Patents

Literature

127results about How to "High industrial utilization value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

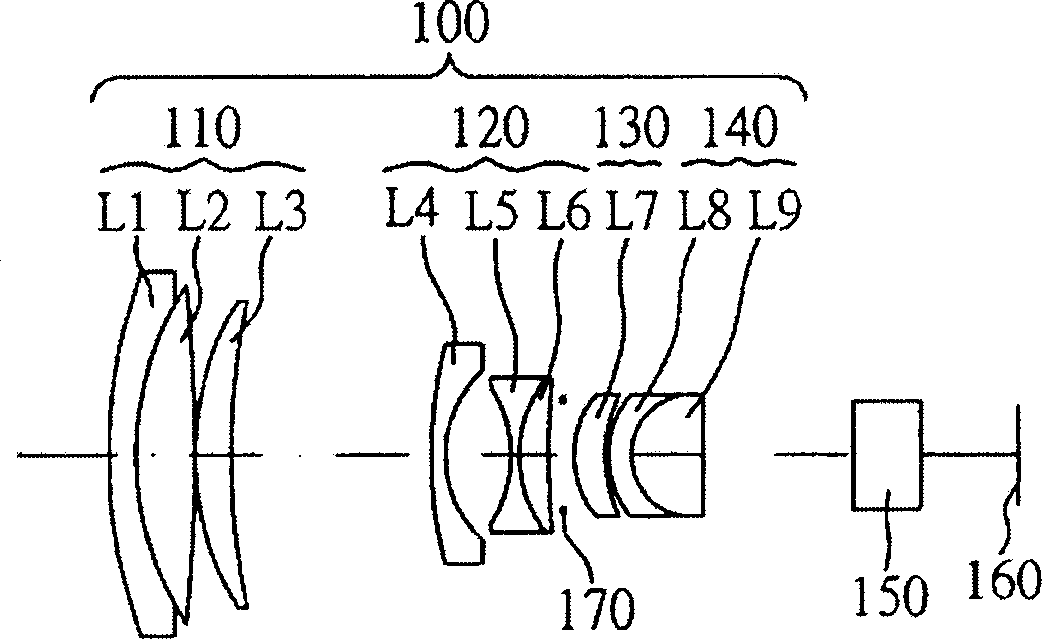

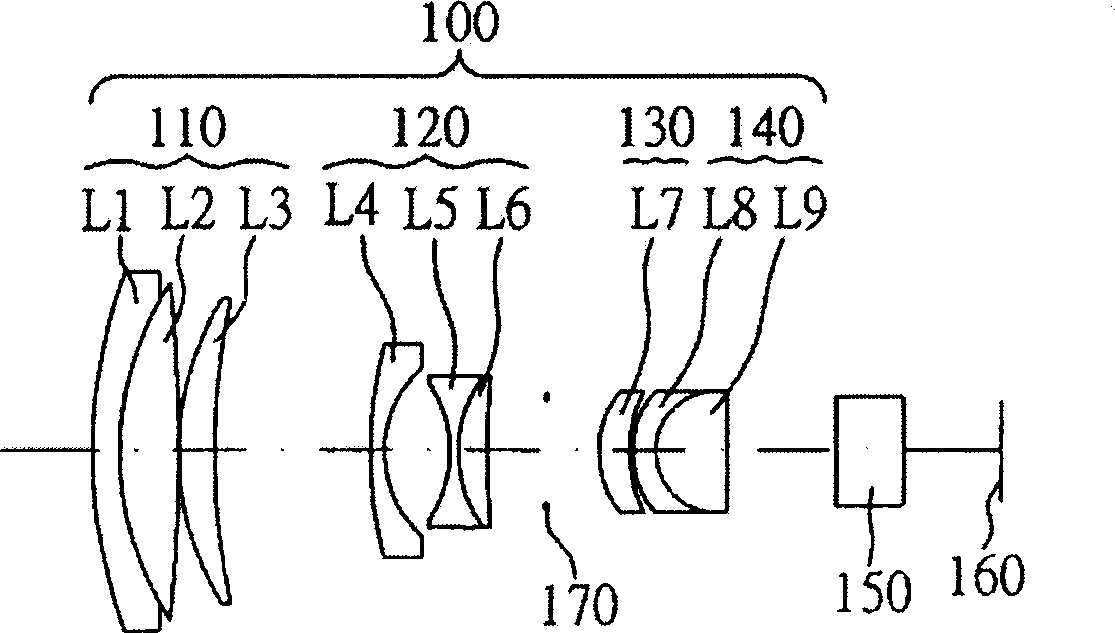

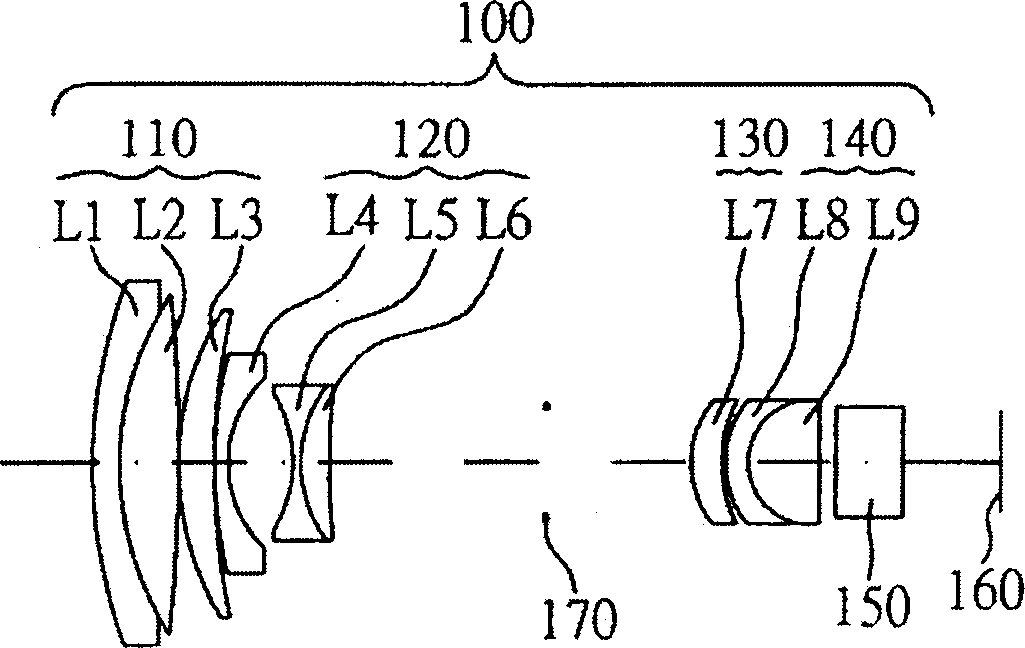

Zooming lens

The disclosed zoom lens comprises: from object end to image end, the first lens group with positive focus, the second lens group with positive lens group, the third lens group with positive focus to move and share the compensation function with the fourth, and the fourth lens group with positive lens group. This invention has high scaling factor and pixel, reduces lens number and cost, and fit to different request.

Owner:宇机科技股份有限公司

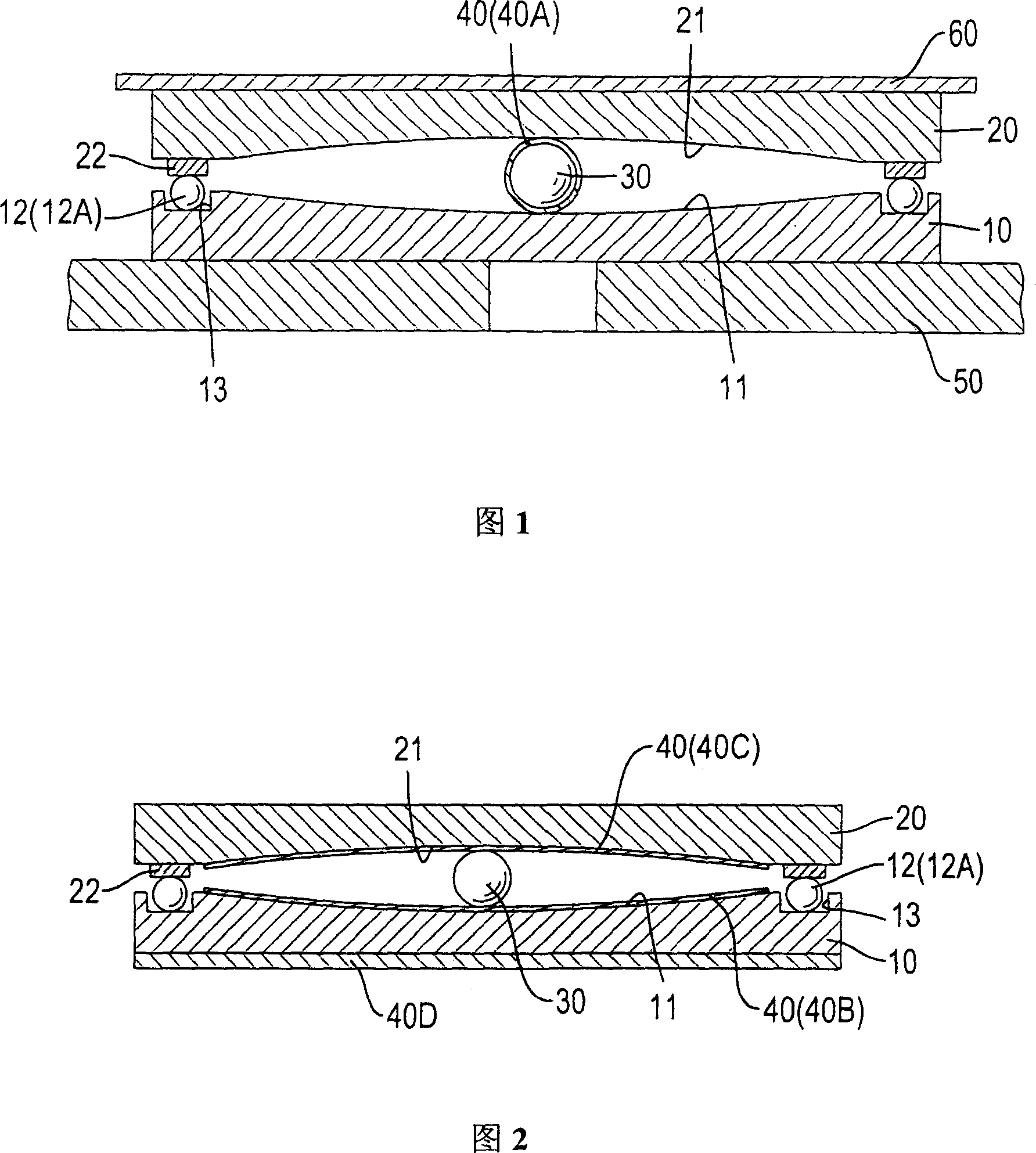

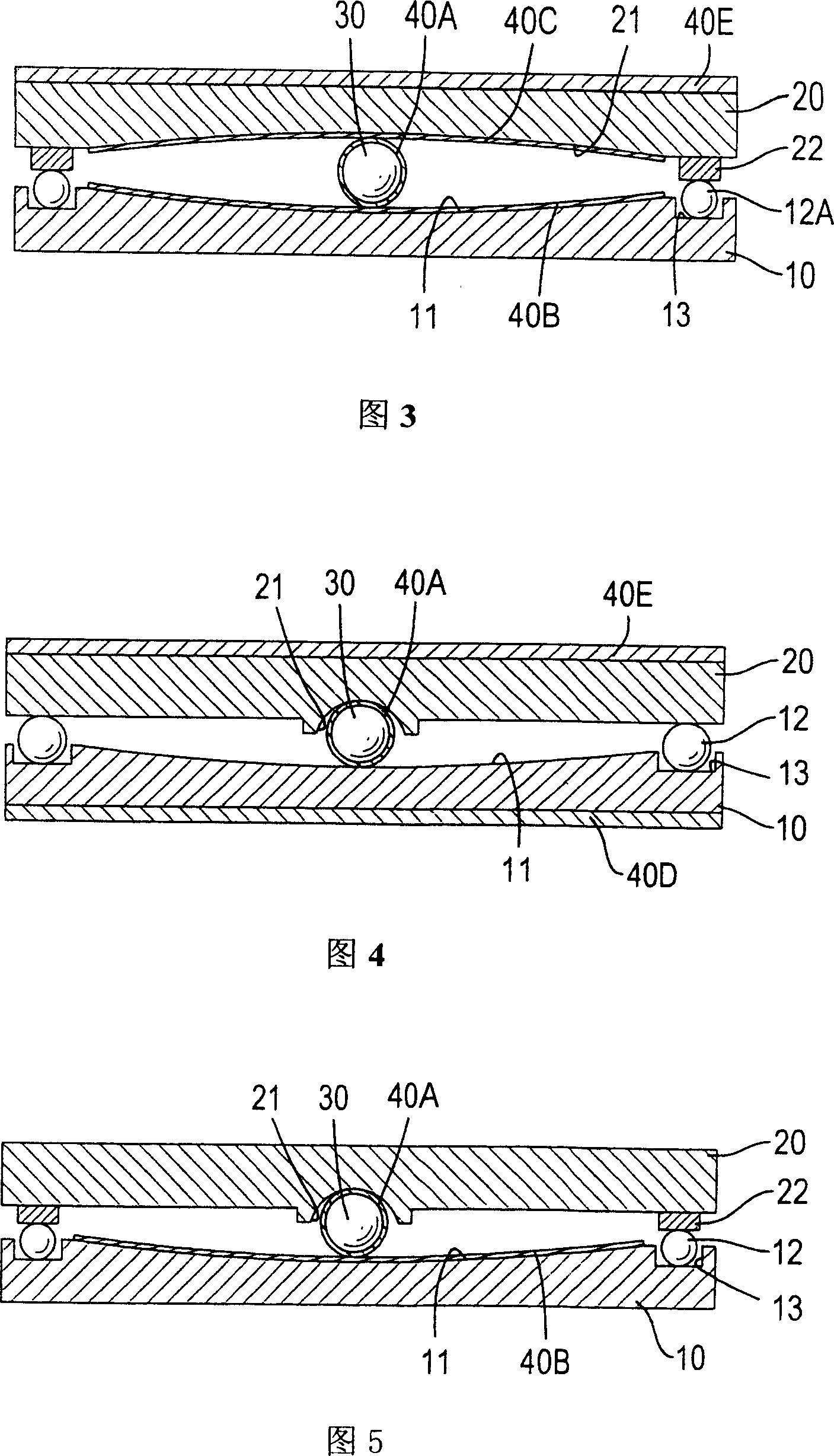

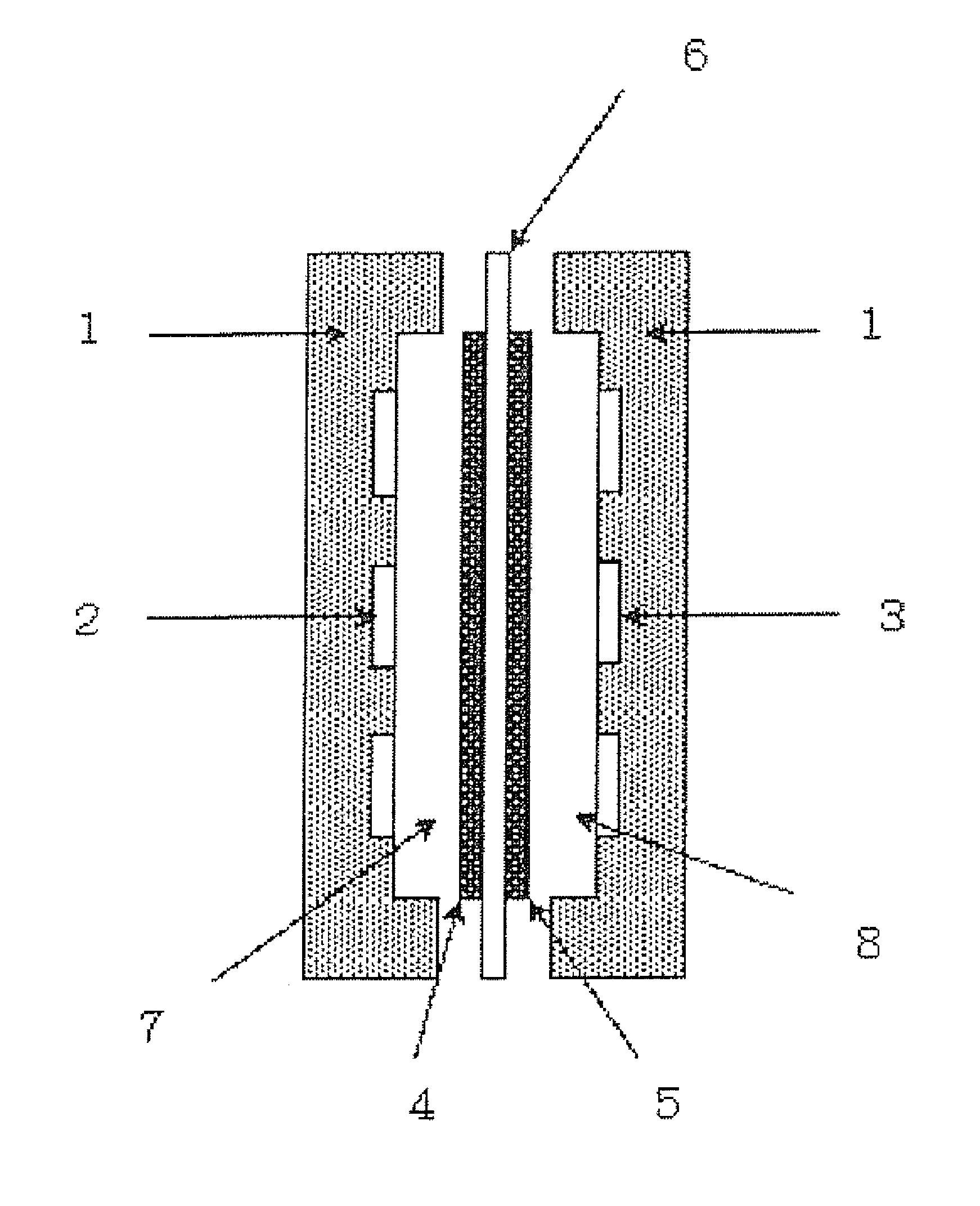

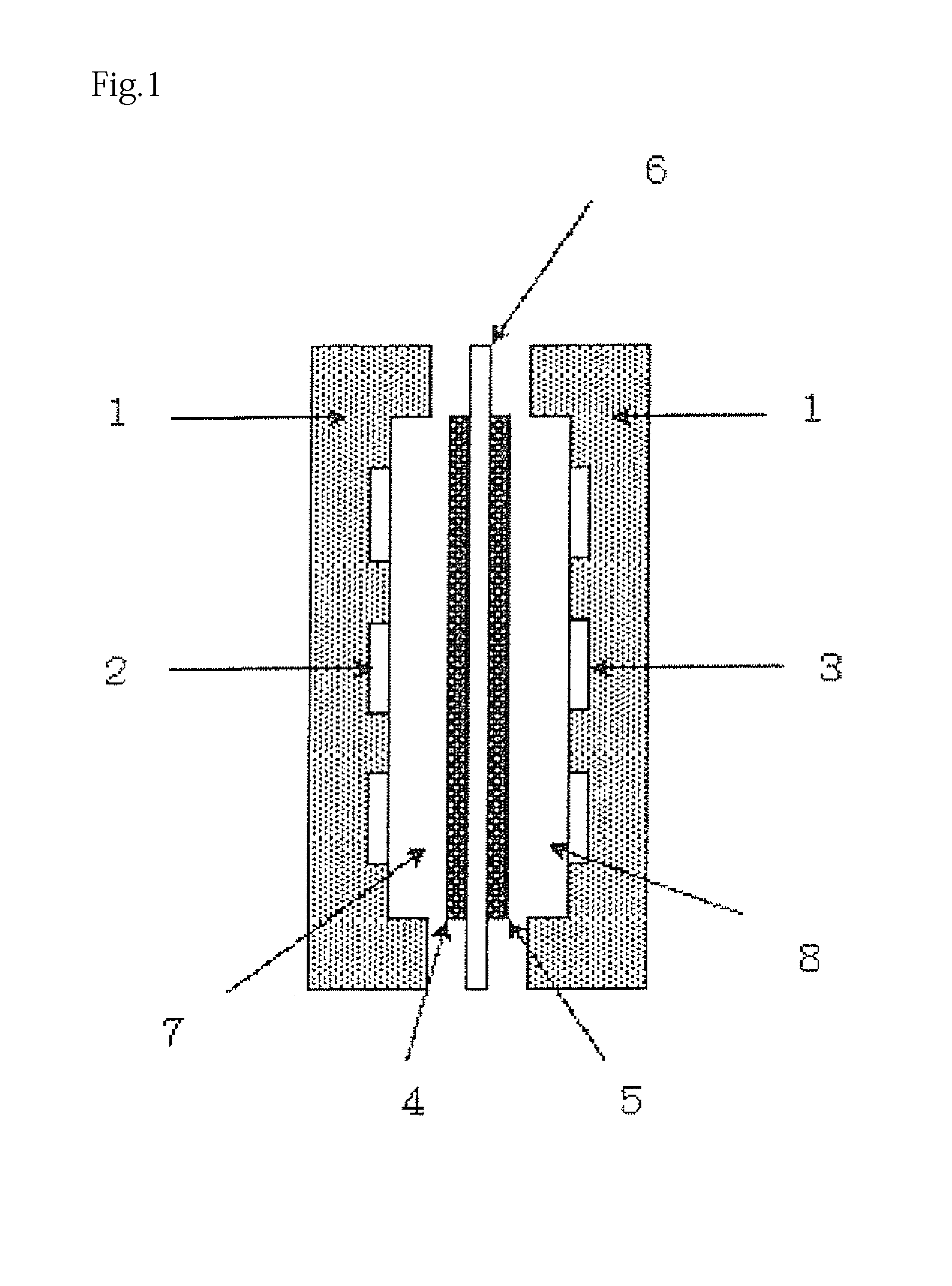

Shock proof apparatus with static and motive force exchanging mechanism

InactiveCN101024979ASolve easy wear or compression setAvoid lengthy workShock proofingStatic forceCompression set

The invention is a vibration damping device with static and dynamic switching mechanism, corresponding arranging above one group of concave surfaces on the opposite surfaces of bases and bearings spaced in parallel, arranging a rolling ball body between each group of concave surfaces and arranging at least a damping device between each group of concave surfaces and the ball body, and the invention skillfully staggers multiple static bearing bodies for the bearings to butt against, in the positions on the bases different from those of the concave surfaces, thus letting the vibration damping device ordinarily able to bear the weight on the bearings with the static bearing bodies, so as to implement the static and dynamic switching mechanism composed of the static bearing bodies, effectively solving the problem that a damping device is easy to wear or permanently deforms once compressed, and improving practical efficiency of the vibration damping device.

