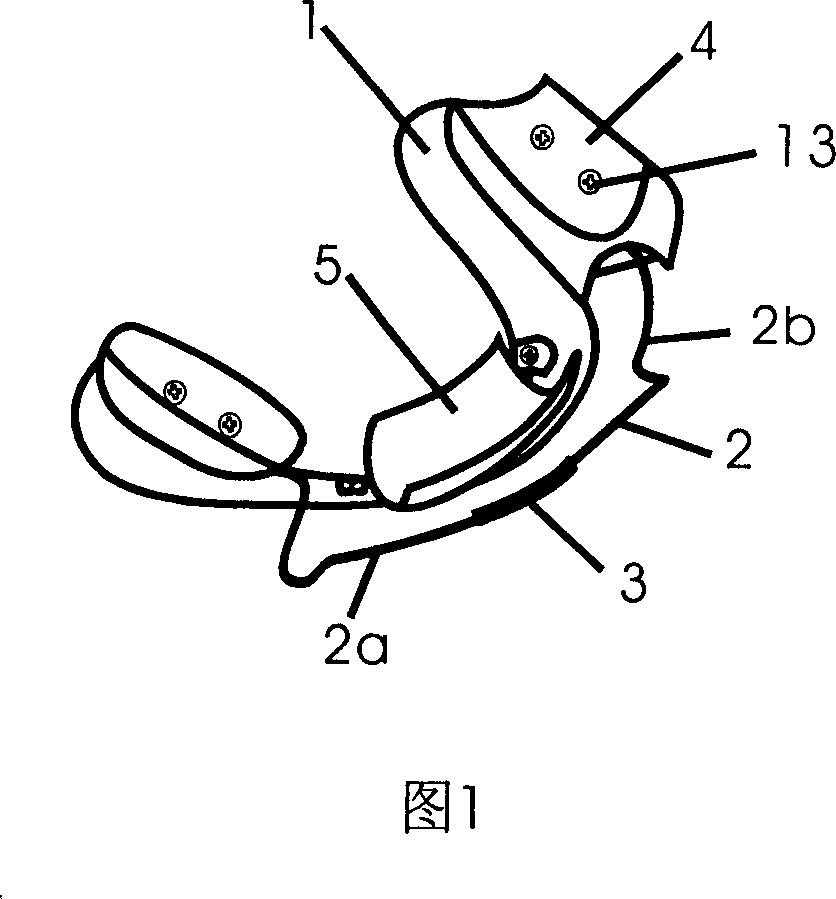

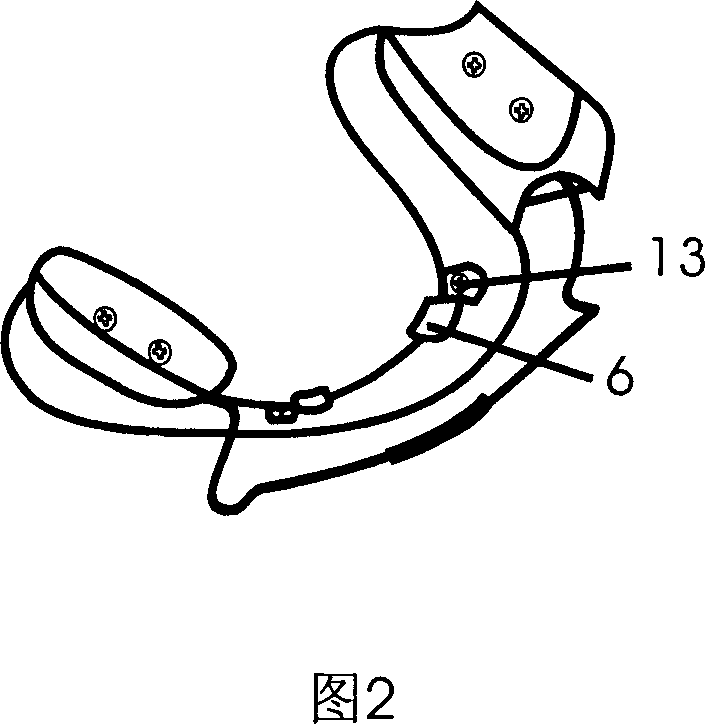

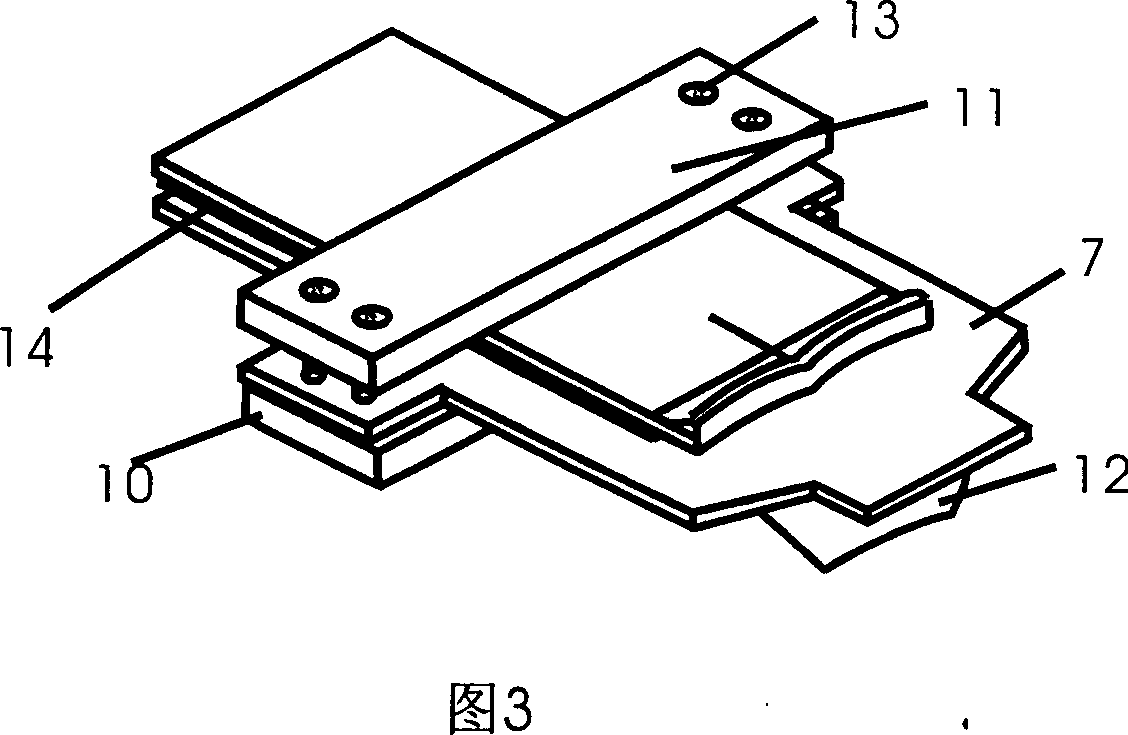

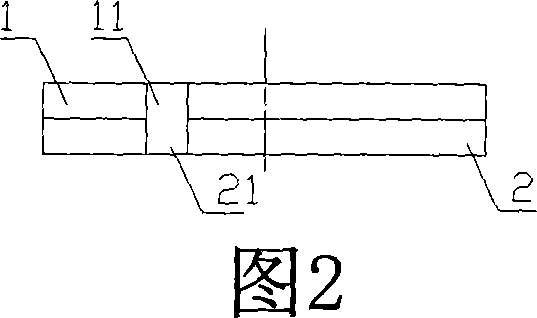

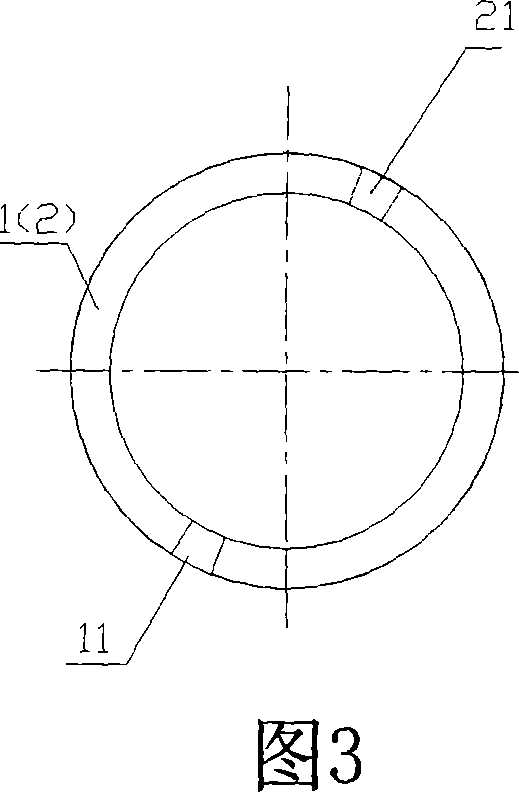

Embedded brake pad

The invention relates to an embedded brake pad. The brake pad, namely an embedded friction body type brake pad, is characterized in that a plurality of friction block components forming friction with a brake disc are arranged on a backboard of the embedded friction body type brake pad; each friction block component is a base plate combined friction block component, a base plate-free combined friction block component or a round recessed fixed plate type friction block component embedded in the backboard; the base plate combined friction block component consists of a friction block, a base plate and an embedded pin; the base plate-free combined friction block component consists of a friction block and an embedded pin; the round recessed fixed plate type friction block component consists of a friction block, a round recessed base plate, an elastic gasket, an embedded cylindrical pin and a dowel. The embedded brake pad is reasonable in design and simple in structure, and has the characteristics of uniform stress, reliable performance, prolonged service life, simplified manufacturing process, improved production efficiency, easiness for assembly, disassembly and replacement, reduction in cost and the like, and the load bearing capability of the friction block is improved while the breakage risks of the friction block are greatly reduced.

