Multi-color photoelectric coating procedure and its products

A photoelectric and coating technology, which is applied in the field of multi-color photoelectric coating process and its products, can solve problems such as poor light transmission, reduced process efficiency, and film shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

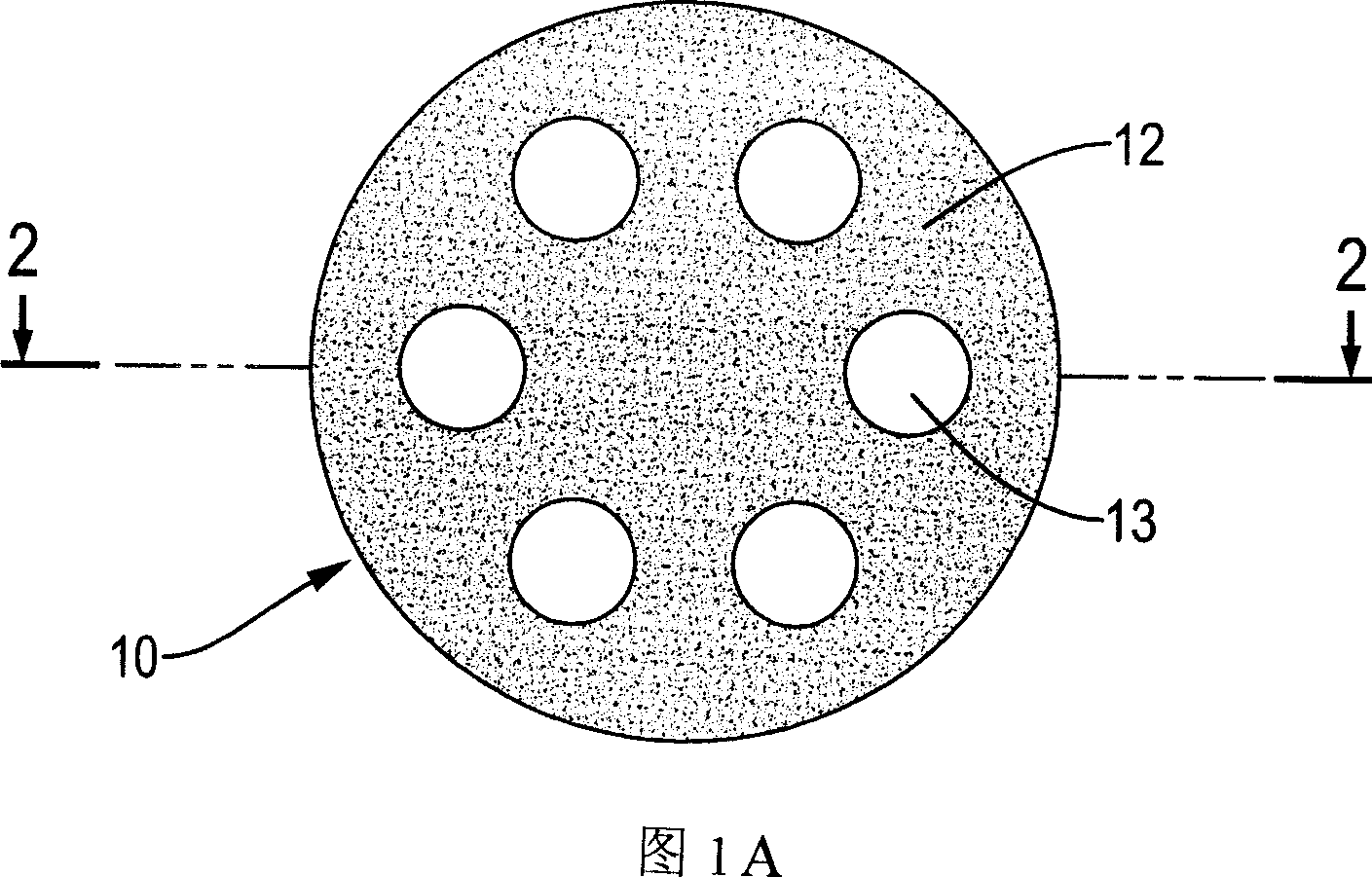

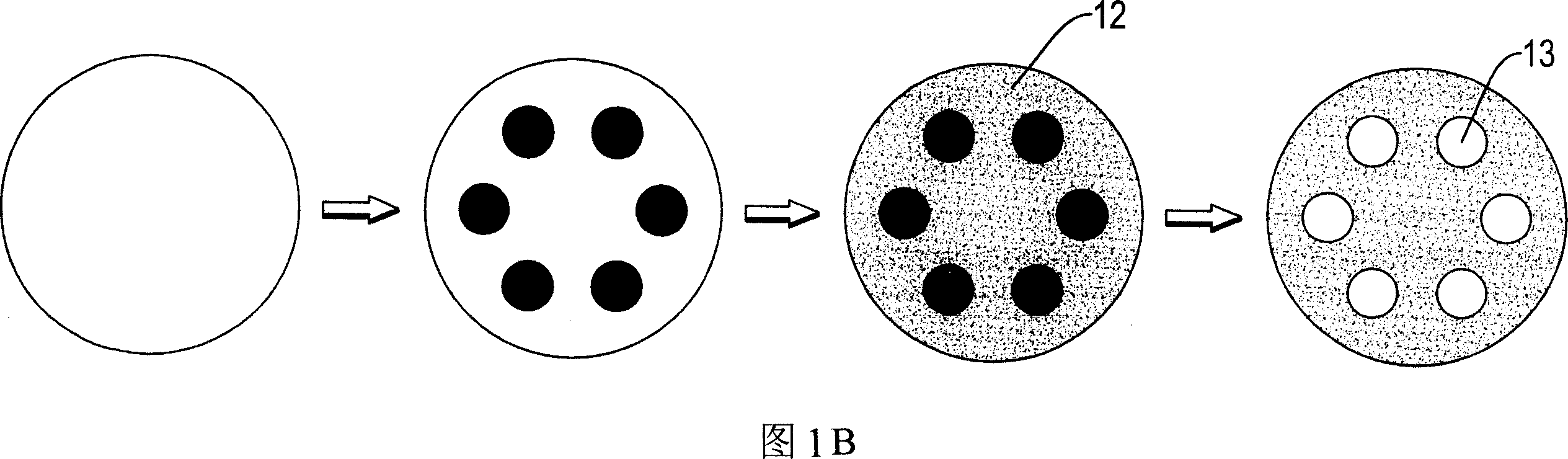

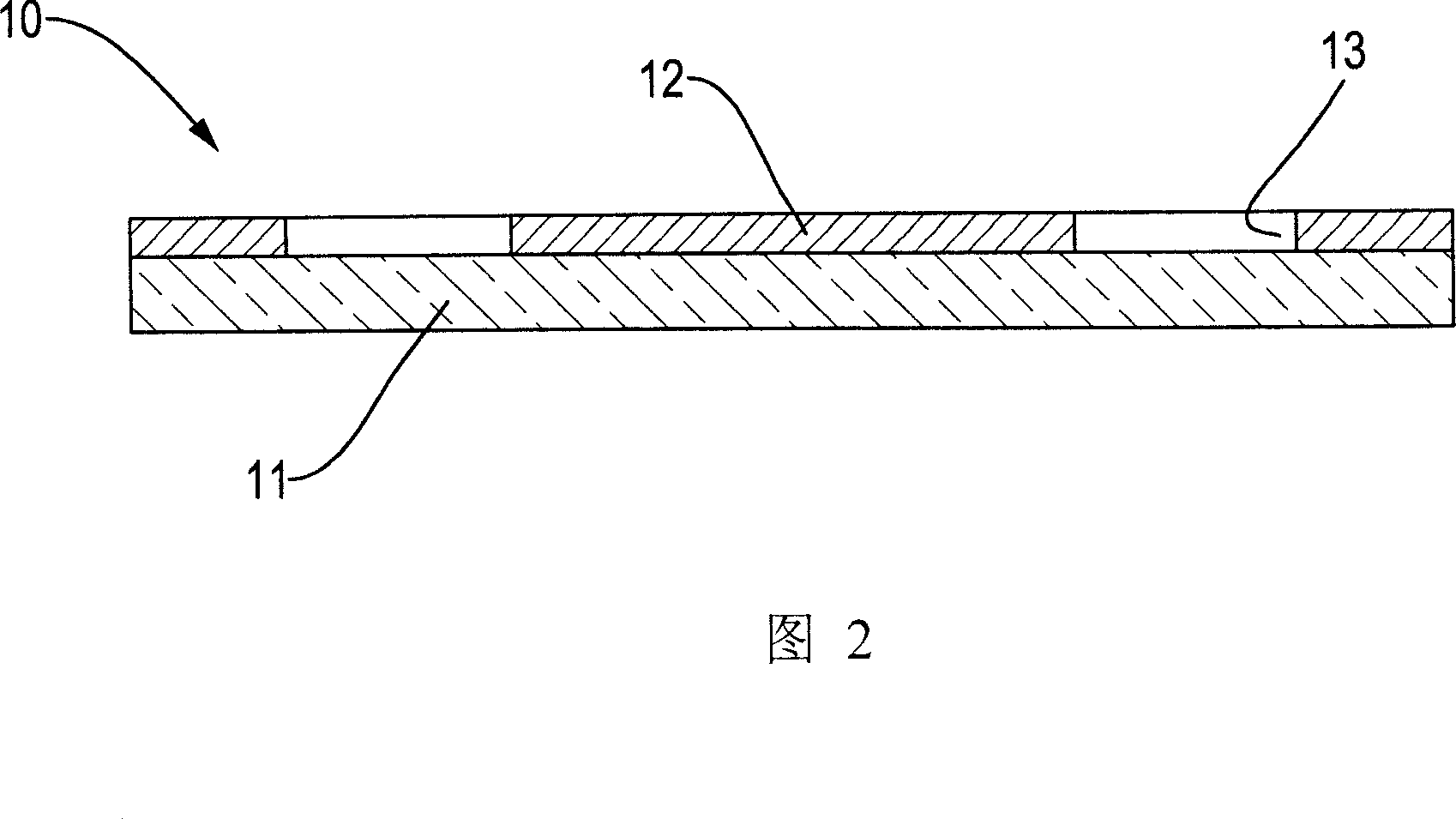

[0044] Embodiment one: the making of monochrome pattern sheet 10 (as shown in Figure 1A, Figure 1B and Figure 2)

[0045] Step 1: cleaning the base material 11 with ultrasonic waves.

