Variable-air-volume heat dissipation method for direct-current charger

A heat dissipation method and a DC charging technology, which are applied in the modification of power electronics, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as the inability to dissipate heat from the charger, reduce the utilization rate of electric energy, and increase the operating burden of the charger. Achieve considerable industrial utilization value, reduce energy consumption, and improve the effect of electric energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

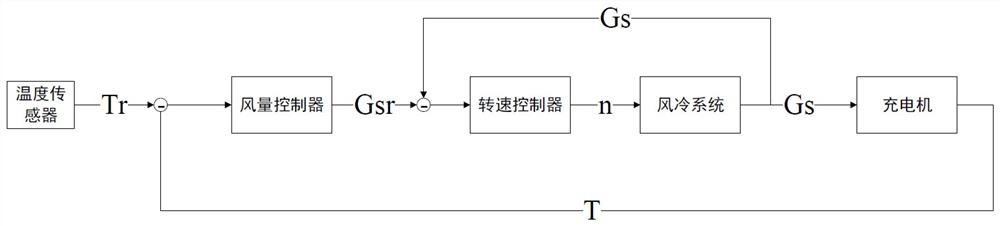

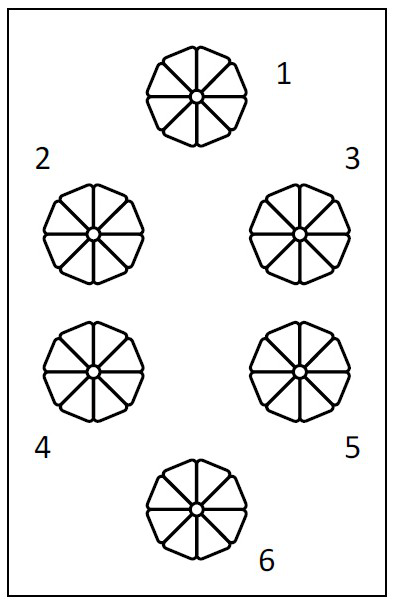

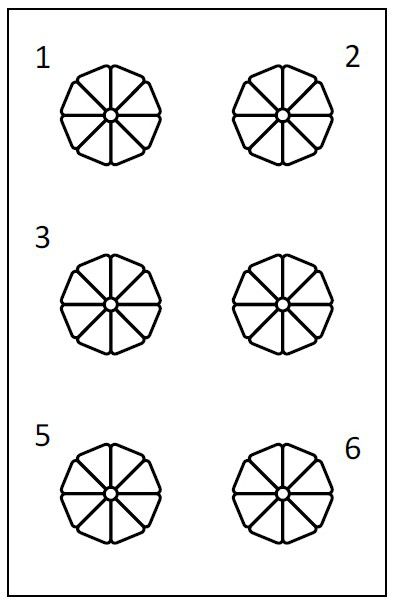

[0018] See attached figure 1 , the variable air volume heat dissipation method for a DC charger of the present invention is based on a variable air volume heat dissipation system, and the variable air volume heat dissipation system includes an air volume controller arranged in the DC charger, a temperature sensor connected to the air volume controller, a speed controller, and a An air-cooling system composed of multiple groups of cooling fans connected to the speed controller. The air volume controller can estimate the current preset air volume of the charger according to the temperature deviation feedback. The speed controller controls the start and stop of the fan according to the air volume deviation feedback, and adjusts the fan speed to change the internal air supply volume of the charger. One or more temperature sensors are provided for detecting the temperature of each position.

[0019] The method of the present invention establishes the temperature model and the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com