LED epitaxial structure and preparation method thereof

A technology of epitaxial structure and confinement layer, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of high difficulty of epitaxial preparation process, reduce growth warpage, avoid preparation process, reduce process The effect of preparation difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

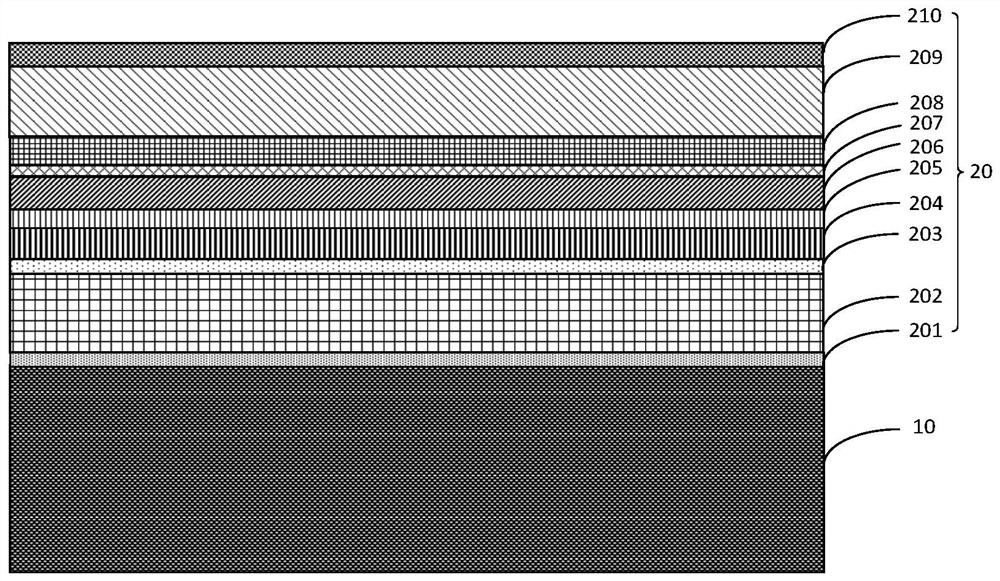

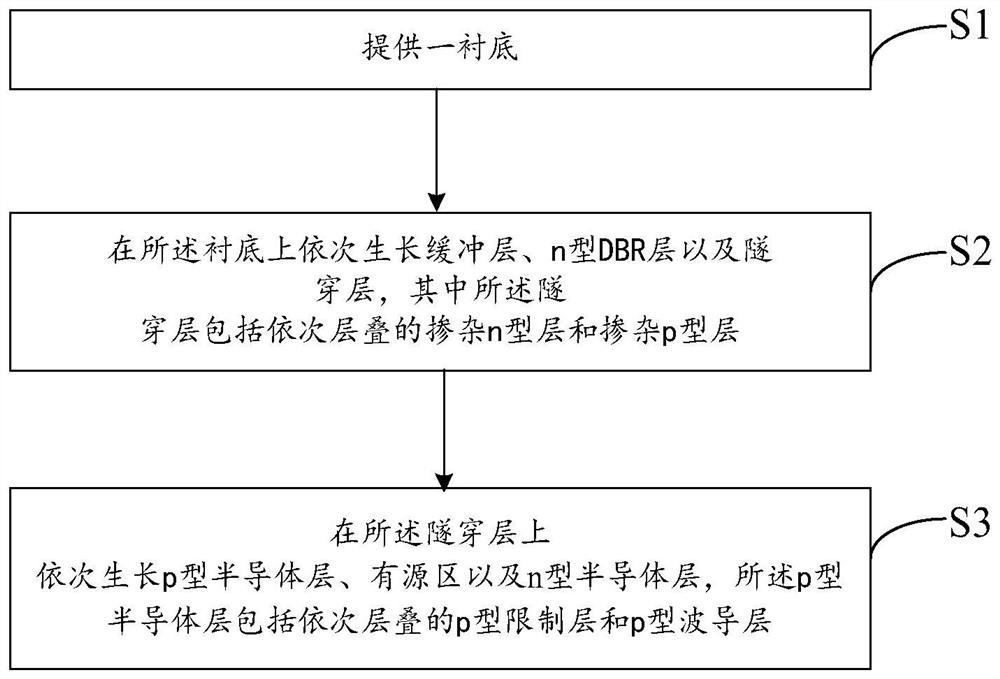

[0048] see figure 2 , the preparation method of the LED epitaxial structure 20 specifically includes the following steps:

[0049] Step S1: providing a substrate 10;

[0050] Step S2 : growing a buffer layer 201 , an n-type DBR layer 202 and a tunneling layer 203 sequentially on the substrate 10 , wherein the tunneling layer 203 includes a doped n-type layer and a doped p-type layer stacked in sequence.

[0051] Step S3 : growing a p-type semiconductor layer, an active layer 206 and an n-type semiconductor layer in sequence on the tunneling layer 203 , where the p-type semiconductor layer includes a p-type confinement layer 204 and a p-type waveguide layer 205 stacked in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com