Owner:蔡崇兴

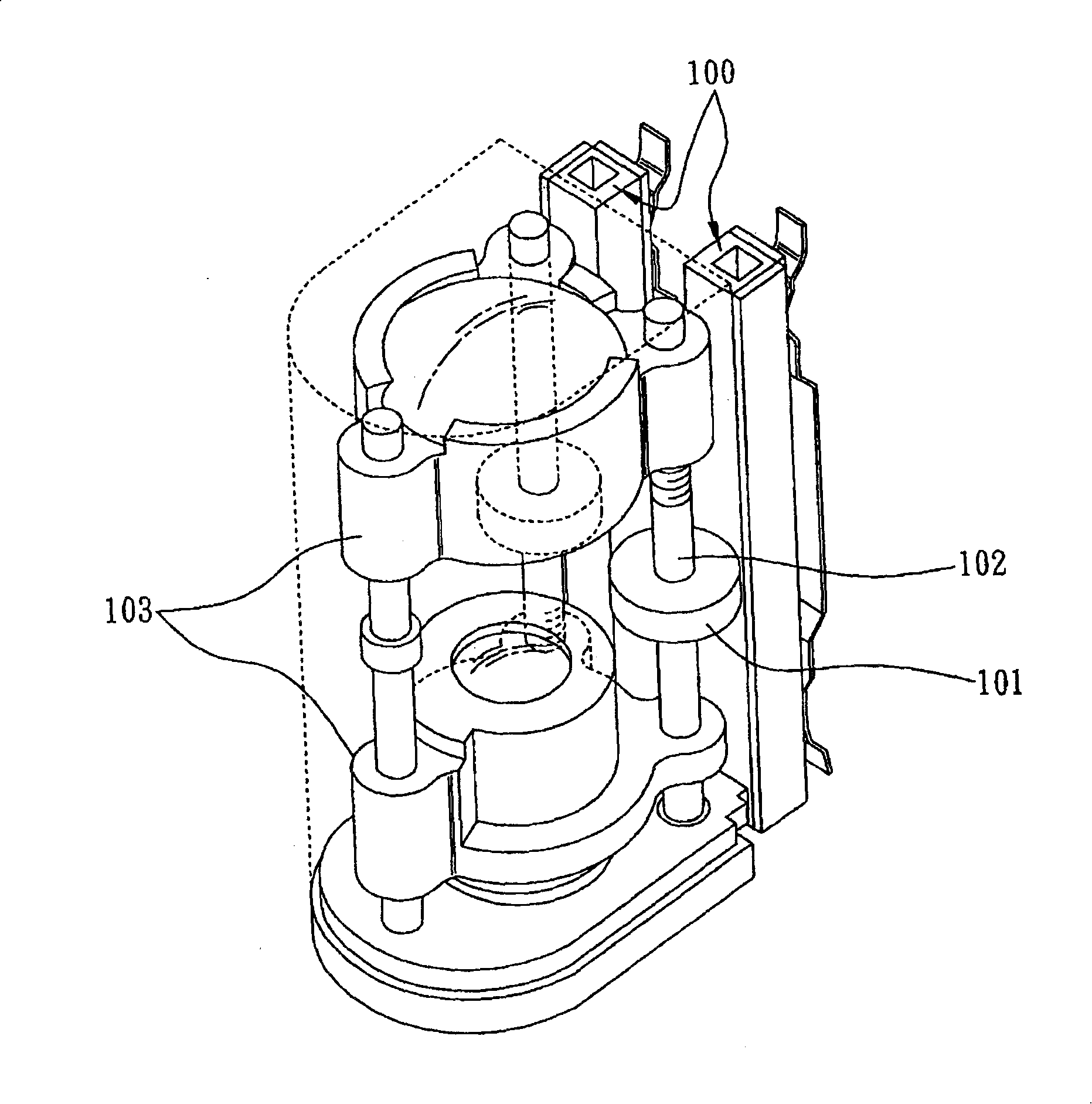

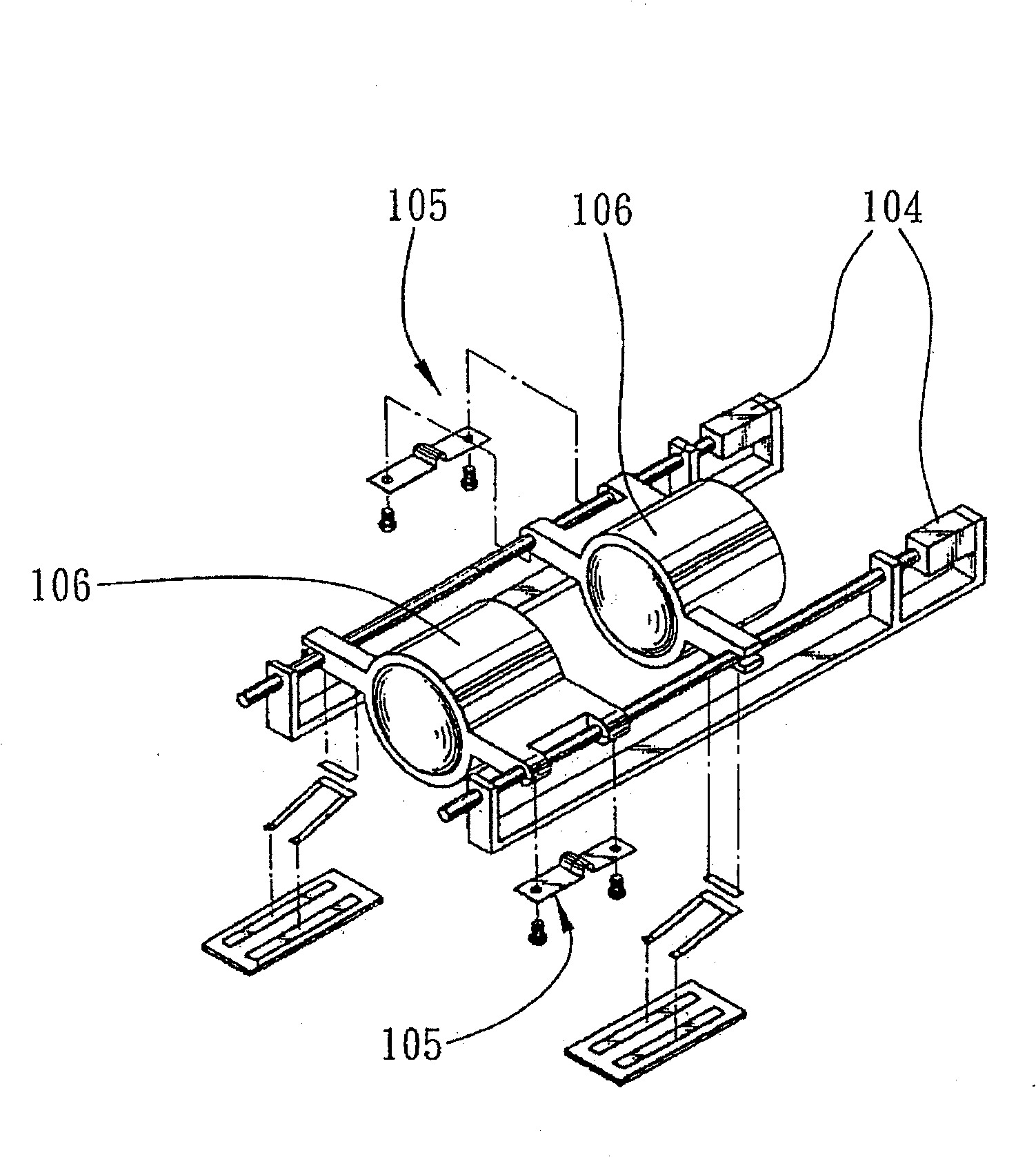

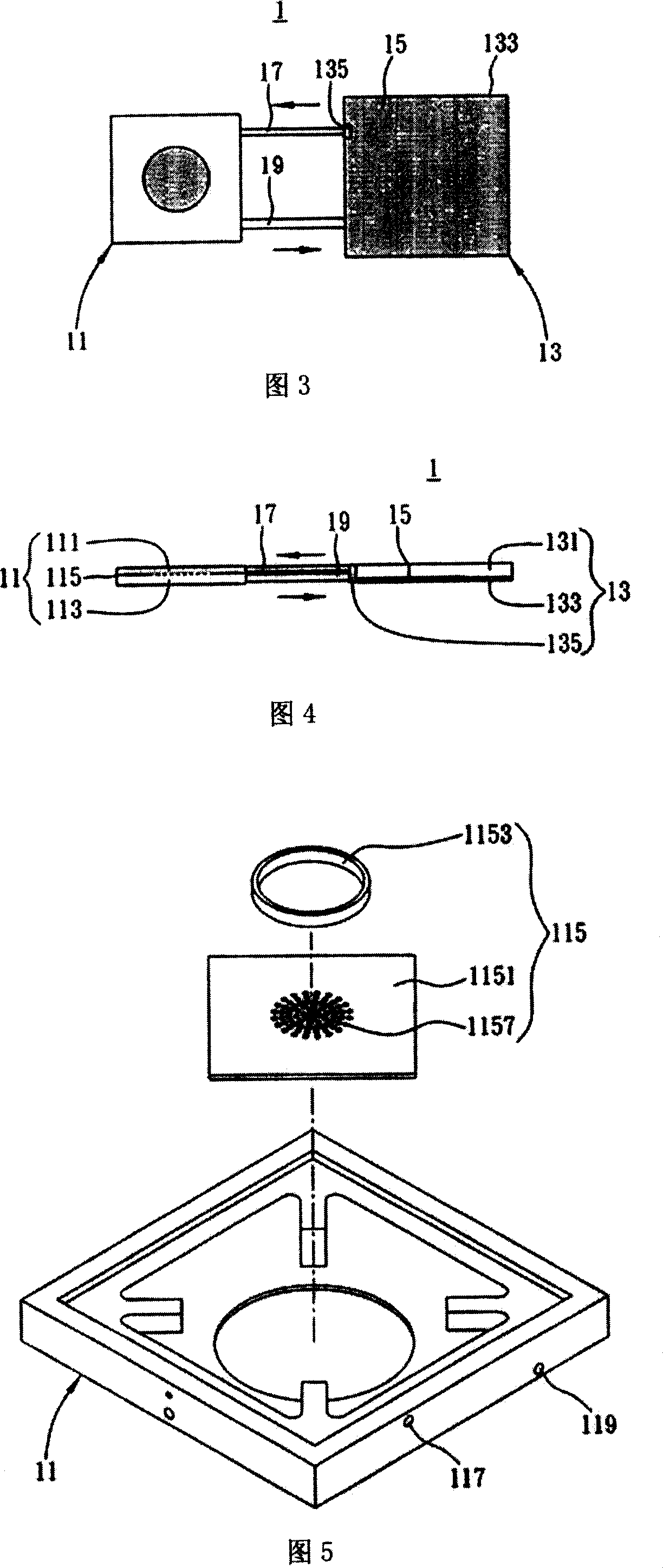

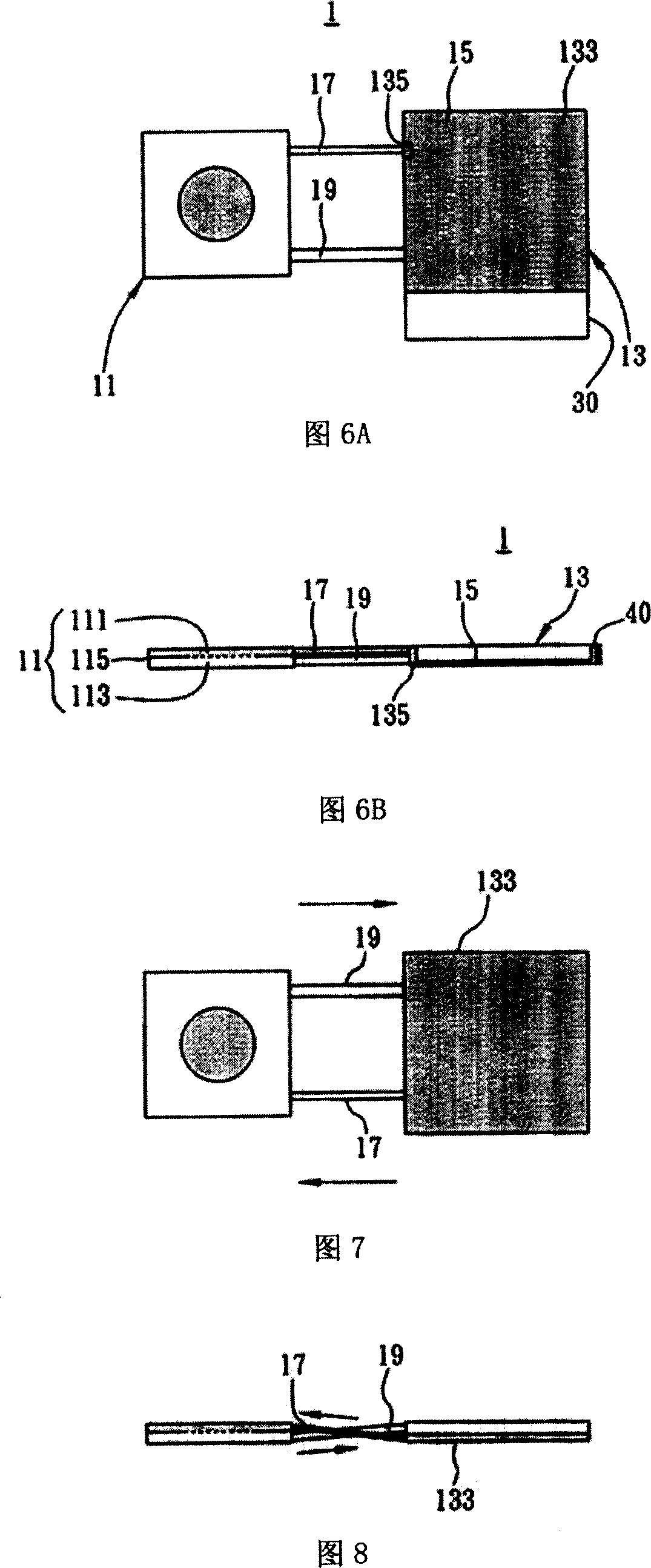

Piezo-electricity drive type optical lens

InactiveCN101206297AHigh torqueReduce volumeMountingsPiezoelectric/electrostrictive/magnetostrictive devicesCamera lensElectricity

A piezoelectric drive type optical camera lens comprises a camera lens body, a piezoelectric actuator used to provide driving force and a position sensing device used for sensing position change, wherein, the camera lens body at least has a hollow seat body, a lens barrel capable of moving in axial direction and positioned inside the hollow seat body, and a lens group fixed on the lens barrel; the piezoelectric actuator is used to drive the lens barrel to move along axial direction relative to the hollow seat body, thereby completing telescopic zooming; while the position sensing device is used for sensing the axial position of the lens barrel relative to the hollow seat body. Therefore, the simple piezoelectric drive type optical camera lens is formed through adopting the members, and overcomes the disadvantage of complicated members of the prior art.

Owner:IND TECH RES INST

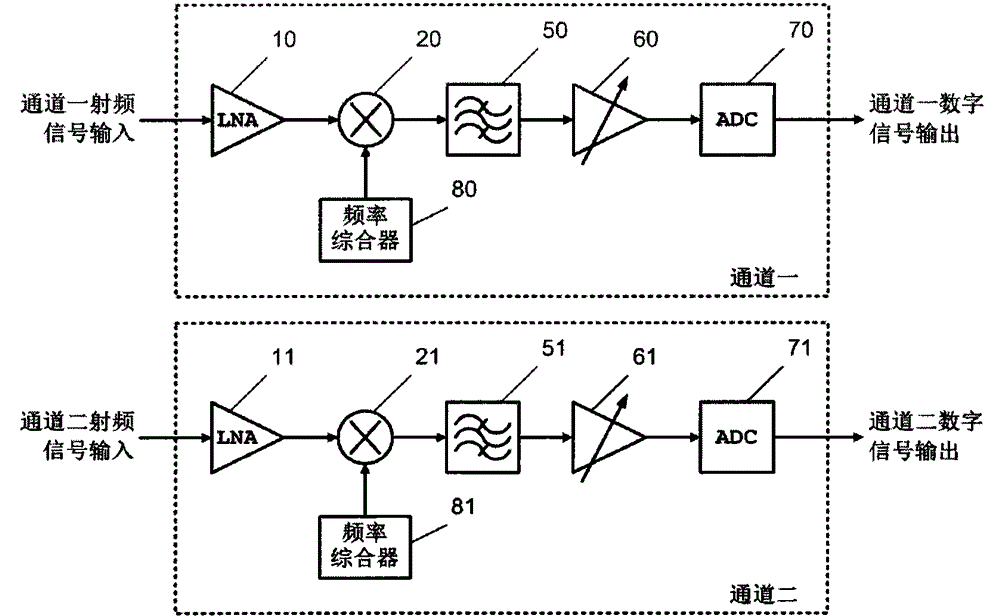

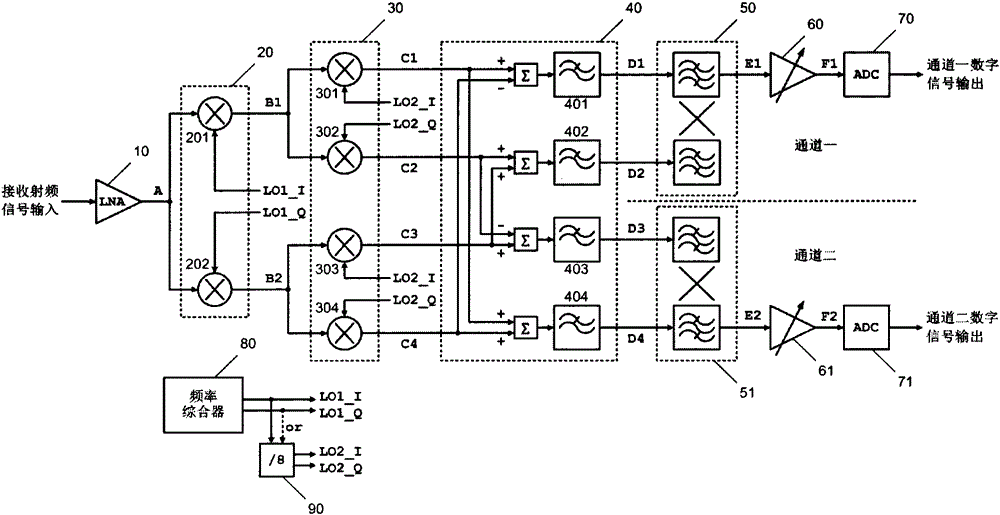

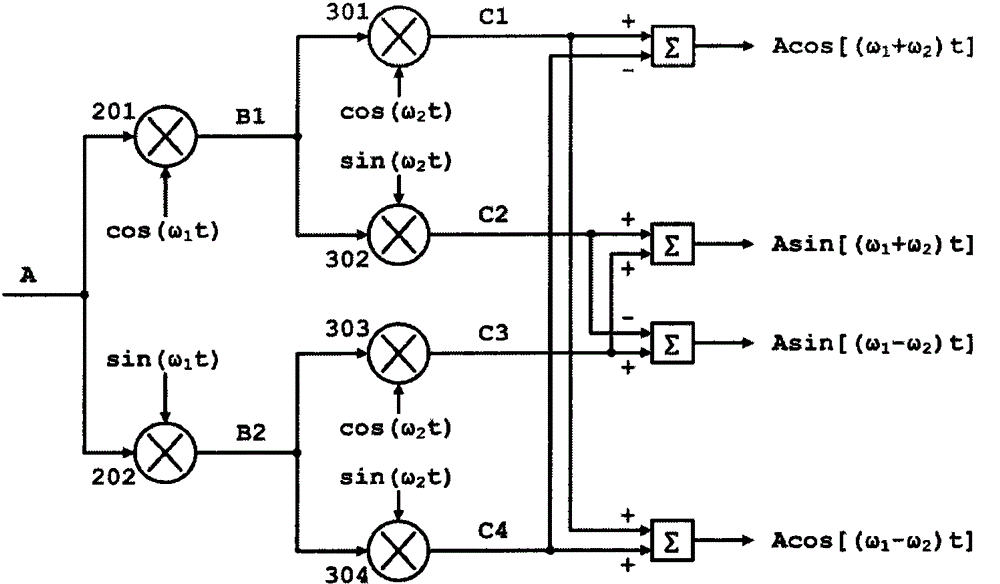

Radio frequency front-end circuit of L1-L2 dual-band satellite navigation receiver

ActiveCN105549038AReduce power consumptionLow costSatellite radio beaconingTransmissionVIT signalsFrequency mixer

Disclosed in the invention is a radio frequency front-end circuit of an L1-L2 dual-band satellite navigation receiver. The radio frequency front-end circuit is composed of a radio frequency low-noise amplifier, a first-stage mixer, a second-stage mixer, a low-pass filter, a configurable complex band-pass filter, a variable-gain intermediate-frequency amplifier, an analog-digital converter, a frequency synthesizer and an eight-frequency divider. The circuit is capable of receiving dual-band satellite signals like GPS L1 and L2 signals, Beidou B1 and B2 signals, Glonass L1 and L2 signals; and demands of high-precision dual-band satellite positioning and navigation can be satisfied. Meanwhile, the circuit is characterized in that the circuit structure of the traditional dual-band receiver is simplified and simultaneous receiving of dual-band signals can be realized only by using one frequency synthesizer; single-antenna inputting is supported and image rejection by using an off-chip radio frequency unit and an intermediate-frequency filter is not needed, so that the power consumption and cost of the receiver radio frequency front-end circuit can be effectively reduced. Therefore, the provided circuit has the great industrial value in use.

Owner:ALLYSTAR TECH SHENZHEN CO LTD

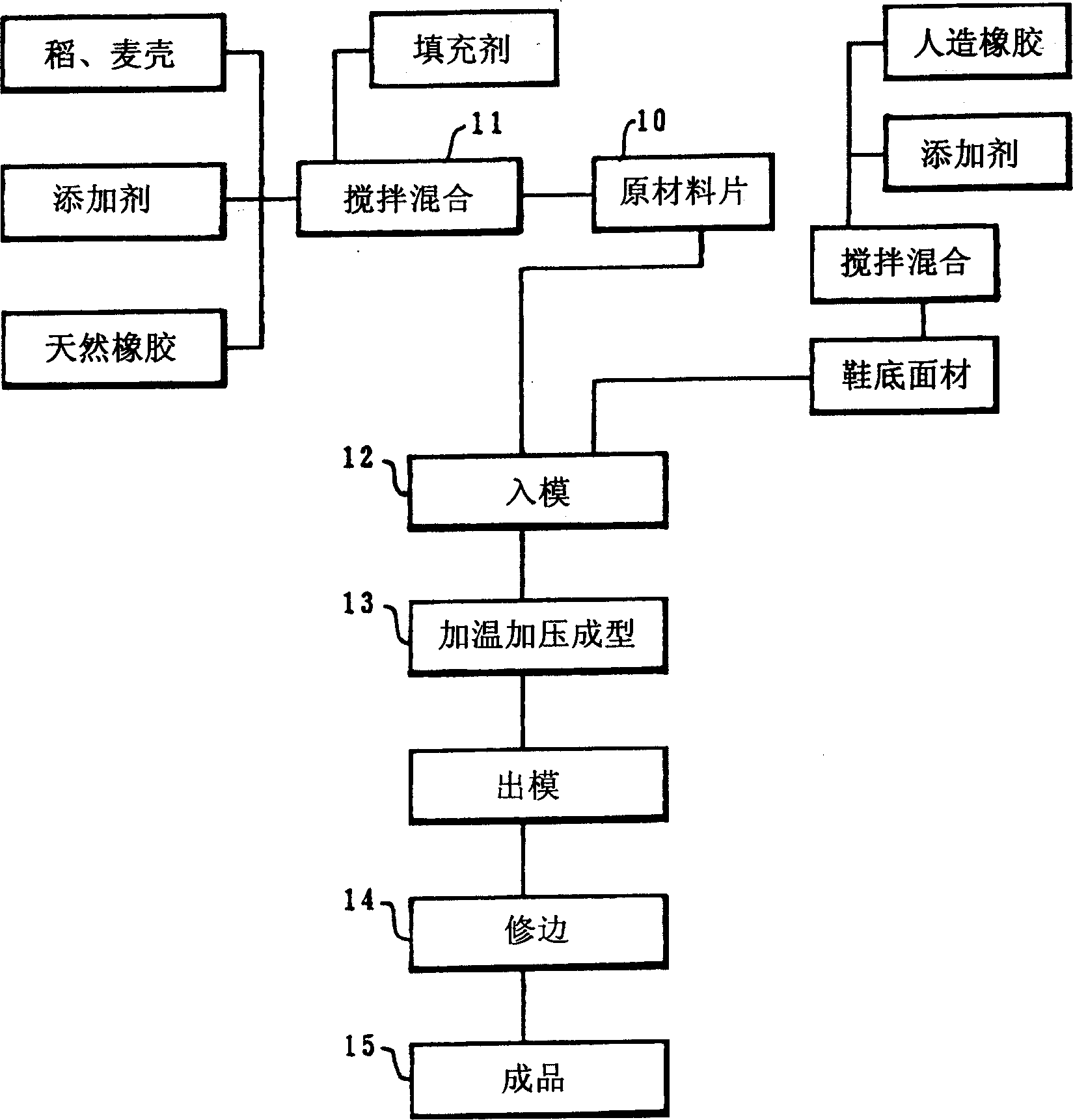

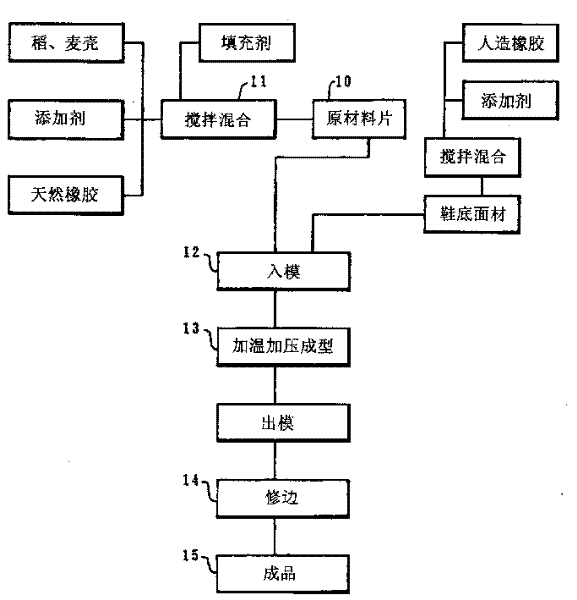

Method for fabricating sole for footwear in environment protection

An environmental protection type shoe sole is made up of the fibrous plant material such as rice husk, wheat husk, etc. natural or artificial rubber material, ageing additive, activating promoter, and filler through mechanical mixing and stirring, making sheets, and hot die pressing.

