Flexible porous polypyrrole film, preparation method and application of flexible porous polypyrrole film as electrode

A pyrrole film and flexible technology, which is applied in the field of preparation of polypyrrole electrodes, can solve the problems of reducing the conductivity of electrode materials, complicated electrode material processes, etc., and achieves the effects of low cost, guaranteed porosity and conductivity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

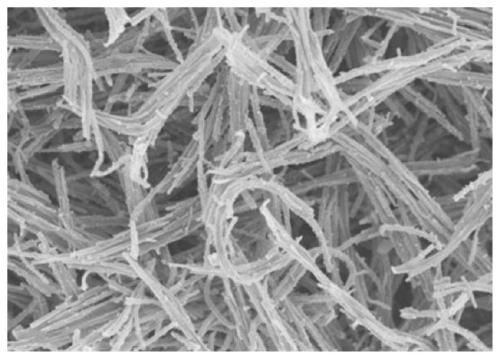

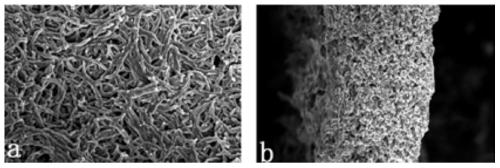

[0033] 1) Weigh 4mg of PPy nanotubes, add 40g of deionized water, and add 0.08g of hexadecyltrimethylammonium bromide to stir evenly, and continue ultrasonication for 30min to fully disperse the PPy nanotubes in deionized water; 0.1um, 0.3mm thick titanium foam plate, instead of filter paper, put it into the sand core filter, and slowly filter the mixture of PPy nanotubes and deionized water under negative pressure conditions (0.3 atmospheric pressure), that is, form a foam on the surface of the titanium foam plate. layer of black PPy nanotubes, put the titanium foam plate and PPy nanotube film into an oven, dry at 60°C for 3 hours, and finally form a layer of PPy nanotube film on the titanium foam plate; weigh and find the pyrrole on the titanium foam plate 3mg tube;

