System and method for simultaneously machining non-standard parts based on numerical control machining center

A technology for machining centers and parts, applied in metal processing machinery parts, general control systems, control/adjustment systems, etc., can solve the problems of low machining utilization rate of CNC machining centers, cumbersome processing quality control, and high manufacturing costs, Achieve the effect of avoiding participation time, reducing auxiliary time, and ensuring utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

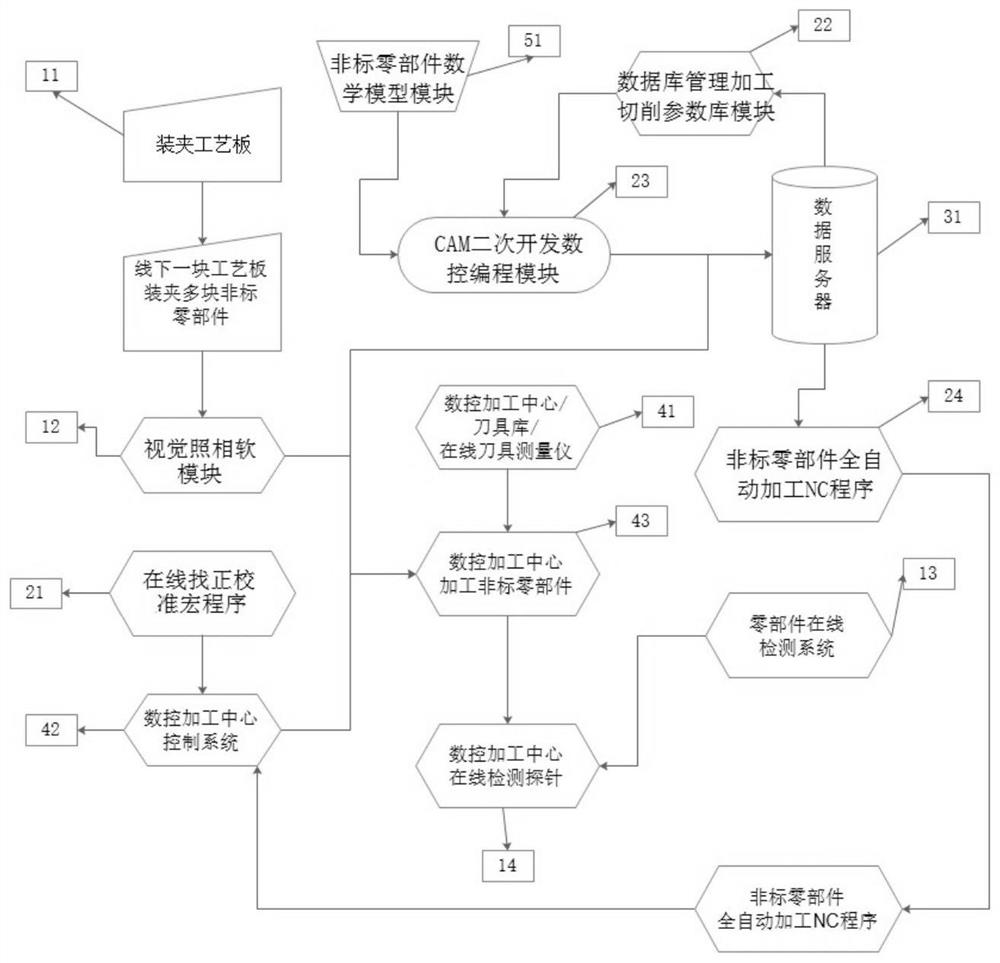

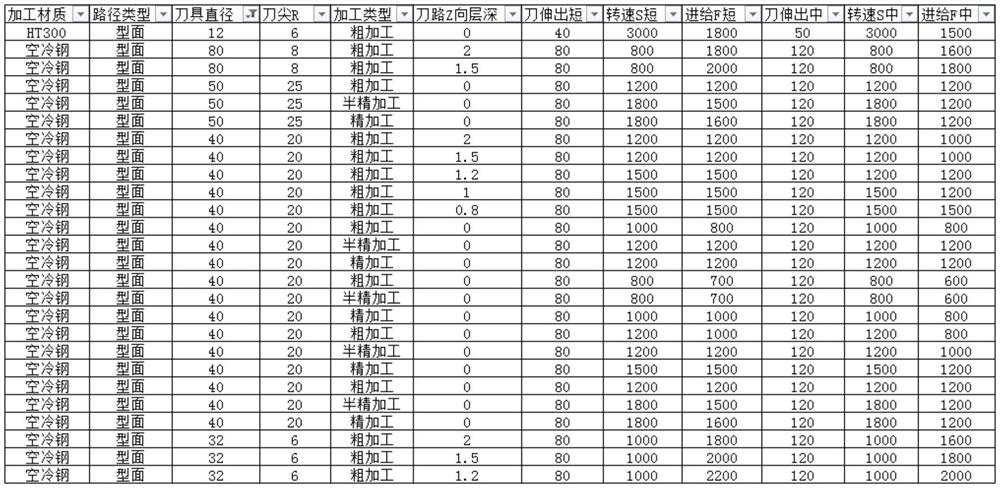

[0052] refer to figure 1 , the present invention is based on the CNC machining center (WELL AA1165 hard rail is suitable for rough machining, WELLAQ850 line rail is suitable for high-speed finishing) and simultaneously processes non-standard parts and components system, including: the clamping process board located inside the CNC machining center, visual camera Soft module, machining center online alignment and calibration module, CAM secondary development NC programming module, parts online detection module;

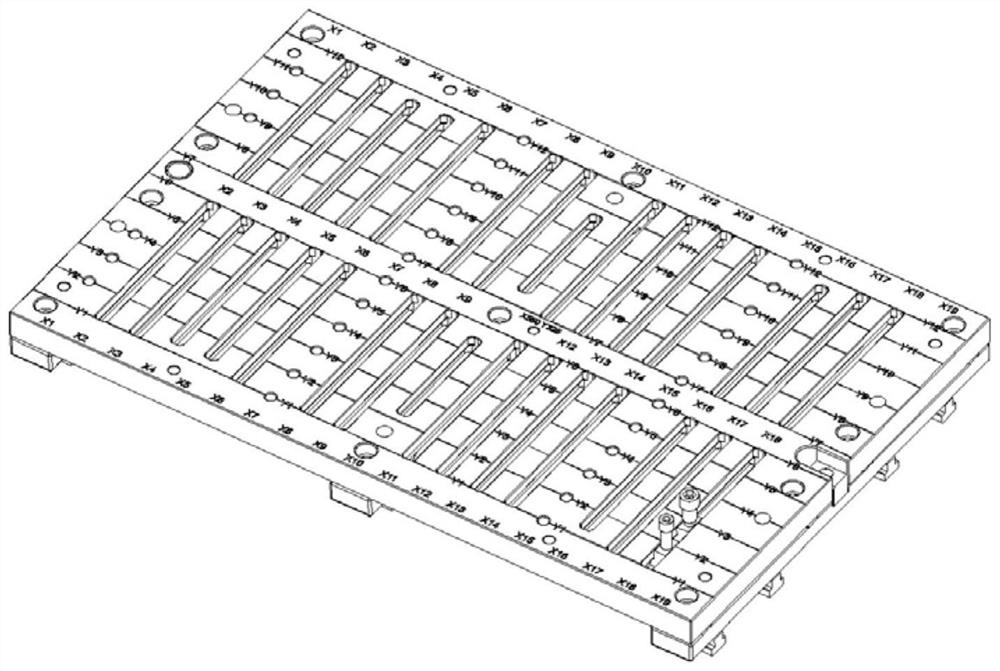

[0053] The clamping process board 11 in this embodiment is used to clamp multiple non-standard parts to one process board according to the requirements of the system specification, and the clamping process board with multiple non-standard parts is clamped to the CNC machining Unattended full-automatic processing is carried out on the central workbench. The clamping process plate 11 is small in size and easy to fix on the machine bed, and has oblong grooves for insert po...

Embodiment 2

[0074] In this embodiment, a control method based on a CNC machining center for simultaneous processing of non-standard parts and components system specifically includes the following steps: Step S1: The clamping process board located inside the CNC machining center assembles multiple non-standard parts according to the requirements of the system specification The components are clamped to a process board, and the clamped process plate with multiple non-standard parts is clamped to the workbench of the CNC machining center for unattended automatic processing;

[0075] Step S2: Use the visual camera soft module of the CNC machining center to perform the initial alignment and calibration of the parts on the process board through visual photography, wherein the visual camera of the visual camera soft module captures the relevant position data of the target parts, the The relative distance between the defined center and the defined center of the process board is converted into an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com