Patents

Literature

102results about How to "Eliminate turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

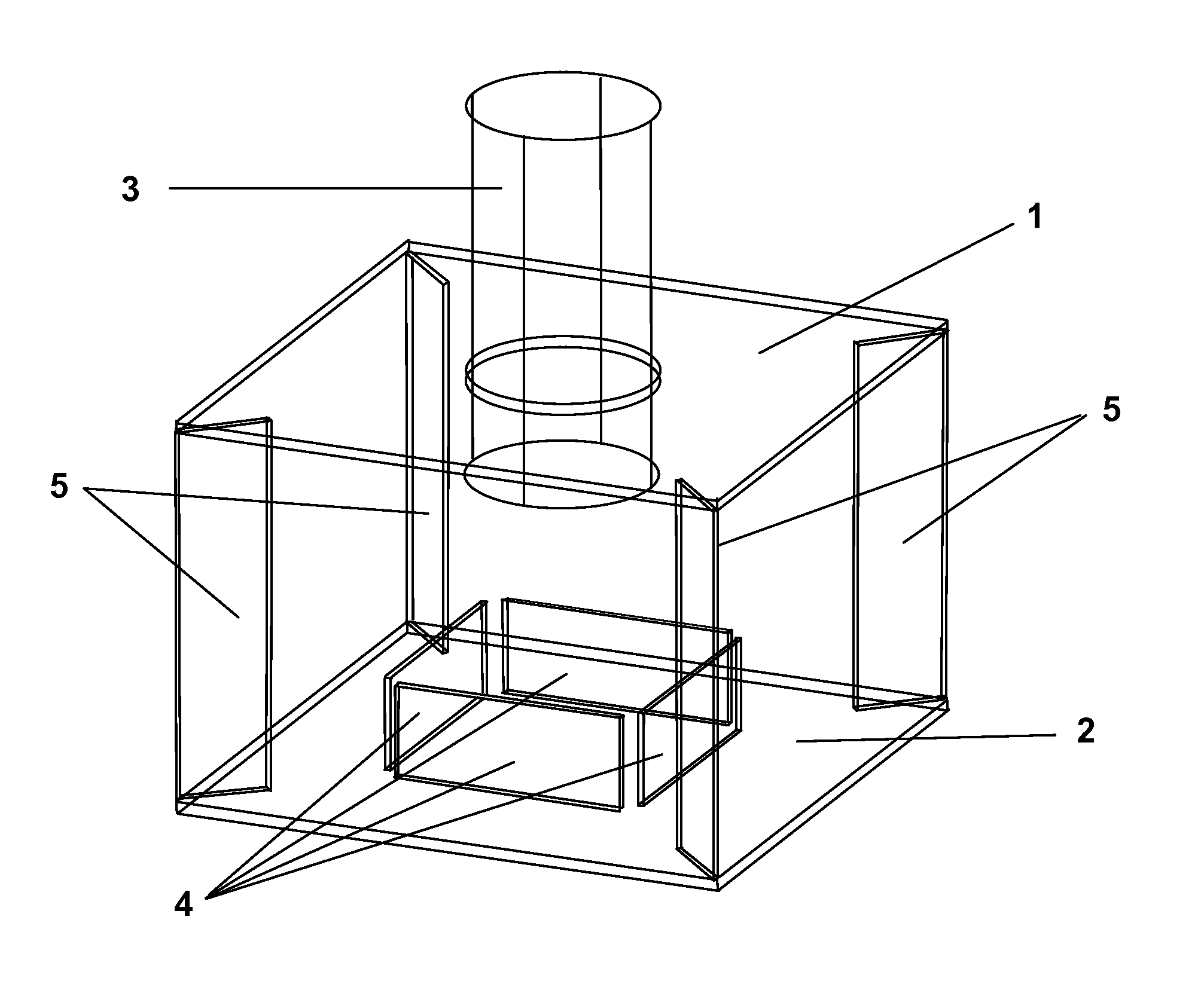

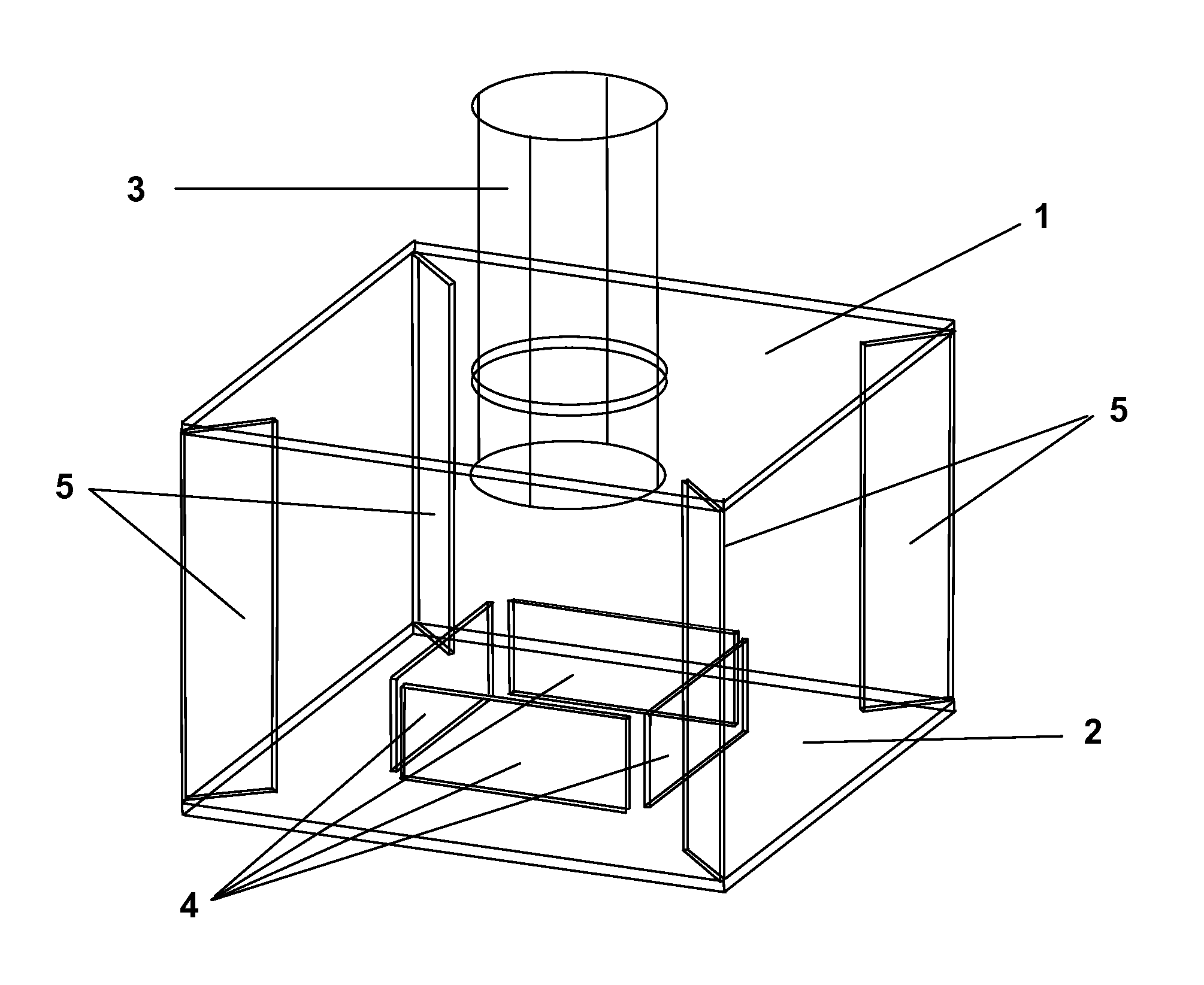

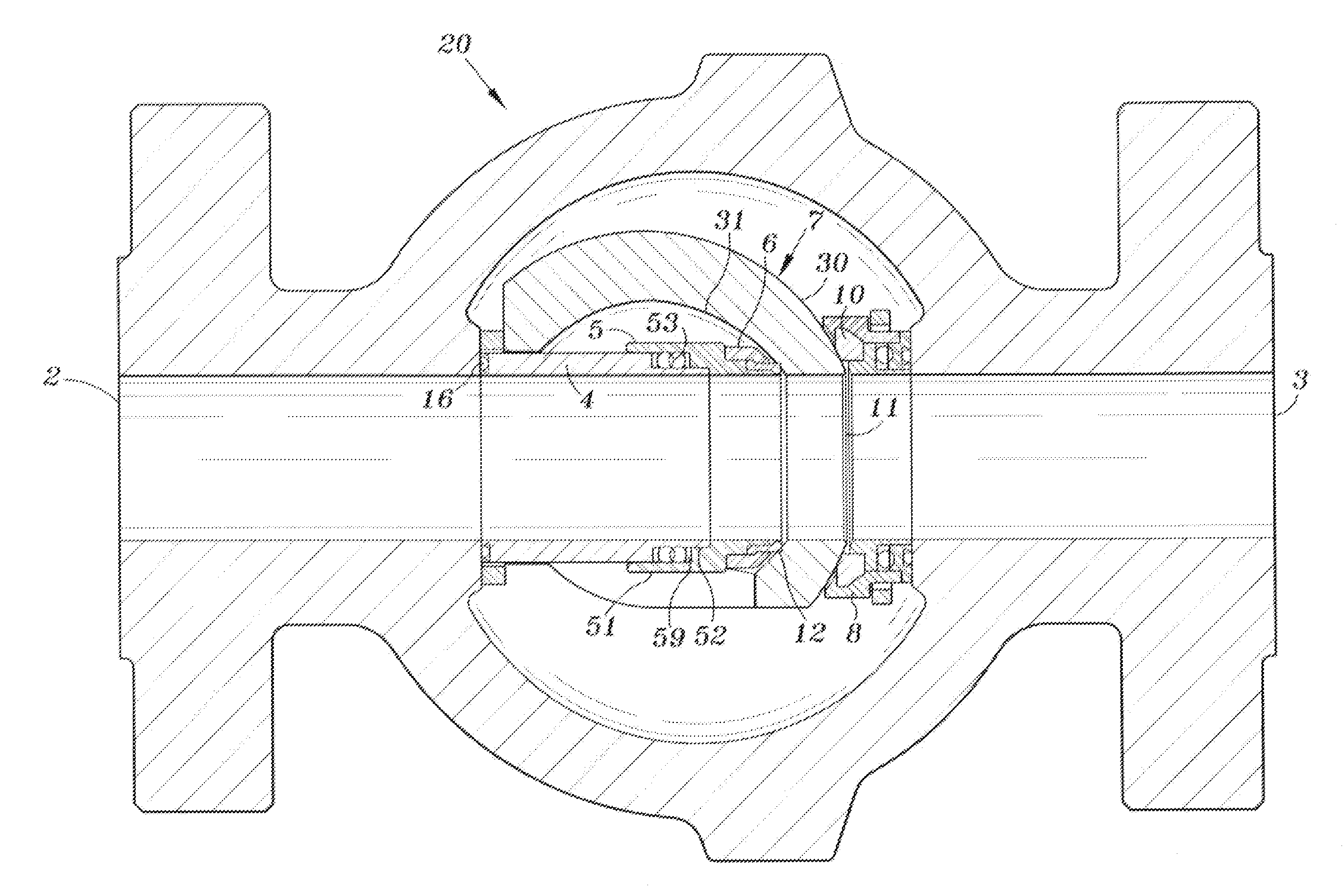