Owner:高幼华

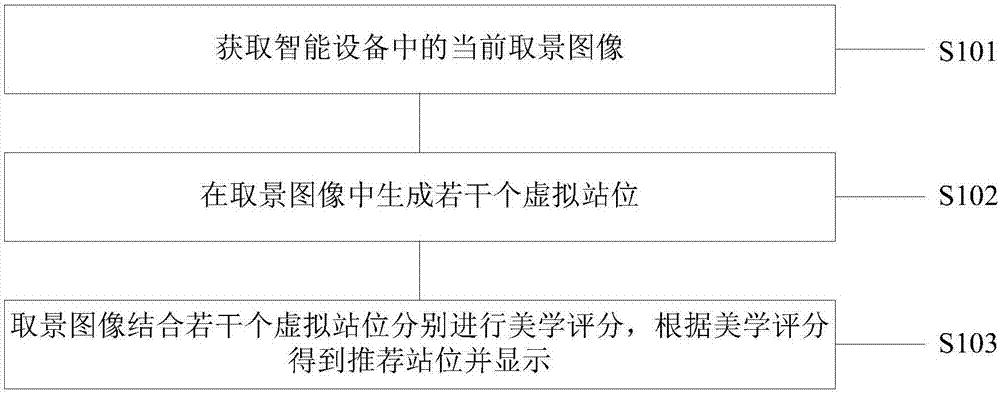

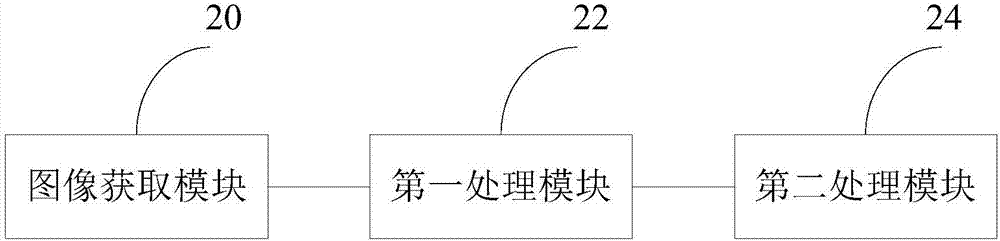

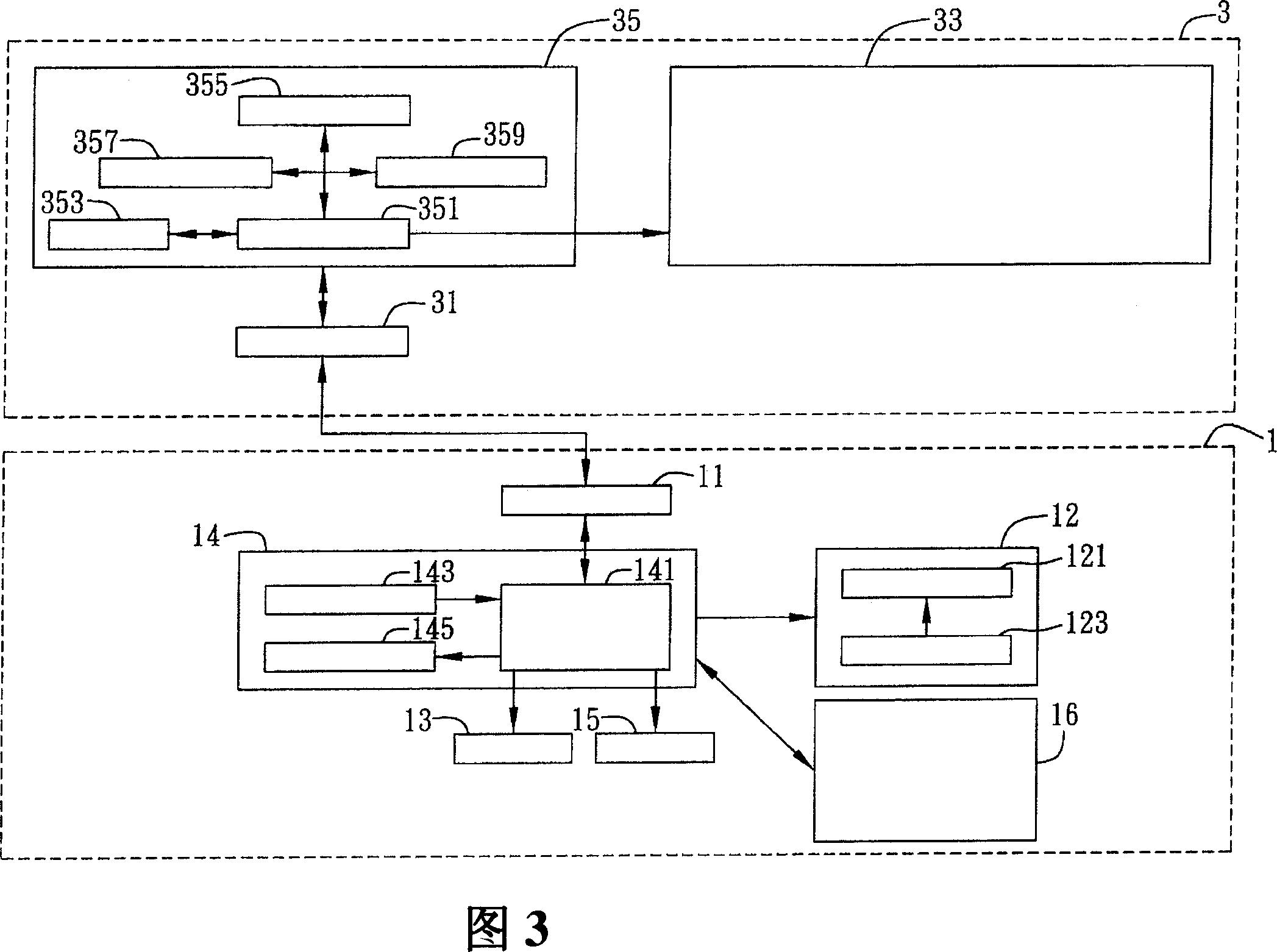

Real-time photographing guidance method and device

InactiveCN107018330AHigh industrial utilization valueHas high industrial utilization valueTelevision system detailsCharacter and pattern recognitionComputer visionComputer graphics (images)

The invention discloses a real-time photographing guidance method and device. The method comprises the following steps: acquiring a current view-finding image in intelligent equipment; generating a plurality of virtual stations in the view-finding image; and combining the view-finding image with the plurality of virtual stations to separately perform aesthetic scoring, obtaining a recommended station according to aesthetic scores, and displaying the recommended station. According to the real-time photographing guidance method disclosed by the invention, the recommended station is obtained by intelligently identifying a photographing scene so as to ensure that users without professional photography knowledge can also easily photograph high aesthetic portrait photos, various shortcomings of the prior art can be effectively overcome, and a high degree of industrial utilization value can be achieved.

Owner:CHINA ACADEMY OF ELECTRONICS & INFORMATION TECH OF CETC

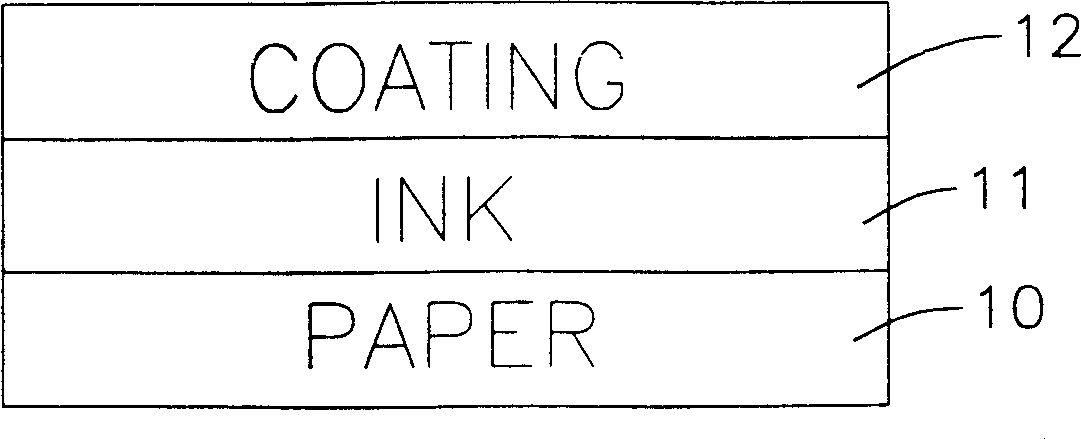

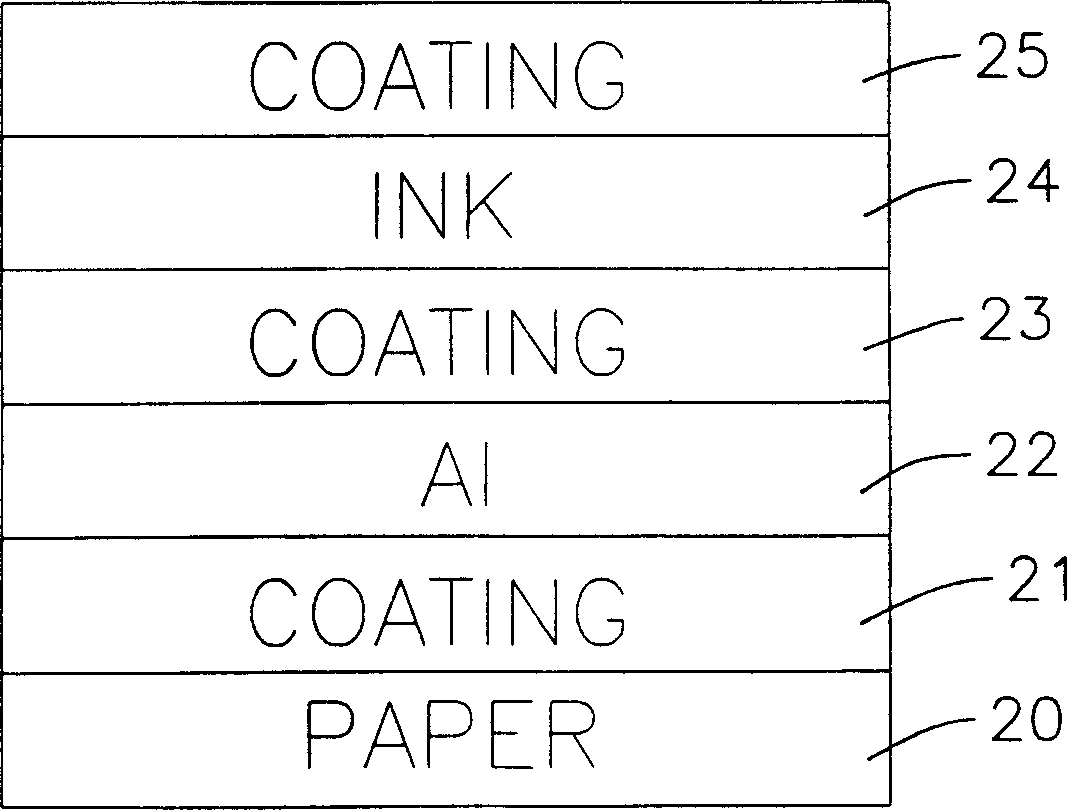

Production process of composite cover paper for bowl noodle

InactiveCN1789557AKeep Printing AutomatedGuaranteed normal operationSpecial paperPaper coatingLow-density polyethyleneRough surface

The invention discloses the manufacturing technique of composite paper, comprising the following steps: a. the rough surface of paper and the bright surface of aluminum foil are glued by LDPE; b. drenching film on the surface of aluminium; c. the second drenching film, and adding antistatic agent into the drenching film material. The technology removes the package pollution from maize flour and possesses the high utilization value.

Owner:上海金叶包装材料有限公司 +1

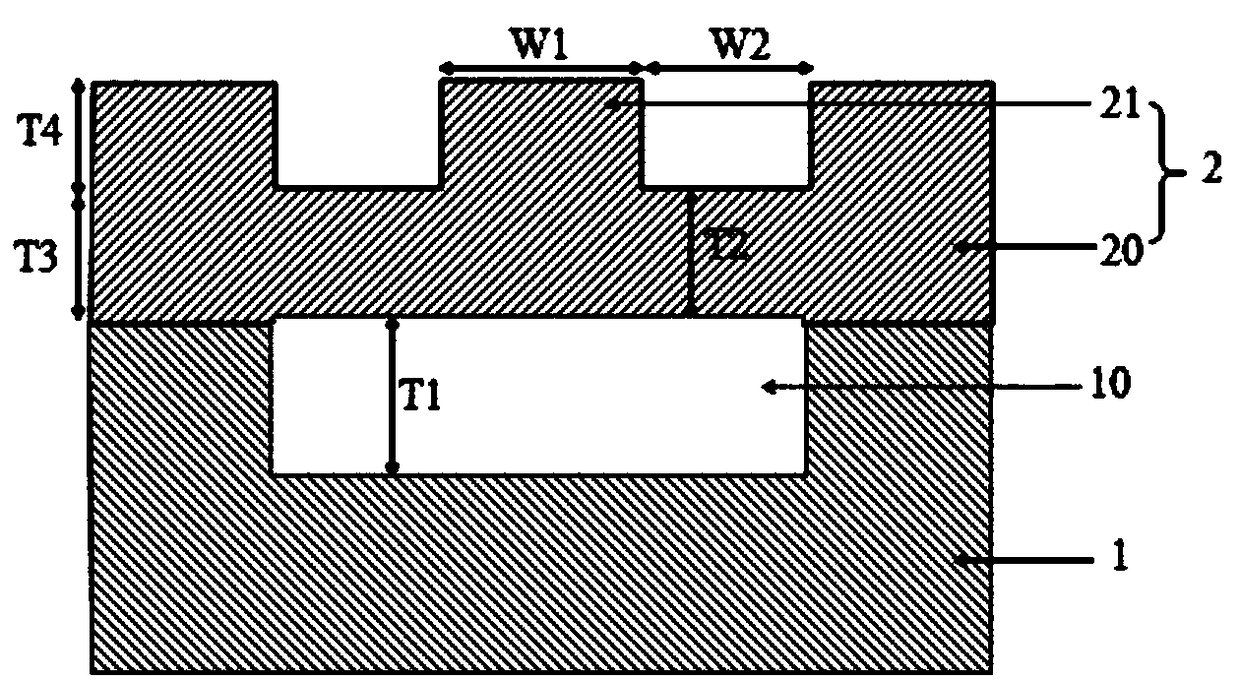

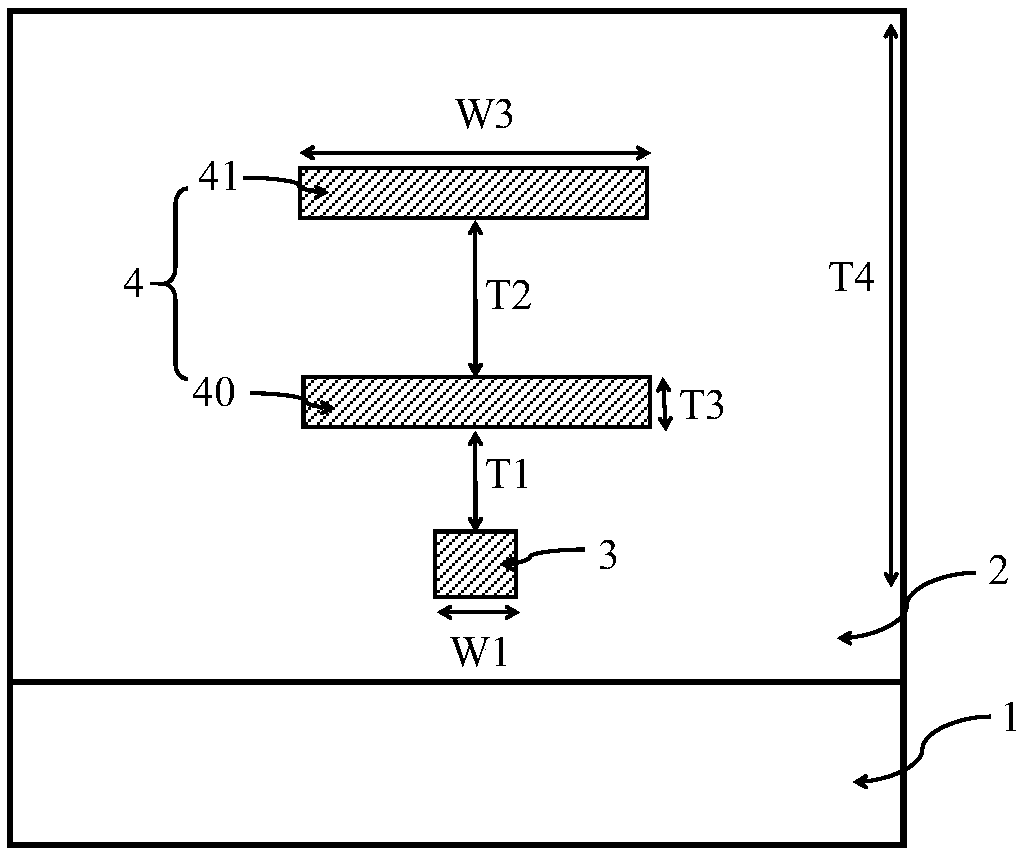

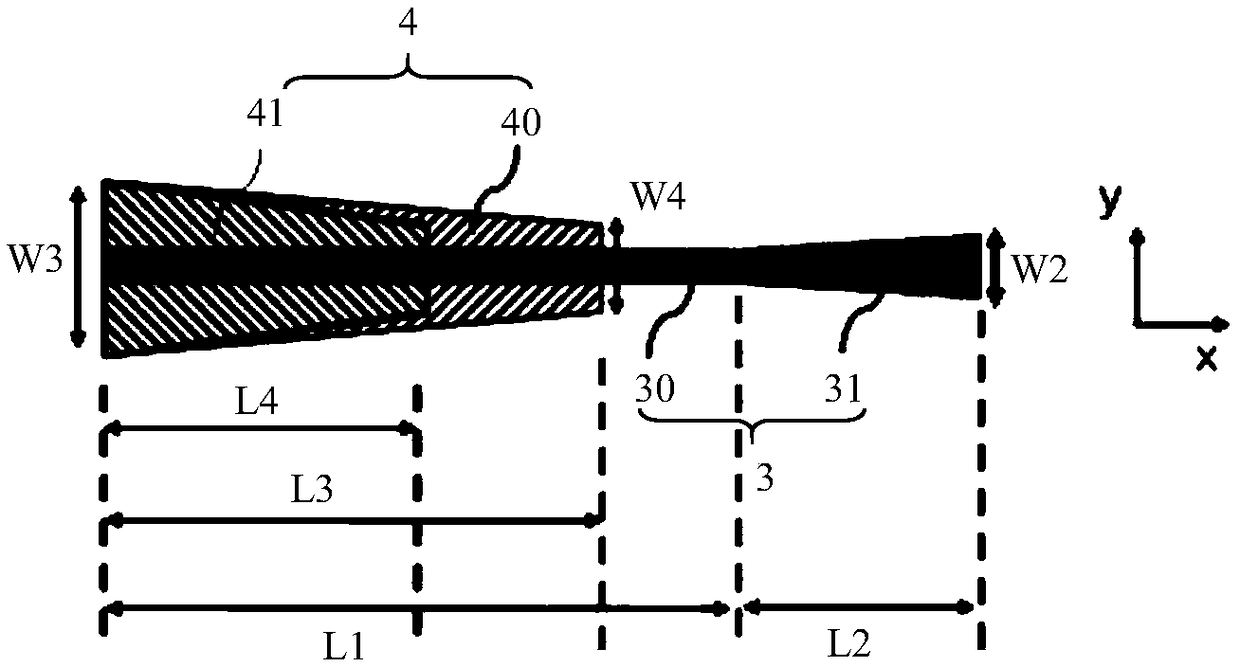

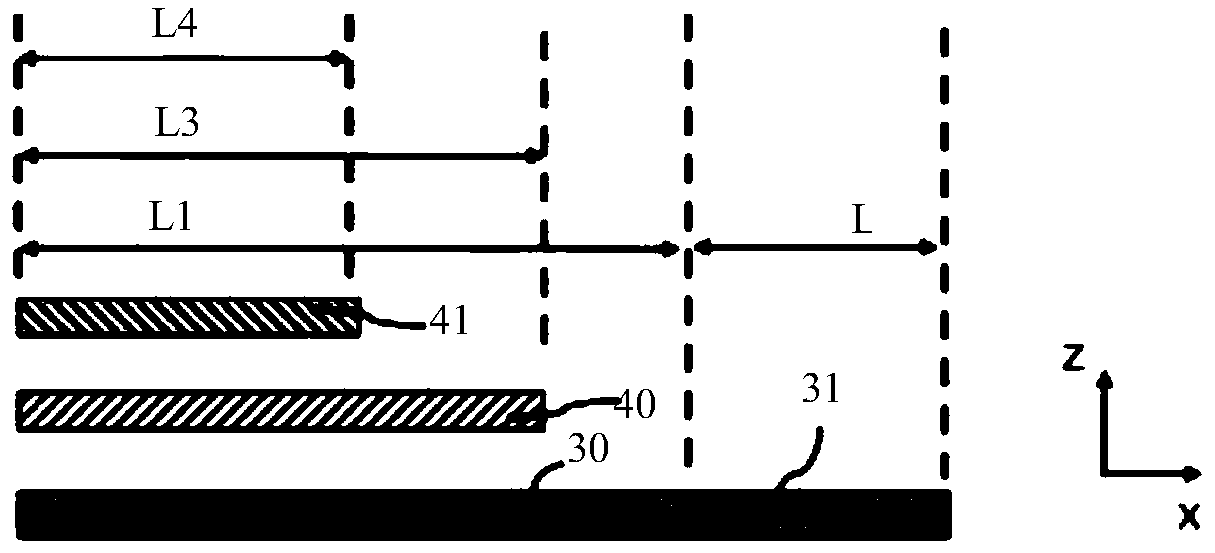

Cantilever type end face coupler

ActiveCN109031518ASimple preparation processHigh industrial utilization valueOptical waveguide light guideMechanical stabilityRefractive index matching

The invention discloses a cantilever type end face coupler. The cantilever type end face coupler comprises a silicon substrate, a buried oxide layer, a silicon waveguide and a silicon nitride waveguide; a groove having the first pre-set height is etched on the silicon substrate; the buried oxide layer is formed on the upper surface of the silicon substrate; the buried oxide layer comprises a flatplate layer and a ridge type layer; the flat plate layer is formed on the upper surface of the silicon substrate; the ridge type layer is formed on the upper surface of the flat plate layer, and horizontally extends out of the flat plate layer; the silicon waveguide is formed in the buried oxide layer, and positioned over the ridge type layer; and the silicon nitride waveguide is formed in the buried oxide layer, and positioned over the silicon waveguide. The cantilever type end face coupler in the invention has the benefits that: the ridge type buried oxide layer is adopted; the end face coupler matched with the light-field speckle of a single-mode optical fibre is realized; the flat plate layer is used as the support structure of the cantilever type end face coupler; the mechanical stability is ensured; the flat plate layer serves as the index-matching fluid; the dependence of the cantilever type end face coupler on the index-matching fluid is reduced; the silicon nitride waveguide is used as the intermediate transition layer; and thus, the light field of the single-mode optical fibre can enter the silicon waveguide with the relatively high coupling efficiency.