Owner:DALIAN JIAOTONG UNIVERSITY

Universal fully-effective generating power machine

InactiveCN101871415AImprove efficiencyNo leakage lossFrom solar energyFinal product manufactureTidal waterWind force

The invention relates to a universal fully-effective generating power machine belonging to generating power equipment which can fully and effectively convert conventional energy resources such as water energy, steam energy and the like and new energy resources such as wind energy, steam energy formed by solar heating, tidal water energy and the like into rotating mechanical energy. The machine mainly comprises one or a plurality of jet orifices, a regulating mechanism of the jet orifices, one or a plurality of universal fully-effective rotating wheels, a speed regulator and the like, wherein, the universal fully-effective rotating wheels correspond to the jet orifices and are arranged on a main shaft. The machine can fully develop and utilize water energy, steam energy and wind energy of all types, can fully and effectively convert the utilized water energy, steam energy and wind energy into rotating mechanical energy, can fully replace all current water turbines, steam turbines and wind turbines, and has the advantages of simple structure, reliable performance, low manufacturing cost and easy implementation. Thus, the universal fully-effective generating power machine can replace equipment of hydraulic, thermal and wind power generation industries, and can promote rapid development of new energy resource generating industries such as hydraulic fully-effective power generation, hydraulic wind power generation, solar steam power generation and the like to become main energy source power generating modes.

Owner:黄国宏

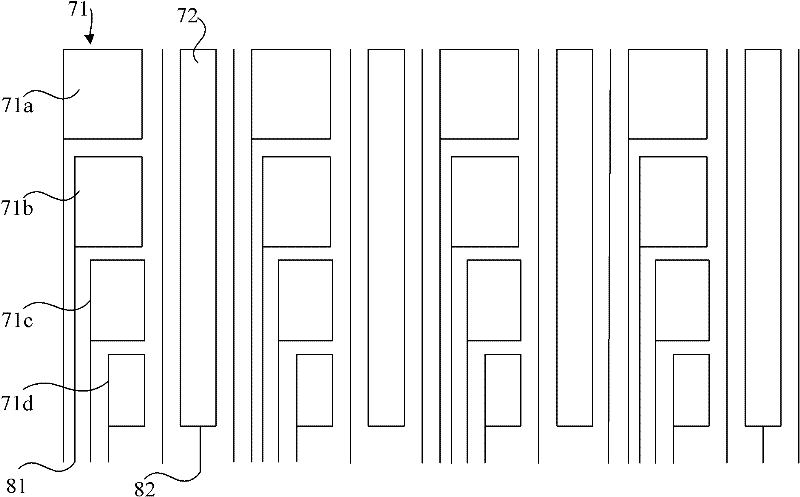

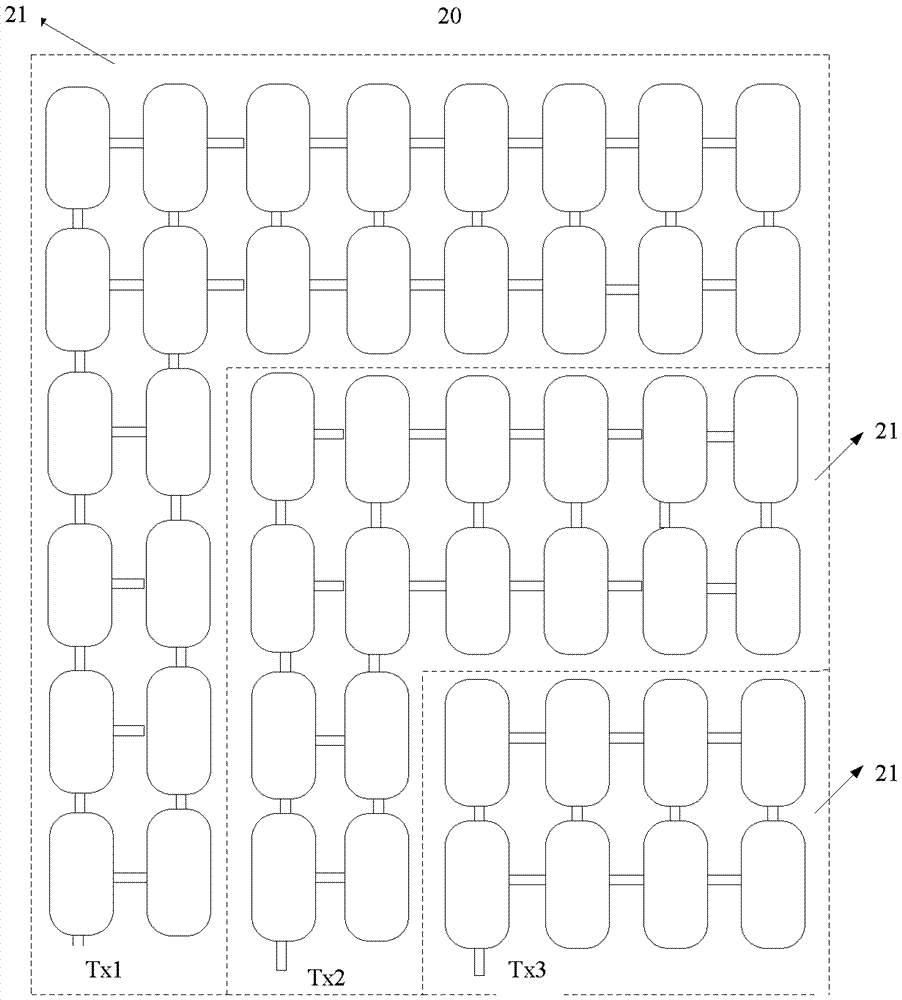

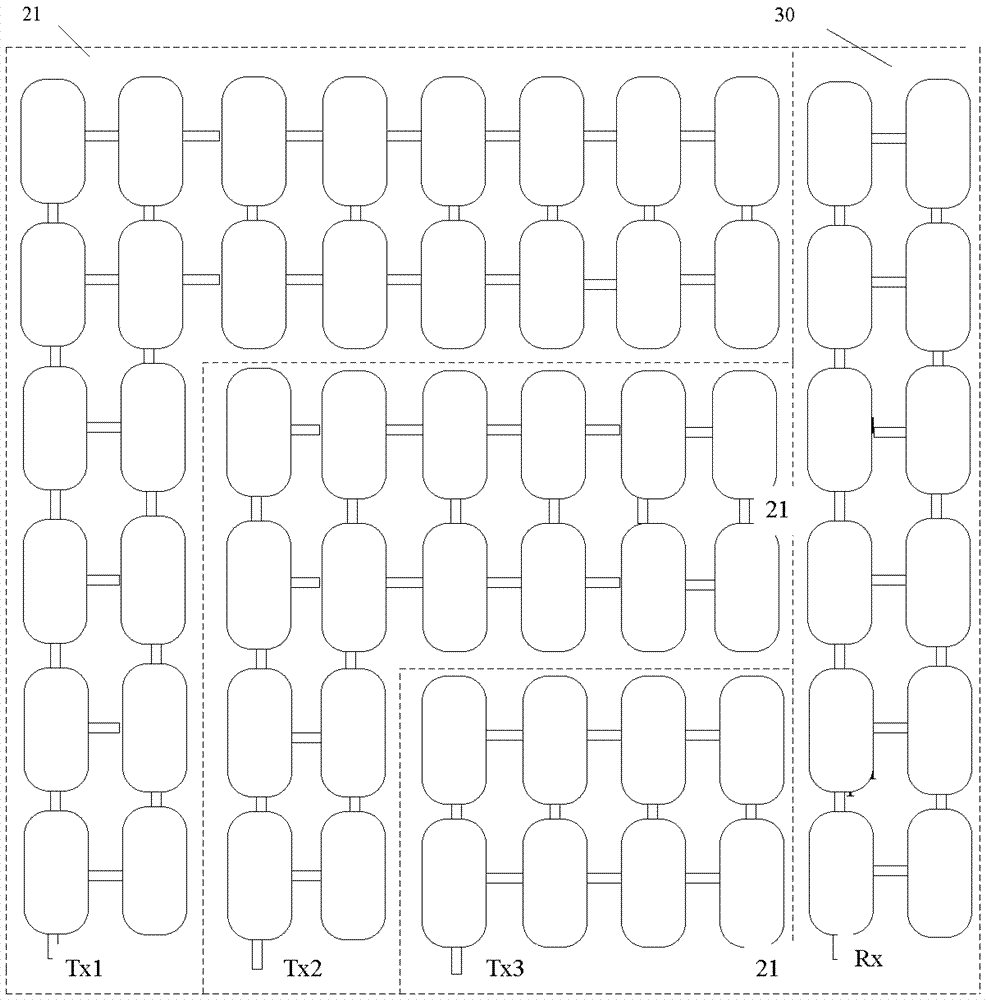

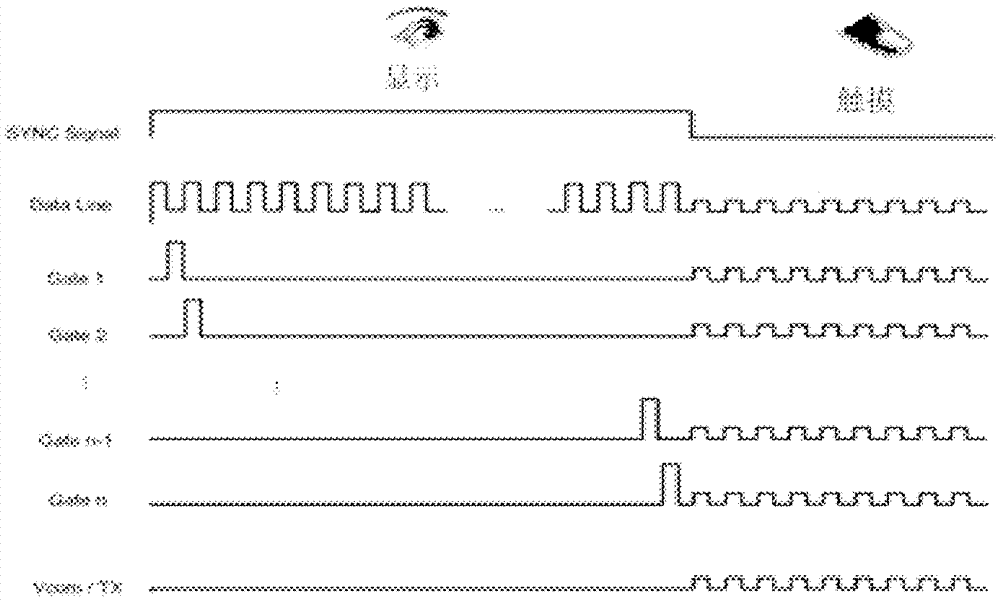

Touch-sensitive element and touch display device

ActiveCN105446535AQuality improvementImprove visual effectsInput/output processes for data processingManufacturing technologyImaging quality

The embodiment of the invention provides a touch-sensitive element and a touch display device. The touch-sensitive element comprises a plurality of touch-sensitive units, wherein each touch-sensitive unit comprises a plurality of first touch-sensitive subunits which at least can receive driving signals; each first touch-sensitive subunit comprises an electrode block array; and in the electrode block array of each first touch-sensitive subunit, any two adjacent electrode blocks are mutually connected in a line direction or row direction. The touch-sensitive element can be applied to the display device to realize touch control. Compared with the prior art, the touch-sensitive element omits TPM (Touch Pattern Metal), so that the aperture ratio of the pixel of the display device is improved so as to be favorable for improving the image quality and the visual effect of the display device, meanwhile, the manufacture technology of the TPM is omitted, and the cost of a touch panel or the display device can be lowered.