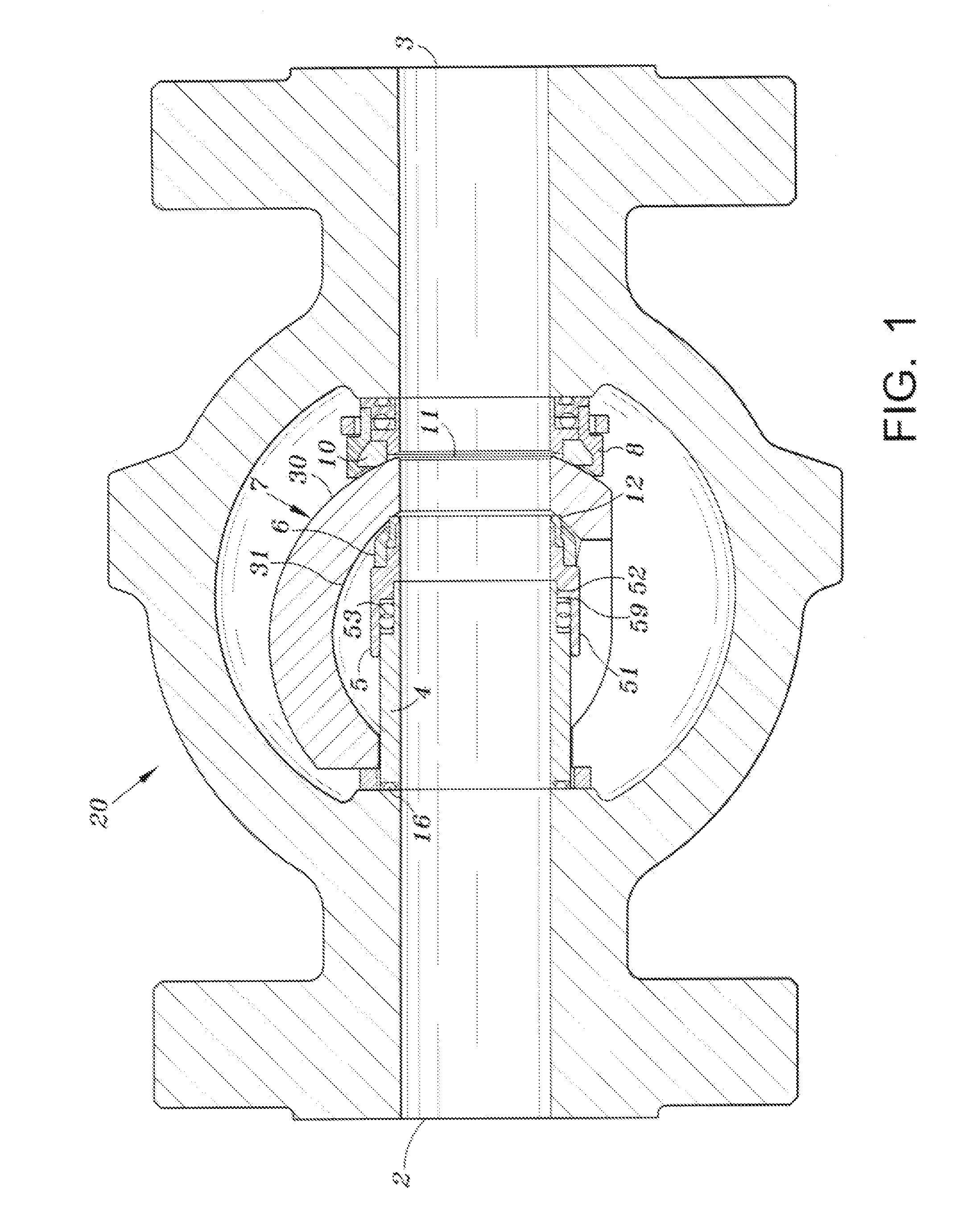

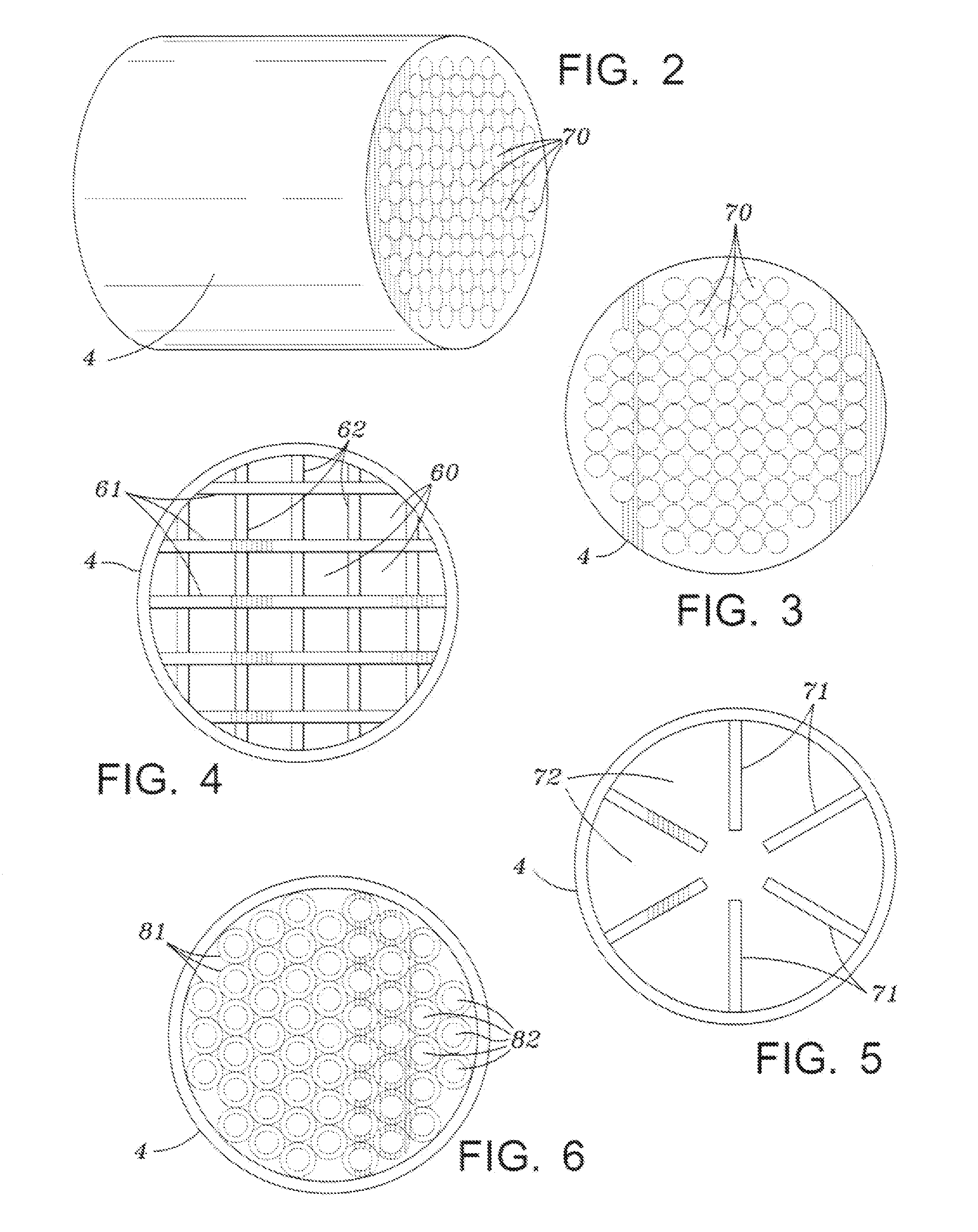

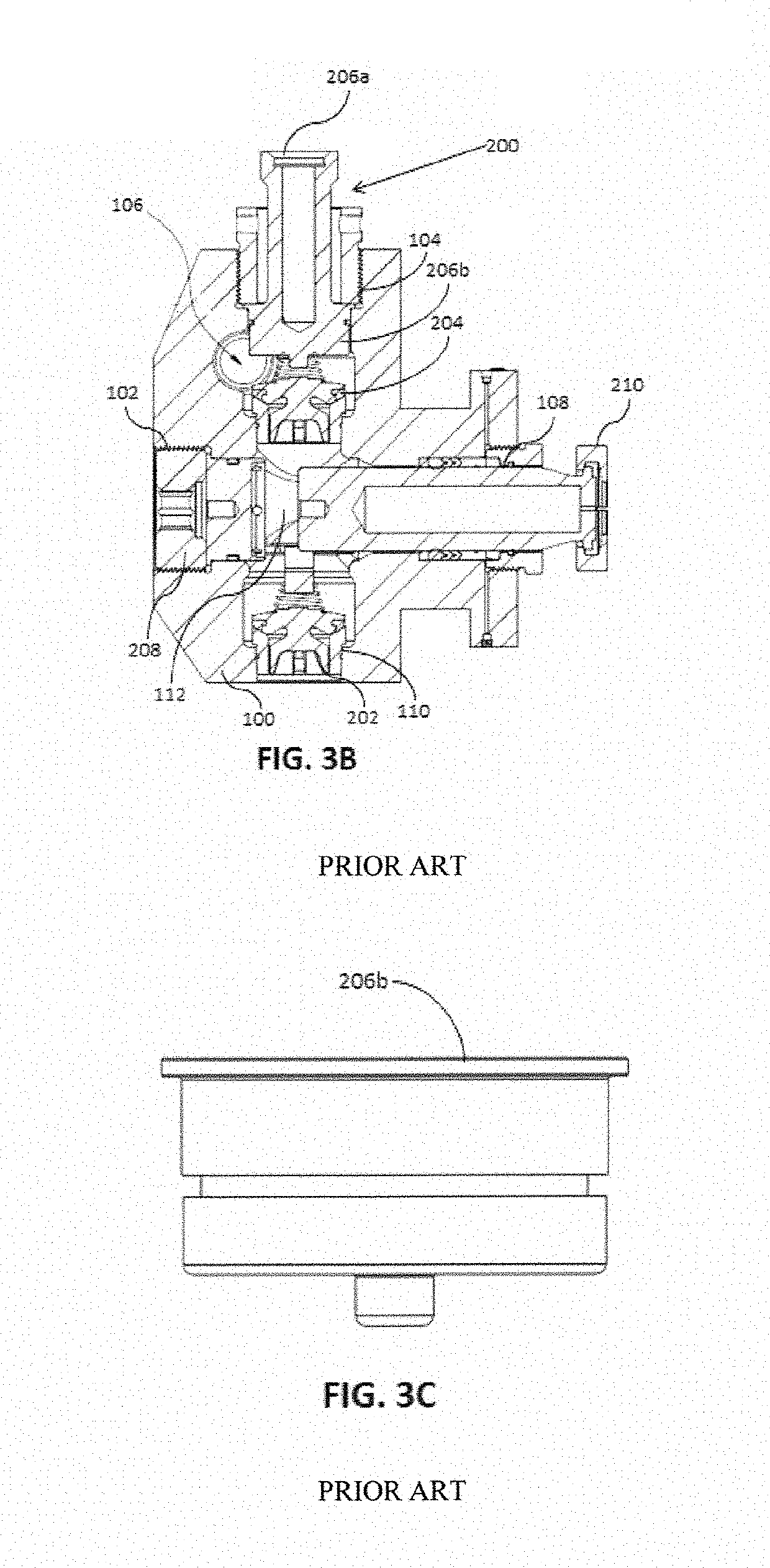

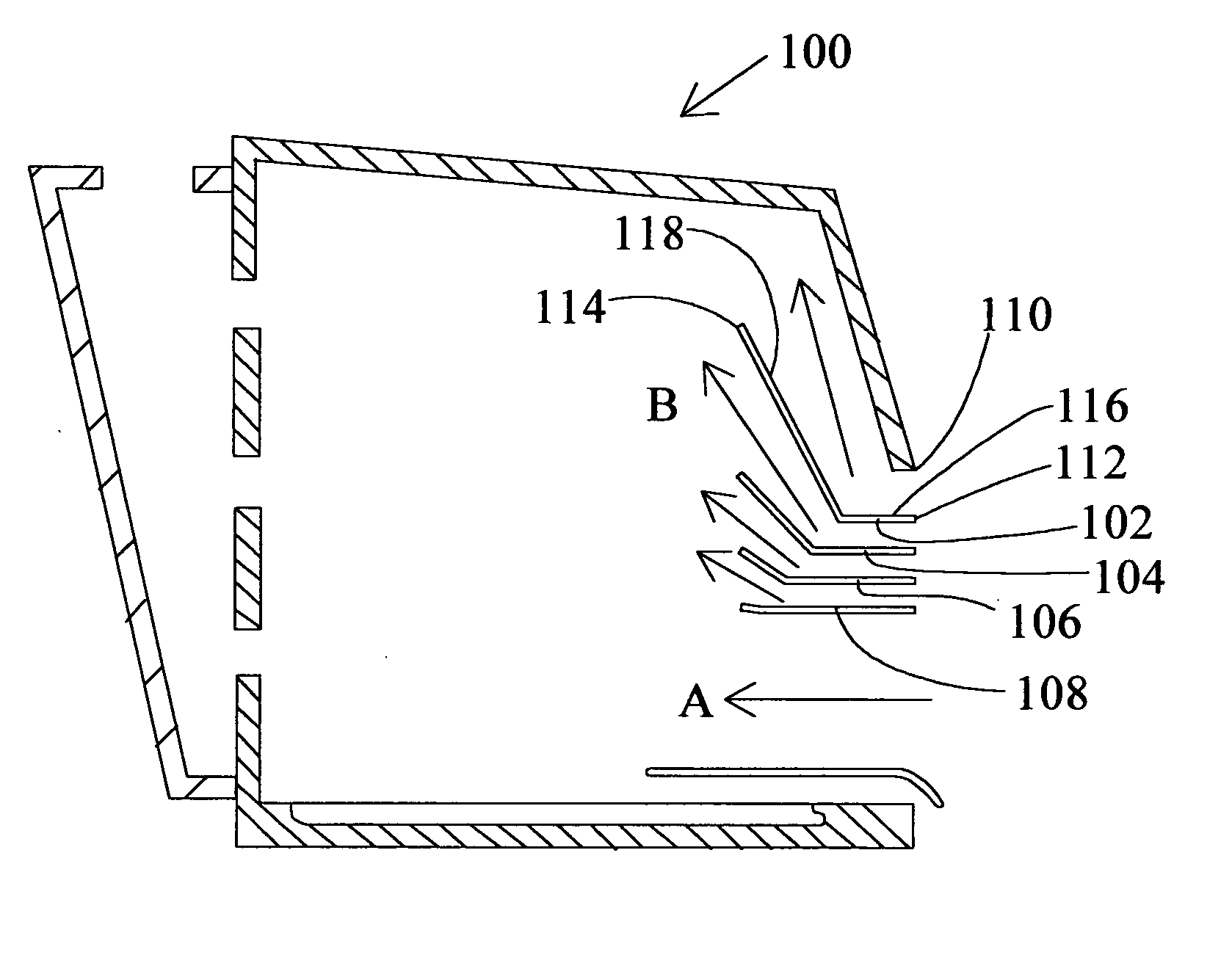

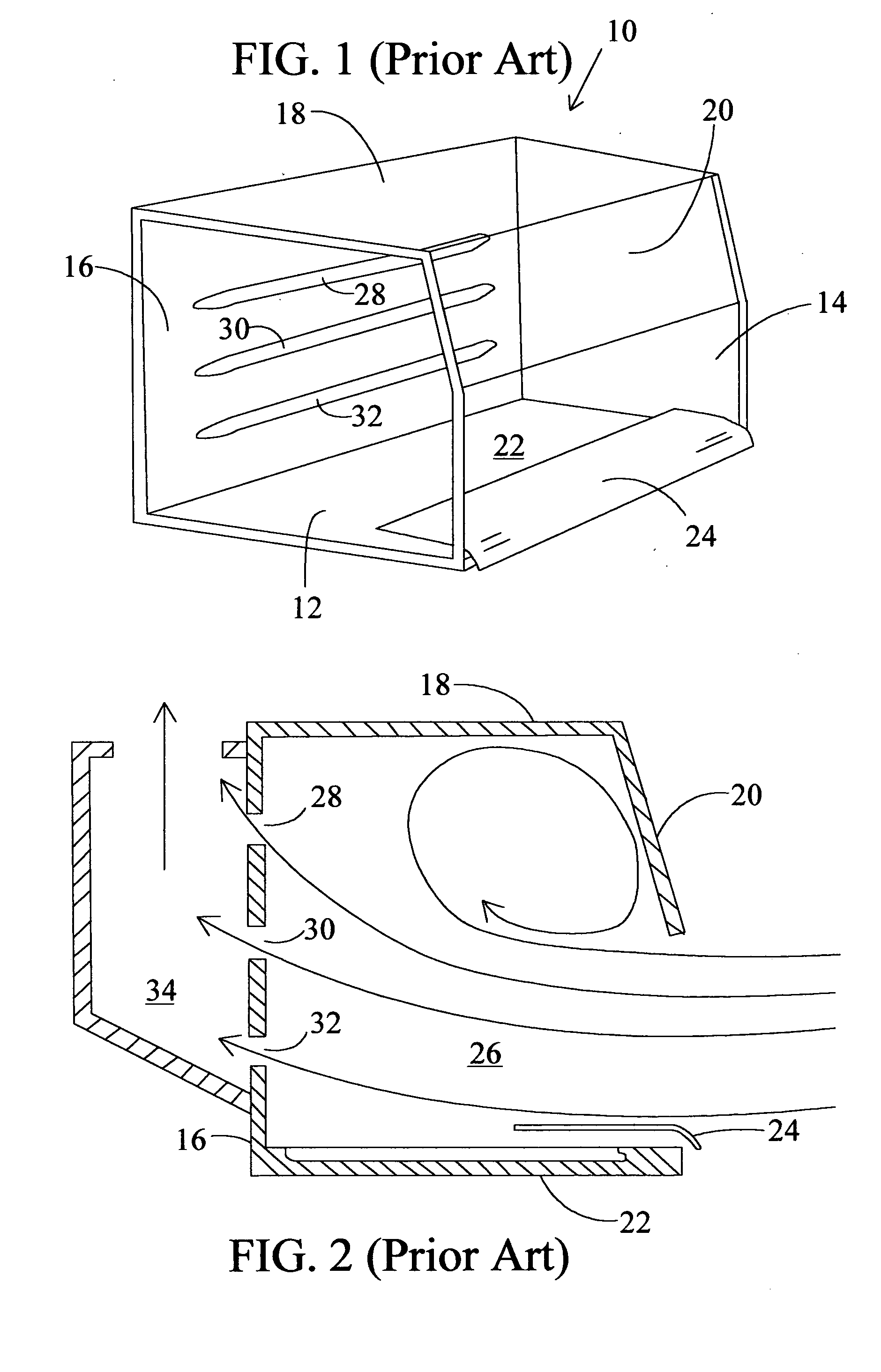

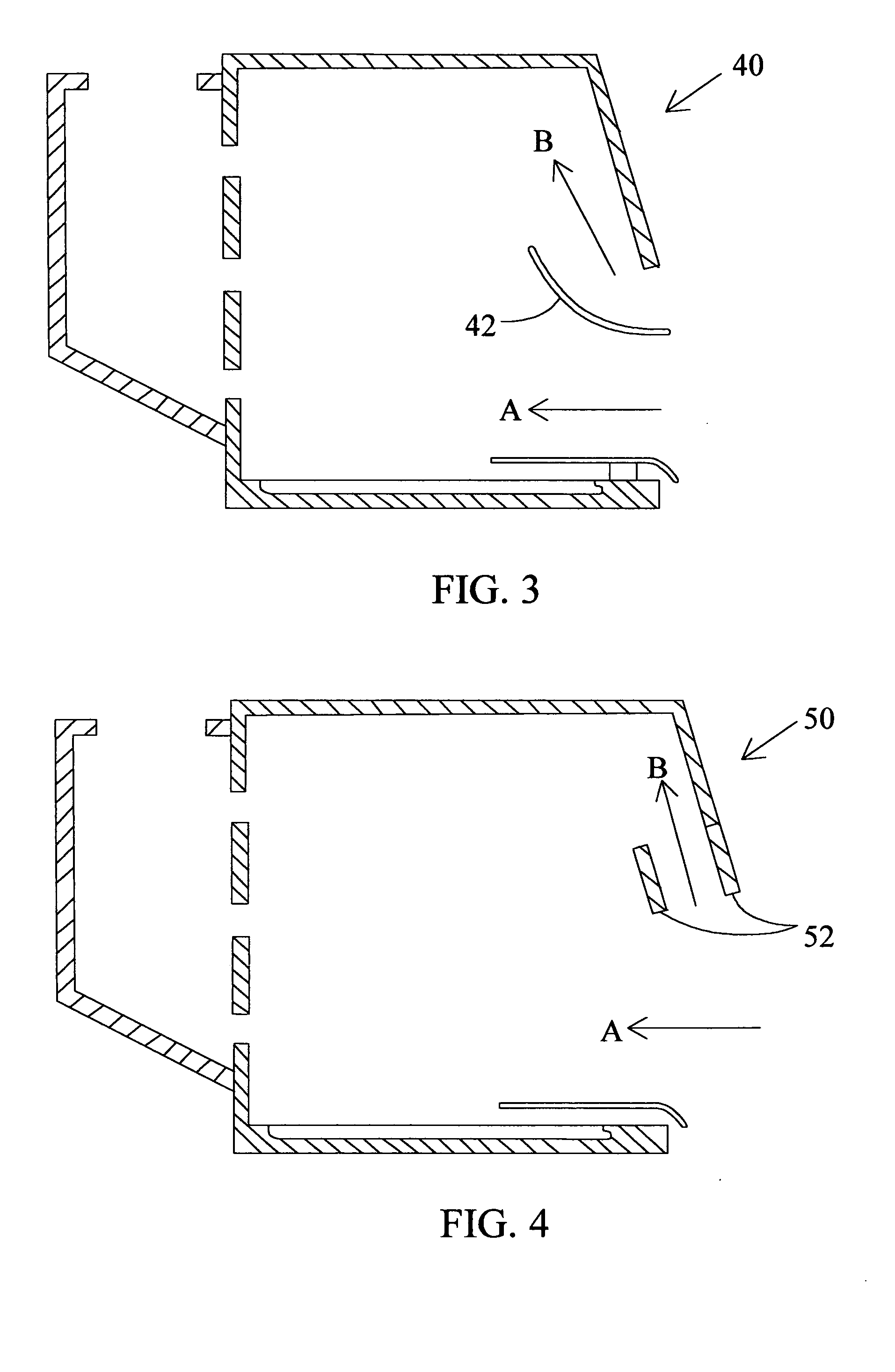