Owner:南通赛勒光电科技有限公司

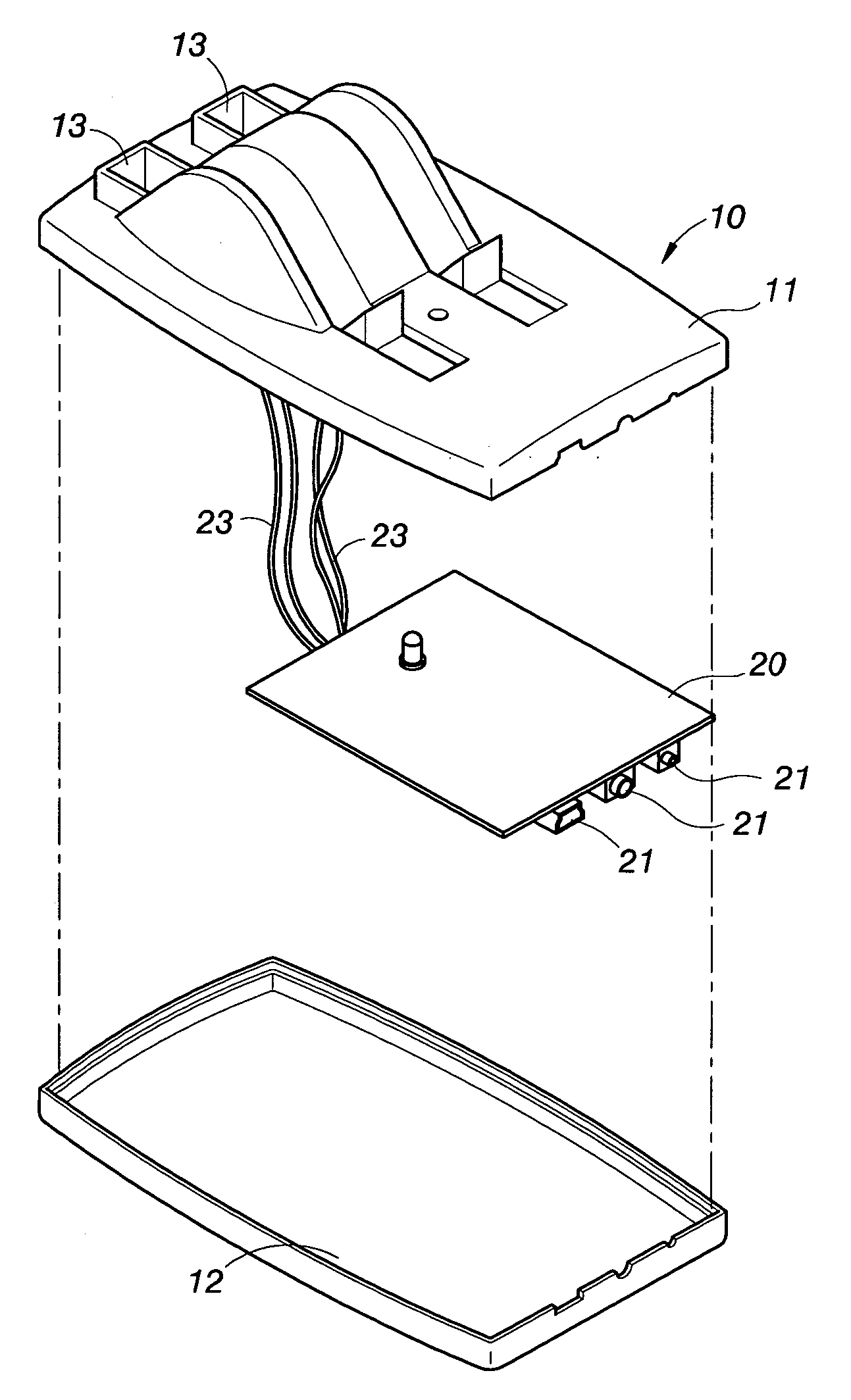

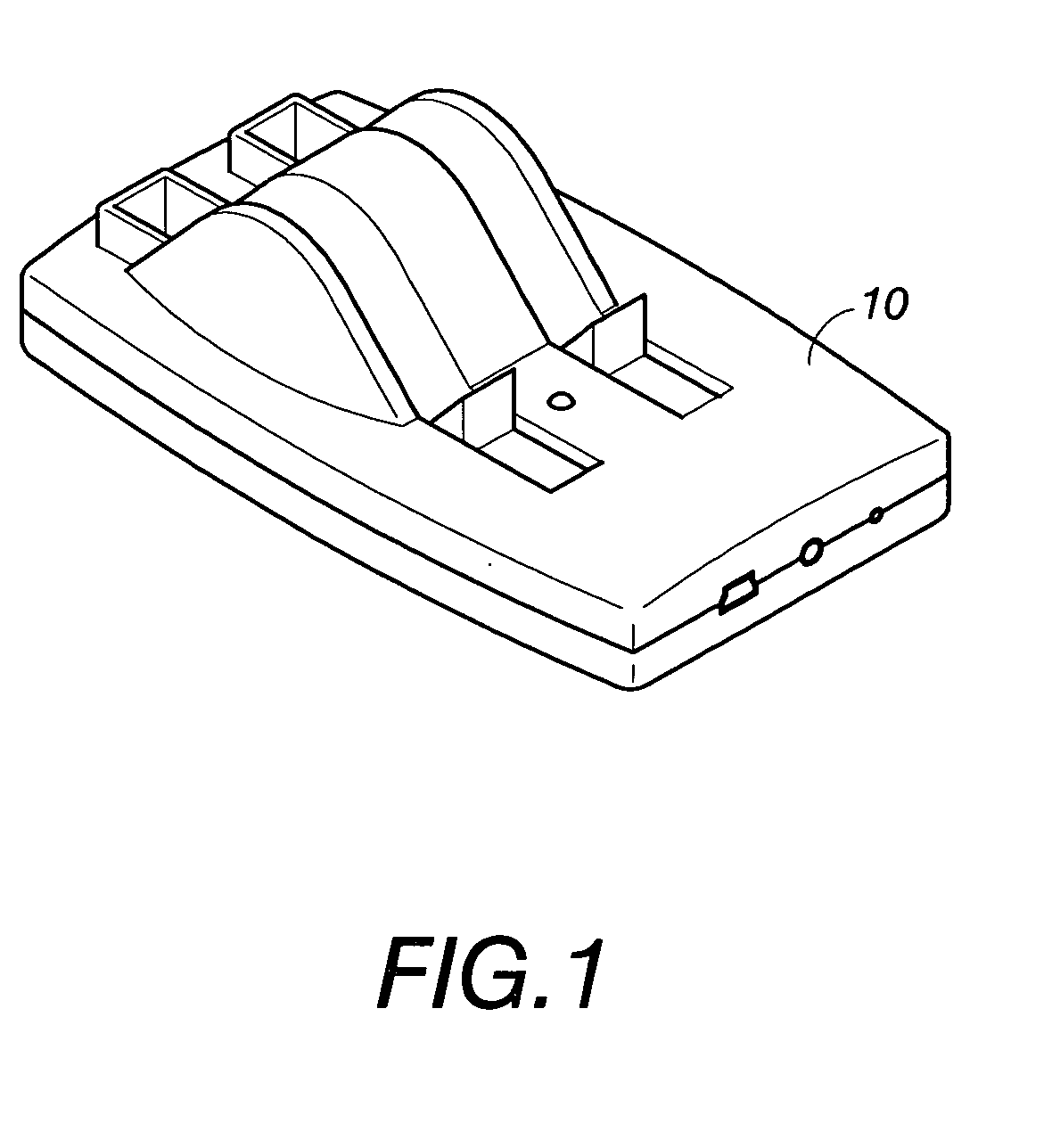

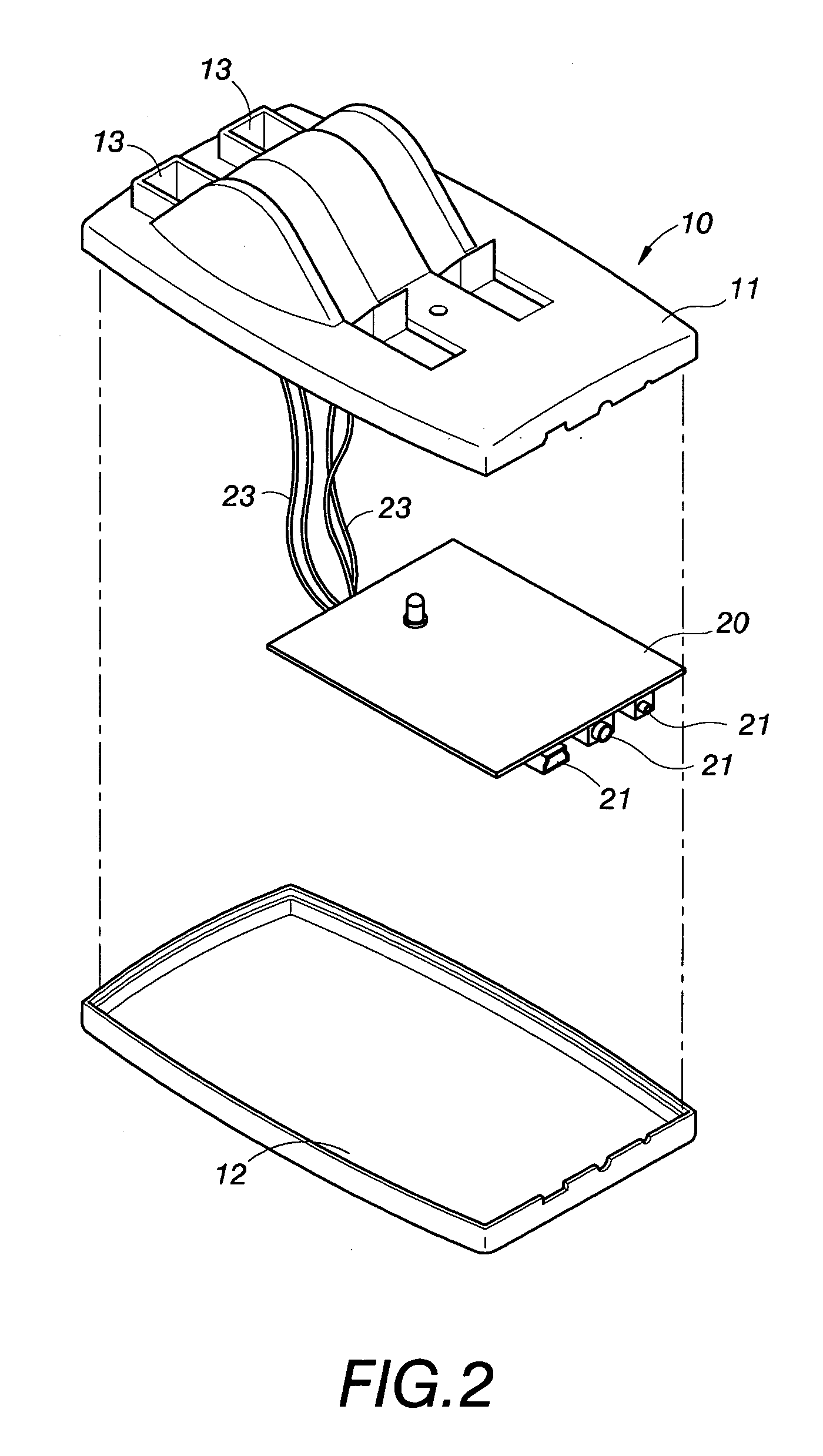

Composite charging cradle for rechargeable battery

InactiveUS20100090645A1Avoid misusePlace safeDifferent batteries chargingElectric powerRechargeable cellConfusion

The present invention provides a composite charging cradle for charging rechargeable batteries of several different specifications to solve the problem of confusion between the specifications of rechargeable batteries. The charging cradle includes a cradle body and a circuit board disposed in the cradle body. The cradle body has a plurality of insertion slots for inserting rechargeable batteries of different specifications therein, and each of the insertion slots is provided therein with at least one set of terminals for outputting power; the circuit board is disposed in the foregoing cradle body, including a plurality of power input ports of different specifications exposed out of the cradle body, and an integrated unit for integrating all the foregoing power input ports; the integrated unit is electrically connected with each set of terminals such that rechargeable batteries and plug adapters of several different specifications can be charged according to the present invention.

Owner:HUANG PO CHIN

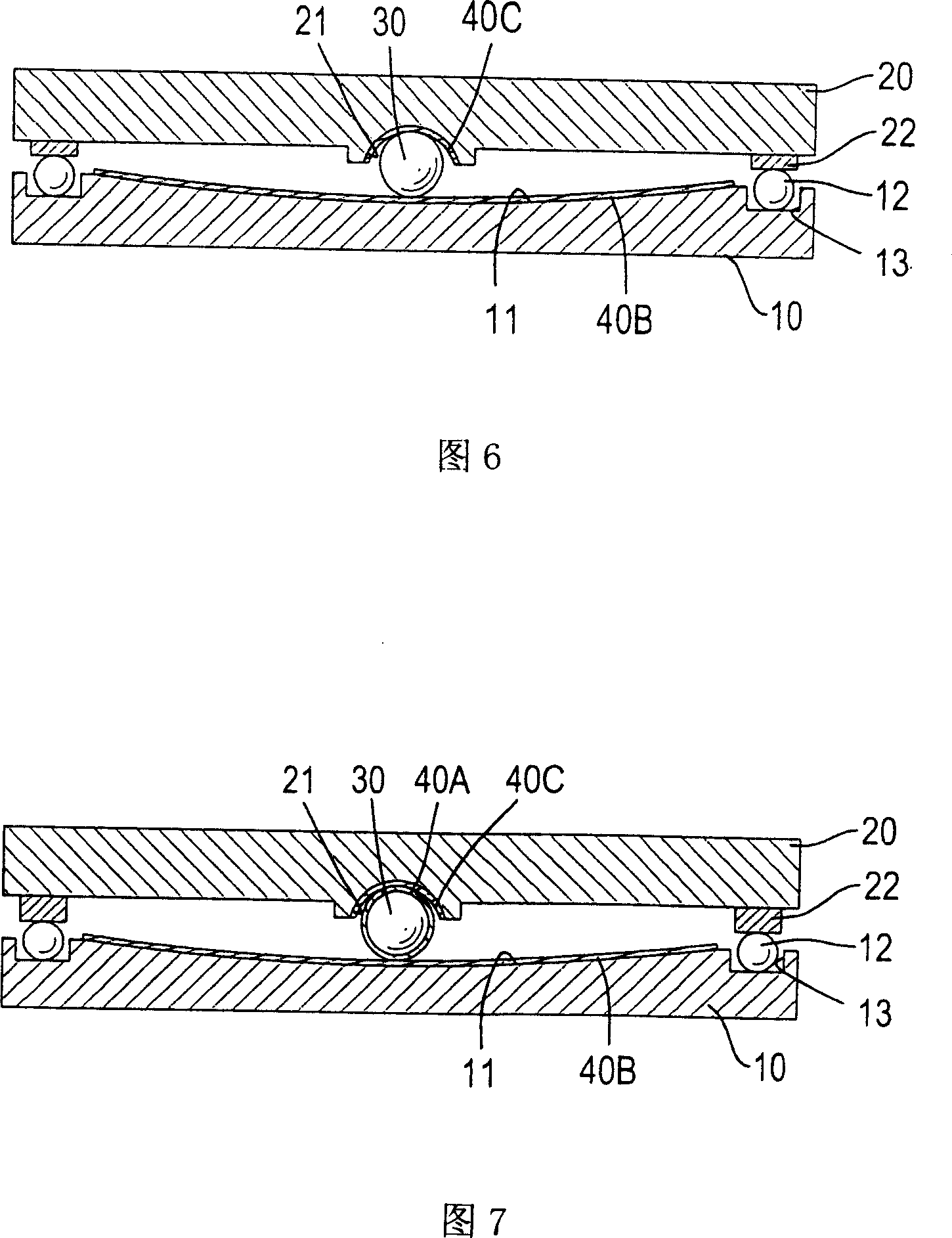

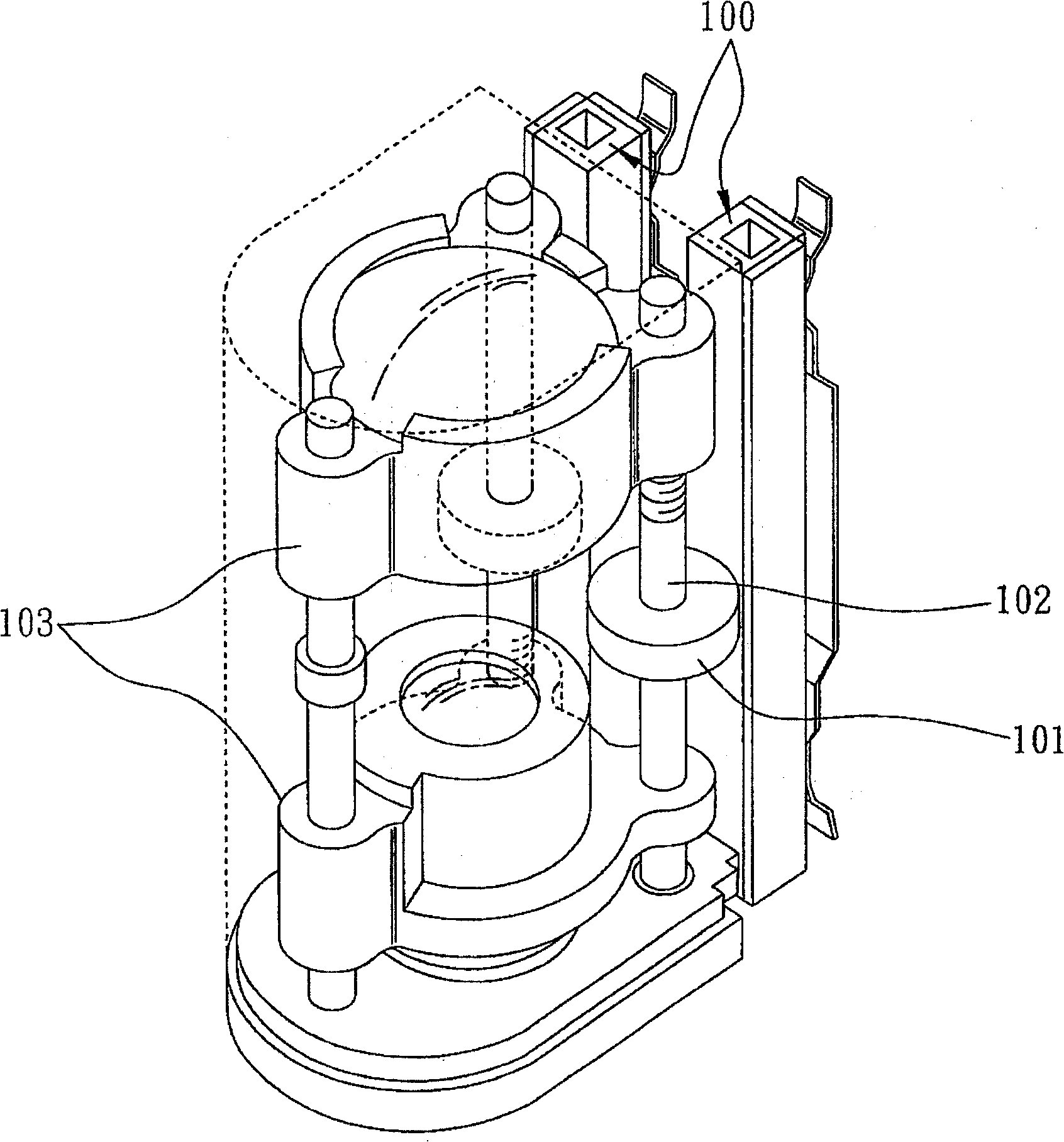

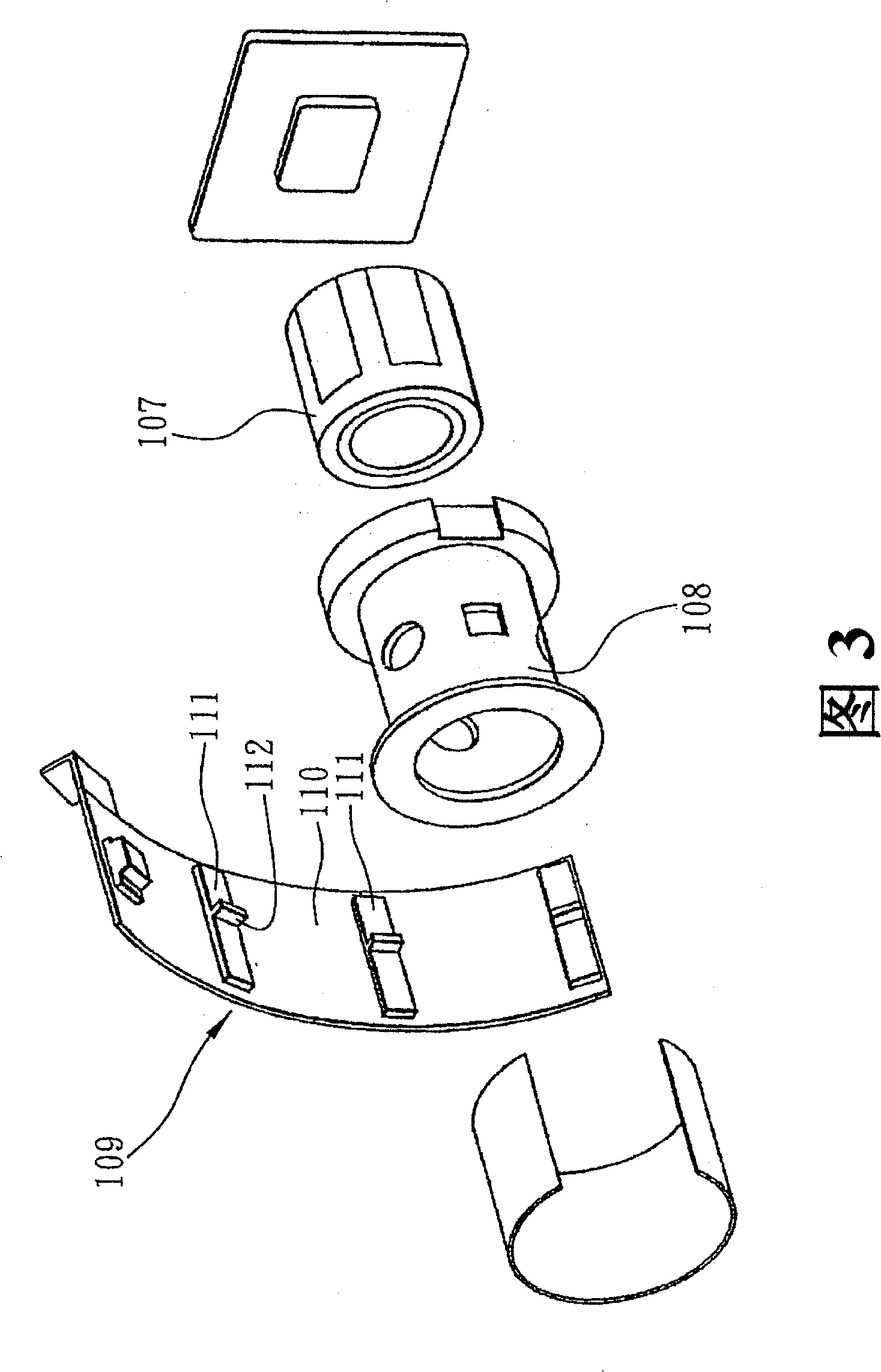

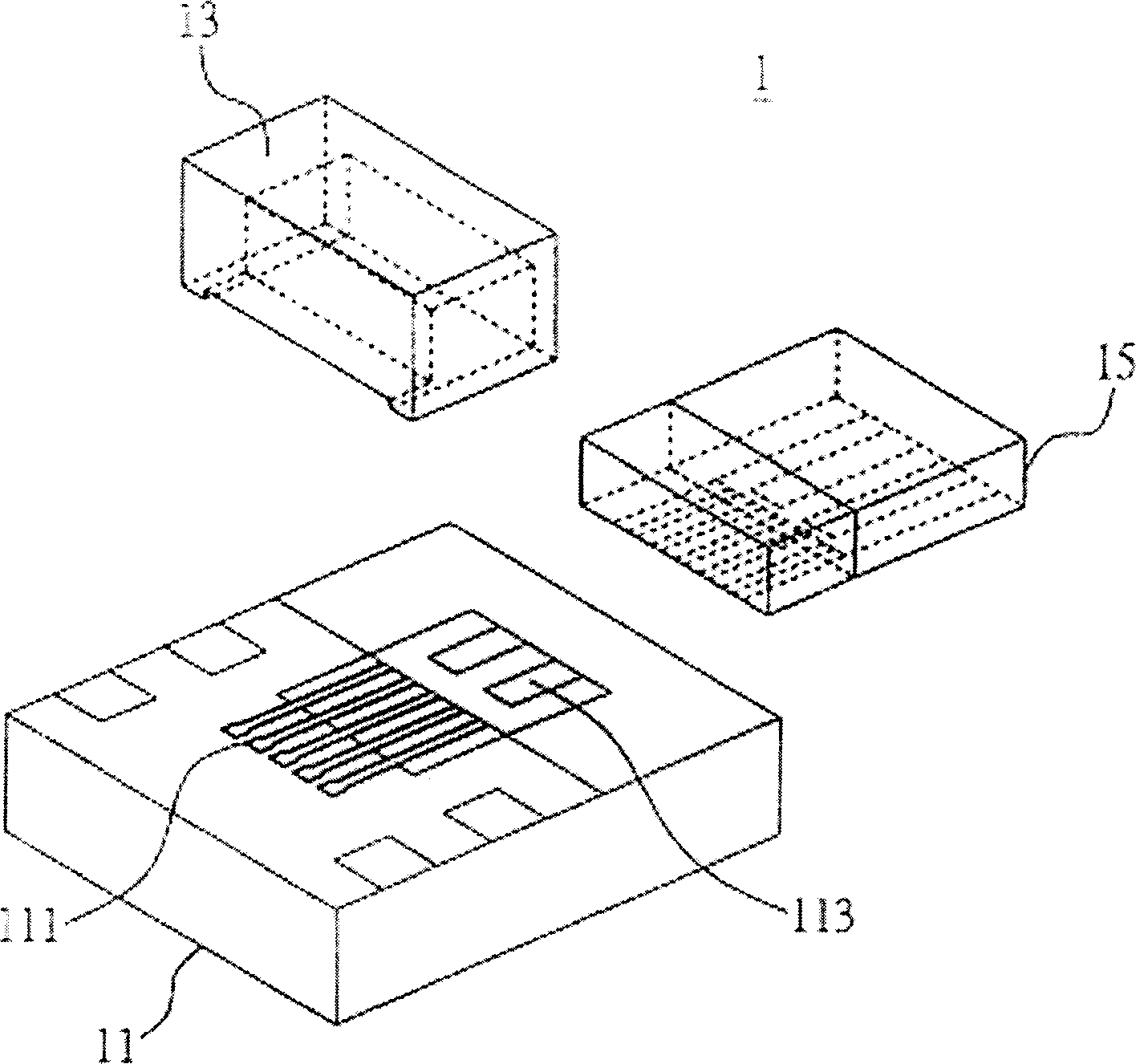

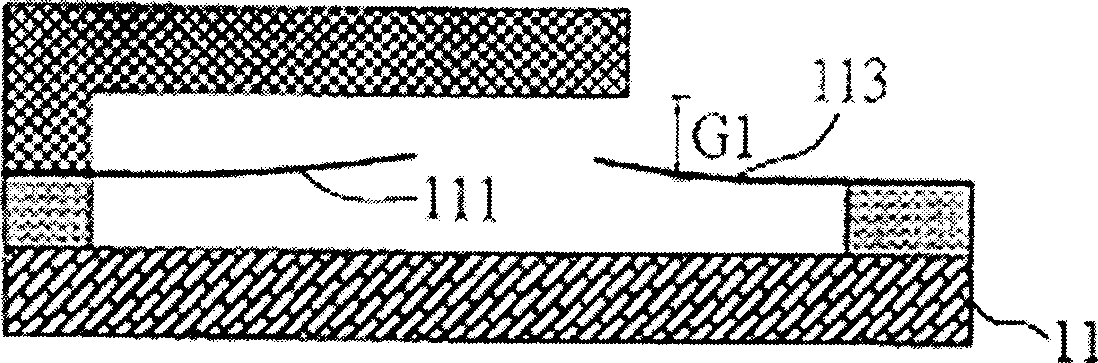

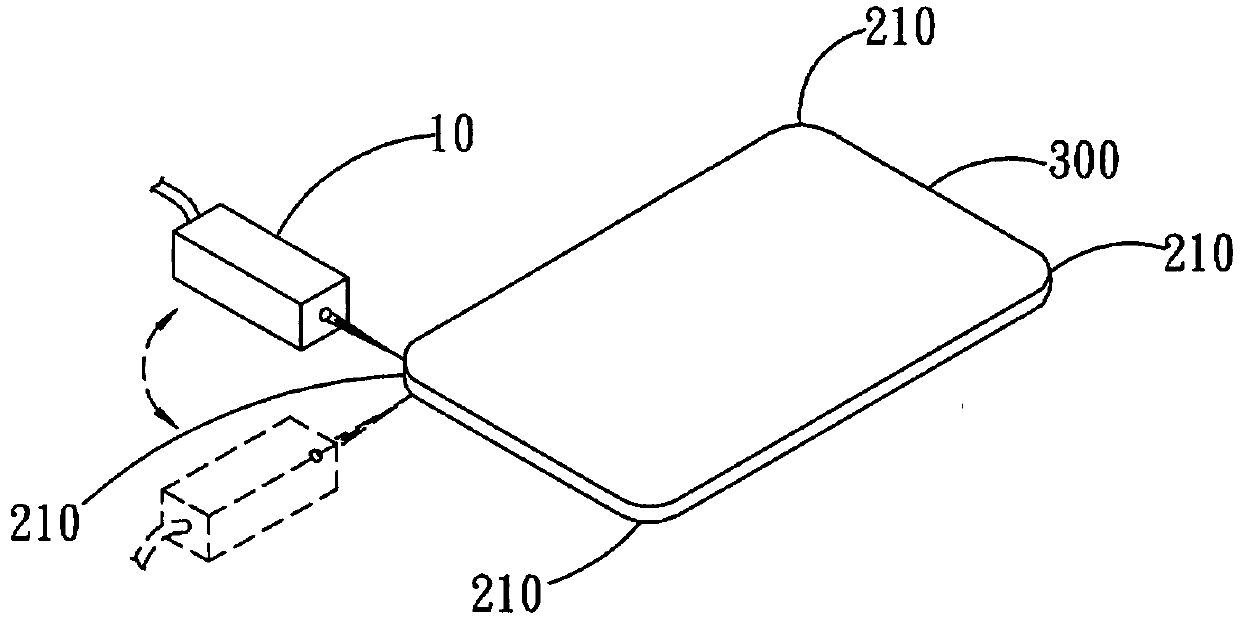

Optical focusing mechanism

InactiveCN101246243AIncreased drive torqueReduce volumeMountingsPiezoelectric/electrostrictive devicesCamera lensEngineering

The invention provides an optical focusing device, including base, sleeve which is coupled with the base, screw thread is connected with lens of the sleeve, and piezoelectric actuator which is fixed in the base for contiguously driving sleeve rotating, the base and the lens are respectively equipped with corresponding locating sliding first guiding part and second guiding part, then the sleeve is driven to rotate for converting and forcing the lens to focus. So the optical focusing device having simple components improves the driving force and overcomes the defects that the component with prior art is complex.

