Remote Intelligent Digital Flameproof Submersible Slurry Pump

A slurry pump and explosion-proof technology, which is applied in the field of electric drive submersible devices, can solve the problems of slurry pump blockage, abnormal operation, motor blockage, etc., prevent blockage and dry grinding, solve manual inconvenience, The effect of ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

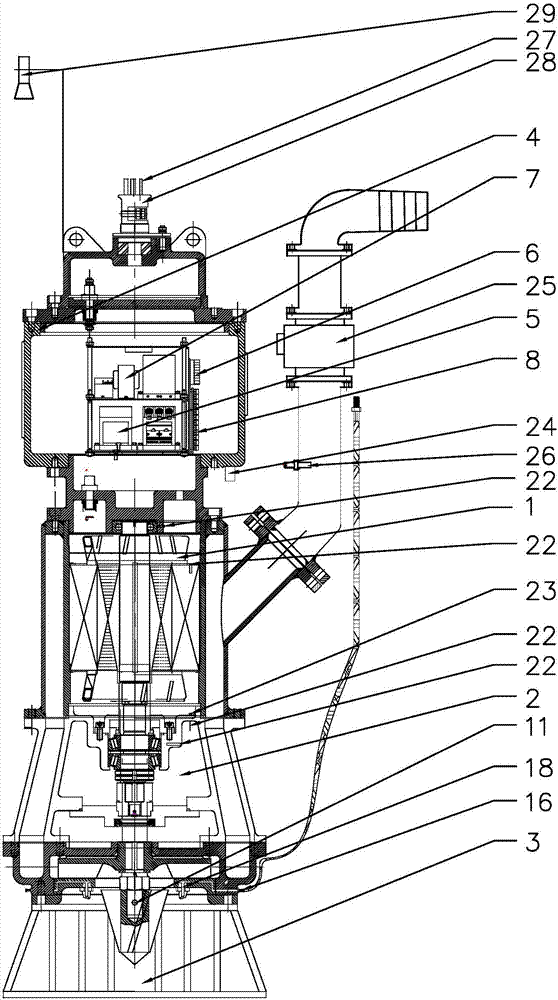

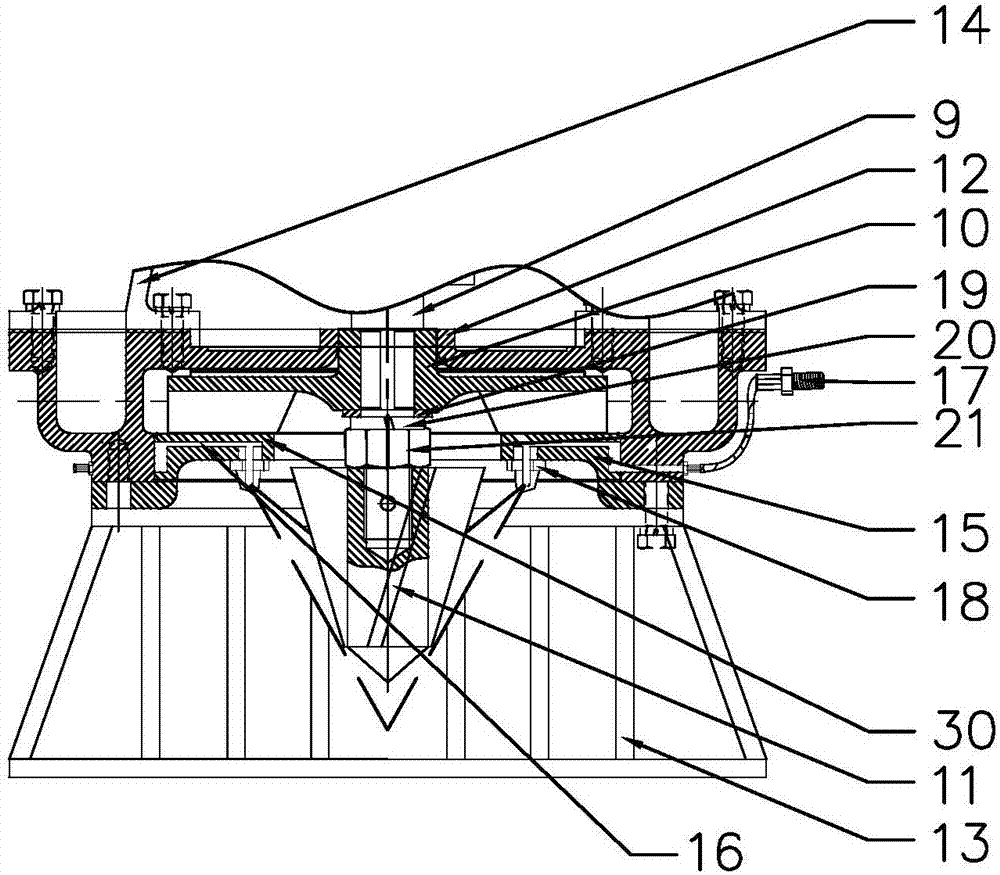

[0024] Such as Figure 1-2 As shown, the remote intelligent digital explosion-proof submersible slurry pump of the present invention includes a submersible motor 1, an oil chamber 2 and a slurry pump 3, and the submersible motor 1, the oil chamber 2 and the slurry pump 3 are coaxially connected, The top of the submersible motor 1 is provided with an electrical seal chamber 4, and the electrical seal chamber 4 is provided with a control unit 5, a power supply unit 6, a motor detection unit 7 and a data transmission unit 8, and the slurry pump 3 is connected to the submersible motor 1 through a pump shaft 9. The rotating shaft is connected, the impeller 10 and the stirring breaker 11 are arranged in sequence on the pump shaft 9, and the high-pressure cleaning component is set corresponding to the stirring breaker 11, and the motor detection unit 7 and the data transmission unit 8 are connected to the control unit 5 respectively.

[0025] Wherein, the motor detection unit 7 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com