Manufacturing process of special-shaped ferrite magnetic core

A ferrite core and manufacturing process technology, which is applied in the fields of magnetic core manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as product deformation, and achieve convenient processing, easy industrialization, and novel design considerations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

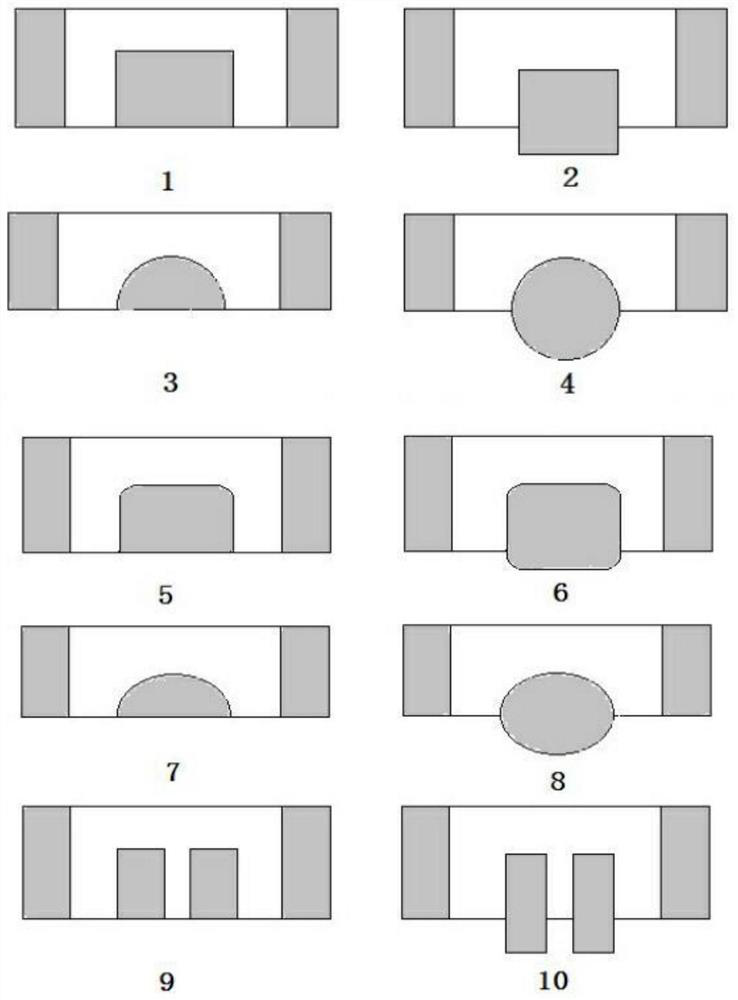

[0040] Such as figure 1 Shown is the shape design and finished product appearance of 10 special-shaped magnetic core components;

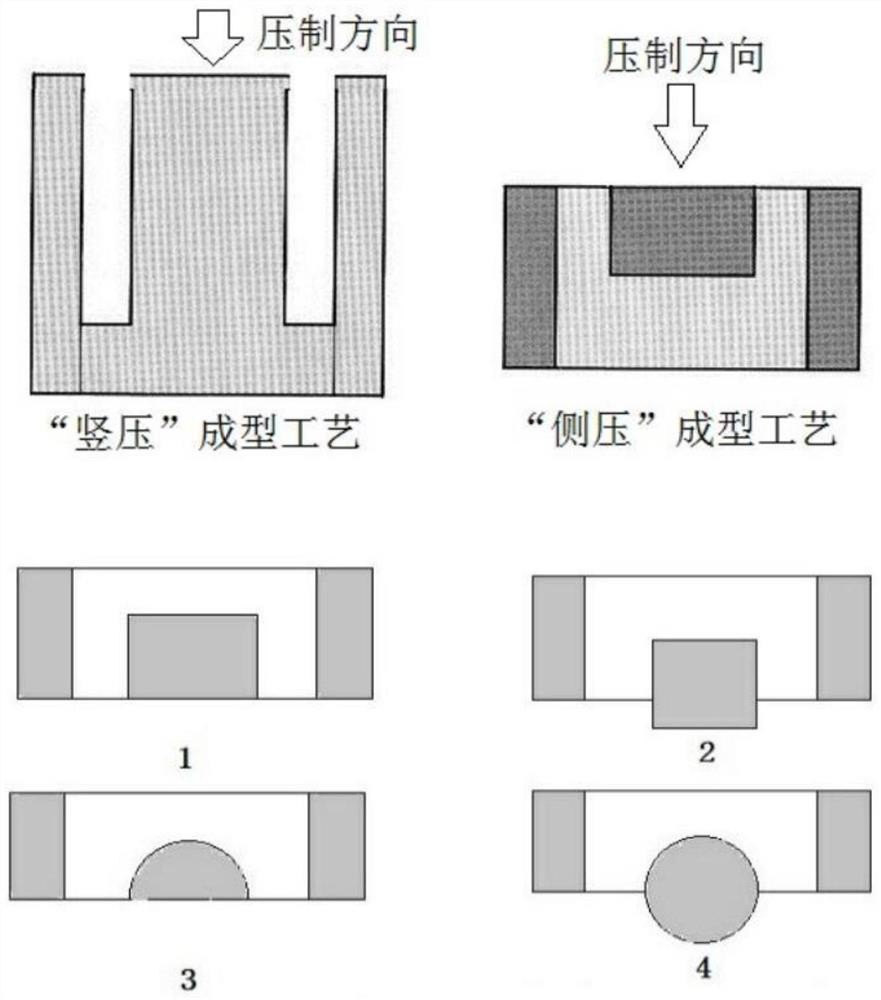

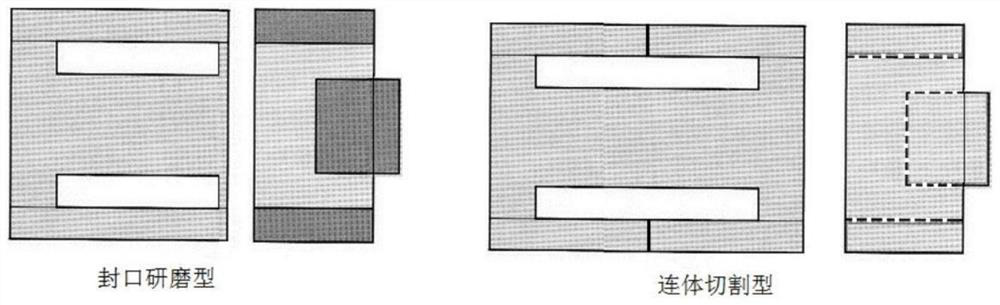

[0041] (1) Select soft magnetic ferrite particle powder, on the high-speed rotary molding machine, adopt the bidirectional stamping of the mold to prepare the sealing type blank or the conjoined type blank of the process design;

[0042] The soft magnetic ferrite particle powder includes main components, auxiliary components and additives, and the main components include Fe 2 o 3 , Mn 3 o 4 , NiO and ZnO, the auxiliary component is Nd 2 o 3 ; Taking the amount of the main component as a benchmark, Fe in the main component 2 o 3 The content is 56.2mol%, Mn 3 o 4 The content of NiO is 15.8mol%, the content of NiO is 27.3mol%, and the content of ZnO is 10.7mol%. Based on the weight of the main component, the auxiliary component Nd 2 o 3 The content is 0.25wt%; the additive consists of V 2 o 5 and SiO 2 According to the composition by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com