P type GaN cadmium-indium-oxygen transparent electrode and method for producing the same

A technology of transparent electrodes and transparent conductive films, applied in circuits, electrical components, laser parts, etc., can solve problems such as affecting the uniform current diffusion and thermal stability, reducing specific contact resistivity, and reducing the concentration of P-type GaN holes. , to achieve high industrial utilization value and improve the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

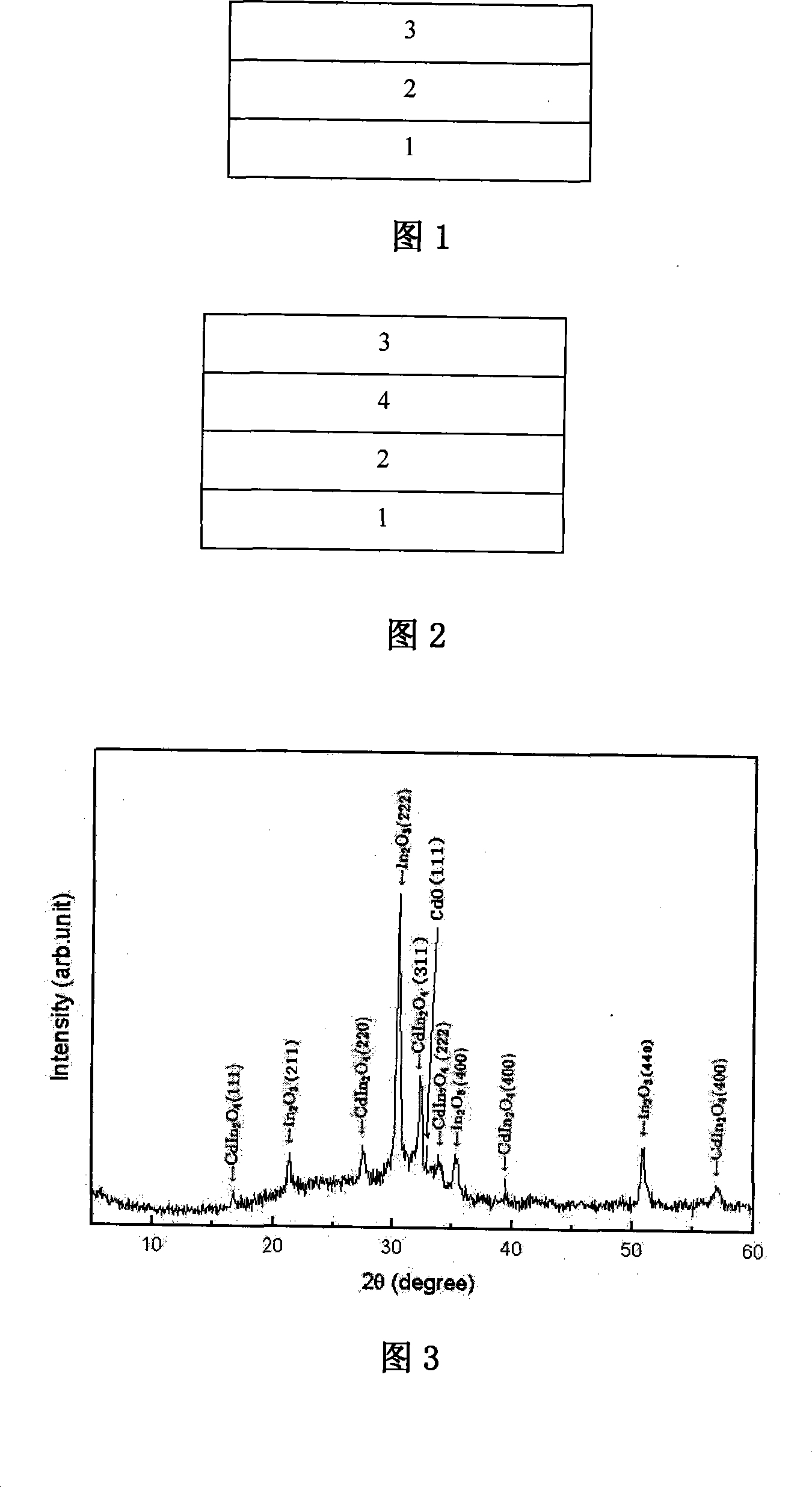

[0033] Embodiment 1: referring to accompanying drawing 1, a P-type GaN 1 has a first conductive layer 2 on the P-type GaN 1, and is characterized in that: a CIO transparent conductive film 3 is arranged on the first conductive layer 2, and this example is When the conductive layer only comprises the first conductive layer 2, the steps are as follows:

[0034] 1) P-type GaN 1 (carrier concentration 3.37×10 17 cm -3 , mobility 4.34cm 2 / V.s) Immerse in aqua regia solution for 3-5 minutes, and use acetone, alcohol and deionized water to vibrate ultrasonically for 5 minutes respectively (the purpose is to remove surface impurities and oxide layers to reduce the barrier height);

[0035]2) Blow dry the sample obtained in the previous step with nitrogen, immediately place it in an electron gun evaporation system, vacuumize it, and evaporate and deposit a metal Ni (ie, the first conductive layer 2) with a thickness of 5 nm on the P-type GaN 1. The process conditions are: high volt...

Embodiment 2

[0042] Embodiment 2: referring to accompanying drawing 1, accompanying drawing 2, this example is the situation of re-depositing a second conducting layer 4 between the first conducting layer 2 and the CIO transparent conducting film 3, and its steps are as follows:

[0043] 1) Immerse P-type GaN 1 in aqua regia solution for 3-5 minutes, and use acetone, alcohol and deionized water to ultrasonically oscillate for 5 minutes respectively (the purpose is to remove surface impurities and oxide layers to reduce the barrier height);

[0044] 2) Dry the sample obtained in the previous step with nitrogen, immediately place it in the electron gun evaporation system, vacuumize it, and evaporate and deposit metal Ni (ie, the first conductive layer 2) with a thickness of 5 nm on the P-type GaN 1, and then use The same method deposits a layer of 5nm thick gold Au (i.e. the second conductive layer 4), and its process conditions are: high voltage 6KV, beam current 155mA, working pressure: 2.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com