Coating machine and method for detecting and removing dust particles thereof

A coating machine and dust particle technology, which is applied to the device, coating, measuring device and other directions for coating liquid on the surface, which can solve the waste of production raw materials, the inability to accurately determine the specific location of dust particles, and reduce the production line utilization rate, etc. problems, to achieve the effect of ensuring the utilization rate, saving production materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

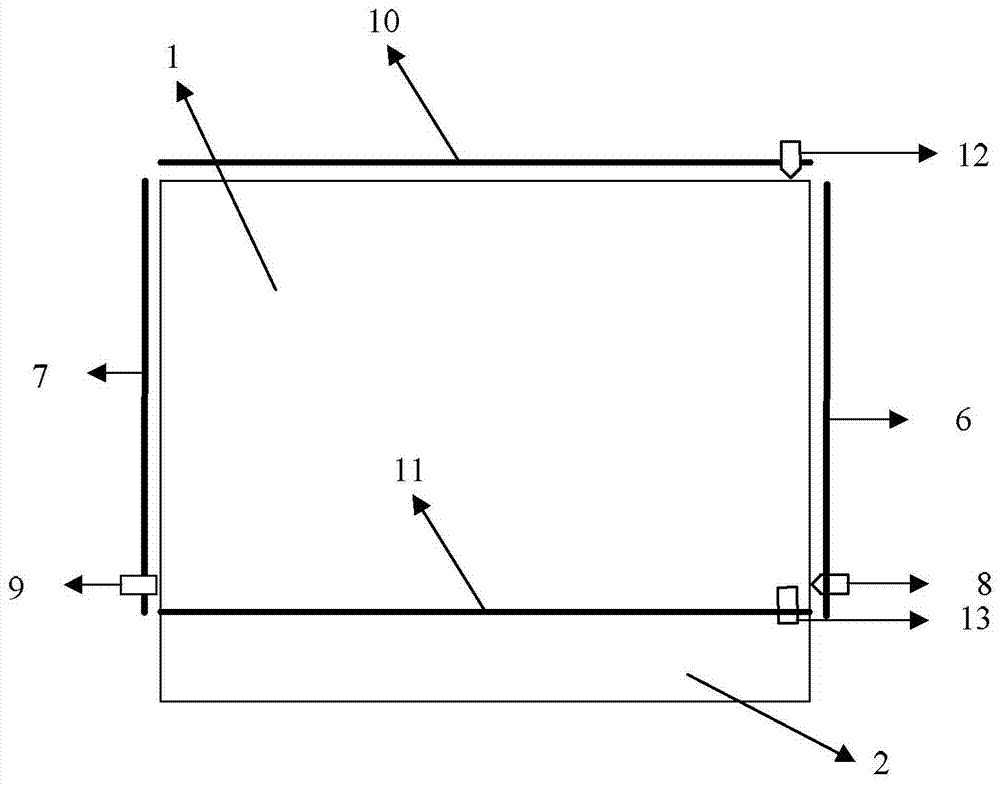

[0037] The basic idea of the embodiment of the present invention is: a group of detection devices are respectively installed in the coating direction and the vertical coating direction, and the purpose of accurately detecting the specific position of dust particles is achieved through the combined use of the two groups of detection devices; The advanced cleaning device achieves the purpose of removing dust particles at one time without causing secondary pollution.

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

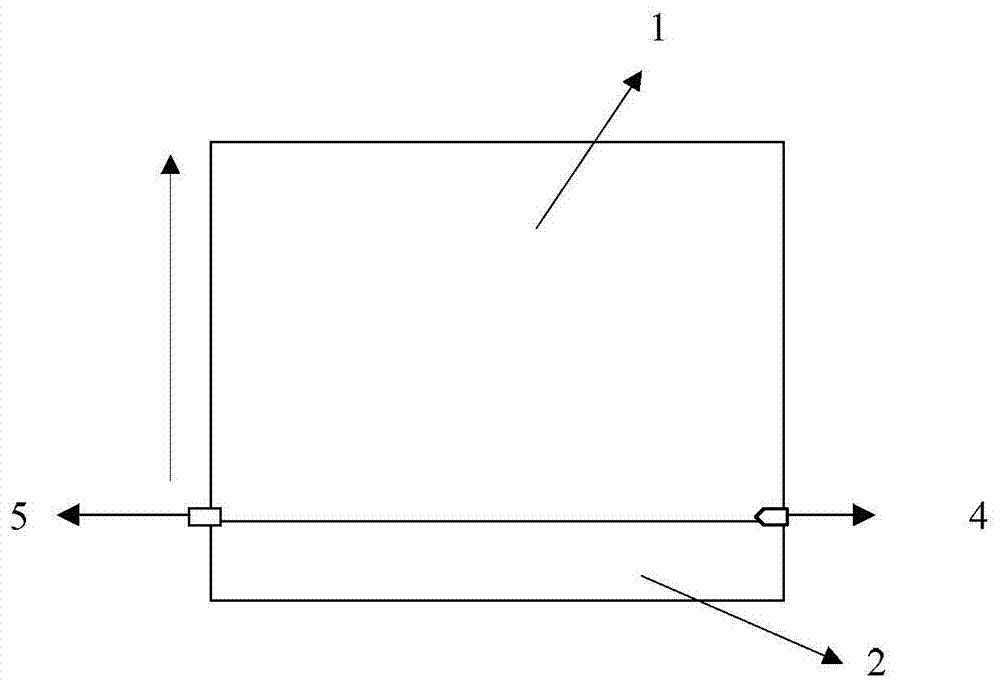

[0039] image 3 It is the top view of the coating machine described in the embodiment of the present invention, as image 3 As shown, on the machine platform, a guide rail parallel to the moving direction of the gantry is provided on the left and right sides of the gantry, namely: the first transmitter guide rail 6 and the first receiver guide rail 7, The first transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com