Device for turbulence reduction

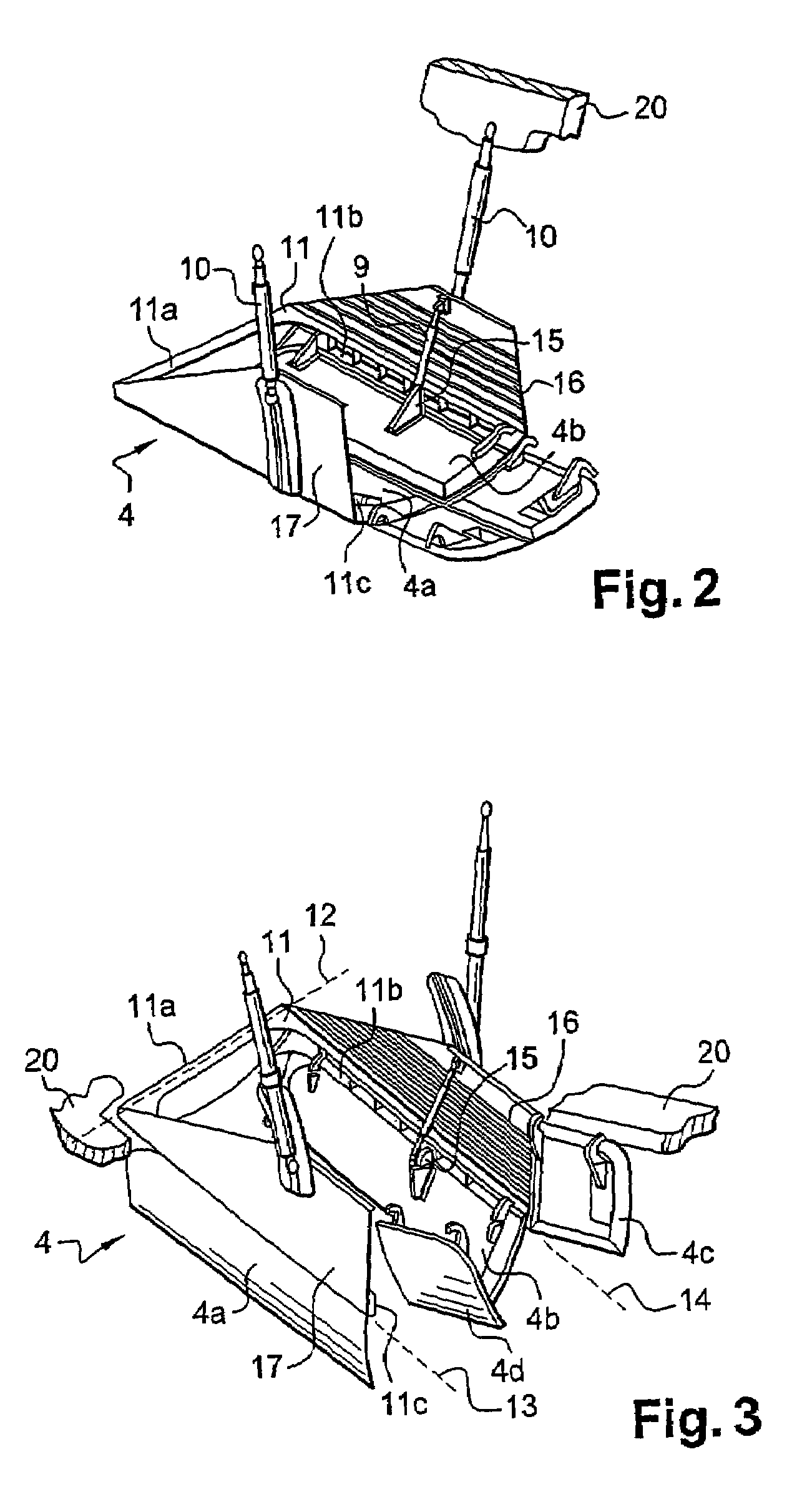

ActiveUS9023216B2Reducing momentum and velocityReduce or even eliminate large-scale turbulent eddiesJuice extractionFluid dynamicsMomentumMechanical engineering

