Glass panel 3D curved surface non-contact processing system and method

A processing system, non-contact technology, applied in glass forming, glass re-molding, glass manufacturing equipment and other directions, can solve the problems of glass sheet size error, high process cost, short mold service life, etc., to achieve accurate size, process Simple, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

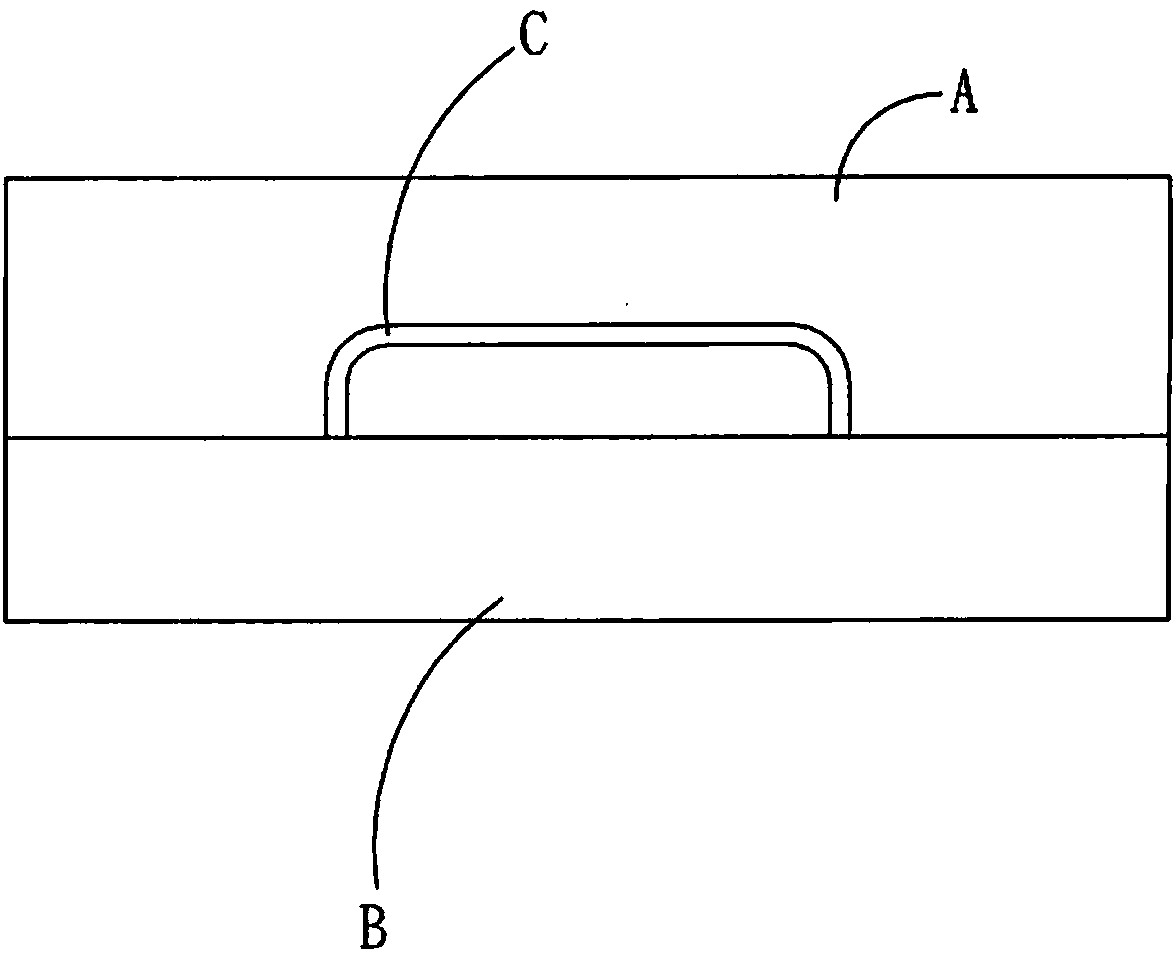

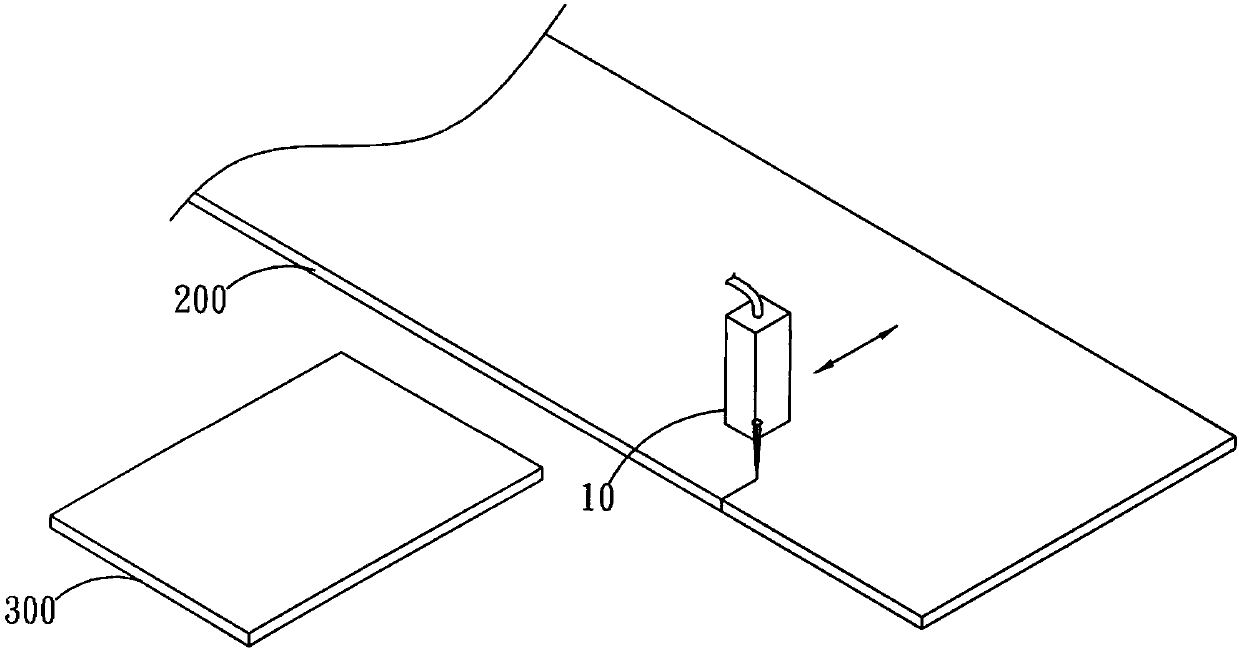

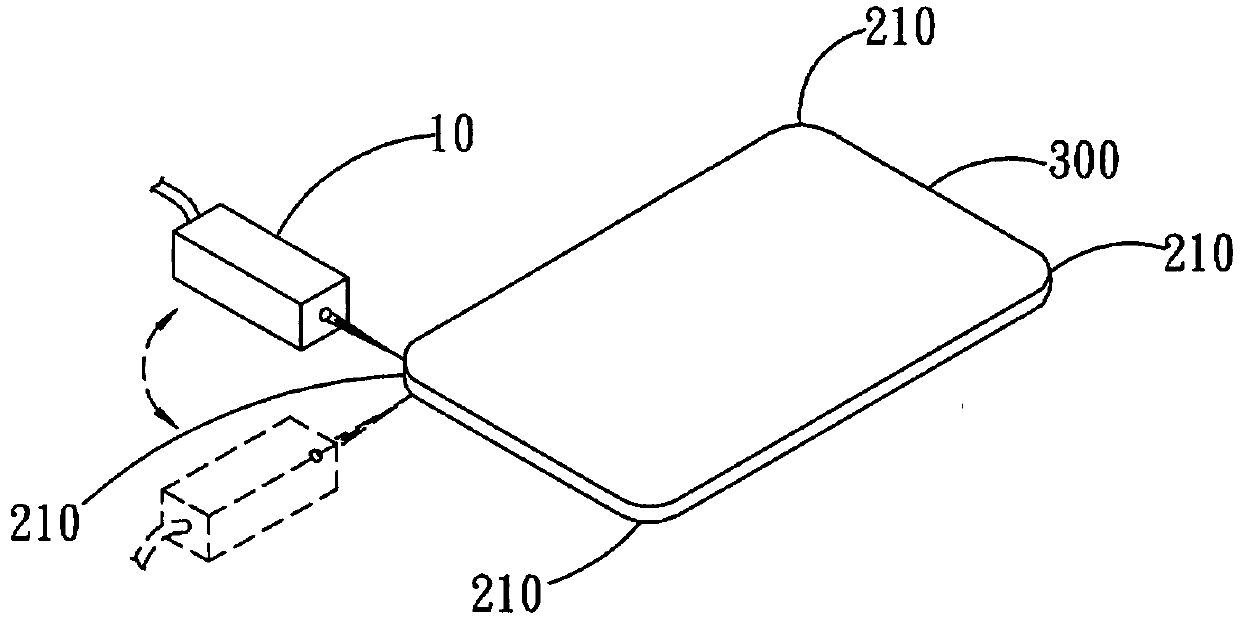

[0065] See first figure 2 and image 3 As shown, the glass plate 3D curved surface non-contact processing system 100 of the present invention includes at least one movable radiant heat source cutting device 10 for generating a radiant heat source for non-contact edge cutting of a glass plate 200 (such as figure 2 shown) and chamfer 210 (such as image 3 shown) cutting process to form a flat glass plate 300, the type of the radiant heat source cutting device 10 is not limited, it can be formed by an infrared cutter or a laser cutter, and the mobile platform of the radiant heat source cutting device 10 is not limited limited, it can be composed of a CNC three-axis processing platform or a multi-axis processing platform. The above-mentioned cutting and processing mode of the chamfer 210 does not image 3 Shown as limit.

[0066] please cooperate Figure 4 Shown is another embodiment of the radiant heat source cutting device 10 of the glass plate 3D curved surface non-contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com