All-ceramic tooth production method

A production method and technology for porcelain teeth, which are applied to dentures and other directions, can solve the problems of high technical content, high time cost requirements, difficult control of color presentation, and difficult control of the shrinkage ratio of porcelain powder, so as to reduce production costs and production difficulties. The effect of improving aesthetics and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Embodiment: a kind of all-ceramic tooth manufacturing method, comprises the following steps:

[0040] Step 1: Set in place:

[0041] According to the condition of the patient's teeth, set up the positioning channel, adjust the appropriate positioning direction, so that there are no undercuts at the two cervical margins;

[0042] Step 2: Set the edge line:

[0043] Adjust the appropriate edge line position so that the edge line is located at the most prominent part of the neck, and the entire edge line is required to be connected smoothly;

[0044] Step 3: Set the parameters in place: set the parameters of the reference crown that needs to be generated;

[0045] Step 4: Establish the shape of the full crown according to the condition of the all-ceramic tooth;

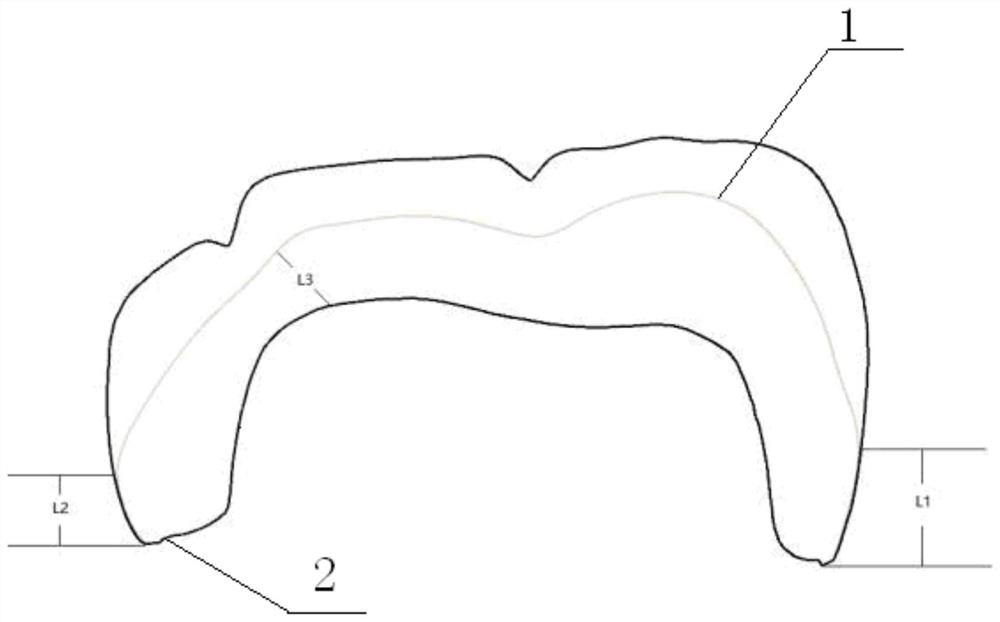

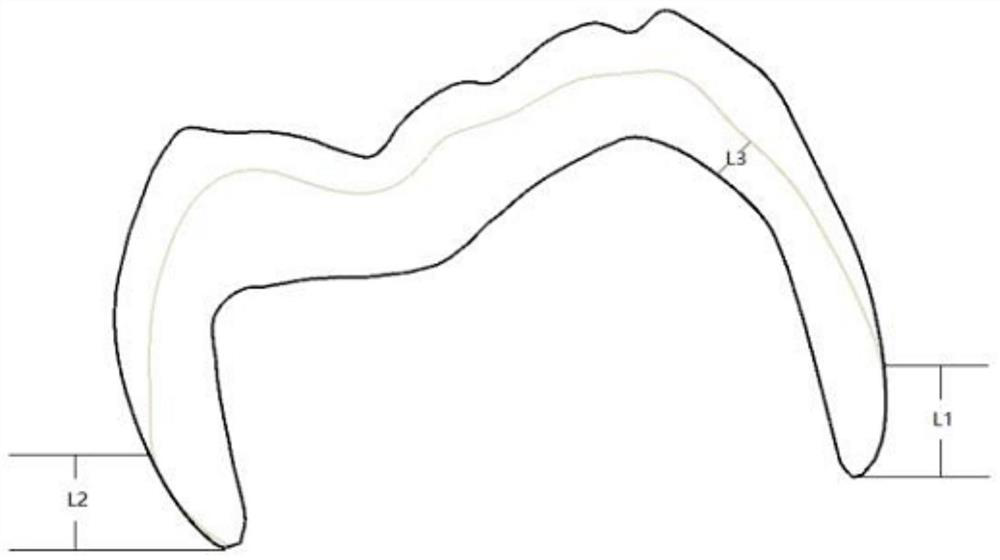

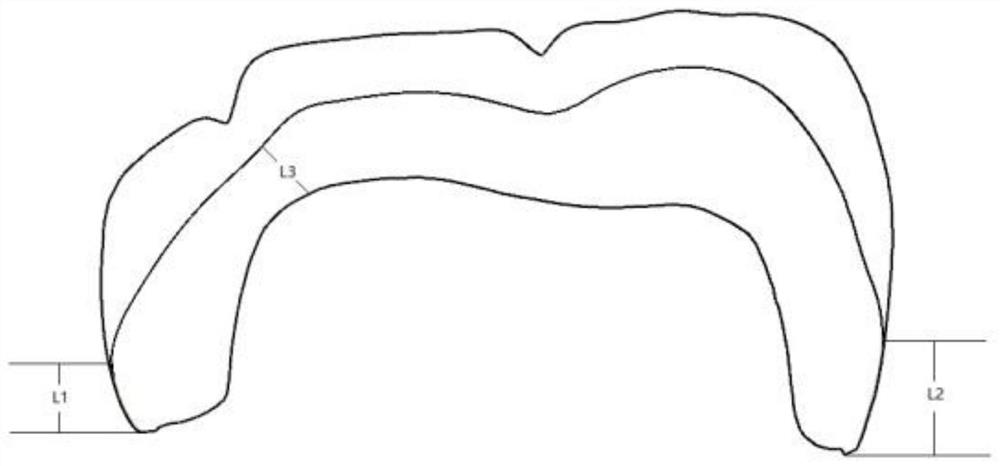

[0046] Step 5: Cut back the inner crown:

[0047] a. Draw back tangent line 1:

[0048] Anterior teeth: buccolingual side, tangent line 1 is located 1.5-2mm above the cervical margin line 2, parallel to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com