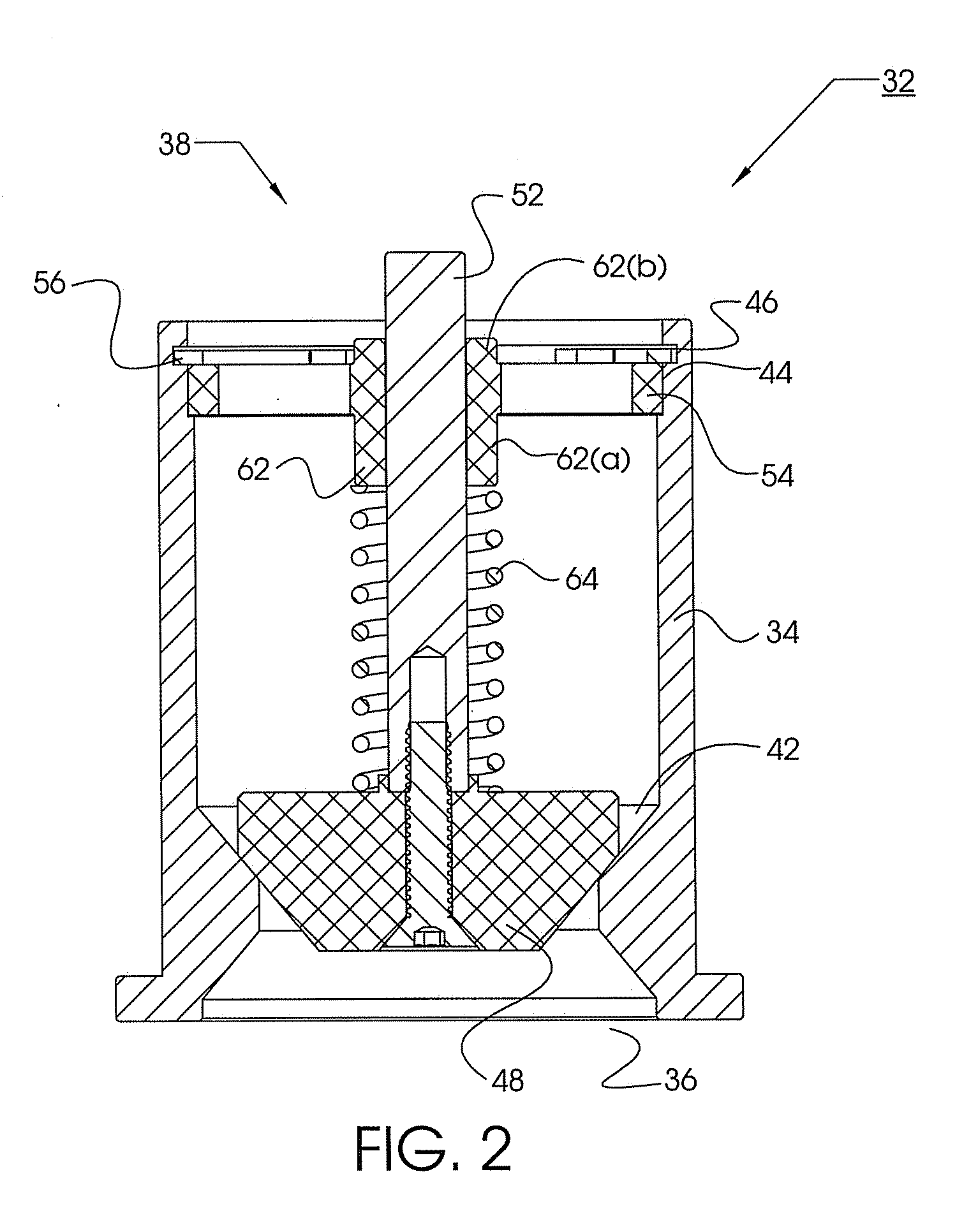

Apparatus is disclosed for substantially reducing the momentum, velocity, or both of a first liquid that is flowing into a second liquid. The device allows one to substantially reduce or even eliminate large-scale turbulent eddies that could otherwise be produced by liquid flowing into or within a vessel, for example in a clarifier. Suitably-sized and positioned plates and baffles induce changes of flow direction in a limited volume. By the time the fluid leaves this volume, the fluid velocity is low, and turbulence is nearly or entirely eliminated. Several of the devices may be placed at different inputs within a single clarifier, and thus increase efficiency further.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