Owner:IND TECH RES INST

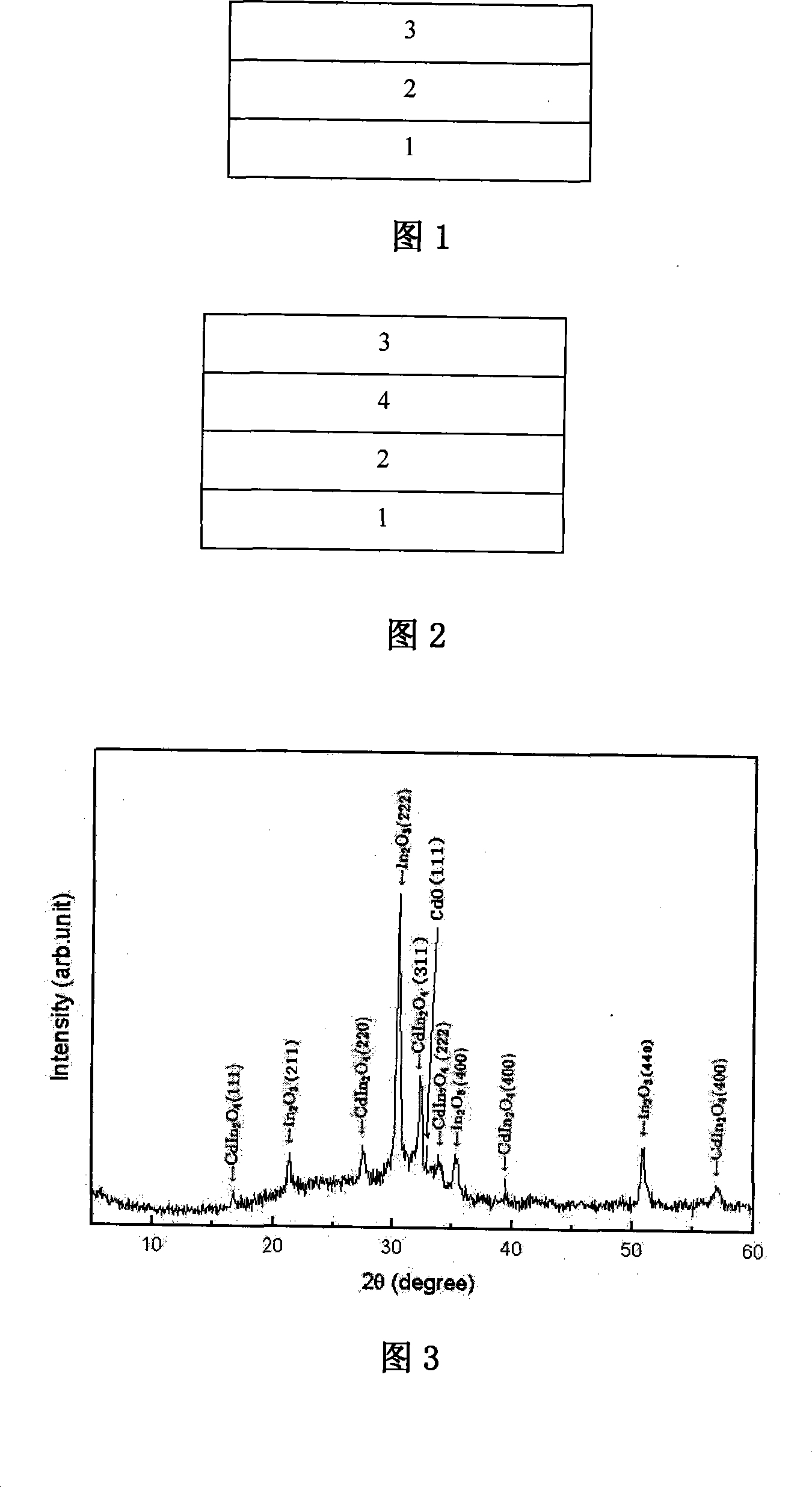

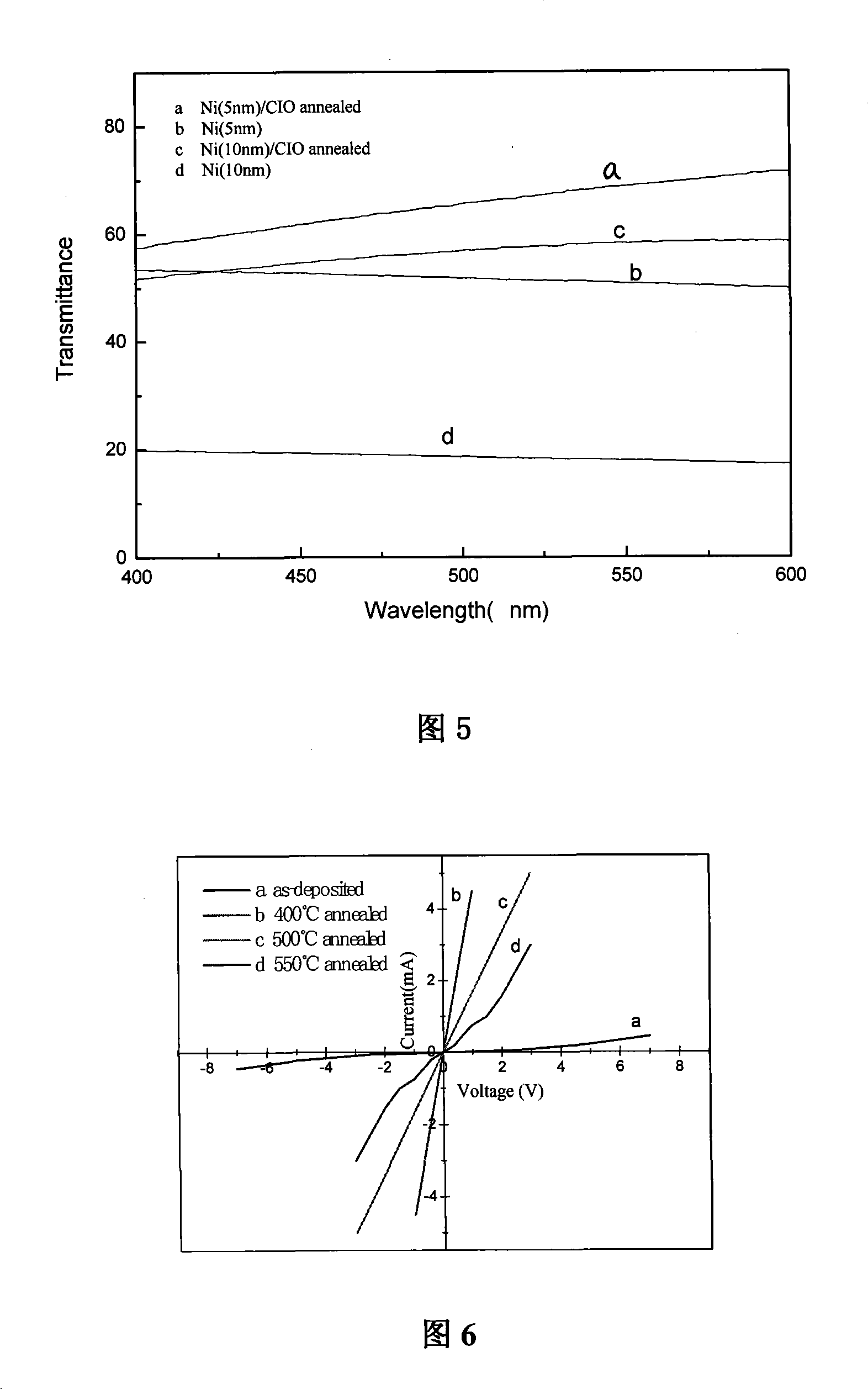

P type GaN cadmium-indium-oxygen transparent electrode and method for producing the same

InactiveCN101162751AHigh light transmittanceImprove light extraction efficiencyLaser detailsSemiconductor lasersIndiumOxygen

The present invention discloses a cadmium indium oxygen (CIO) transparent electrode of P-type GaN; with the adoption of the CIO transparent conductive film structure, the light transmittance of the transparent electrode improves more 15 percent than that of the prior metal (Ni or Ni / Au) electrode; the invention can be applied to GaN-based blue-ray light-emitting diodes or laser diodes to improve luminous efficiency or can be applied to GaN-based photodetectors to improve responsivity, thereby having high industrial utility value. The invention also discloses a preparation method of transparent electrode which solves the problem that the COI transparent conductive film is difficult to achieve ohmic contact on the P-type GaN.

Owner:CHONGQING UNIV

End face coupler and manufacturing method therefor

ActiveCN108983352AImprove coupling efficiencyShorten the lengthOptical waveguide light guideCmos processLight field

The invention discloses an end face coupler and a preparation method therefor, and the coupler comprises a silicon substrate; a buried oxide layer which is formed on an upper surface of the silicon substrate; top silicon which is formed in the buried oxide layer, and has first top silicon and second top silicon; silicon nitride waveguides formed on the top silicon, wherein the silicon nitride waveguides include a first silicon nitride waveguide and a second silicon nitride waveguide, wherein the central lines of the first silicon nitride waveguide and the second silicon nitride waveguide are located on the central line of the top silicon. The beneficial effects are that by growing a plurality of silicon nitride waveguides at different heights above the top silicon, a light field of a largeplaque size is realized, and the length of the longitudinal structure is reduced by combining the design of a longitudinal wedge structure, and finally a waveguide end face coupler with the high coupling efficiency is formed; the end face coupler is simple in fabrication process, is compatible with CMOS process, can be used for mass production, has low cost, and has a high industrial utilizationvalue.

Owner:南通赛勒光电科技有限公司

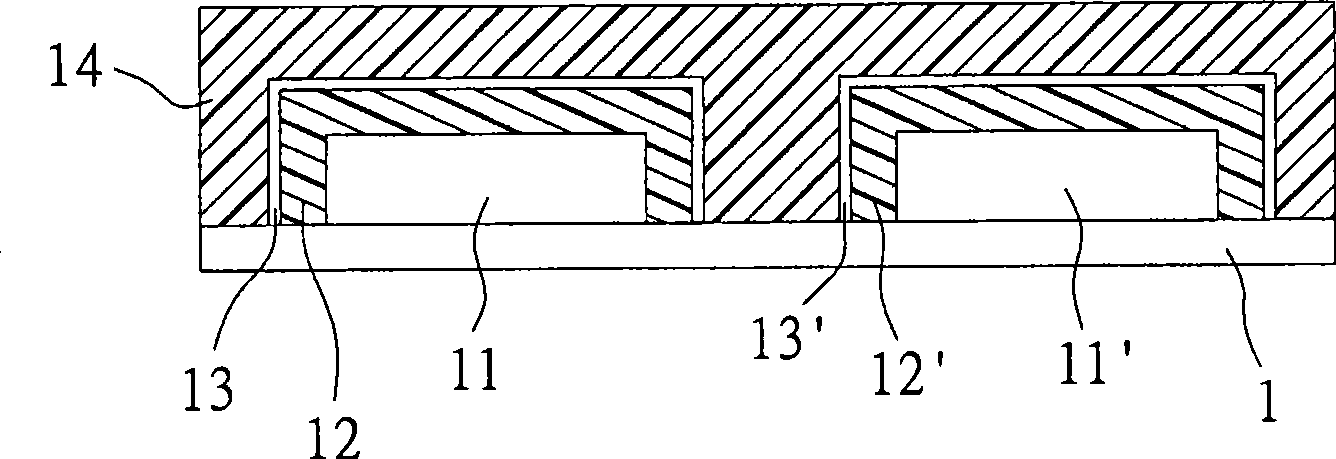

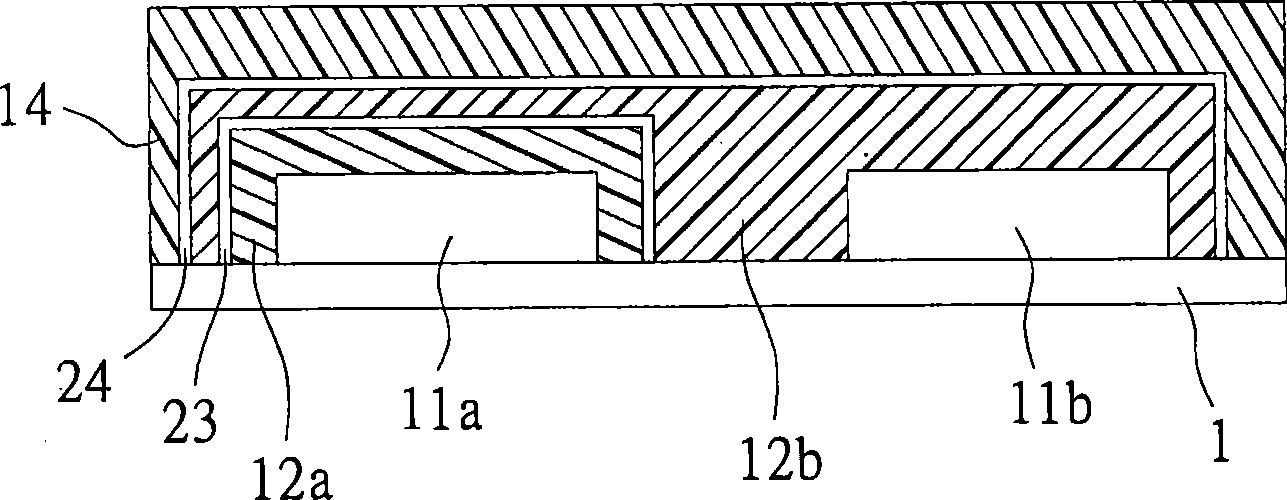

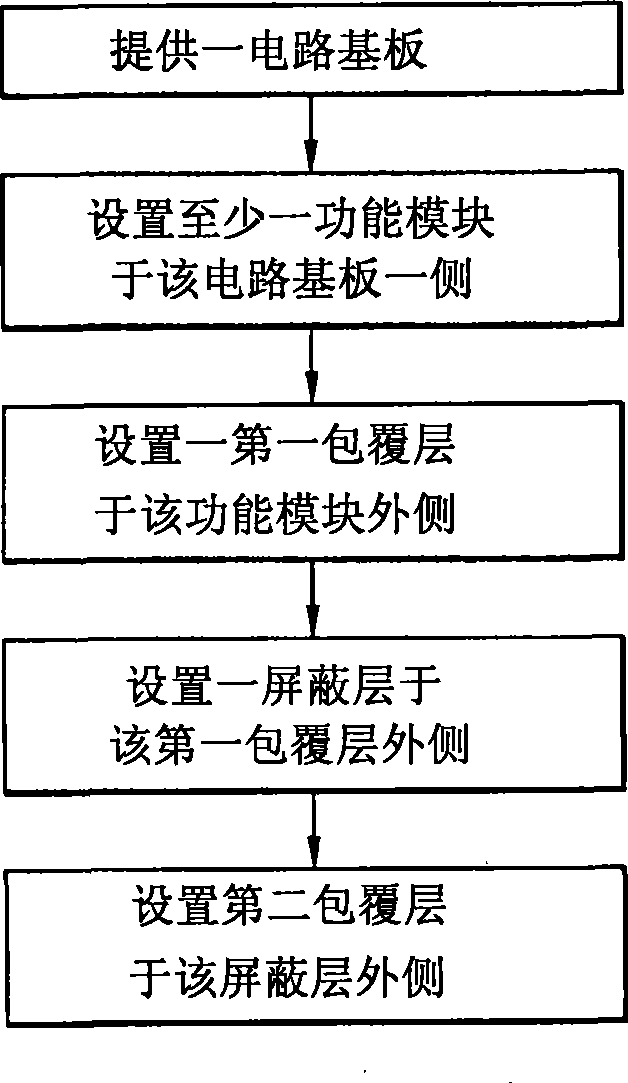

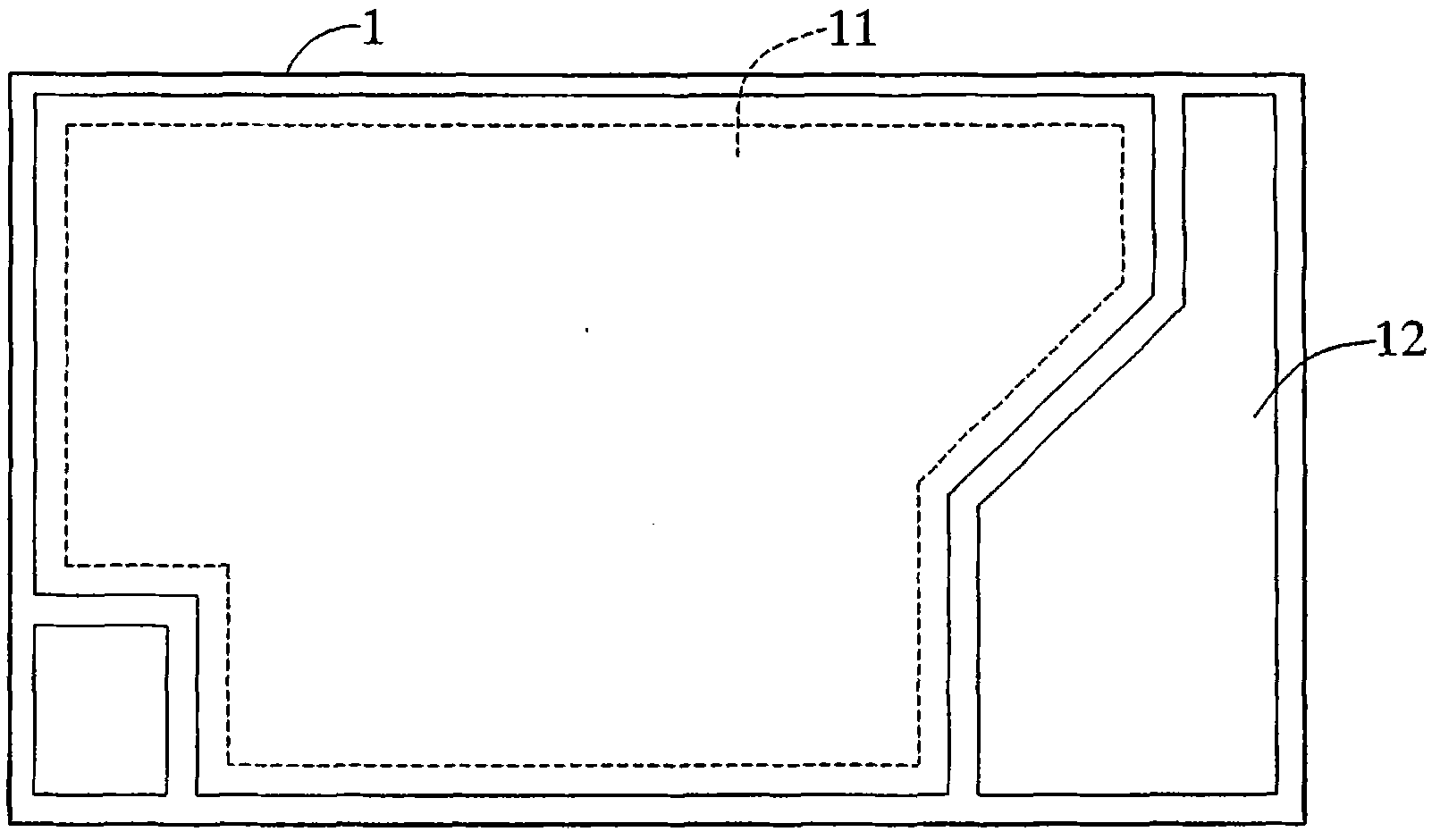

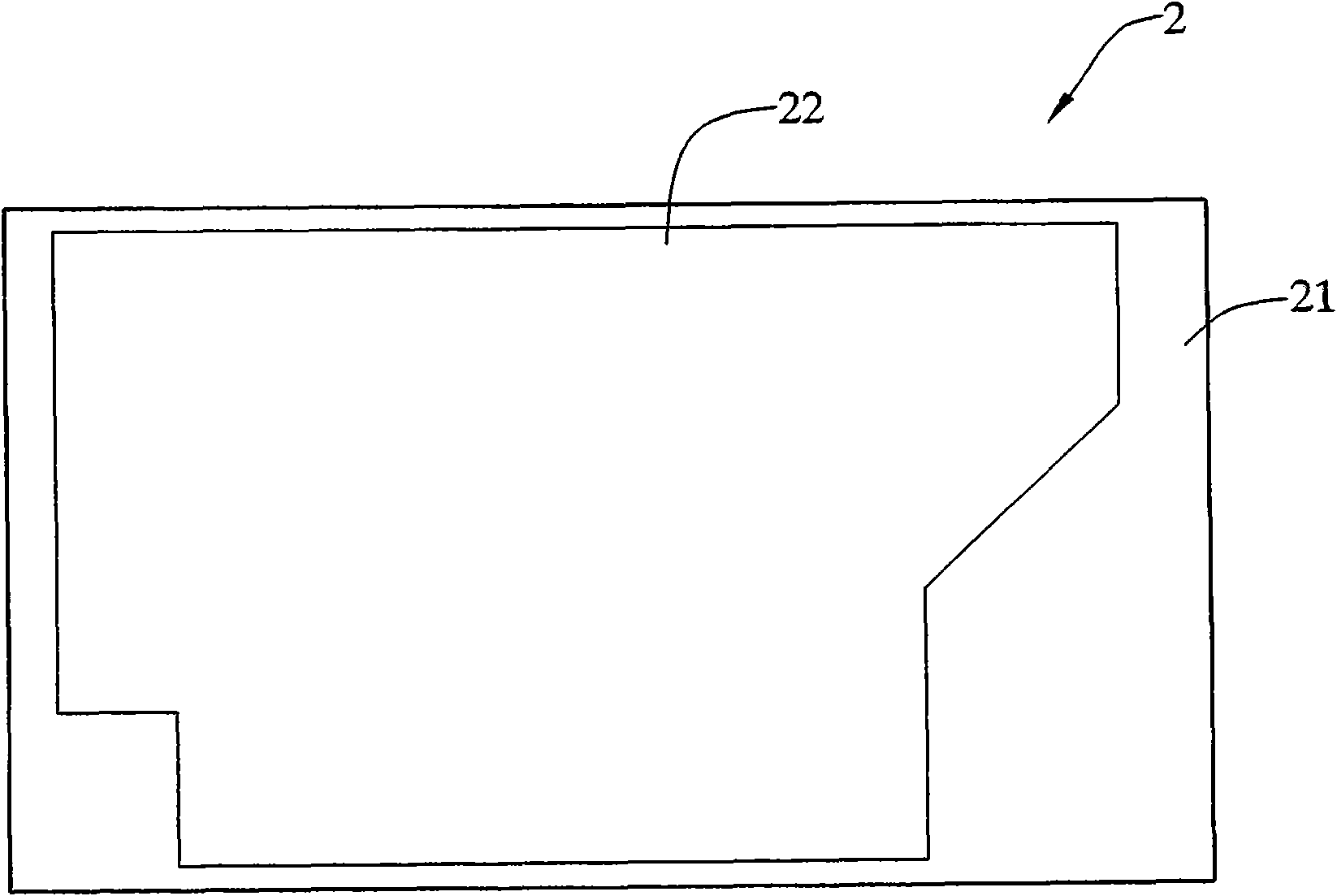

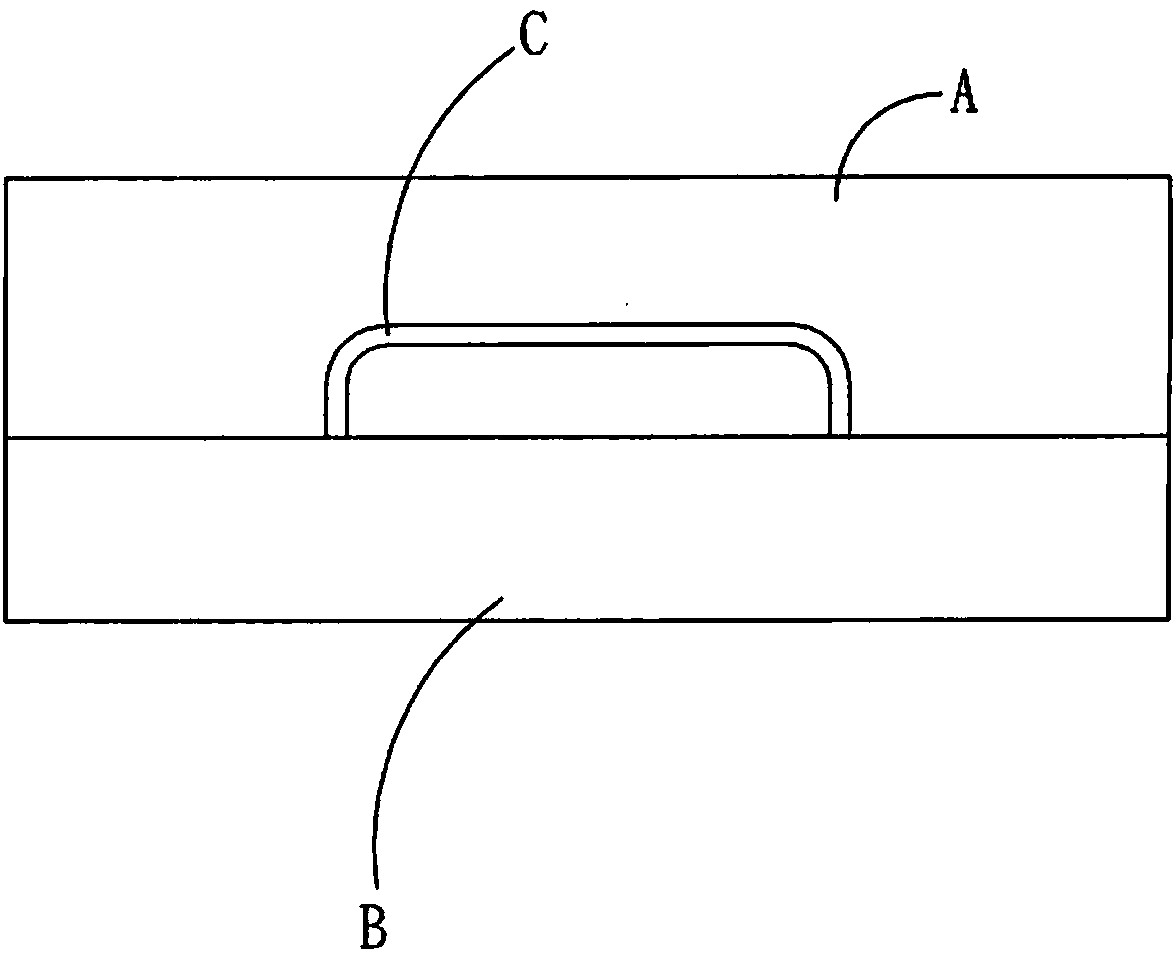

Shielding structure of electronic device and manufacturing method thereof

InactiveCN101374403ALow costHigh industrial utilization valueMagnetic/electric field screeningEngineeringElectromagnetic shielding

The invention relates to a shield structure of an electronic device, which includes: a circuit substrate; at least one function module, which is equipped on one side of the circuit substrate and is electrically connected on the circuit substrate; at least one first coating module layer, which is combined outside the function module; at least one shield layer, which is combined outside the first coating module layer; and one second coating module layer, which is combined outside the shield layer. Wherein, the shield layer is formed outside the first coating module layer by the spray finishing, printing and other modes for realizing the effect of electromagnetic shielding, thereby the shield layer can effectively reduce the production time and cost.