Owner:BOE TECH GRP CO LTD +1

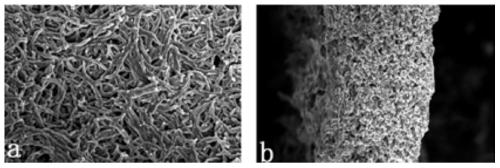

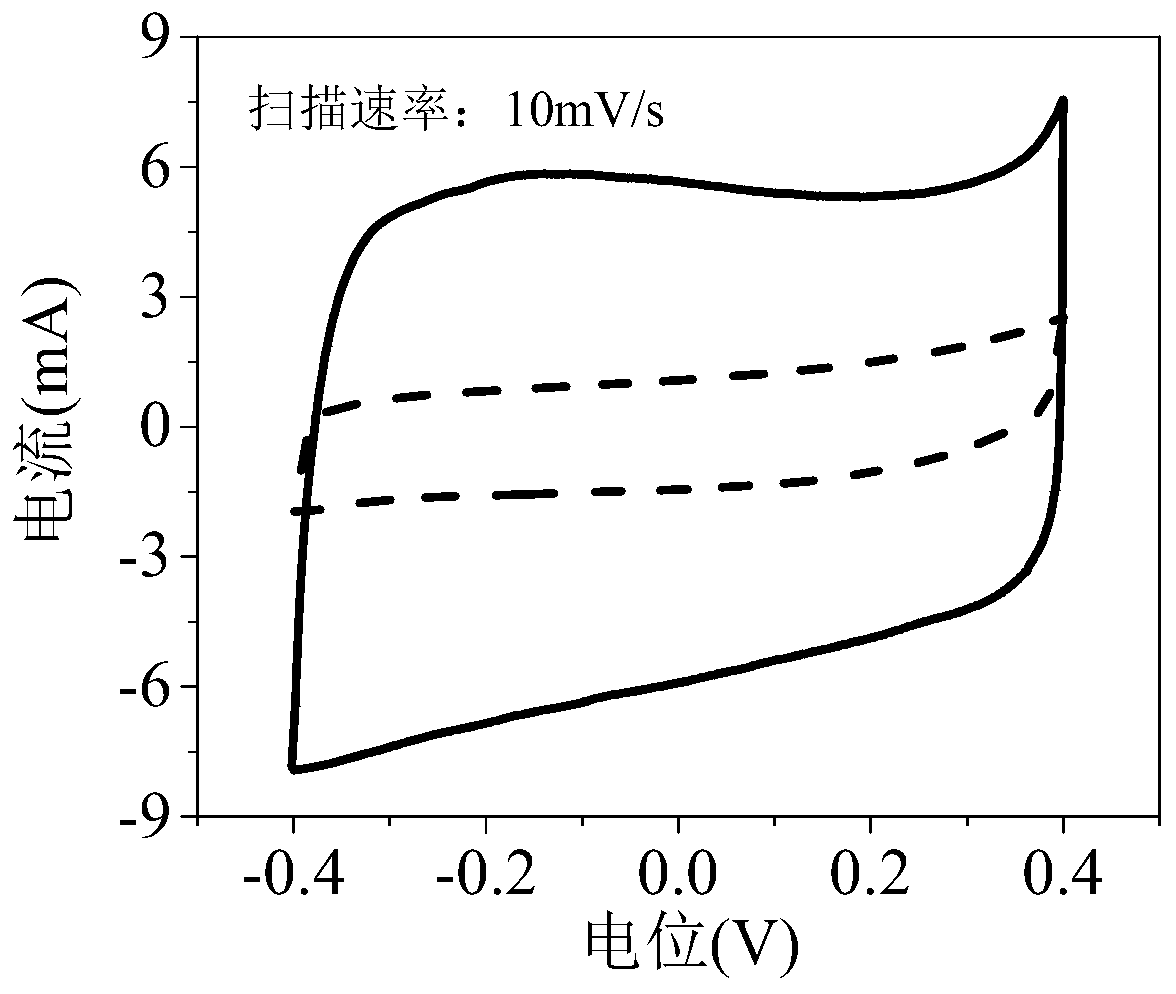

Flexible porous polypyrrole film, preparation method and application of flexible porous polypyrrole film as electrode

ActiveCN110004475AAvoid craftGuaranteed porosityElectrolytic organic material coatingPolypyrroleAqueous solution

The invention discloses a flexible porous polypyrrole film, a preparation method and application of the flexible porous polypyrrole film as an electrode and belongs to the field of preparation of polypyrrole electrodes. The preparation method of the flexible porous polypyrrole film comprises the following steps that 1) a PPy nanotube water solution is placed on an inert metal foam plate to be filtered, then drying is carried out, and an inert metal foam plate to which a PPy nanotube is attached is obtained; 2) the inert metal foam plate to which the PPy nanotube is attached is adopted as a positive electrode, and immersed in electrolyte containing monomer pyrrole and doping ions for electrochemical polymerization, and an inert metal foam plate to which a PPy layer is attached is obtained,wherein the pH of the electrolyte ranges from 2 to 5; and 3) the inert metal foam plate to which the PPy layer is attached is washed and dried, then the PPy layer is taken down from the inert metal foam plate, and the flexible porous polypyrrole film is obtained. The PPy film prepared through the steps is good in integrity and electrical conductivity and high in porosity and electrochemical activity.

Owner:SHAANXI UNIV OF SCI & TECH

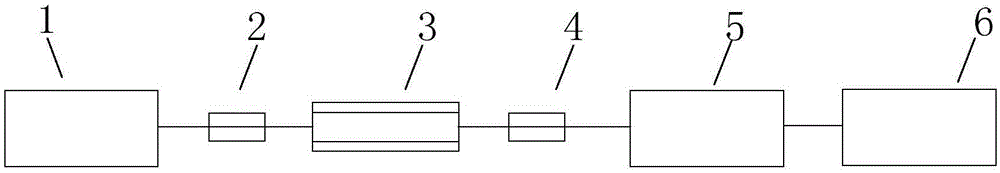

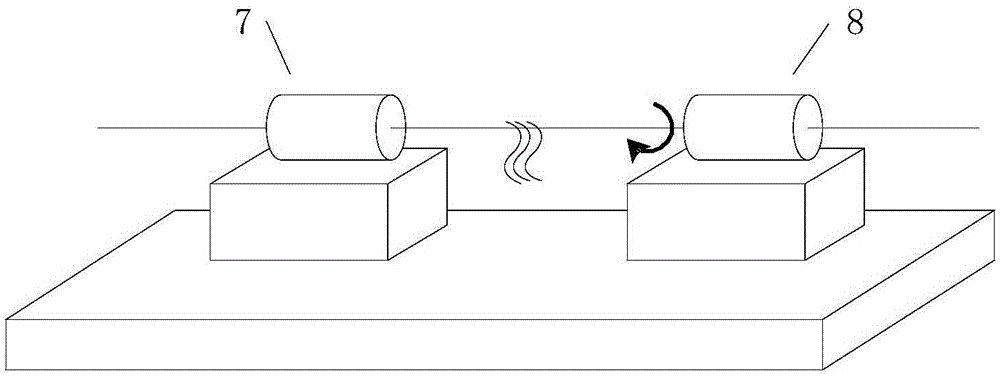

Multimode fiber strain sensor with high sensitivity and measuring system

The present invention relates to a chiral multimode fiber strain sensor with high sensitivity and a strain measuring system belonging to the technical field of fiber strain measurement. An existing fiber strain sensor is composed of a single mode fiber, a multimode fiber and a single mode fiber by fusion splicing, and has low measuring sensitivity. The multimode fiber strain sensor provided by the invention is composed of a single mode fiber, a twisted chiral multimode fiber and a single mode fiber by fusion splicing. A preparation method for the chiral multimode fiber includes the steps of fixing two ends of the multimode fiber through a fixture, heating the middle region and twisting simultaneously, and cooling to acquire the chiral multimode fiber. The strain measuring system includes the multimode fiber strain sensor with high sensitivity, a broadband light source, a spectrum analyzer and a signal processor. The broadband light source connects the fiber strain sensor with high sensitivity, the output end of the sensor connects the spectrum analyzer, and the signal processor analyzes an output spectrum and displays a measuring result. Compared to a traditional fiber strain measuring method, the multimode fiber strain sensor with high sensitivity is simple in preparation, is strong in anti-interference capability, and has highest sensitivity.