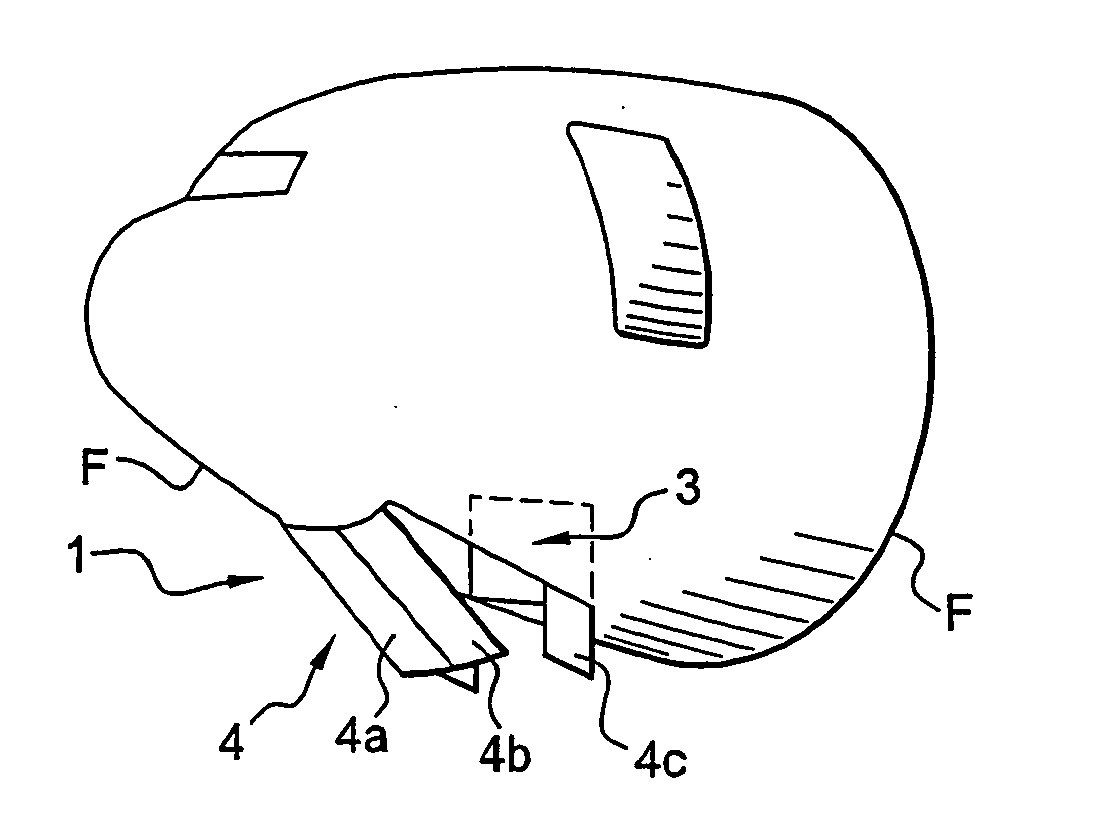

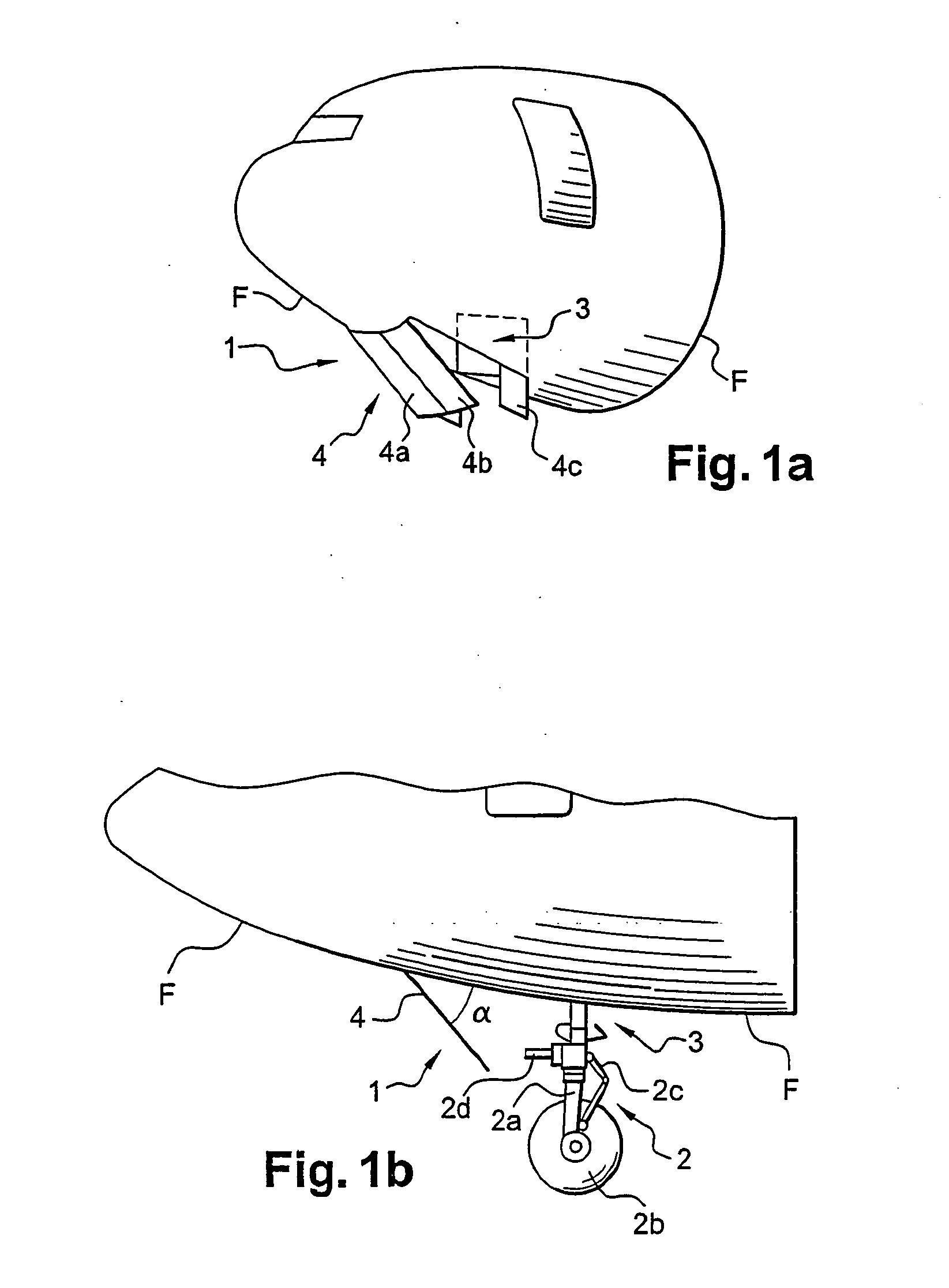

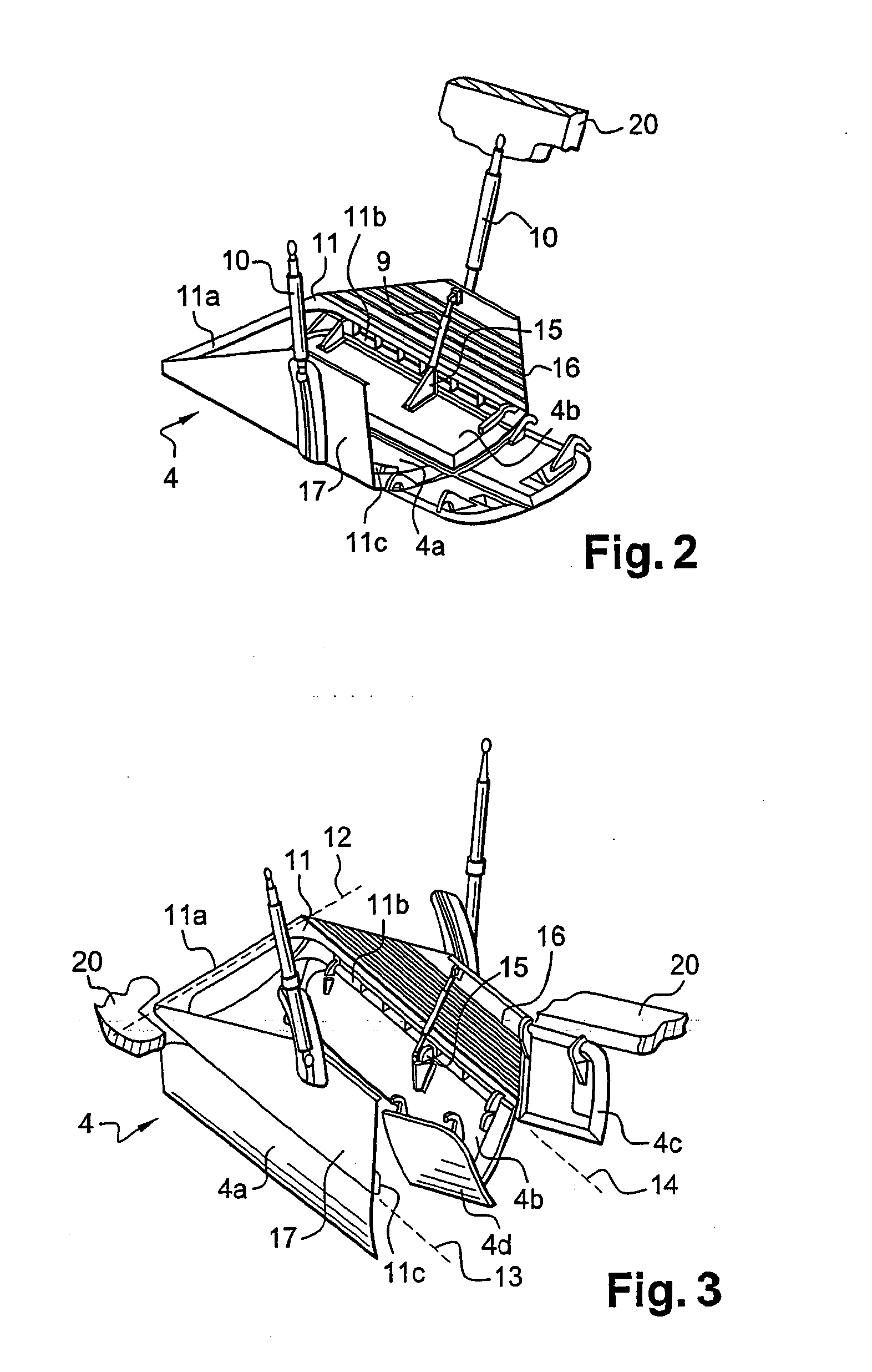

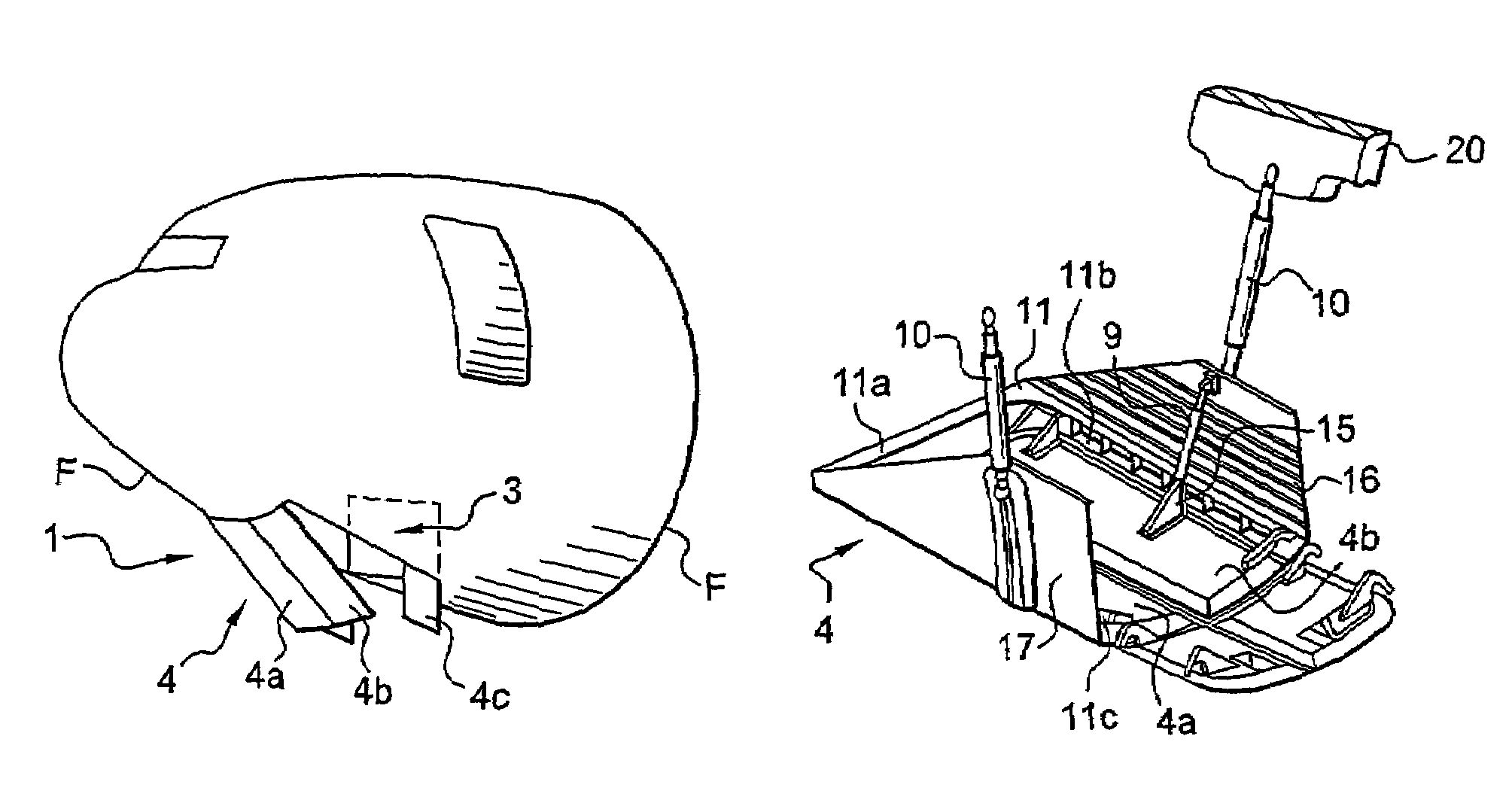

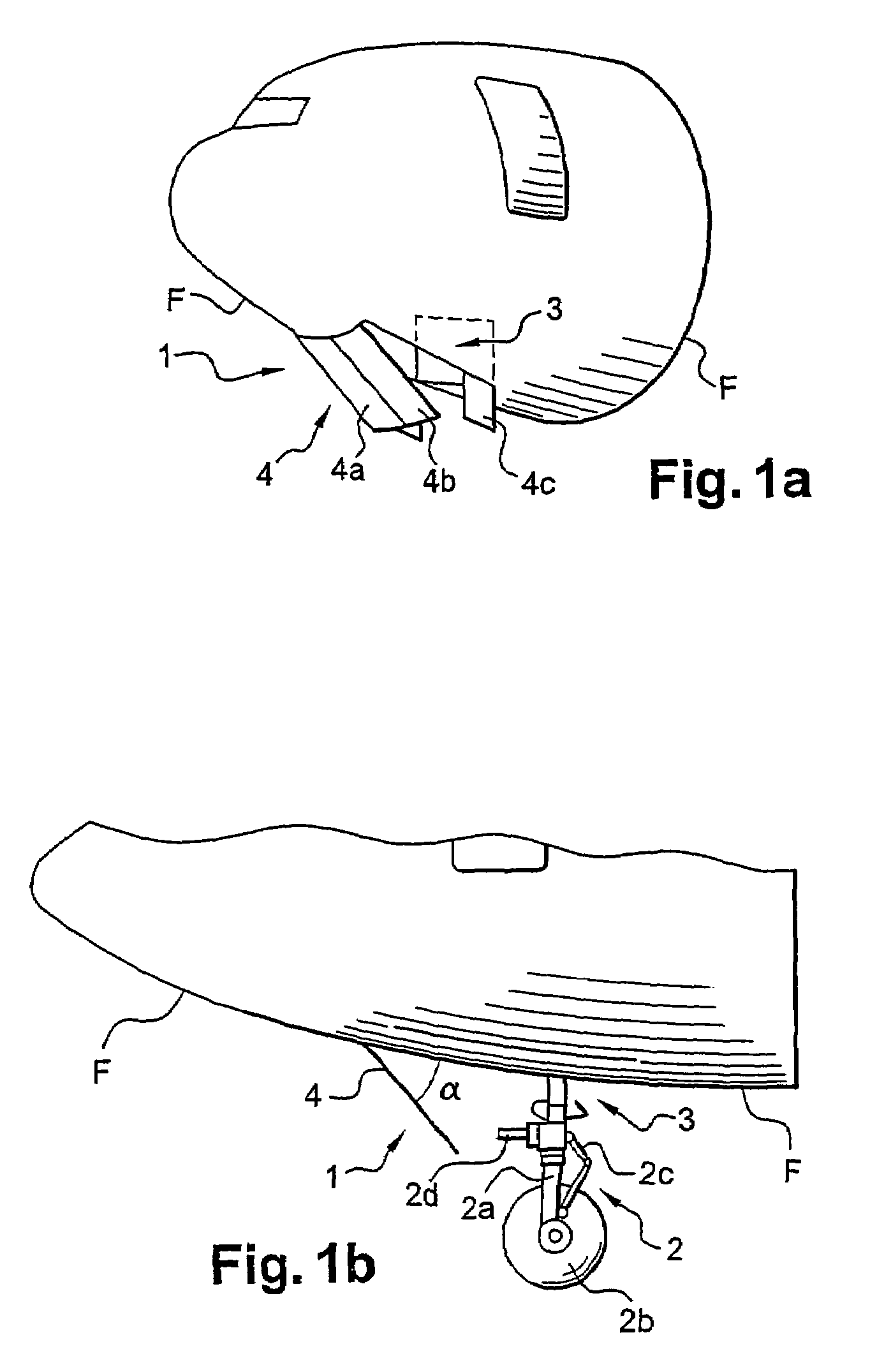

Aerodynamic airflow deflector for aircraft landing gear

InactiveUS20060032981A1Reduce noiseEliminate turbulenceFuselagesAircraft floorsAircraft landingAirplane

An aerodynamic airflow deflecting device for a landing gear retracting into a housing of an aircraft, comprising at least one element for closing the housing that is, through the action of a control device, able to occupy a position for shielding at least a part of the landing gear against the aerodynamic airflow, thus constituting a noise reducing aerodynamic device. The closing element can in particular include at least one trap door element that is, through the action of the control device, movable between a first position for closing the housing, a second position allowing the landing gear to exit and a third position constituting said shielding position.