[0046] Step 2: reverse-print the desired pattern 13 on the substrate 11 .

[0047] Step 3: coating the substrate 11 with the required color 12 (such as blue-green Cyan) by means of IAD coating.

[0048] Step 4: cleaning the printing oil printed on the substrate 11 .

Embodiment 2

[0049] Embodiment two: the making of multi-color pattern sheet 20 (as shown in Figure 3A, Figure 3B and Figure 4)

[0050] Step 1: cleaning the base material 21 with ultrasonic waves;

[0051] Step 2: Cover the positions on the substrate 21 where Magenta, Yellow and Red are to be formed with oil printing;

[0052] Step 3: Plating the desired color 22 such as cyan (Cyan) in the IAD way

[0053] Step 4: Clean the printing oil;

[0054] Step 5: Cover the positions on the substrate 21 where blue, cyan and magenta are to be formed with printing oil;

[0055] Step 6: Plating the required color 23 (such as yellow Yellow) in IAD way

[0056] Step 7: Clean the printing oil;

[0057] Step 8: Cover the position where yellow, cyan and green are to be formed on the substrate 21 with oil printing;

[0058] The ninth step: plate the desired color 24 (such as magenta Magenta) in the IAD manner;

[0059] Step 10: Clean the printing oil.

[0060] The GOBO film produced through the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com