Mass transfer device and related method for micro LED array device

A transfer device and device technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of light consumption, poor utilization of light, etc., to improve efficiency, simplify transfer methods, avoid manufacturing and removal processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

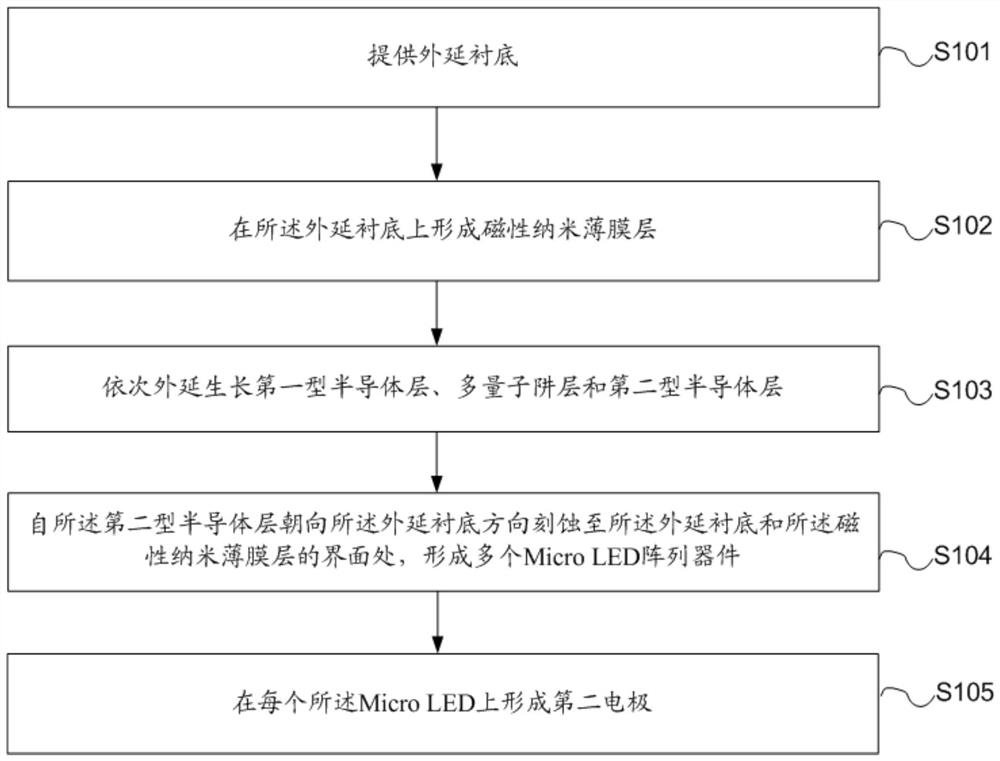

[0030] As mentioned in the background technology section, one of the difficulties in the development of Micro LED technology currently lies in the mass transfer process of Micro LED.

[0031] The inventors found that, in the prior art, methods such as bonding are provided for mass transfer, but the bonding method requires the setting of an adhesive layer and subsequent removal, which makes the process of mass transfer less efficient. Or the prior art also provides a structure in which a magnetic layer is added to the external structure of the light-emitting diode and adsorbed by magnetic force. However, since an adhesive layer is required to adhere multiple Micro LED array devices together, the adhesion needs to be removed later. The attached layer and the additional magnetic layer make the operation complicated and many steps in the mass transfer process of Micro LED array devices.

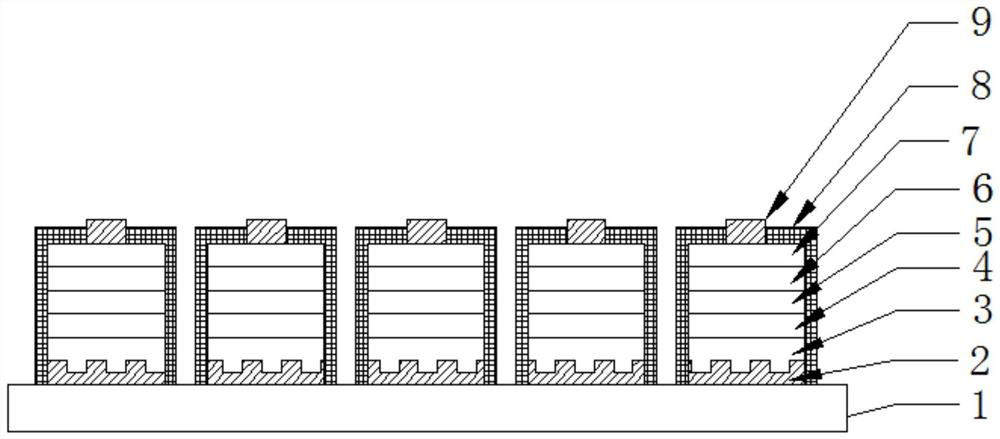

[0032] Based on this, the present invention provides a Micro LED array device, including:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com