Owner:AIRBUS OPERATIONS (SAS)

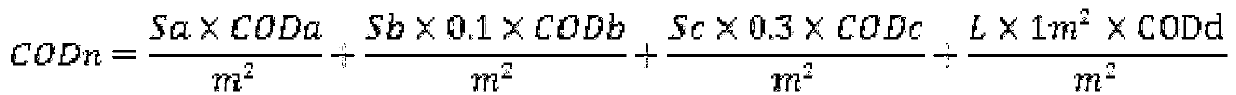

Integrated method of lake water environment management

ActiveCN103103960AEfficient repairImprove water qualityCoastlines protectionStream regulationEmergency treatmentEnvironmental engineering

The invention discloses an integrated method of lake water environment management. The integrated method of the lake water environment management comprises the steps of making first-phase preparations for lake water environment integrated management, analyzing a landform, designing the type of a side slope, determining the self-cleaning capacity of a lake, controlling pollution sources around the lake, conducting a silt-removing treatment on a water body, managing the side slope, conducting ecological restoration on the lake, and conducting monitoring and emergency treatment on the lake. The integrated method of the lake water environment management is used for enabling a lake water environment biologic chain to be effectively restored and consolidated and enabling the lake side slope to be stable.

Owner:重庆千洲生态环境工程有限公司

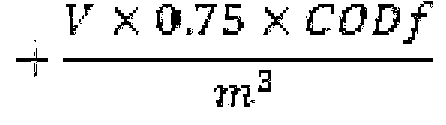

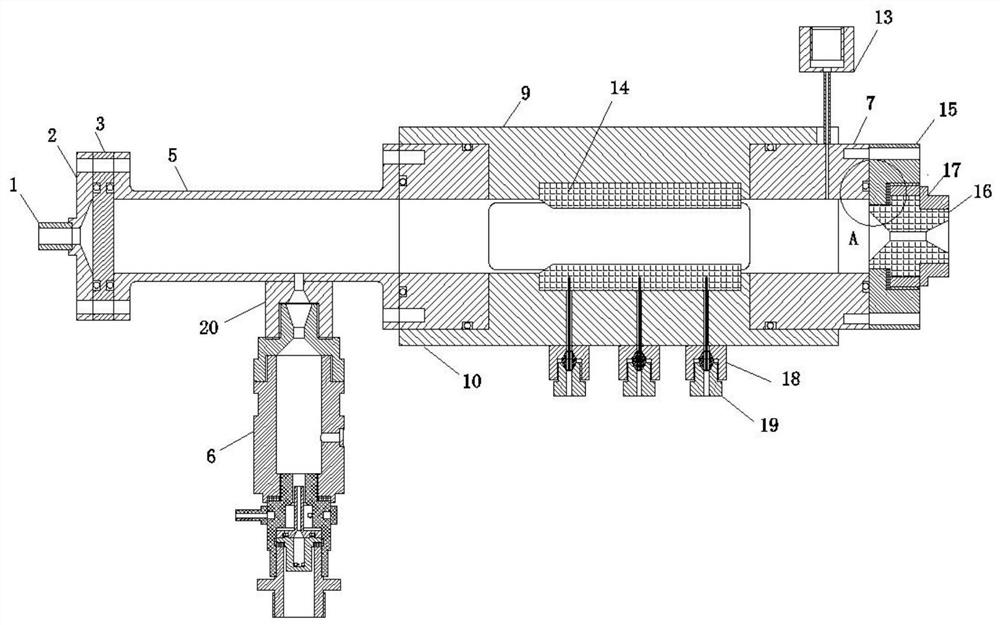

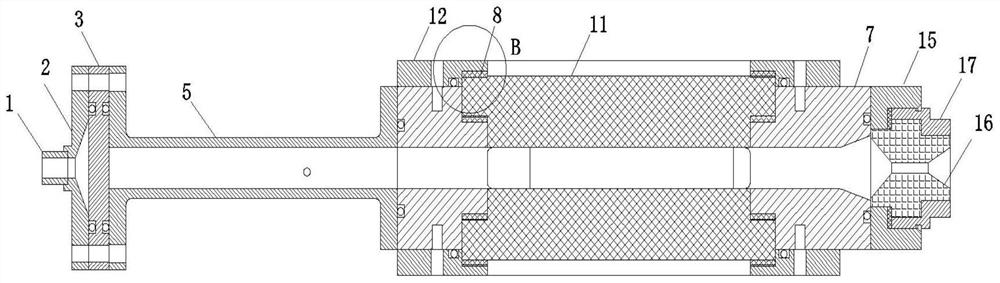

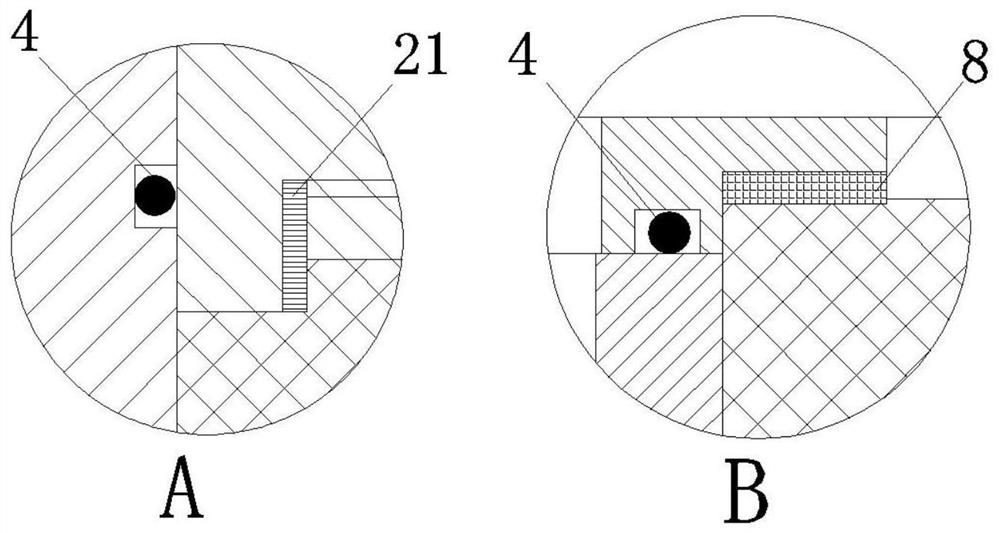

Integrated intelligent flowmeter and measuring method

ActiveCN102393224AEliminate turbulenceOvercoming Pressure FluctuationsVolume/mass flow by differential pressureTraffic volumeDigital conversion

The invention provides an integrated intelligent flowmeter and a measuring method. The integrated intelligent flowmeter comprises a measuring tube, an upstream pressure sensor component, a downstream pressure sensor component, a mounting bracket, a computer data processing unit, an upstream flowing regulator, a built-in core, a downstream flowing regulator and a temperature sensor. By using an inner Venturi tube as a throttle member, the accuracy and stability of measurement are improved; simultaneously, a plurality of pressure sensors are used for collecting pressure signals, an integrated data processing computer performs analog-digital conversion, software filtering, average value calculation and flow velocity and flow calculation on the pressure signals, the pressure signals after temperature compensation are converted into industrial standard digital signals or industrial standard current signals of 4 to 20mA to be output wirelessly or with wires; the invention can realize long-term stable and accurate on-line metering, especially has unique metering advantages at a situation that a long straight pipe section cannot be installed in site.