Owner:AZUREWAVE TEHNOLOGIES INC

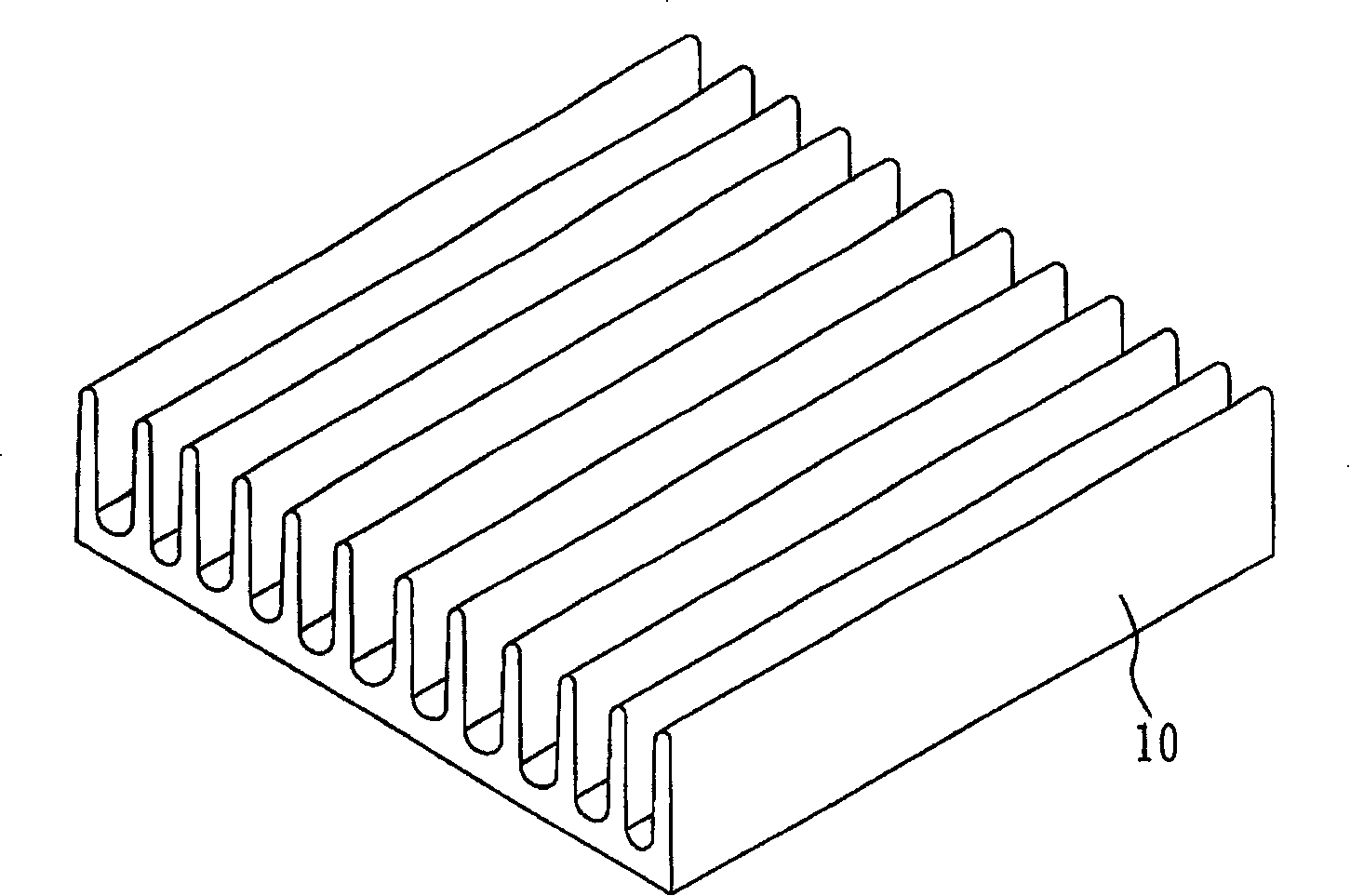

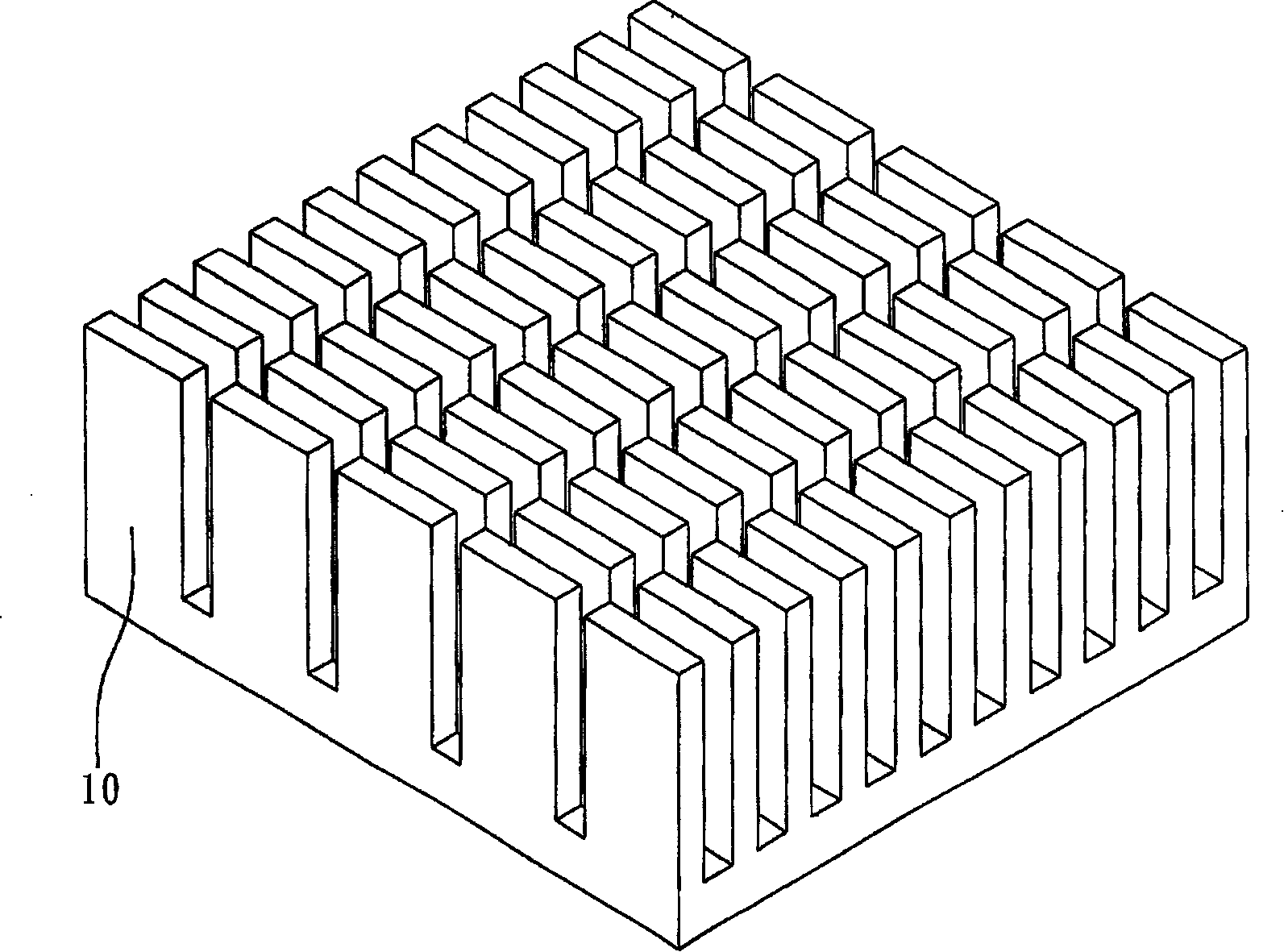

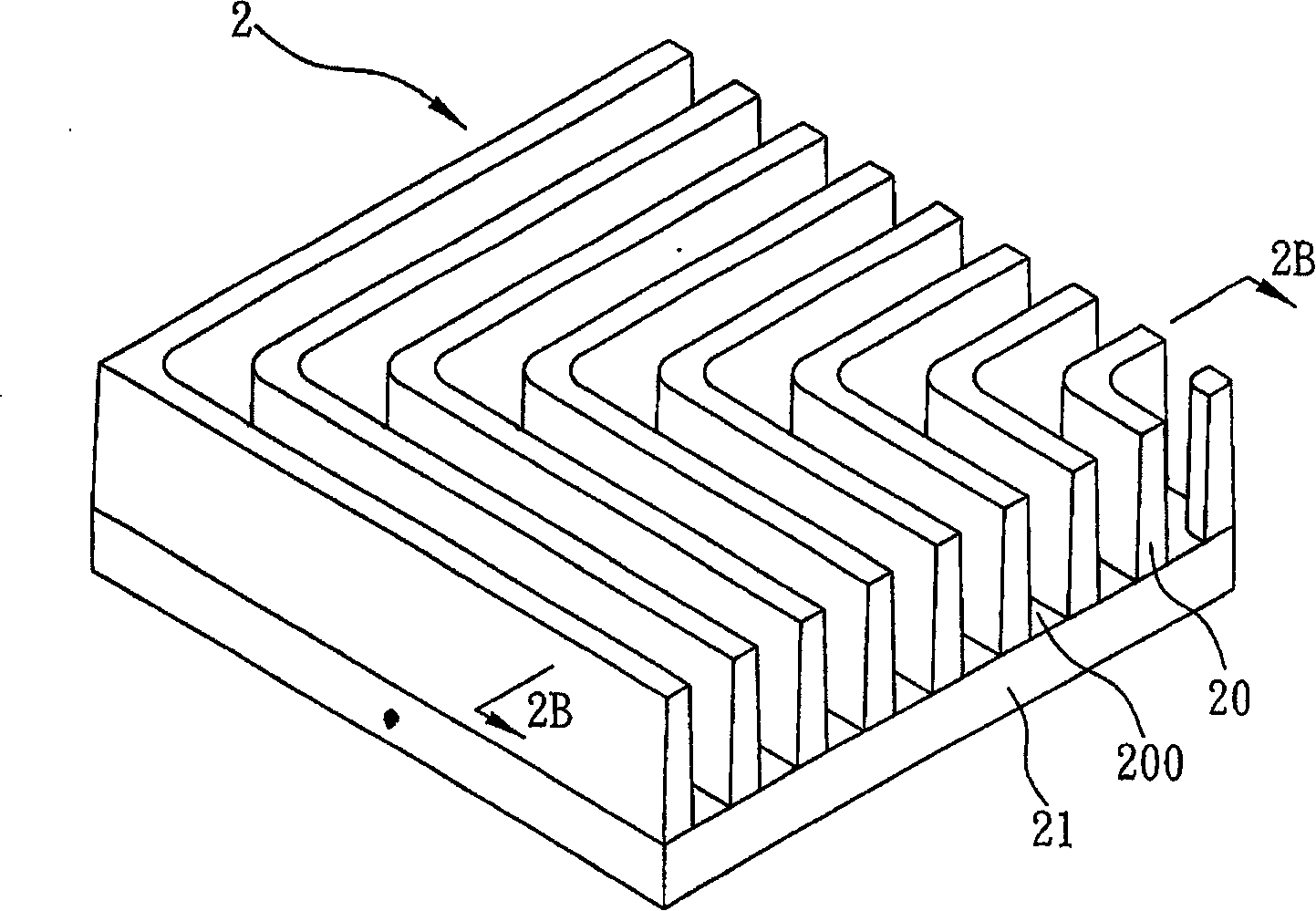

Heat radiation structure

InactiveCN101208000AImprove heat transfer coefficientReduce noiseDigital data processing detailsSemiconductor/solid-state device detailsSection planeComputer engineering

The invention discloses a heat dissipation structurewhich comprises a base seat and heat dissipation fins which are combined on the base seat and are arranged in an interval way; wherein, the heat dissipation fins present a folding line shape, the width of one end of each heat dissipation fin which is connected to the base seat is larger than that of the end which is away from the base seat; thus the heat dissipation fins are formed without enlarging the size and weight of the heat dissipation structure, wherein, the outline of each heat dissipation is f folding line-shaped (that is L-shaped) and the section plane thereof is narrow in upper side and wide in lower side (that is trapezoidal), thereby enhancing the destabilization between the air and the wall surfaces of the heat dissipation fins, and improving the heat transfer rate and heat-sinking rate.

Owner:INVENTEC CORP

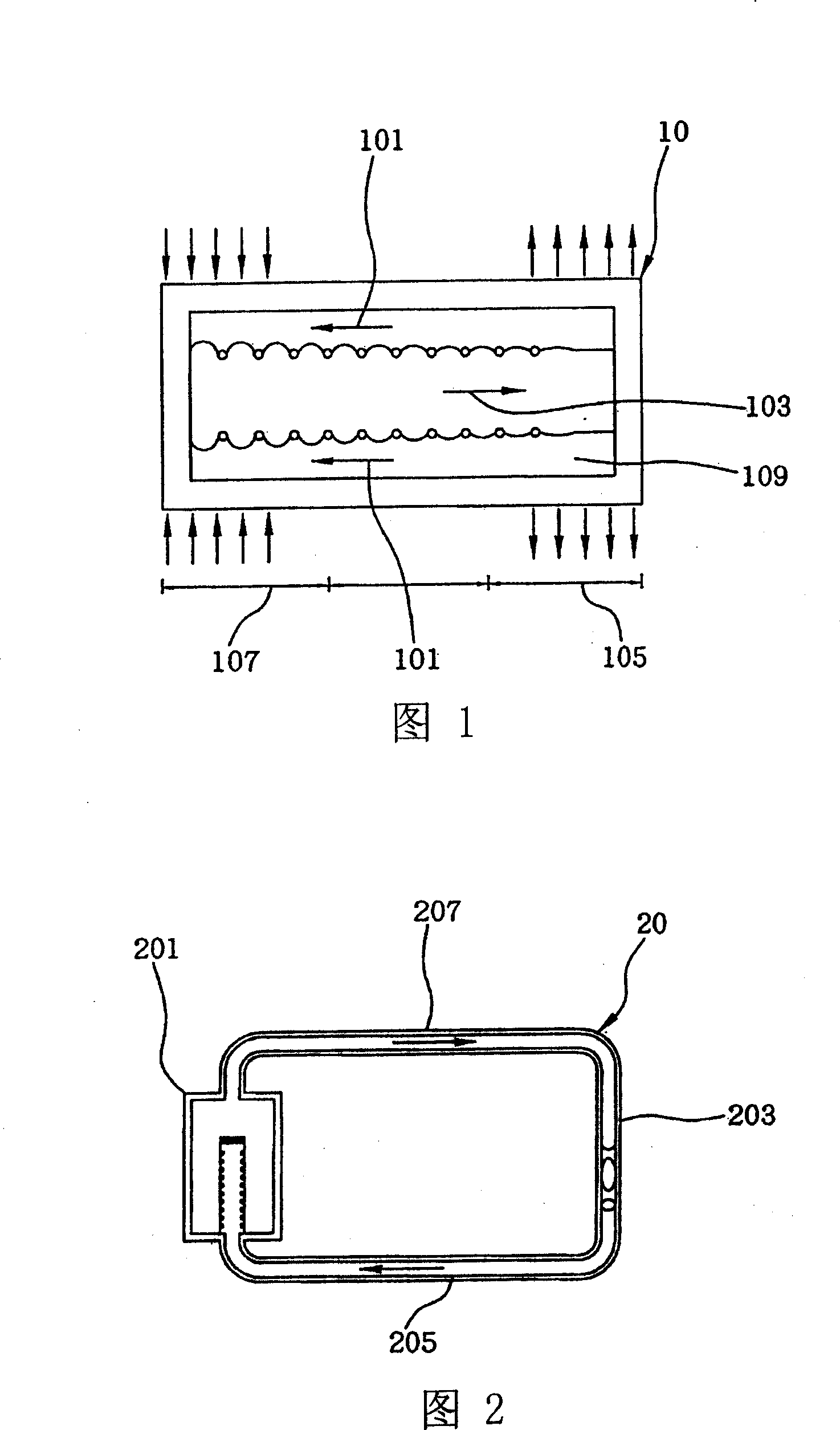

Active loop heat sink device with atomizer

InactiveCN101090625AImprove performanceReduce volumeSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

This invention discloses an active loop radiation device with an atomizer including: an evaporation cavity with a first container, a second container under the first room and an atomizer isolating the two containers, a condensation cavity with a third container connected to the second container and a capillary structure set at one side of the third one and connected to the first container and working fluid filled in the active loop radiation device, which can increase radiation efficiency and reduce heat impedance.

Owner:IND TECH RES INST

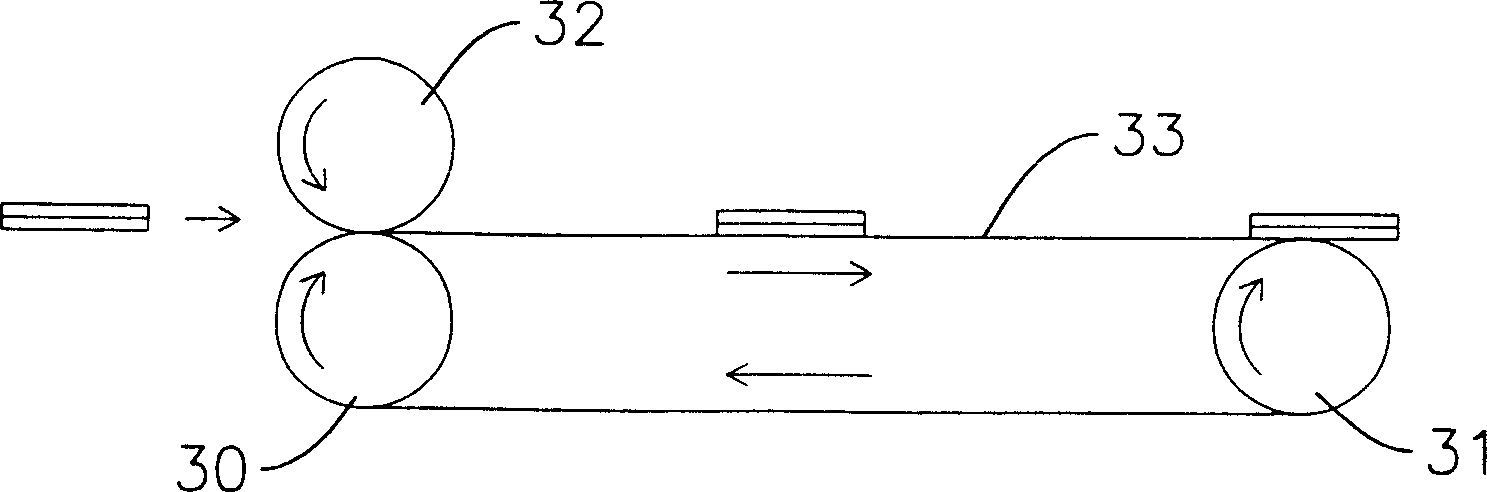

Water environmental protection laser film and its manufacturing method

InactiveCN1824501ANo problem of displacement and aliasingLow costPaper coatingLight effect designsEnvironmental resistanceEngineering

The present invention discloses a water environment-protecting laser film and its preparation method. It is mainly characterized by that on a paper which is printed or aluminium-plated paper the processes of complete or local water laser film-pressing coating; glazing surface mirror treatment and complete or local laser film-pressing operation are successively and directly made so as to form laser grain, so that it has no need of using plastic film as base material for making laser film, and can obtain optimum anti-false effect.

Owner:郑世鸿

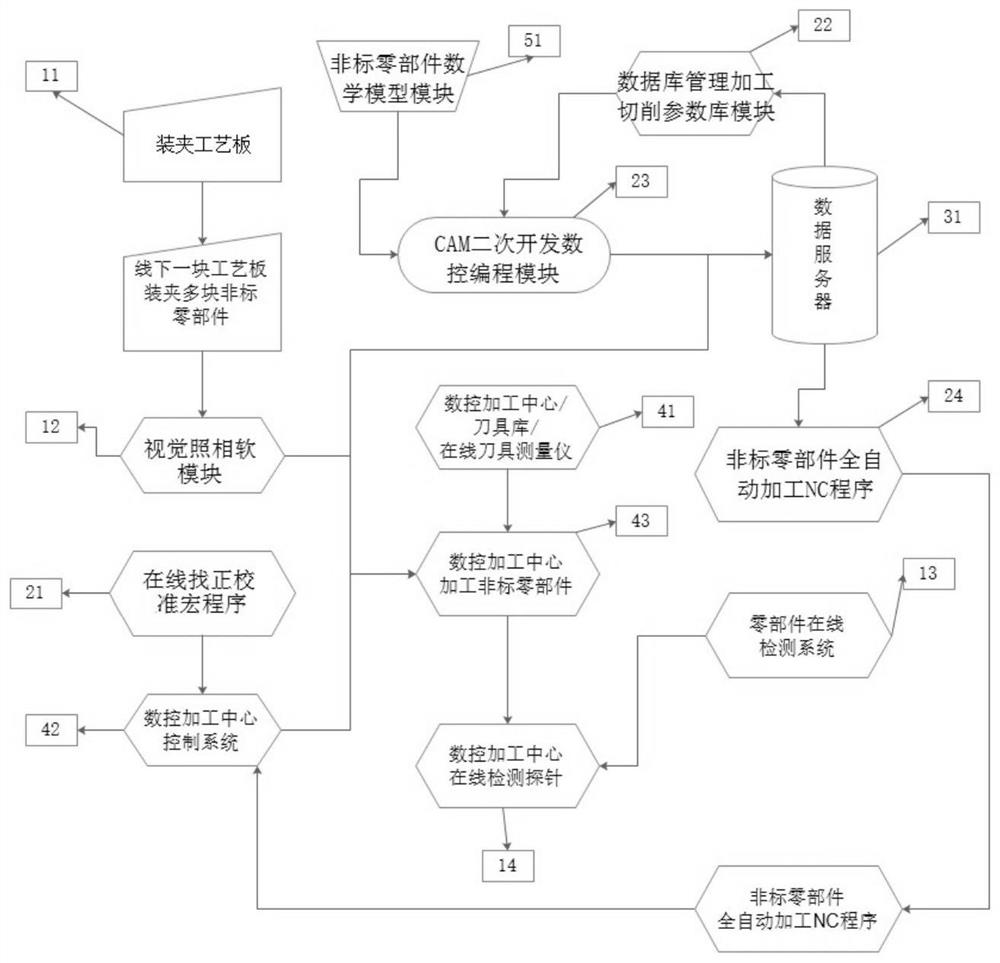

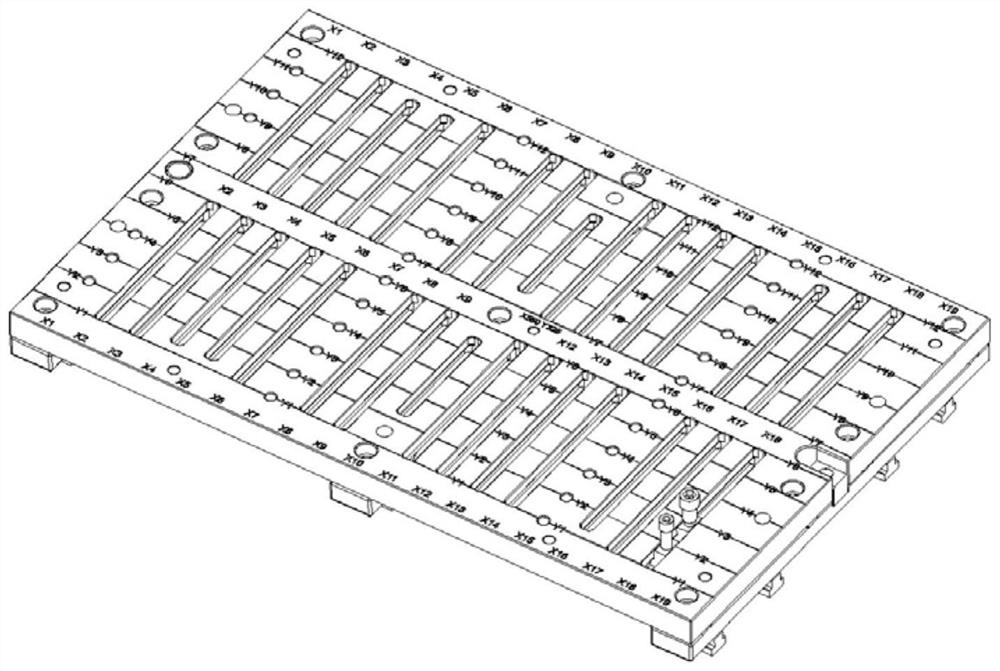

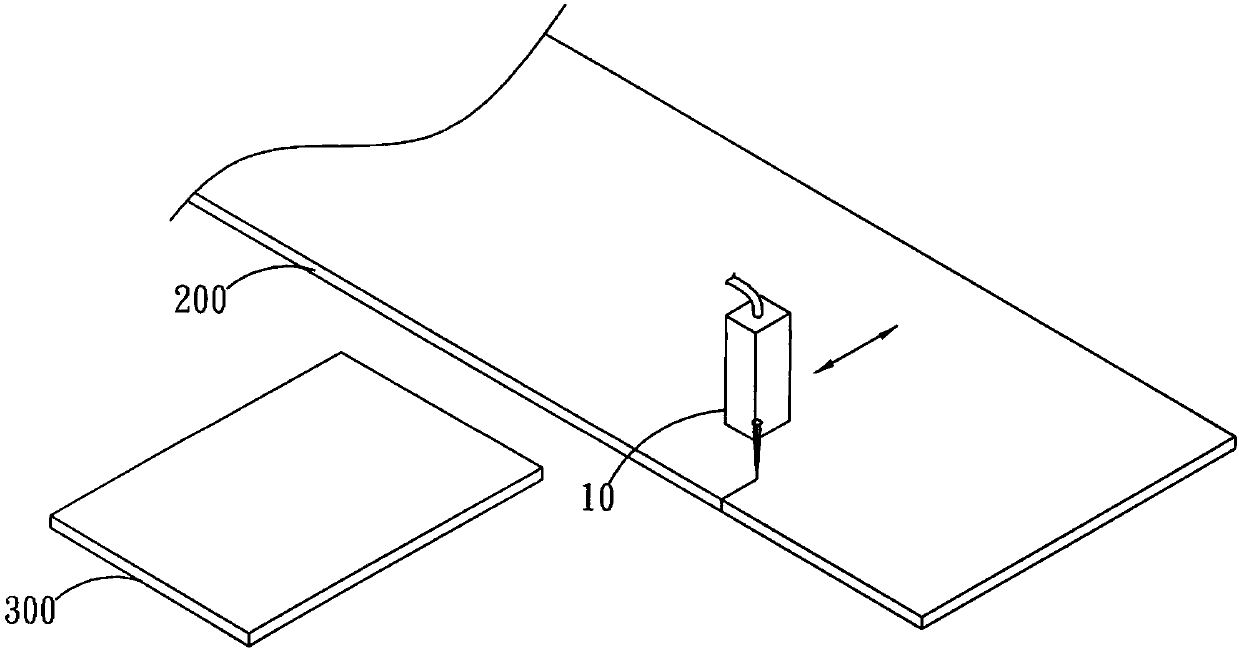

System and method for simultaneously machining non-standard parts based on numerical control machining center