Owner:HUAZHONG UNIV OF SCI & TECH

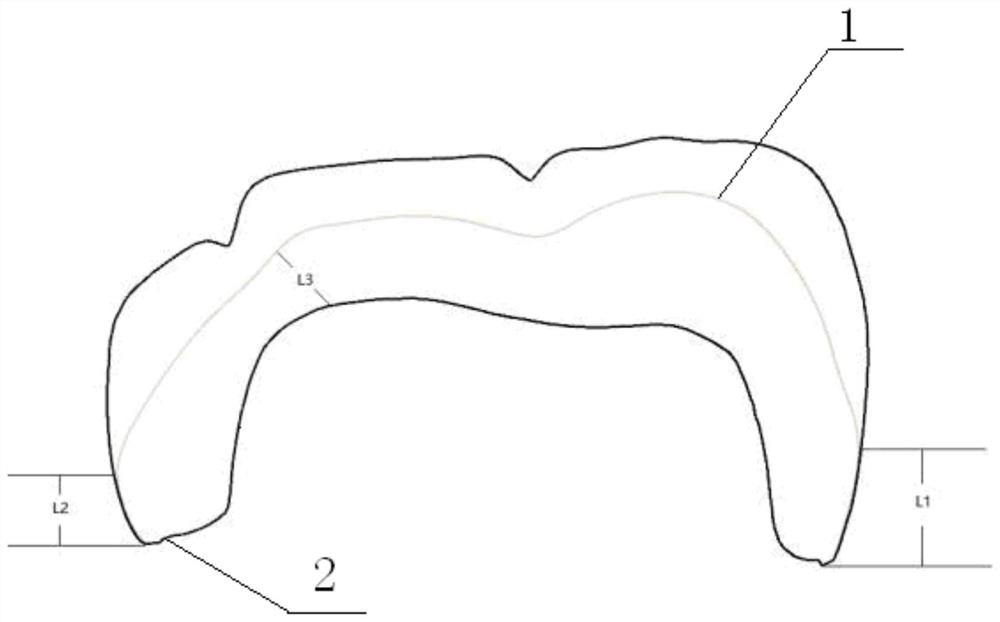

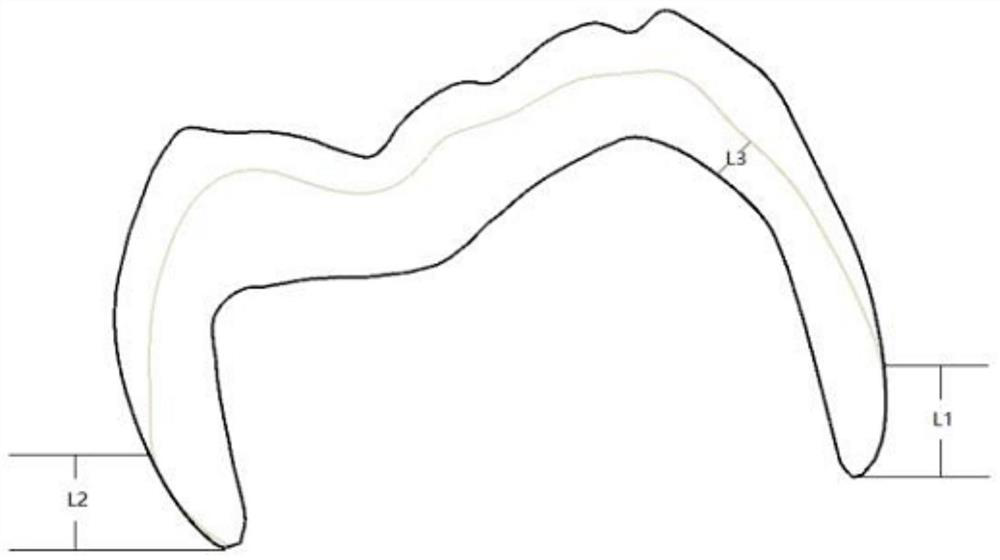

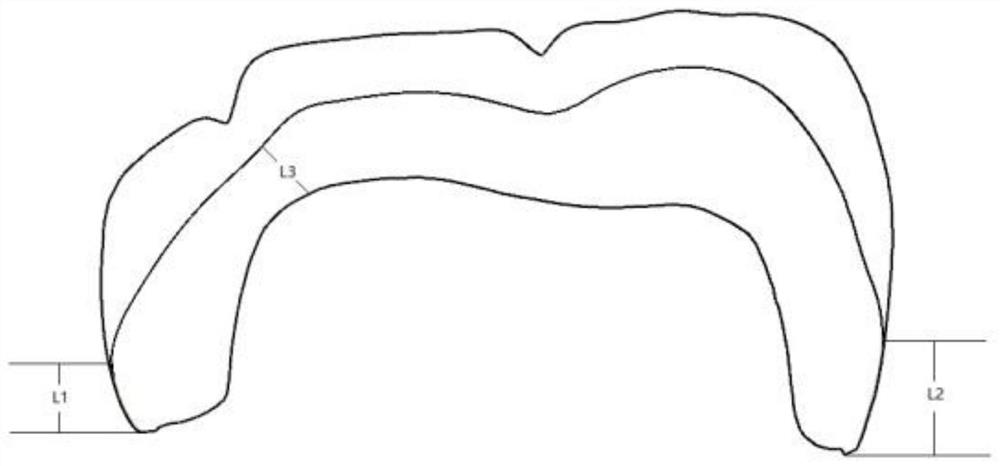

Oral cavity function orthopetical device and its mounting process

The invention relates to a mouse corrector, which comprises corrector and positioning ruler. Wherein, the corrector comprises base support, band ring, left and right pads, upper protective pad and positioning ruler support; the band ring is at the front of base support whose two ends are fixed on the base support; the band ring is formed by two half rings to be connected by muffle to extend; the left and right pads are mounted at left and right of base support, with adjustable left and right positions, to form clamping with the front protective pad; the positioning ruler support is fixed between left and right pads at the back of base support; the positioning ruler comprises connecting bridge, lower cross standard ruler, upper cross ruler, lower compressing bar, upper compressing bar; the connecting bridge is between lower cross standard ruler and upper cross ruler, to be fixed with lower and upper compressing bars; the front of connecting bridge has insert plate inserted into the positioning ruler support; the lower cross standard ruler has cross scale line; the upper cross ruler has cross line without scale; the connecting bridge, lower cross standard ruler and upper cross ruler are made from transparent materials.

Owner:卢崇伟

Method for preparing dendriticnano-silver quickly and conveniently

PendingCN109848433AAvoid preparation and purification processesThe requirements for the preparation environment are lowNanotechnologyChemical synthesisChloride sodium

The invention belongs to the field of chemical synthesis, and discloses a method for preparing dendritic nano-silver quickly and conveniently. The method for preparing the dendritic nano-silver quickly and conveniently comprises the following steps that (1) polyvinylpyrrolidone, silver nitrate and sodium chloride are blended, dissolved in ethylene glycol, and uniformly stirred and mixed; (2) a piecewise heating reaction is conducted on the blended liquid being uniformly stirred and mixed in the step (1), reaction liquid obtained after the reaction is completed is purified, and the dendritic nano-silver is obtained. According to the method for preparing the dendritic nano-silver quickly and conveniently, tedious and complex preparation and purifying technologies in traditional preparation methods are avoided, requirements on the preparation environment are low, and the dendritic nano-silver can be prepared conveniently and quickly.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

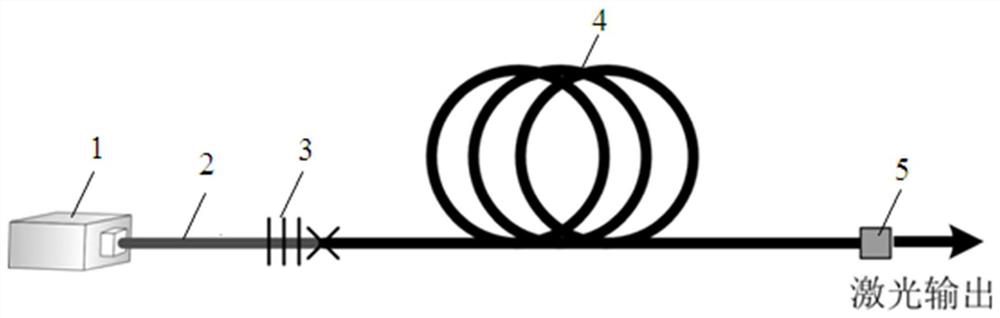

Intermediate infrared laser based on rare earth ion doped ZBLAN optical fiber

InactiveCN112670812AAvoid craftGuaranteed reliabilityActive medium shape and constructionMid infrared laserFiber gratings

The invention relates to an intermediate infrared laser based on a rare earth ion doped ZBLAN optical fiber. The mid-infrared laser is characterized in that the mid-infrared laser is connected with one end of a quartz optical fiber through a pumping source, a quartz optical fiber grating is inscribed at the tail end of the other end of the quartz optical fiber, the other end of the quartz optical fiber is connected with one end of a rare earth ion doped ZBLAN optical fiber, and the other end of the rare earth ion doped ZBLAN optical fiber is connected with an optical fiber end cap; the pump light emitted by the pump source passes through the silica fiber and the silica fiber grating, enters the laser resonant cavity formed between the silica fiber grating and the fiber end cap, is absorbed by the rare earth ion doped ZBLAN fiber, and excites mid-infrared laser; and the intermediate infrared laser oscillates in the laser resonant cavity and is output by the optical fiber end cap plated with the dielectric film which partially reflects and partially transmits the intermediate infrared laser wave band. The fiber end cap plated with the dielectric film is used as the output end of the all-fiber laser instead of a ZBLAN fiber bragg grating, so a complex ZBLAN fiber bragg grating preparation process can be avoided, and the cost of the laser is reduced.