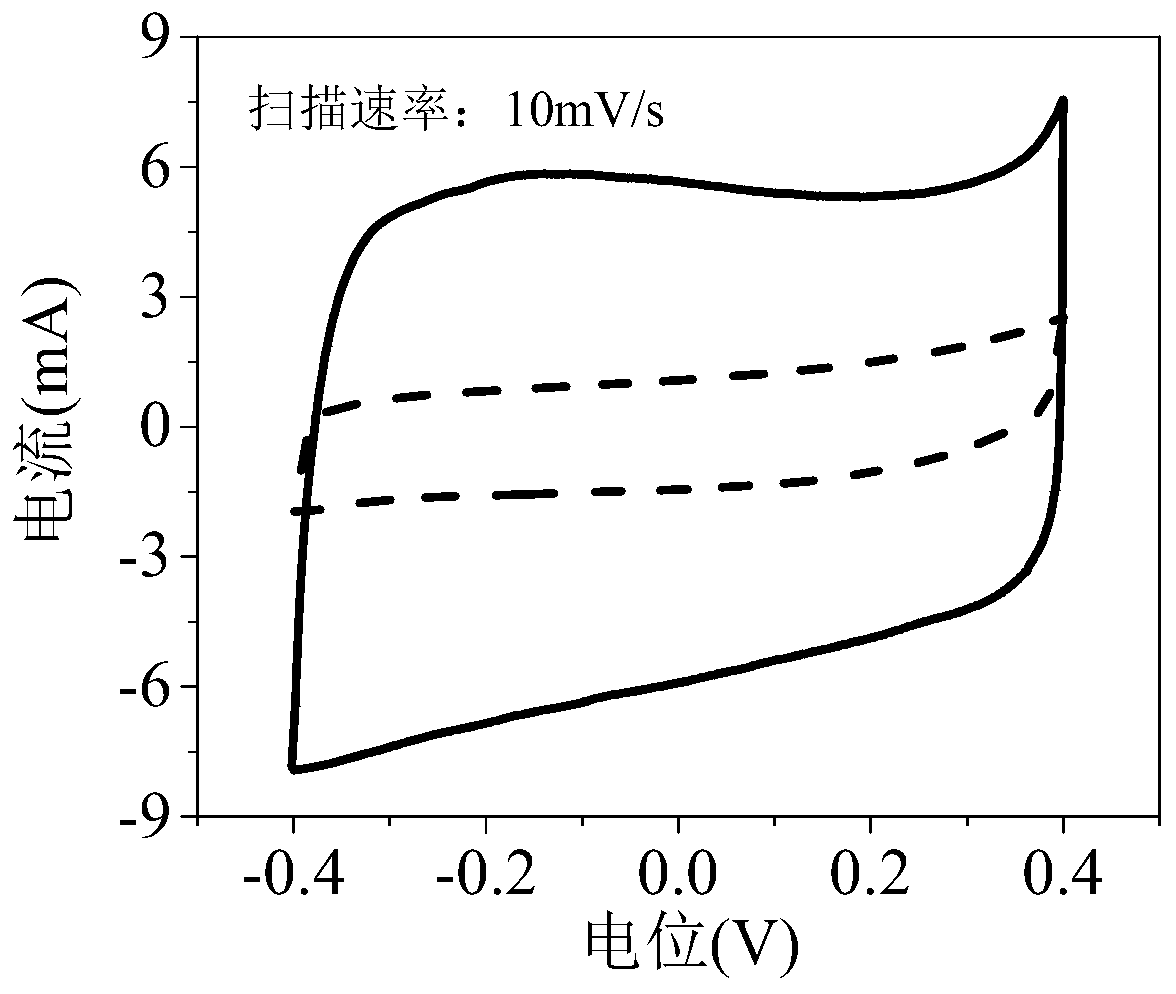

[0034] 2) The PPy nanotube film attached to the foamed titanium plate after drying is used as the positive electrode and immersed in the electrolyte for electrochemical polymerization; the polymerization uses t...

Embodiment 2

[0039] 1) Weigh 8 mg of PPy nanotubes, add 80 g of deionized water, and add 0.16 g of sodium dodecylbenzene sulfonate to stir evenly, and continue ultrasonication for 30 minutes to fully disperse the PPy nanotubes in deionized water; A foam tantalum plate with a thickness of 0.3 mm is placed in a sand core filter, and the mixture of PPy nanotubes and deionized water is slowly filtered under negative pressure conditions (0.5 atmospheres), that is, a layer of black PPy nanotubes is formed on the surface of the foam tantalum plate; Put the foamed tantalum plate and the PPy nanotube film together in an oven, dry at 60°C for 4 hours, and finally form a layer of PPy nanotube film on the foamed tantalum plate; weigh and find that the pyrrole tube on the inert metal plate is 4.5 mg.

[0040] 2) The PPy nanotube film attached to the foamed tantalum plate after drying is used as the positive electrode and immersed in the electrolyte for electrochemical polymerization. The PPy prepared by...

Embodiment 3

[0043] 1) Weigh 15 mg of PPy nanotubes prepared by the chemical oxidation method, add 150 g of deionized water, and add 0.3 g of sodium methylene bis-naphthalene sulfonate to stir evenly, and continue ultrasonication for 30 minutes to fully disperse the PPy nanotubes in the deionized In water; put the titanium foam plate with a pore size of 5um and a thickness of 0.7mm into a sand core filter, and slowly filter the mixture of PPy nanotubes and deionized water under negative pressure conditions (0.6 atmospheric pressure), that is, form a foam on the surface of the titanium plate. layer of black PPy nanotubes; put the foamed titanium plate and PPy nanotube film into an oven, dry at 60°C for 6 hours, and finally form a layer of PPy nanotube film on the foamed titanium plate; weigh and find the pyrrole on the inert metal plate 8mg tube;

[0044] 2) The PPy nanotube film attached to the foamed titanium plate after drying is used as the positive electrode and immersed in the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com