ActiveCN111993161AGuaranteed utilityGuaranteed processing efficiencyProgramme controlComputer controlNumerical controlData acquisition

The invention provides a system and method for simultaneously machining non-standard parts based on a numerical control machining center. The system comprises a clamping process plate, a visual photographing soft module, a machining center online alignment and calibration module, a CAM secondary development numerical control programming module and a part online detection module. The clamping process plate is used for clamping a plurality of non-standard parts onto one process plate; the visual photographing soft module is used for carrying out workpiece primary alignment calibration on parts on a process plate through visual photographing, the machining center online alignment calibration module is used for detecting probe movement online, and the CAM secondary development numerical control programming module is used for compiling a non-standard part full-automatic machining NC program for a numerical control machining center. The system has the advantages that data of non-standard parts are collected and processed, it is guaranteed that the numerical control machining center can clamp multiple non-standard parts on one process plate at the same time for unattended full-automatic machining, the auxiliary time of the machining and manufacturing process of a numerical control machine is shortened, and the utilization rate of the numerical control machining center is guaranteed.

Owner:格致汽车科技股份有限公司

Multi-color photoelectric coating procedure and its products

The invention discloses a preparation process of a multicolor photoelectric coating and its product. The main process is to anti-white print cleaned substrate of needed painting by lithographic printing so that pictorial is covered in the printed oil and the printed substrate placed on the coating machine for coating. Single color graphics tablet is obtained after the substrate coating on with printing of oil cleaned. Multicolor designs are obtained in a single substrate by the circulation of duplication and printing, coating and cleaning printing oil.

Owner:BOHHEN OPTRONICS +1

Catalyst Electrode Layer and Method for Producing Same

InactiveUS20150017566A1Improve catalytic performanceIncreased durabilitySolid electrolytesOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkElastomer

A catalyst electrode layer includes an anion conductive elastomer in which a quaternary base type anion exchange group is introduced into at least a part of an aromatic ring of a copolymer of an aromatic vinyl compound, and a conjugated diene compound or a copolymer where a double bond of a main chain is partially or completely saturated by hydrogenating a conjugated diene part of the copolymer, and in which at least a part of the quaternary base type anion exchange group forms a cross-linked structure; and an electrode catalyst.

Owner:TOKUYAMA CORP

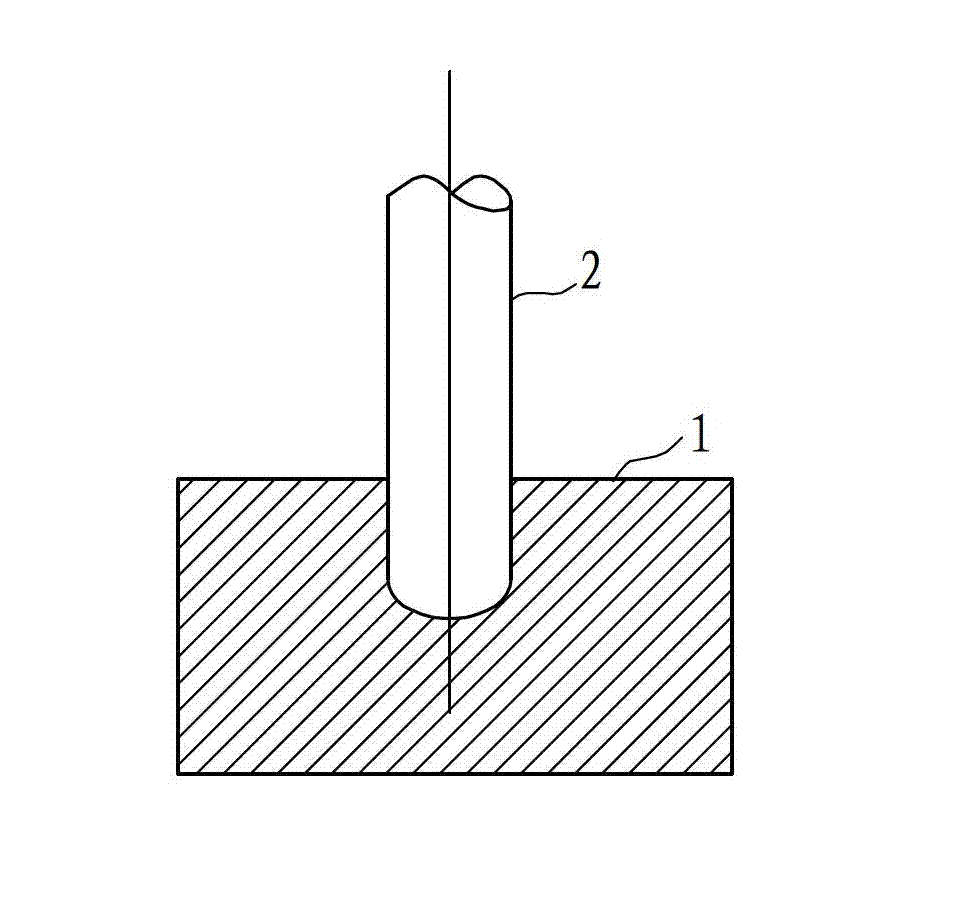

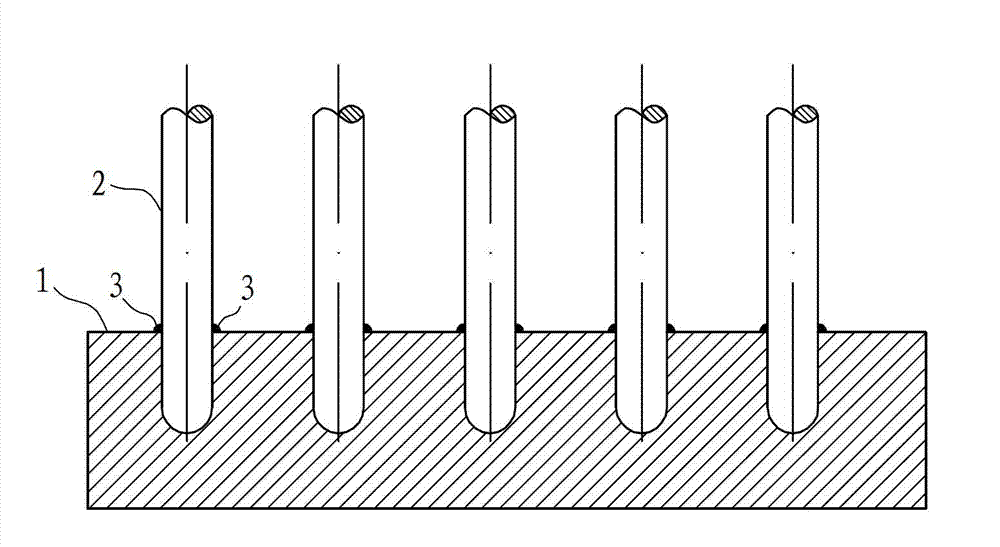

Lead-free high-frequency brazing method for deformed zinc alloy grafting structure

InactiveCN102886579AShort liquefaction processReduce the degree of oxidationWelding/cutting media/materialsWelding/soldering/cutting articlesZinc alloysFiller metal

The invention discloses a lead-free high-frequency brazing method for a deformed zinc alloy grafting structure. The lead-free high-frequency brazing method is characterized by comprising the following steps of: a, inspection process: inspecting a weldment and a brazing filler metal; b, treatment process before assembling: using abrasive paper to grind a brazing part, and using acetone to clean the brazing part; c, assembling process: inserting a zinc alloy bar in an inserting hole, keeping the zinc alloy bar in an upright state and inserting the zinc alloy bar to the bottom, annularly sleeving the the brazing filler metal at a part to be brazed, and coating a brazing flux at a brazing seam; d, high-frequency sensing brazing process: adjusting specification parameters according to the type of a brazing machine to weld; and e, treatment process after brazing: timely using clear water to clean residuals at the brazing seam. Compared with the existing technology, the lead-free high-frequency brazing method has the advantages that: the lead-free brazing filler metal is used so that the working condition is greatly improved, the lead-free high-frequency brazing of the deformed zinc alloy is achieved by the the steps of assembling before brazing, the adjustment of the high-frequency sensing brazing process parameters and the treatment after brazing, the obtained brazing seam is full and smooth, and the connection strength is improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

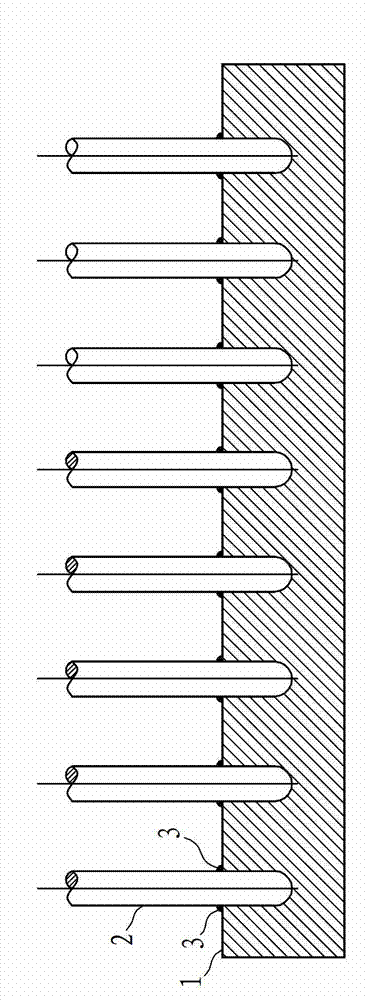

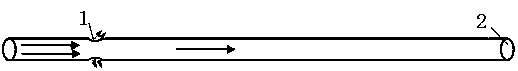

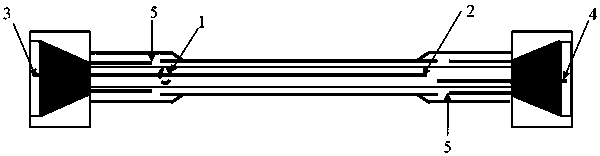

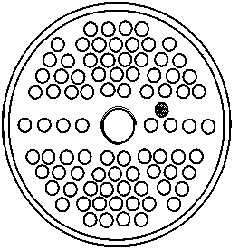

Air inlet pipe structure for dry air dehumidification and implementation method thereof

PendingCN108589530AEliminate turbulenceImprove dehumidification efficiencyBridge structural detailsInlet pressureMechanical engineering

The invention discloses an air inlet pipe structure for dry air dehumidification and an implementation method thereof. A plurality of air outlets are formed in the pouring-anchorage face of an upper anchorage device on a pulling cable, and an air outlet port of the air inlet pipe extends to close to the pouring-anchorage face of a lower anchorage device on the pulling cable. In this way, the dry air dehumidification effect of the pulling cable, especially a long pulling cable is effectively improved. The defect of the pulling cable dry air dehumidification system is effectively overcome; the pulling cable dehumidification efficiency is improved; air inlet pressure is reduced; energy source is saved; and the industrial utility value is achieved.

Owner:FASTEN HONGSHENG GRP CO LTD

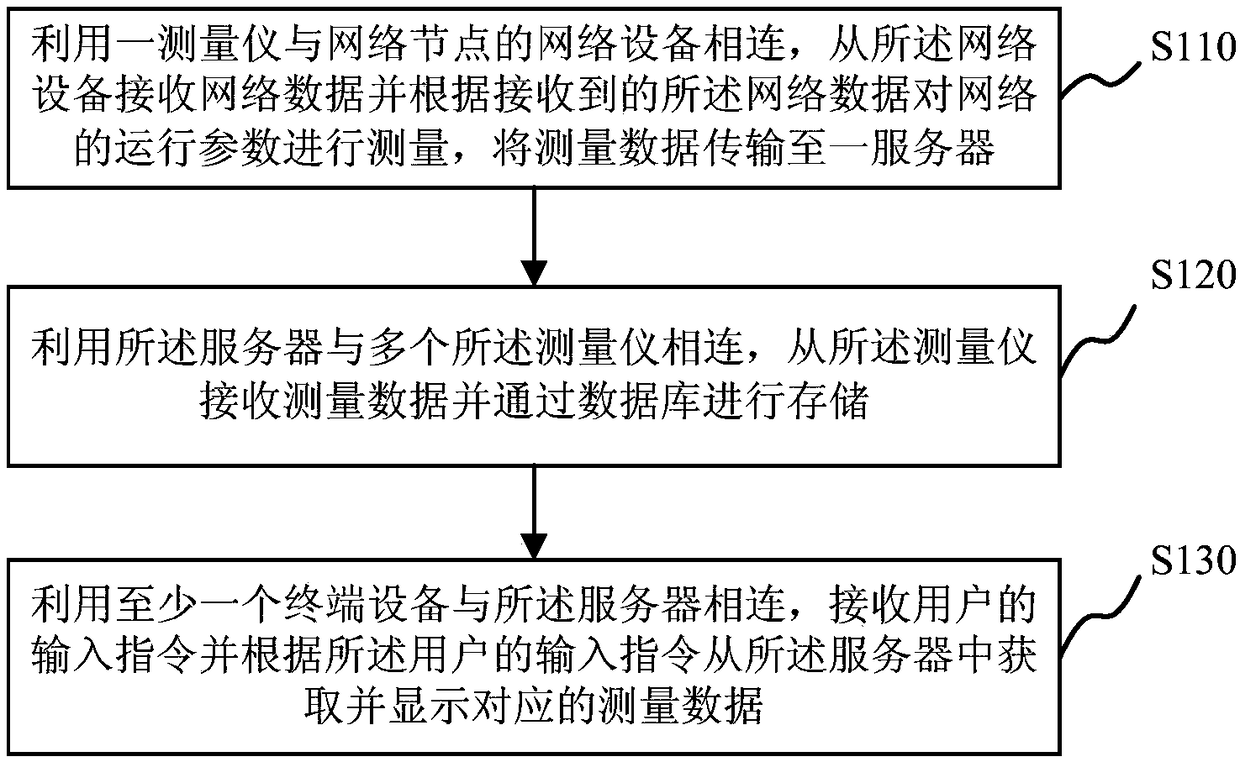

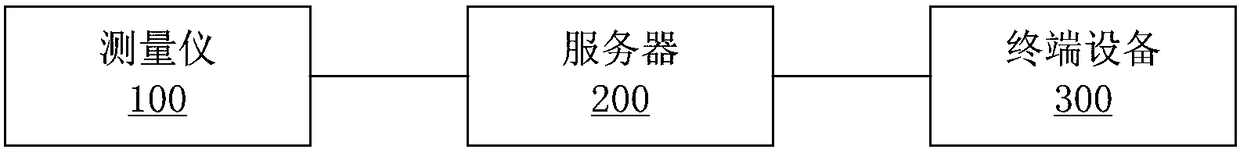

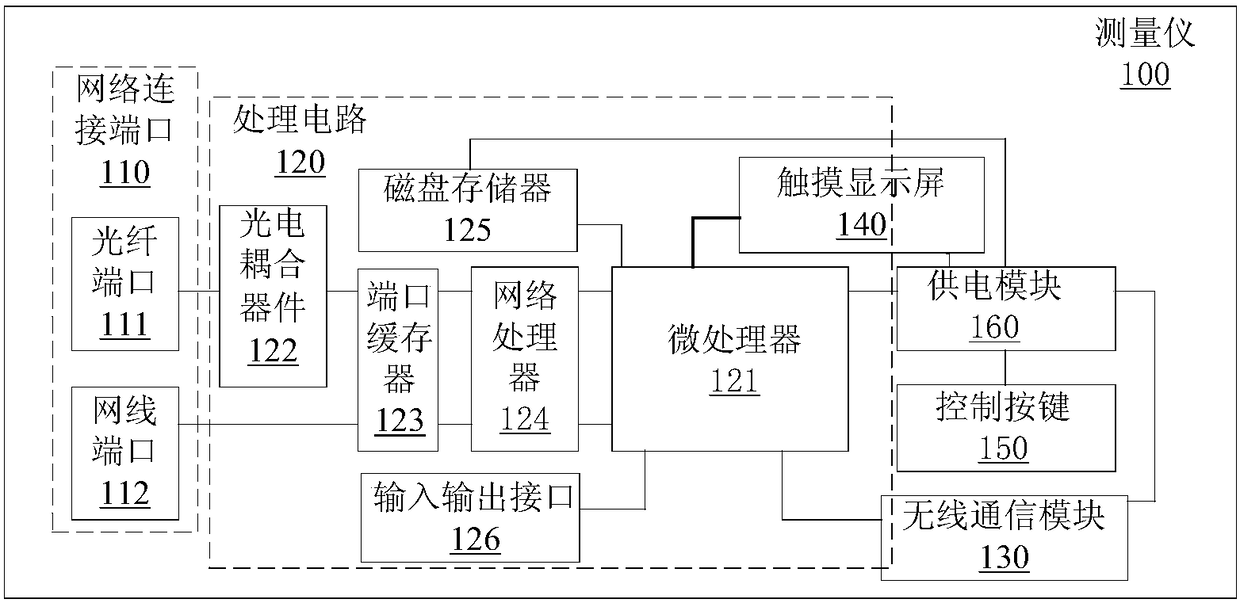

Measuring instrument, intelligent network instrument system and intelligent network test method

PendingCN108199929ARealize the use of networkingEasy to useTransmission systemsData switching networksIntelligent NetworkMeasuring instrument

The invention provides a measuring instrument, an intelligent network instrument system and an intelligent network test method. The intelligent network instrument system comprises at least one measuring instrument; a server connected with the plurality of measuring instruments, and used for receiving measured data from the measuring instrument and storing the same via a database; and at least onepiece of terminal equipment connected with the server, and used for receiving an input command of a user, acquiring the corresponding measured data from the server according to the input command of the user and displaying the same. According to the intelligent network instrument system provided by the invention, the measuring instrument in a network is connected with the terminal equipment and theserver, so that data in the measuring instrument is sent to the server and the data can be checked via the terminal equipment, the usage is convenient, the application of multi-user networking is achieved at any time, and the measured data is displayed, recorded and dynamically monitored in real time.

Owner:SHANGHAI INFORMATION NETWORK

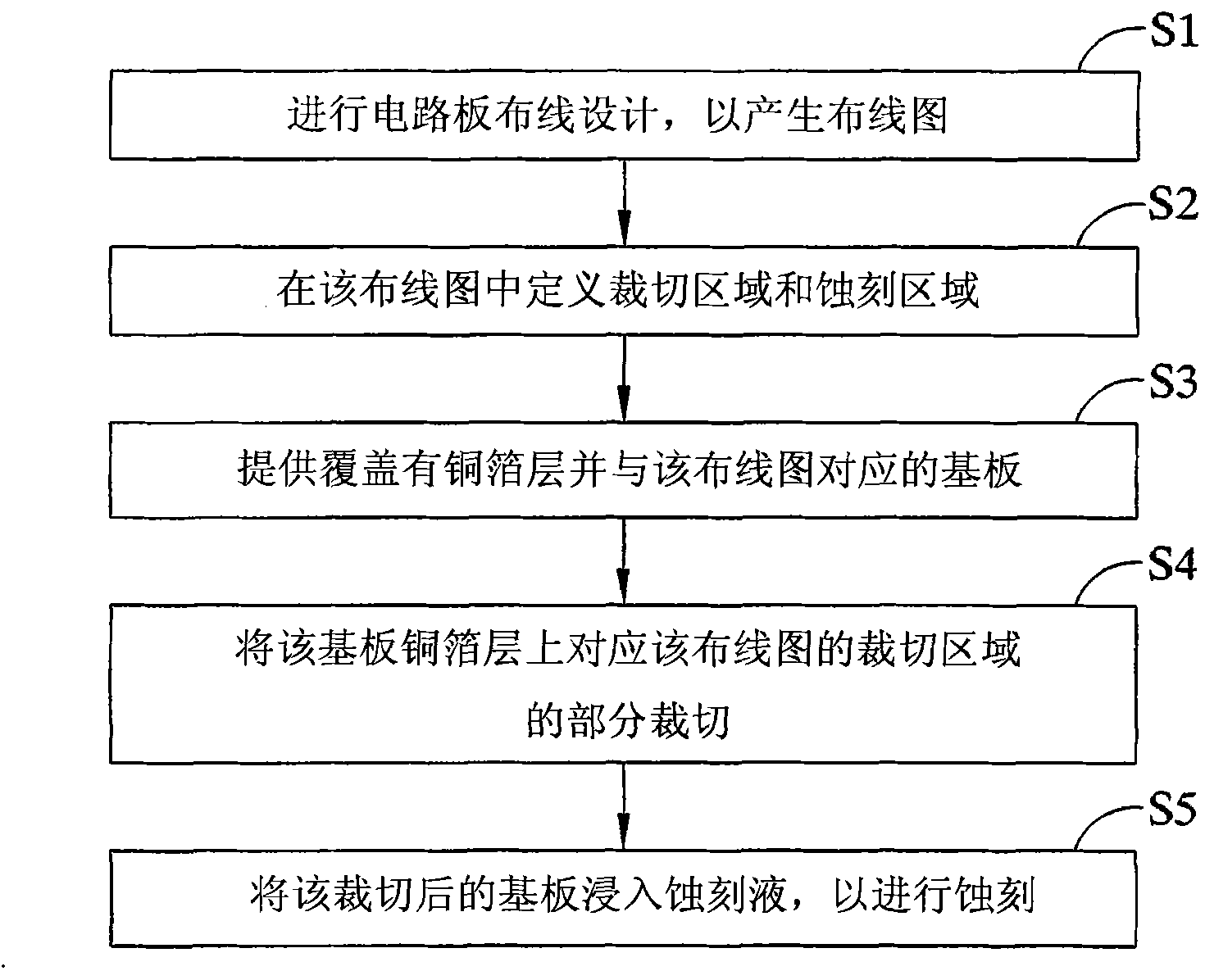

Method for manufacturing printed circuit board (PCB)

InactiveCN102083274AReduce the use effectReduce etch timeConductive material chemical/electrolytical removalManufacturing cost reductionCopper foil

The invention provides a method for manufacturing a printed circuit board (PCB). The method comprises the following steps: firstly carrying out PCB wiring design to generate a wiring pattern; defining a cropping area and an etching area in the wiring pattern; then providing a substrate corresponding to the wiring pattern, wherein the substrate is covered by a copper foil layer; cropping the part corresponding to the cropping area in the wiring pattern, of the copper foil layer on the substrate; and finally soaking the cropped substrate into an etchant for etching, and forming a wiring circuit on the copper foil layer on the substrate, so the method has the following beneficial effects: the copper foil layer part dispensing with wiring, on the substrate can be cropped before etching so as to reduce the usage amount of the etchant for etching the copper foils and the time required for etching and conduce to recycling the waste copper foils, thus reducing the environmental pollution caused by manufacturing the PCB and achieving the effects of lowering the manufacturing cost, and the like.