Owner:中红外激光研究院(江苏)有限公司

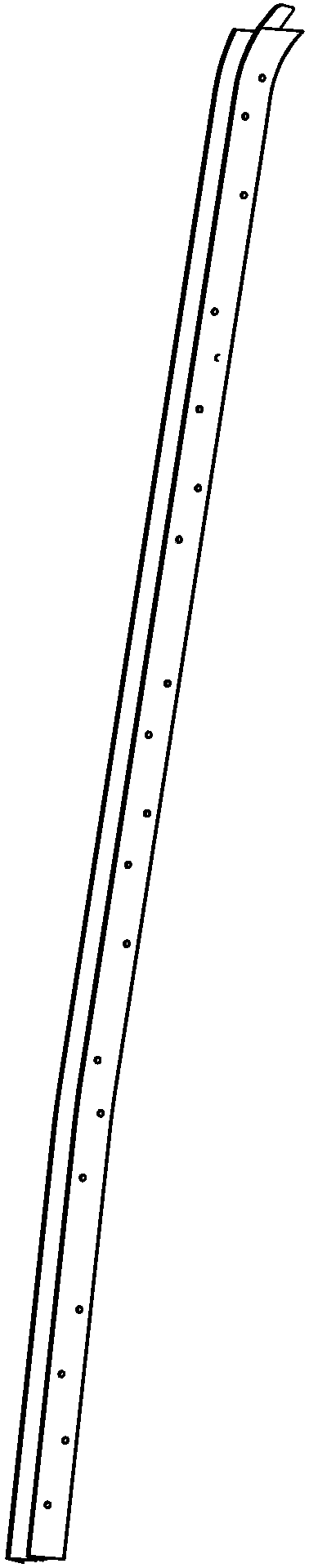

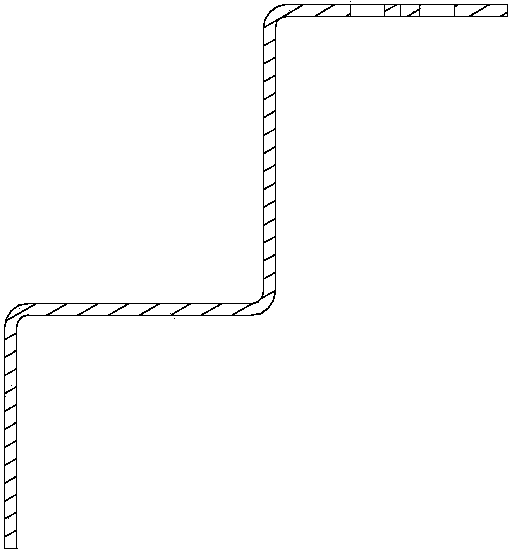

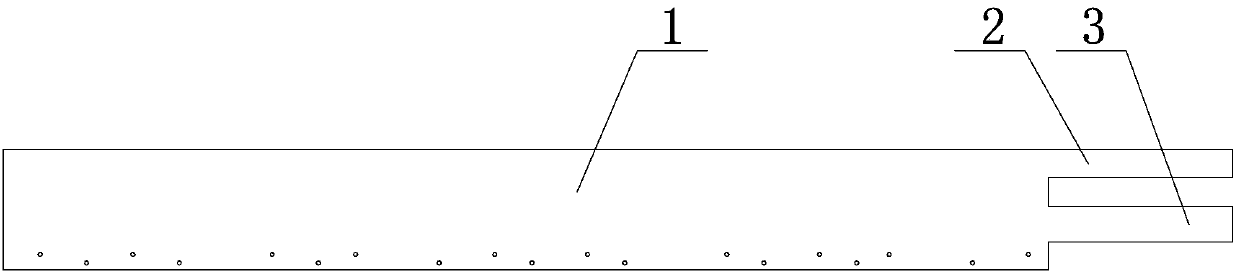

End corner post molding process of track vehicle

The invention relates to an end corner post molding process of a track vehicle. The process comprises the steps of obtaining a strip-shaped main material panel by utilizing a laser cutter for cutting and blanking; cutting a first supplement plate and a second supplement plate, with radian at side edges, by the laser cutter; bending the main material panel to form an end corner post with an W-shaped section by a bending machine; bending the middle lower part of the end corner post in a simmering mode to form a bending part consistent with a vehicle body drum shape in angle; bending a first plate and a second plate at the upper part of the end corner post to form the arc connected with a vehicle top; and welding the first and second supplement plates. The process analysis is performed according to design paper, the scheme combining the bending, the simmering and additionally welding the supplement plates is made; the end corner post quality is greatly improved by technological innovation, all sizes are controlled, the demands of paper and assembly are met, the quality and work efficiency are improved, the cost is reduced, the manufacturing process for forming a complicated workpiece is realized and the experience is accumulated for later forming of the complicated workpiece.

Owner:CRRC NANJING PUZHEN CO LTD

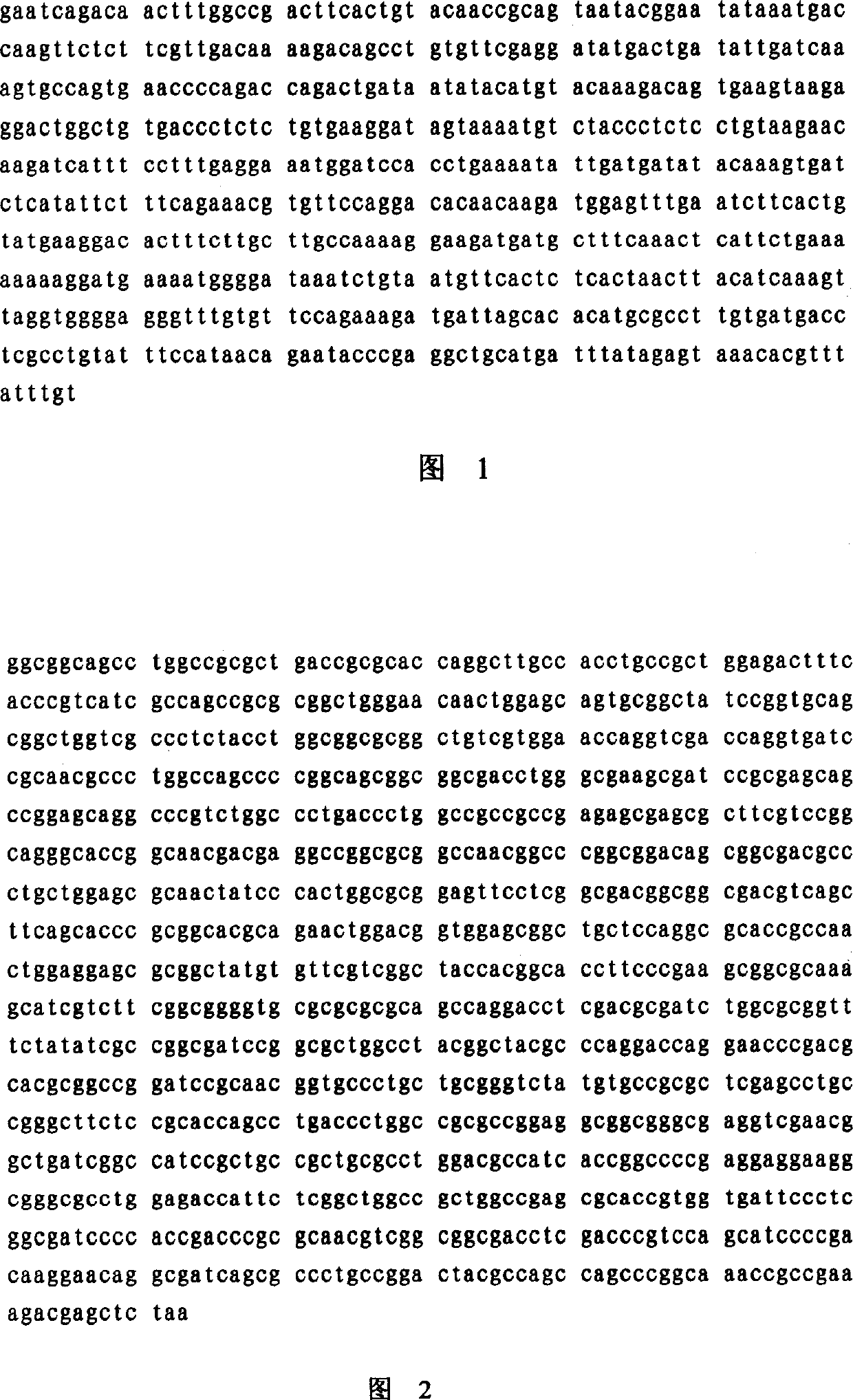

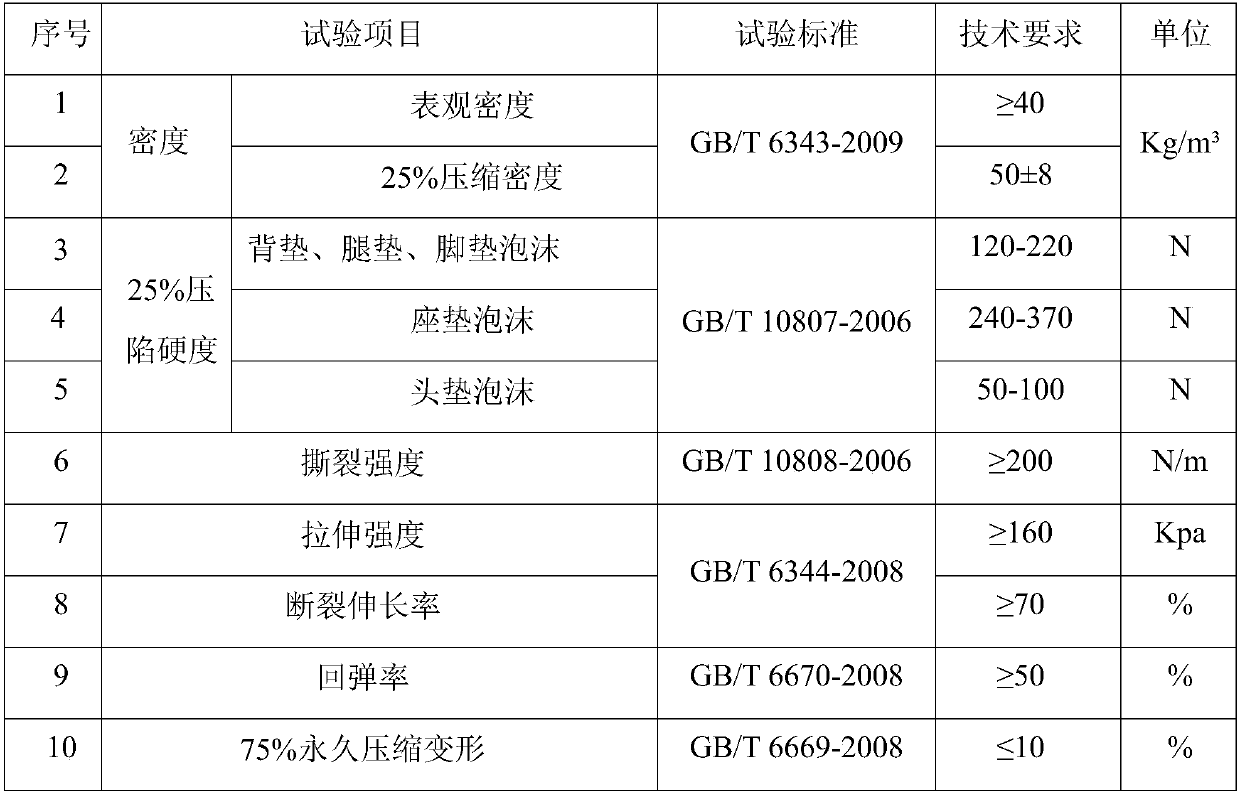

Reorganization immunity toxin with high specificity and its preparing method

InactiveCN1431305ADirected attack specificDirected attack worksImmunoglobulins against virusesImmunoglobulins against plantsDiseaseSpecific immunity

A high-specificity recombinant immunotoxin for preventing and treating autoimmunopathy, rejection reaction and tumors is prepared from IL-18 as target moleculae and the actigve fragment PE38 of pseudomonas aeruginosa's exotoxin through configuring recombinant plasmid, preparing engineering bacteria transfected by said plasmid, expressing immunotoxin IL-18-PE38 and purifying. Its advantage is hightarget kill to TH1 cells.

Owner:SICHUAN UNIV

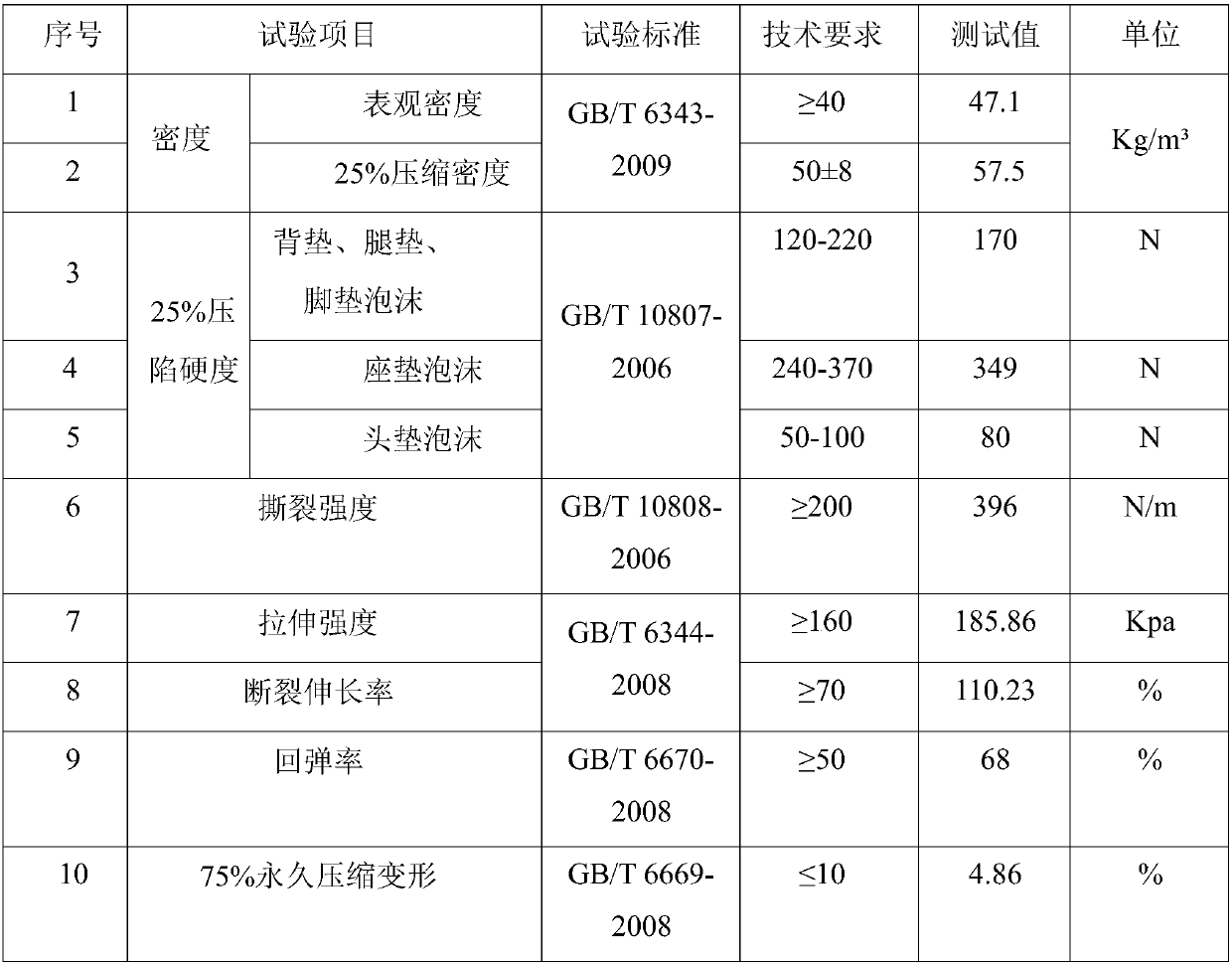

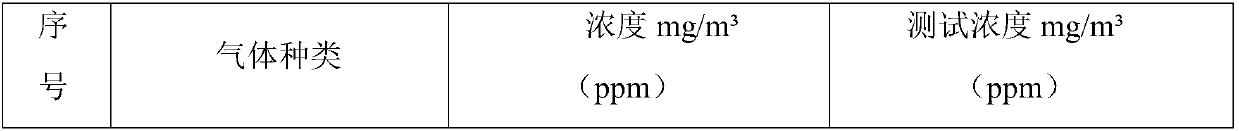

Seat polyurethane foam material with high flame retardation, low volatility and small compressive residual variable, and preparation method and application thereof

The invention discloses a seat polyurethane foam material with high flame retardation, low volatility and small compressive residual variable. The seat polyurethane foam material comprises, by weight,40-60 parts of polyether polyol (PPG), 40-60 parts of polymer polyol (POP), 2.5-3.5 parts of distilled water, 0.8-1.2 parts of a cross-linking agent, 0.4-0.6 part of a gel catalyst, 0.15-0.19 part ofa foaming catalyst and 0.65-0.85 part of a surface stabilizer. The seat polyurethane foam material has the advantages of high flame retardation performance, high safety, low volatile matter content,environmental protection, high rebound rate, comfortableness, small compressive residual variable, good durability, short production cycle and high yield.

Owner:沈阳金杯李尔汽车座椅有限公司

Fully-closed pollution-free digital nucleic acid detection chip and detection method

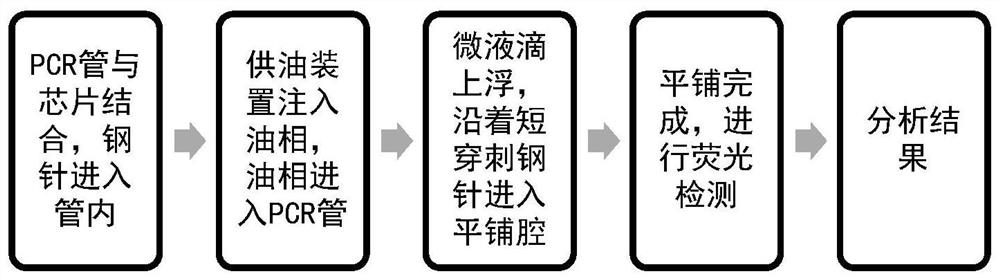

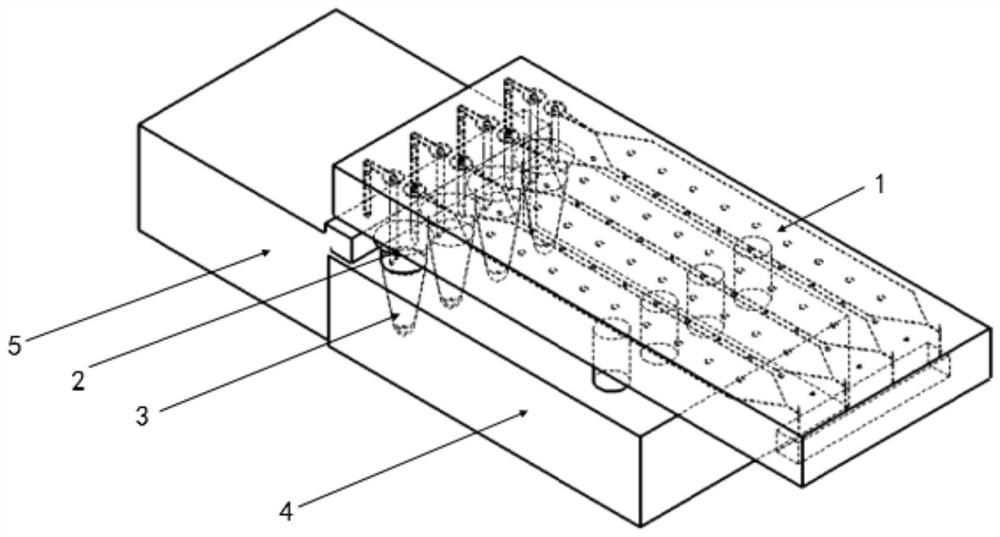

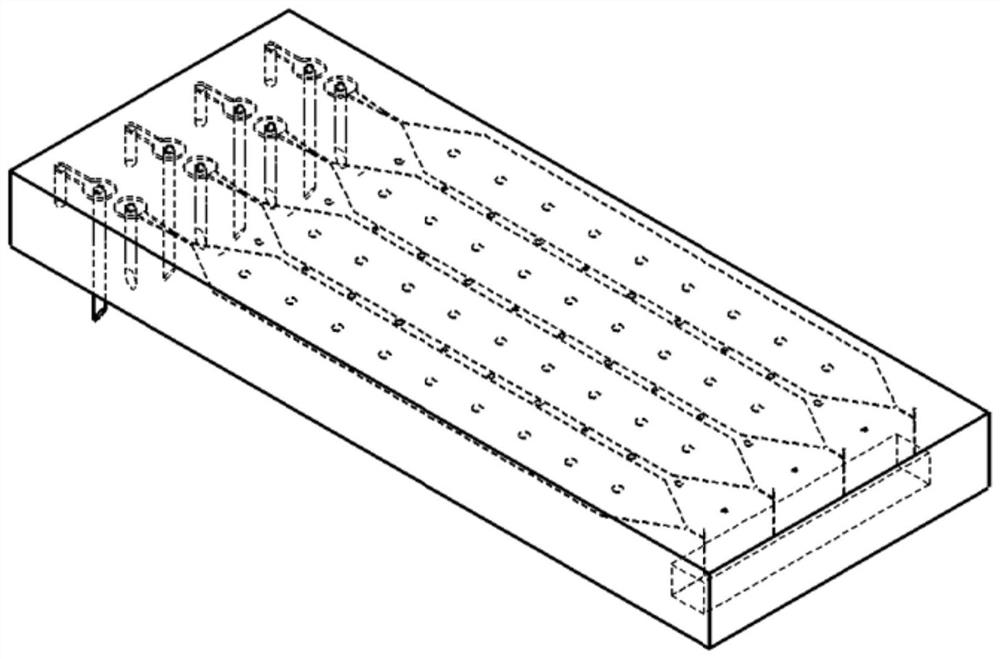

ActiveCN113846002AReduce complexityLess consumablesBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionTest tube

The invention discloses a fully-closed pollution-free digital nucleic acid detection chip which comprises a chip body, a first puncture needle and a second puncture needle, the chip body is made of a transparent material, a plurality of oil inlet through holes are formed in the chip body, outlets of the oil inlet through holes are connected with an oil inlet groove, one end, connected with the first puncture needle, of the oil inlet groove is provided with an opening, an opening in the other end of the first puncture needle extends into a test tube, the test tube is used for receiving an oil phase conveyed by the oil inlet through holes, an opening in one end of the second puncture needle is connected into a liquid inlet groove formed in an inner cavity of the chip body, an outlet of the liquid inlet groove is connected with a tiling cavity, the bottom plane of the tiling cavity is in the horizontal direction, and an opening in the other end of the second puncture needle extends into the test tube; and the opening in the other end of the first puncture needle extends into the oil phase in the test tube all the time, and when the test tube is filled with the oil phase, the opening in the other end of the second puncture needle is in contact with the top liquid level of the oil phase. The risk of cross contamination is avoided, operation is easy, and consumed time is short.