Owner:INVENTEC CORP

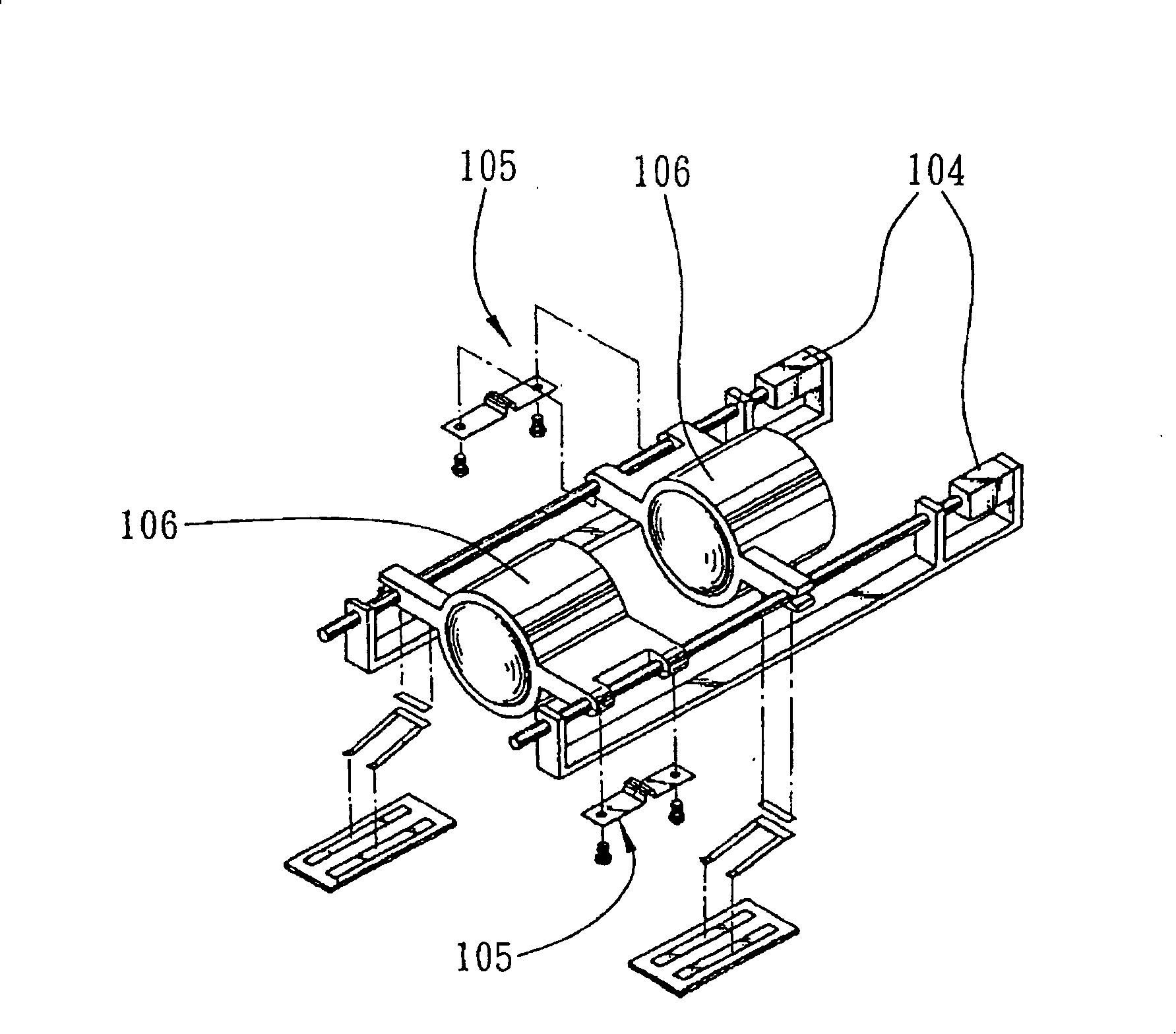

Production of micro-connector and its terminal shape

ActiveCN1897362ASolve problems such as poor contactIncrease contact resistanceEngagement/disengagement of coupling partsContact member manufacturingManufacturing cost reductionRelationship - Father

A minisize connector and the method of the terminal shape, the minisize connector includes: the base, the covering piece and the inserting piece, the base combine with the covering piece as the mother end, the inserting piece inserts between the base and the covering piece as the father end, reduces the distance of the terminal and the size of the whole body, provides the effects that are the low inserting force, the low static actuating force effect and the fixing inserting piece. The invention is: the anti-electromagnetic interference, the adjustable terminal impedance, the low cost.

Owner:IND TECH RES INST

Glass panel 3D curved surface non-contact processing system and method

InactiveCN109678332ASmall sizeReduced service lifeGlass reforming apparatusGlass severing apparatusTemperature controlEngineering

The invention discloses a glass panel 3D curved surface non-contact processing system and method. The non-contact processing system comprises at least one movable radiation heat source cutting device,a taking device, a fixing jig with a temperature adjusting function and with a fixing part arranged at the top, and a movable photo-thermal source processing device capable of controlling the temperature, wherein the radiation heat source cutting devices are used for cutting a glass panel with radiation heat sources to form a planar glass panel, the taking device is used for placing the planar glass panel on the fixing part of the fixing jig, the photo-thermal source processing device moves to the position above the fixing jig and then carries out non-contact and temperature-controlled heating on four peripheral predetermined heating portions on the upper, lower, left and right sides of the planar glass panel, and thus the four peripheral portions of the planar glass panel are softened and bend and droop along the edges of the fixing part so as to be shaped; then 3D curved glass is formed after the fixing jig carries out temperature-reduced shaping, and the photo-thermal source processing device is used for carrying out non-contact perforating and polishing on the 3D curved glass.

Owner:HI NANO MICROMACHINING SERVICES

Novel anti-shake pan-tilt for camera and anti-shake method

PendingCN113339663AImprove image qualityLarge anti-shake angleTelevision system detailsColor television detailsImaging qualityEngineering

The invention relates to a novel anti-shake pan-tilt for a camera and an anti-shake method. According to the technical key points, the novel anti-shake pan-tilt for the camera comprises a base, a protective shell, a frame unit, a vibrator unit, a pre-pressing unit and a signal position sensing unit, wherein the frame unit comprises an outer frame located at the inner side of the base and an inner frame arranged at the inner side of the outer frame; the vibrator unit comprises an annular piezoelectric ceramic vibrator assembly for enabling the outer frame to rotate along a first shaft relative to the base and a second annular piezoelectric ceramic vibrator assembly for enabling the inner frame to rotate along a second shaft relative to the outer frame; the first annular piezoelectric ceramic vibrator assembly is arranged between a retaining wall of the base and the side wall of the outer frame; the second annular piezoelectric ceramic vibrator assembly is arranged between the other side wall of the outer frame and the side wall of the inner frame; and the first shaft is perpendicular to the second shaft . According to the novel anti-shake pan-tilt for the camera, the problem that an existing anti-shake device for a pick-up lens cannot eliminate imaging blurring caused by shake and rotation of the lens in multiple directions, the anti-shake pan-tilt has the advantages of being high in response speed, high in load capacity, large in anti-shake angle, resistant to electromagnetic interference and the like, and the imaging quality is greatly improved.

Owner:辽宁中蓝光电科技有限公司

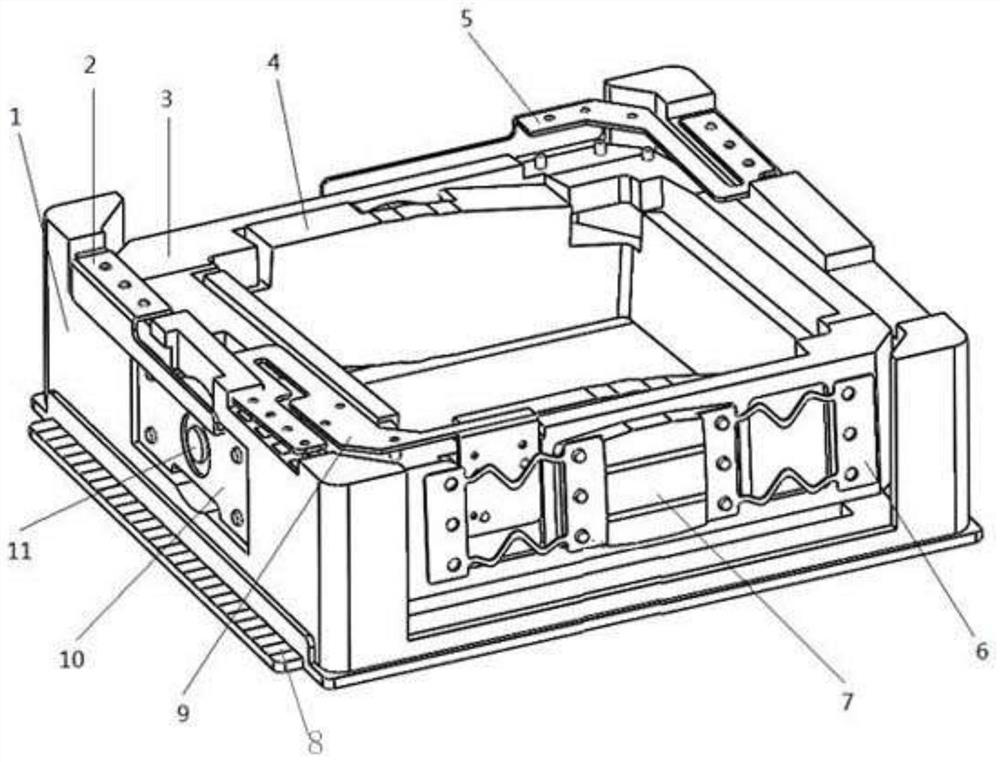

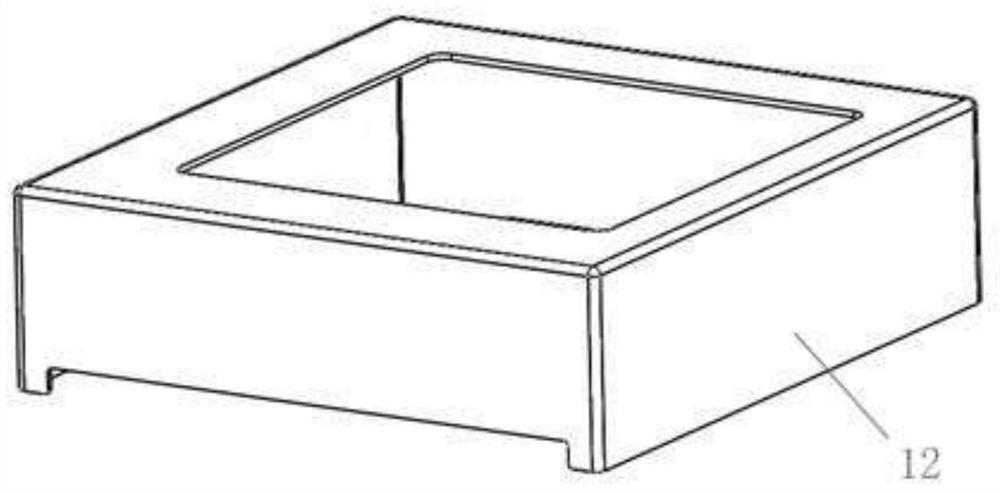

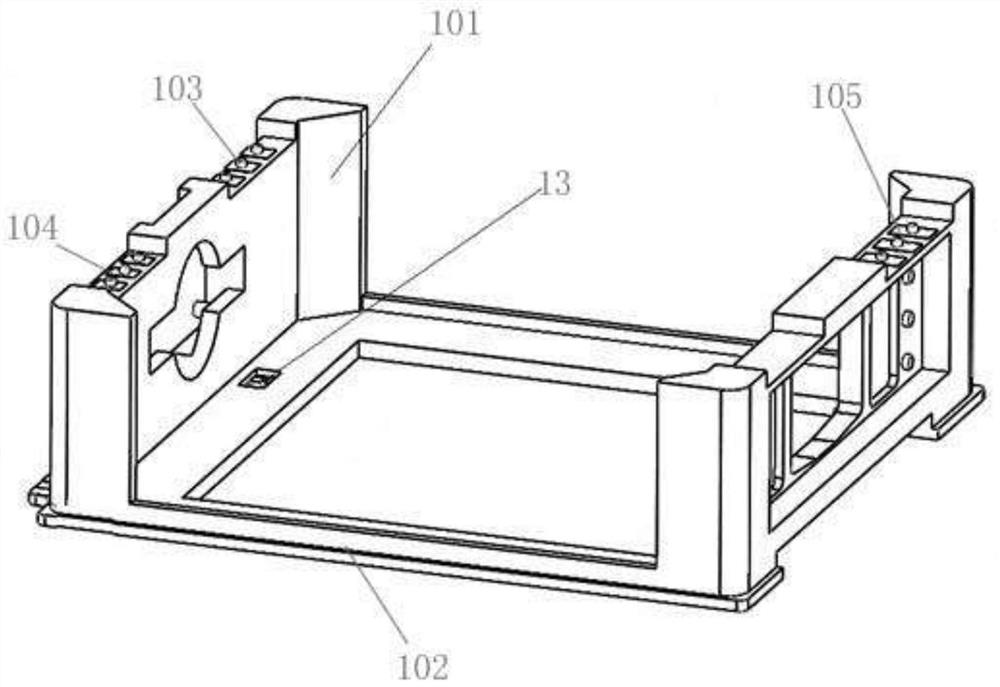

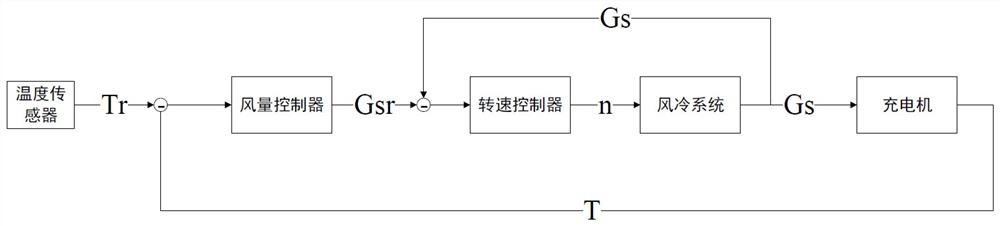

Variable-air-volume heat dissipation method for direct-current charger

ActiveCN111885894AReal-time control start and stopReal-time control speed adjustmentModifications for power electronicsModifications using gaseous coolantsVariable air volumeThermodynamics

Owner:SHIJIAZHUANG KE ELECTRIC

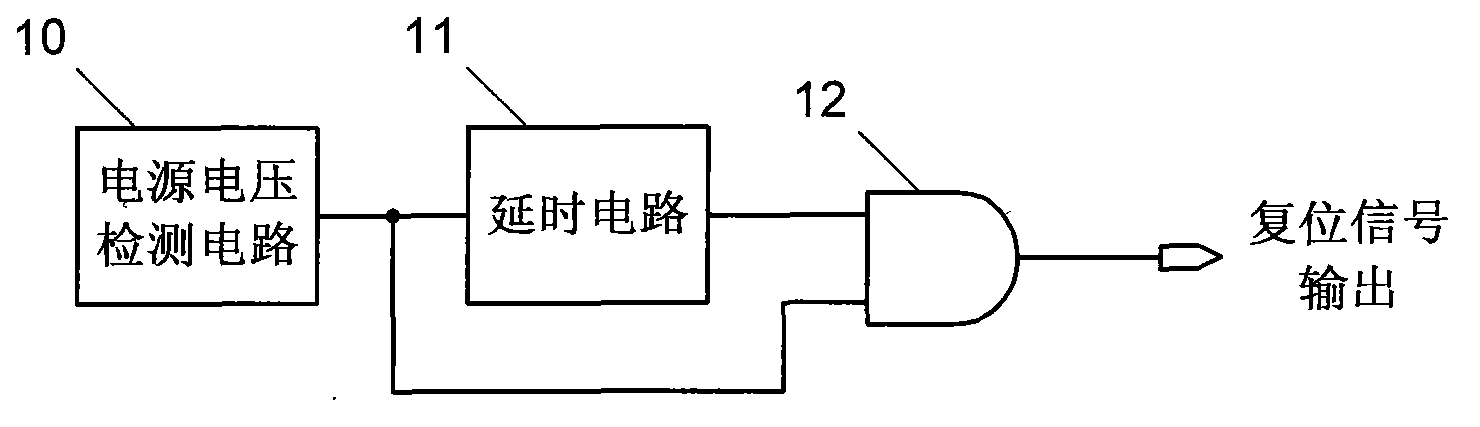

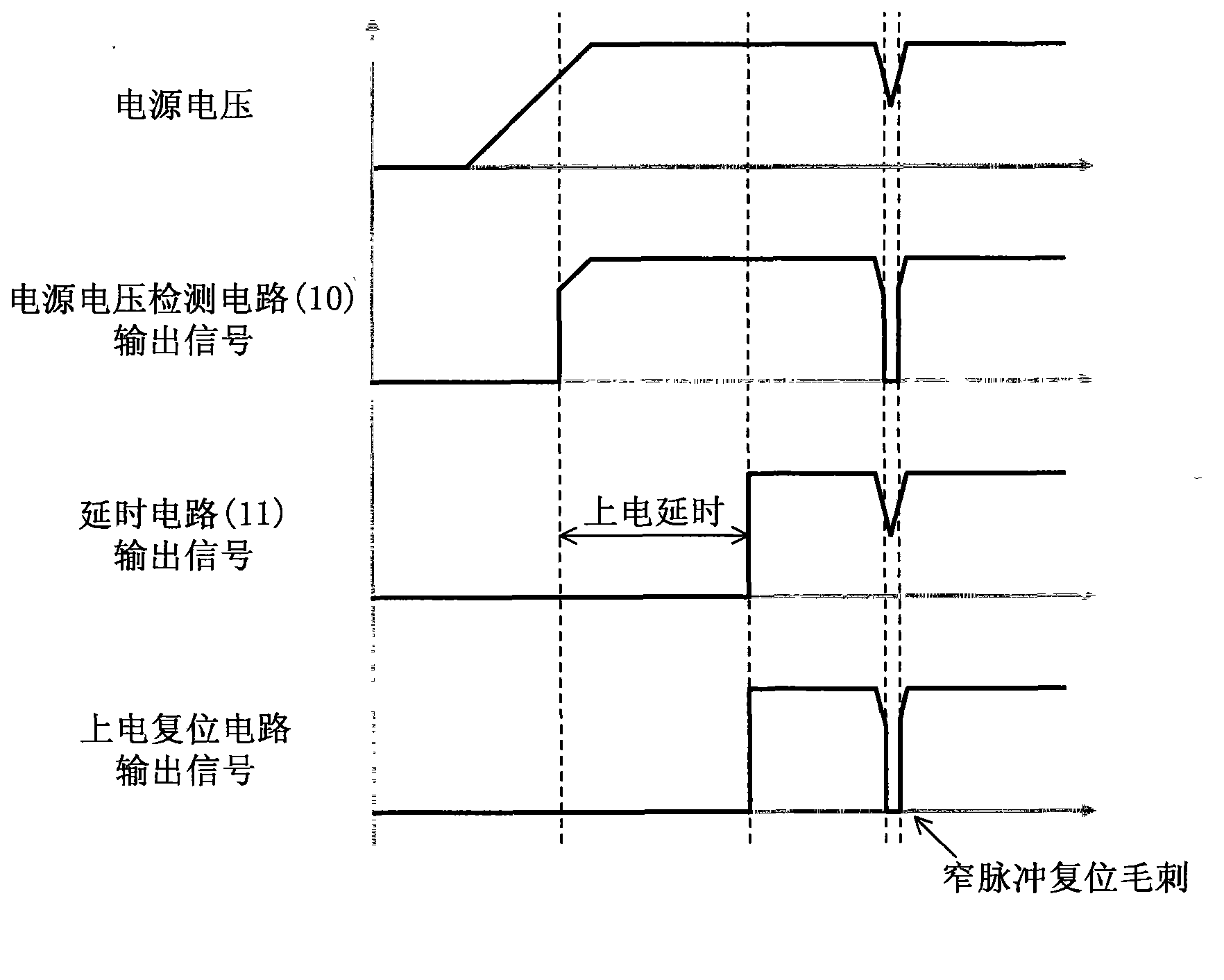

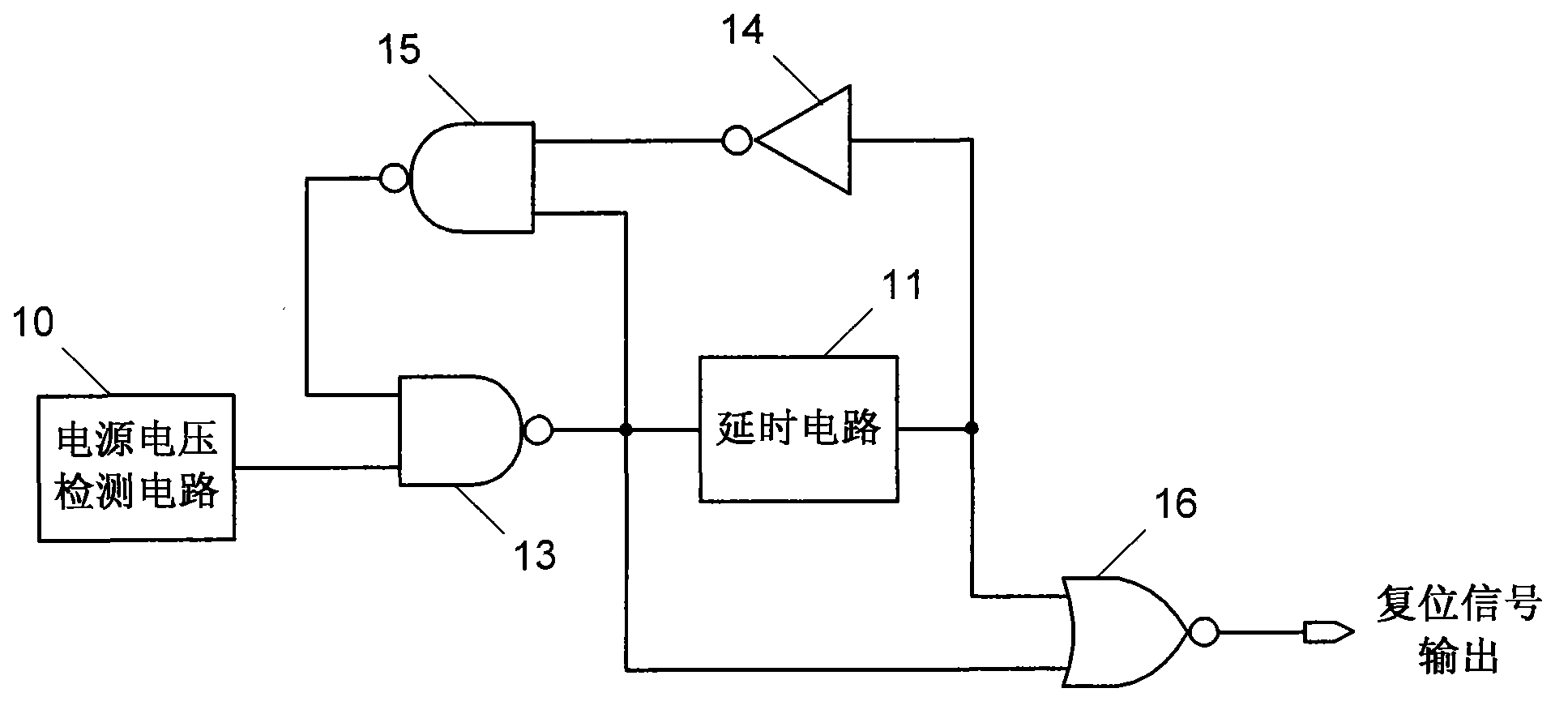

Power-on reset circuit with long power-on reset time-delay and short power-off response time

ActiveCN103916108AImprove reliabilityHigh industrial utilization valueElectronic switchingElectricityPower-on reset

The invention discloses a power-on reset circuit with long power-on reset time-delay and short power-off response time, and belongs to the technical field of integrated circuit design. The invention provides the new power-on reset circuit which is mainly formed by a power supply voltage detection circuit, a time-delay circuit and a few digital logic units. The circuit can realize long power-on reset time-delay and short power-off reset response time; meanwhile, in the power-off process, once the power supply voltage detection circuit generates a reset signal, the circuit is allowed to enter a reset locking state until the output of the time-delay circuit returns to a reset state, so that the circuit is guaranteed to still produce reset signals with enough delay time when the circuit is powered on again, and the problem that a conventional power-on reset circuit generates short pulse width reset signal burrs since the conventional power-on reset circuit is easy to be influenced by power supply fluctuation or the power-on again in the power-off process is solved.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

Gas detecting alarm system

InactiveCN101034073AImprove accuracyImprove securityMaterial analysis by electric/magnetic meansAlarmsEngineeringGas concentration

This invention relates to a kind of gas detection warning system; mostly include mainframe and sensing module that can freely connect this mainframe. This sensing module possesses parameter checking module which has parameter of adjusting and setting gas concentration and alert. this sensing module send corresponding signal to mainframe after detecting gas concentration; mainframe compare gas concentration with signal record value, while exceed default will give out corresponding caution, and by this to solve existing technical deletion.

Owner:林珠美

A kind of preparation method of modified montmorillonite adsorbent for treating zinc-containing wastewater

InactiveCN106423045BImprove adsorption capacityWide range of raw materialsOther chemical processesWater/sewage treatment by sorptionCentrifugationSorbent

A preparation method of a modified montmorillonite adsorbent for treating zinc-bearing wastewater includes the steps of (1), preparing montmorillonite turbid liquid, namely purifying montmorillonite into a fine powder material through pretreatment measurements and preparing the montmorillonite turbid liquid from the fine powder material and distilled water; (2), preparing an FN intercalator; (3), subjecting the FN intercalator to inorganic modification; (4), purifying FN intercalated montmorillonite; (5), preparing an SDS intercalator; (6), subjecting the SDS intercalator to organic modification; (7) preparing a PAM flocculant; (8), purifying SDS intercalated montmorillonite, dropwise adding the PAM flocculant into secondarily-modified montmorillonite turbid liquid obtained in the step (6), stirring evenly rapidly prior to high-speed centrifugation and filtration, washing filter residues with deionized water to be neutral, and drying at a low temperature so as to obtain purified SDS intercalated montmorillonite powder; (9), subjecting the SDS intercalated montmorillonite powder obtained in the step (8) to high-temperature roasting so as to obtain the modified montmorillonite adsorbent.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com