Owner:XI AN JIAOTONG UNIV

Making technology of instant hot and spicy flavored prawns

InactiveCN105614521AAvoid craftSolve the problem that the process is complicated and the process is difficult to operateFood preparationInstant teaFlavor

The invention discloses a making technology of instant hot and spicy flavored prawns. The making technology comprises the following steps of collecting fresh prawns, and cleaning and trimming the collected prawns; pickling the cleaned and trimmed prawns; performing frying and cooking processing on the pickled prawns; and cooling the fried and cooked prawns, sterilizing the cooled prawns, and performing vacuum packing on the sterilized prawns. The making technology of the instant hot and spicy flavored prawns disclosed by the invention is characterized by comprising the following steps of before the prawns are fried and cooked, performing low-temperature pickling on the raw material prawns by adopting a set of formulas, frying and cooking the pickled semi-finished products, cooling the fried and cooked semi-finished products, performing vacuum packing on the cooled semi-finished products and sterilizing the packed semi-finished products so as to obtain the instant hot and spicy flavored prawns which can protect the original wild taste of the prawns, and can enhance the special flavor. The hot and spicy flavored prawns meet different requirements of more consumers for hot foods, and besides, the storage time is greatly prolonged, and the hot and spicy flavored prawns are suitable for production and sale of factories.

Owner:吕艳

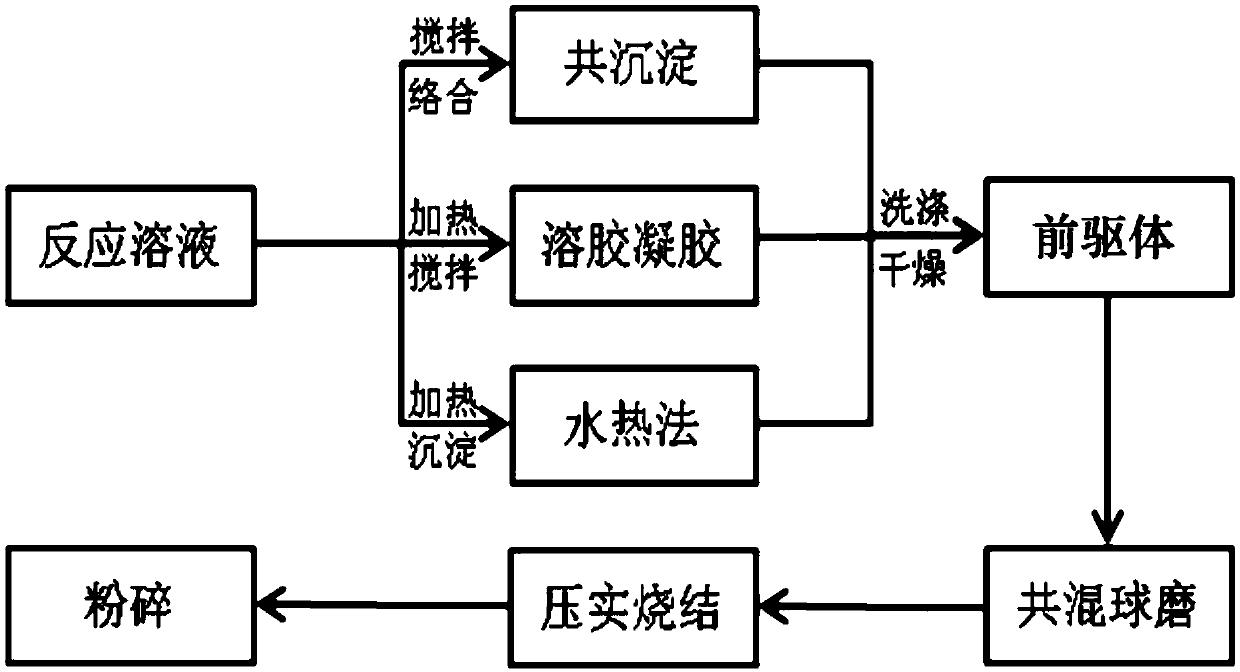

Method for preparing lithium battery positive electrode material based on in-situ composite and recombination

ActiveCN109659539AHigh crystallinityUniform and dense particle size distributionVacuum evaporation coatingSputtering coatingEnvironmental resistanceComposite film

The invention relates to a method for preparing a lithium battery positive electrode material based on in-situ composite and recombination, which belongs to the technical field of lithium battery positive electrode preparation. The method adopts a sputtering process to recombine and grow a pure-phase lithium-rich positive electrode material and a doping substance on a base to obtain a material serving as a lithium battery positive electrode, wherein the doping substance comprises any one or more of a conductive agent, a substance providing anion doping and a substance providing cation protection. The composite film prepared by adopting the method has the advantages of high purity, good crystallinity, stable structure, low catalytic activity of the surface of the material, can be directly used as the lithium battery positive electrode material, significantly improves the electrical conductivity and the coulombic efficiency of the material, stabilizes the voltage window, and protects thecatalytic decomposition of an electrolyte; and the process of the invention realizes one-step electrode plate forming, can avoid the cumbersome slurry and electrode plate preparation process, and simplifies the operation process while improving the material performance. The method disclosed by the invention has the advantages of clean and environmentally-friendly process, simple operation, low cost and high experimental repetition rate, and is favorable for realizing large-scale industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

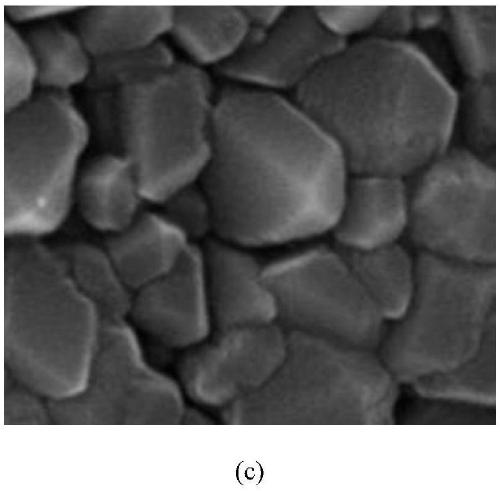

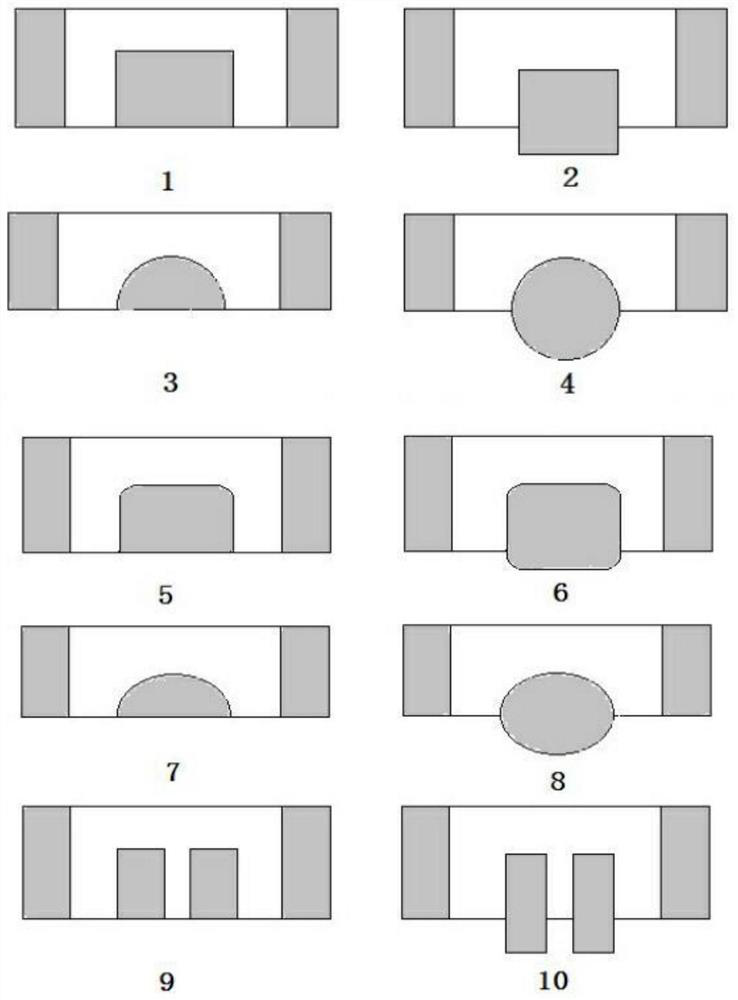

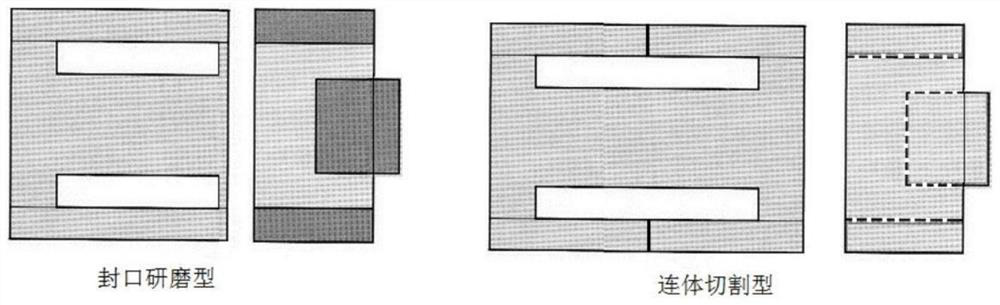

Manufacturing process of special-shaped ferrite magnetic core

PendingCN114005669AHigh dimensional accuracyOvercome the phenomenon that easily leads to product deformationMagnetic core manufactureManufacturing technologyPunching

The invention belongs to the technical field of ferrite, and particularly relates to a manufacturing process of a special-shaped ferrite core. The manufacturing process comprises the steps of (1) conducting punch forming, specifically, selecting soft magnetic ferrite particle powder, and preparing a sealed blank or a connected blank designed by the process on a vertical forming machine or a high-speed rotary forming machine by adopting a mold in a bidirectional punching manner; (2) sintering; (3) cutting and grinding; (4) carrying out ultrasonic cleaning; and (5) inspecting. According to the process, the phenomenon that a conventional preparation method for preparing the special-shaped magnetic core element is prone to causing product deformation can be overcome, the thinking frame that the special-shaped magnetic core element can only be formed in a vertical pressing mode but cannot be formed in a side pressing mode is broken through, and the process is achieved through a density compensation method. The manufacturing process is easy to operate, convenient to process and easy to industrialize, the special-shaped magnetic core element with high dimensional precision can be manufactured, the percent of pass is greatly increased, the cost is saved, and the manufacturing process has high industrial utilization value and is worthy of popularization and application.

Owner:江西尚朋电子科技有限公司

Mass transfer device and related method for micro LED array device

ActiveCN109216400BSimplified transfer methodImprove transfer efficiencySolid-state devicesSemiconductor devicesLed arrayMaterials science

The invention provides a Micro LED array device and a manufacturing method thereof, A mass transfer device and a transfer method, by forming a magnetic nano-film layer on an epitaxial substrate of a Micro LED array device, As one electrode of that Micro LED array device, As a result, the Micro LED array device can be directly adsorbed by the magnetic force without adding an additional magnetic layer, the manufacturing and removing process of the magnetic layer are avoided, the transfer method of the Micro LED array device can be simplified, and the efficiency of the Micro LED mass transfer isfurther improved.

Owner:XIAMEN CHANGELIGHT CO LTD

All-ceramic tooth production method

The invention discloses an all-porcelain tooth preparation method. The method comprises the following steps: firstly providing a seating path; then providing edge lines so that the edge lines are located at the most protuberant point of a neck edge; and then providing a seating parameter; establishing a full crown shape according to all-porcelain conditions; drawing an incising line so that: anterior: at a buccal side and a lingual side, the incising line is located above a neck-edge line for 1.5-2 mm and is parallel to the neck-edge line, and mesial and distal incising lines are located belowa contact point; posterior: at the buccal side and the lingual side, the incising line is located above the neck-edge line for 1.5-2 mm, and mesial and distal incising lines are located below the contact point; and then providing an incising parameter so that the compensation parameter of the anterior is half of an occlusal space, and the compensation parameter of the posterior is half of the occlusal space; an incising amount being 0.5 mm and re-trimming an incising crown; establishing a connector between two adjacent tooth; and finally performing handmade porcelain. The invention greatly improves the strength of dental crown, simultaneously avoids the occurrence of translucency in the case of insufficient tooth preparation, and accelerates the production efficiency of all-porcelain tooth.

Owner:精瓷齿科技术(苏州)有限公司

Combined sealing gas ring

InactiveCN101078382ANo thermal deformationReduce distortionPiston ringsMachines/enginesPiston ringEngineering

The invention discloses a sealing combined pressure ring, comprising upper composition ring, lower composition ring, mutual locking device, sealing device of open of lower composition ring, which are combined in the same piston ring groove. The mutual locating device comprises locating pin and cutting groove corresponding to the locating pin. The sealing device comprises sealing piece of lower composition ring and cutting groove for assemble the sealing piece of lower composition ring. Thereinto, ring cutting grooves are located on inner faces of inner circles of upper and lower composition rings. Opens of upper and lower composition ring and ring cutting grooves are separated in the central angle with 8: -25: respectively and are located in different sides of ring cutting grooves. Locating pin is mated in ring cutting grooves tightly. By adopting the sealing composition pressure ring in invention, not only relative rotation of upper and lower composition rings of piston pressure ring in piston movement process can be prevented but also deformation and bending of upper and lower composition rings of piston pressure ring and manufacturing process problem of combined piston ring can be avoided. Finally performances of oil saving, power increasing and circumstance protection can be realized.

Owner:程磊

A monolithic silicon-based emitter

ActiveCN108183390BRealize coupling integrationAvoid craftLaser detailsSemiconductor lasersBeam splitterPhotonics

Owner:WUHAN POST & TELECOMM RES INST CO LTD

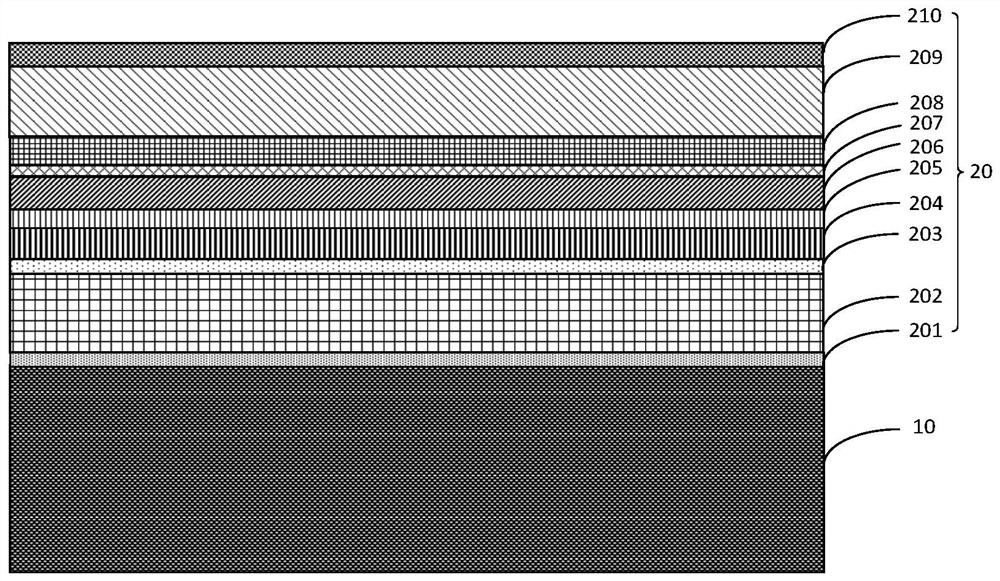

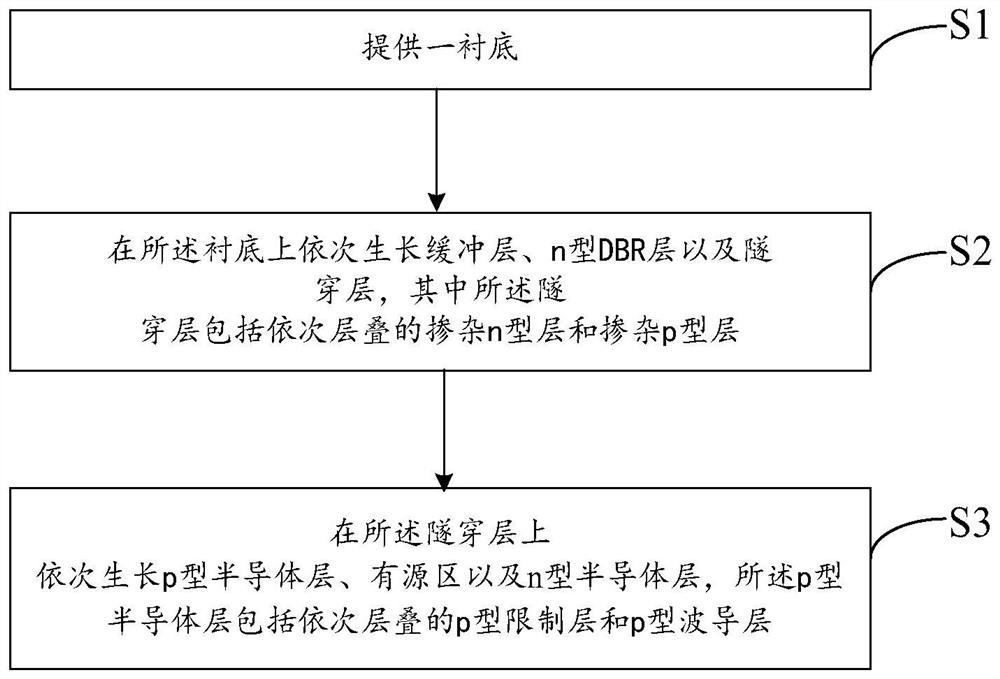

LED epitaxial structure and preparation method thereof

PendingCN114551671AAvoid craftReduced growth warpFinal product manufactureSemiconductor devicesChemical physicsLattice mismatch

The invention provides an LED epitaxial structure and a preparation method thereof.The LED epitaxial structure sequentially comprises a buffer layer, an n-type DBR layer, a tunneling layer, a p-type semiconductor layer, an active layer and an n-type semiconductor layer from bottom to top, the buffer layer, the n-type DBR layer, the tunneling layer, the p-type semiconductor layer, the active layer and the n-type semiconductor layer are located on a substrate, and the p-type semiconductor layer comprises a p-type limiting layer and a p-type waveguide layer which are sequentially stacked; the tunneling layer comprises a doped n-type layer and a doped p-type layer which are stacked in sequence. According to the epitaxial structure, the tunneling layer is introduced between the n-type DBR layer and the p-type limiting layer, so that stress generated by lattice mismatch between the n-type DBR layer and the p-type limiting layer can be reduced, and growth warping of the epitaxial structure can be reduced; and the tunneling layer can also provide tunneling current, so that a reverse PN junction formed by the n-type DBR layer and the p-type limiting layer is conducted. In addition, the preparation method of the LED epitaxial structure is simple.

Owner:XIAMEN SILAN ADVANCED COMPOUND SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com