Owner:法特科技(深圳)有限公司

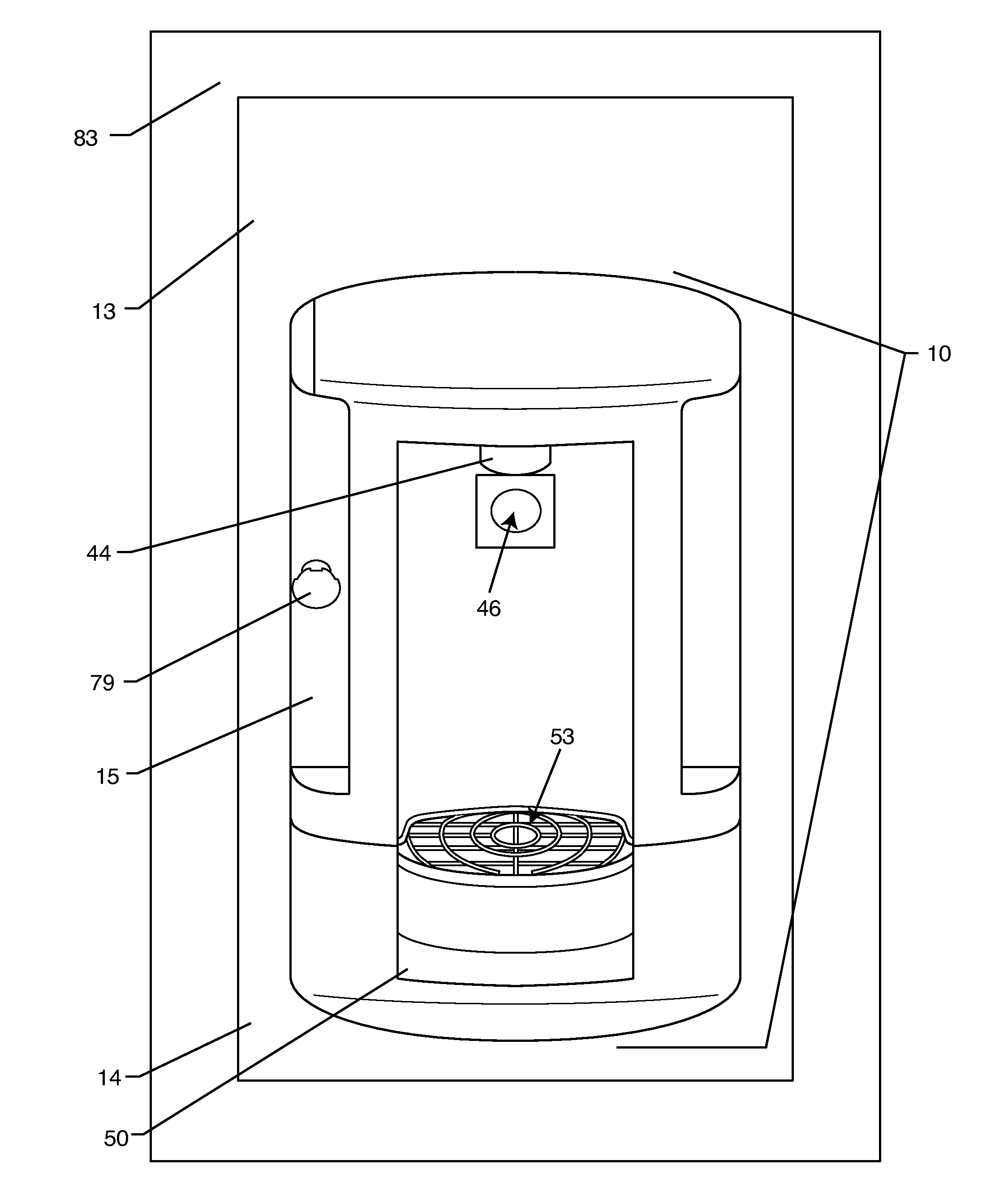

Hydration station

InactiveUS20090308494A1Minimize spreadingMaintenance be expedite and simplifyLiquid flow controllersWater/sewage treatmentEngineeringWall mount

An improved hydration station comprises a wall mounted unit including a stationary lower body panel coupled to a drain, and a hinged upper body panel carrying a nozzle subassembly for dispensing water into a recess alcove defined cooperatively by the lower and upper body panels in response to user-insertion of a water-receiving receptacle into the alcove. The preferred wall unit includes a non-contact sensor for controlling water dispensing flow, and a preferred nozzle assembly includes at least one component having an antimicrobial additive. A preferred control timer automatically dispenses water in the event that the sensor does not detect a user-inserted receptable within a predetermined time interval, such as 24 hours. In addition, in a preferred form, lights on the unit are energized at one level during water dispensing, and at a second level when water is not being dispensed.

Owner:HAWS CORP

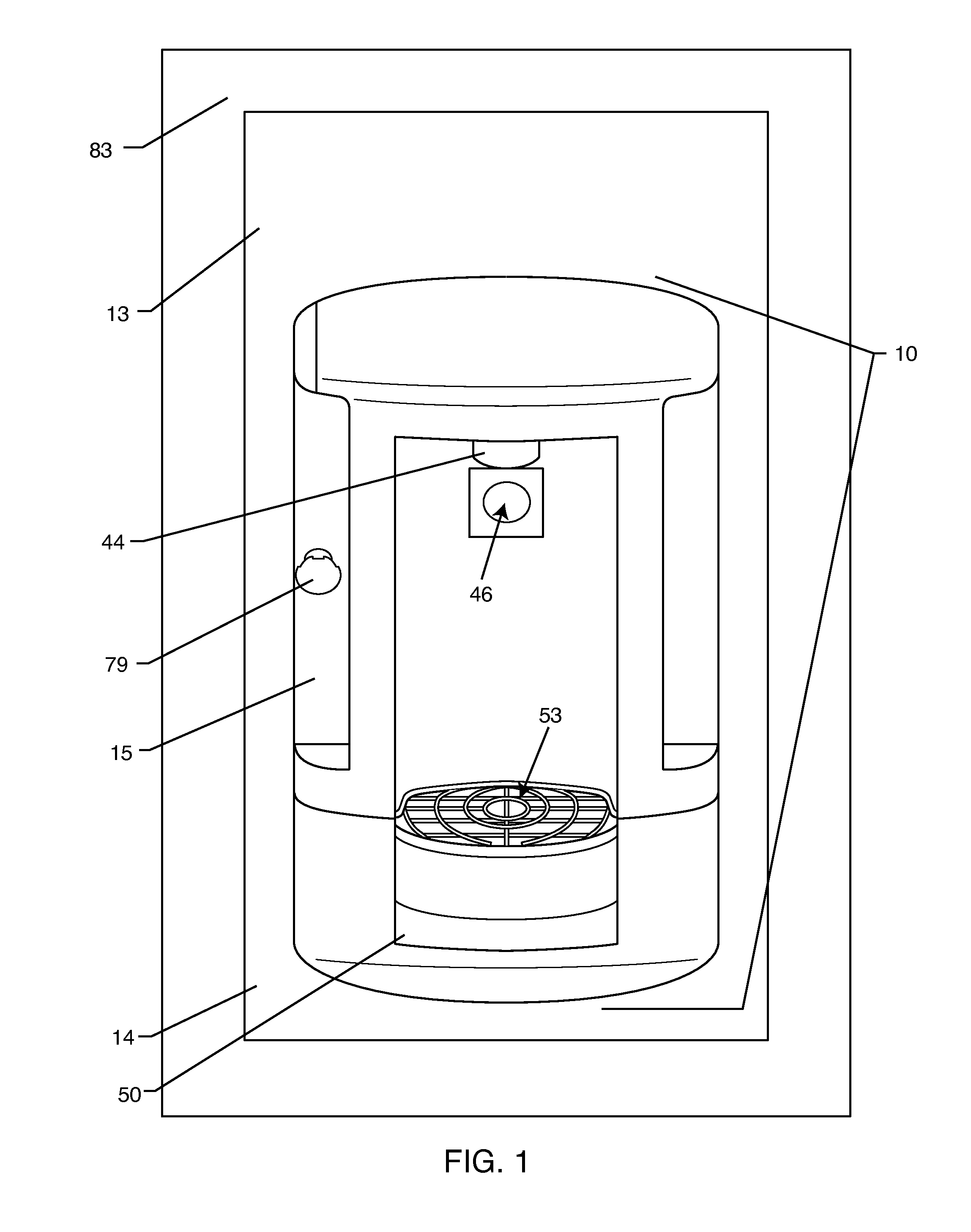

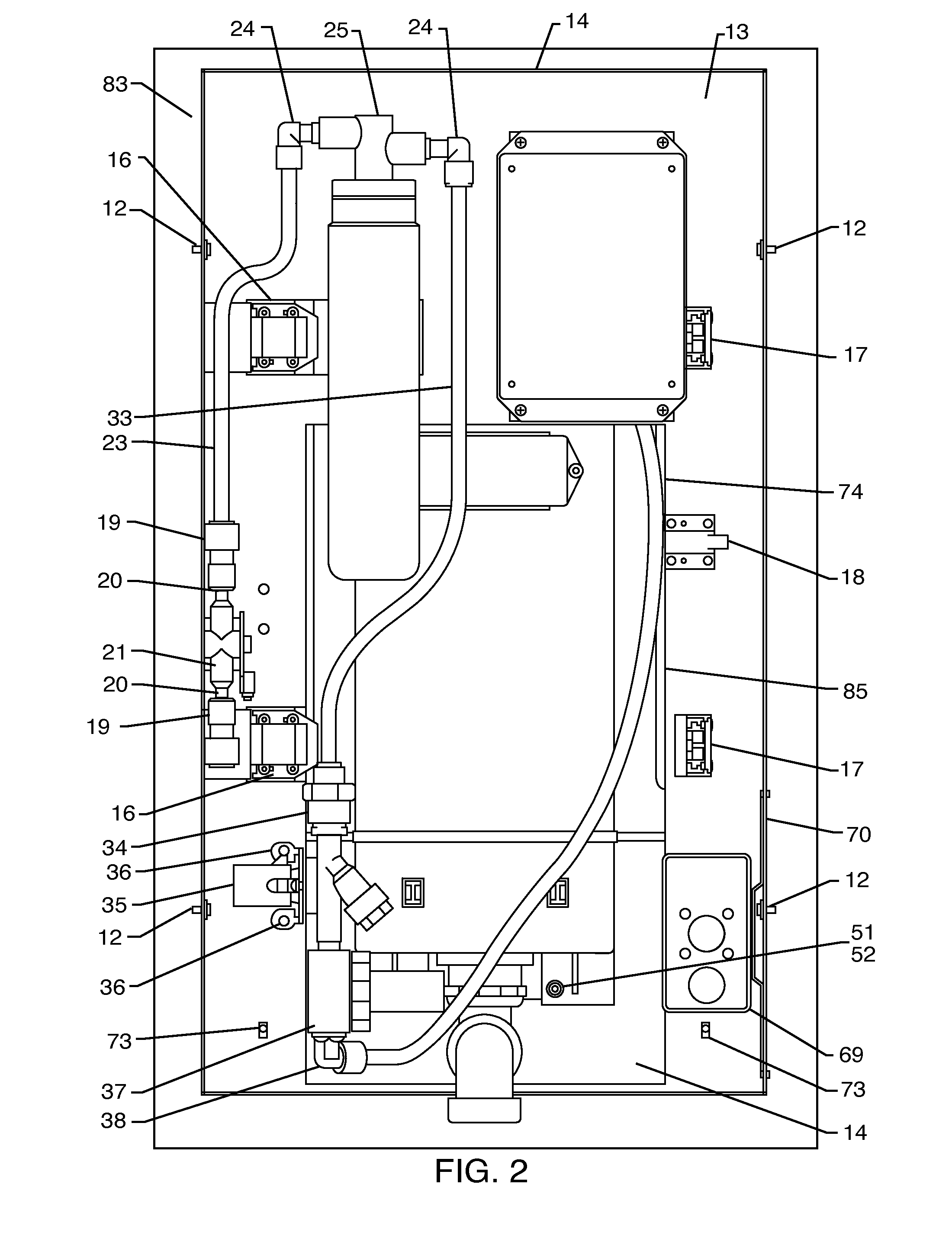

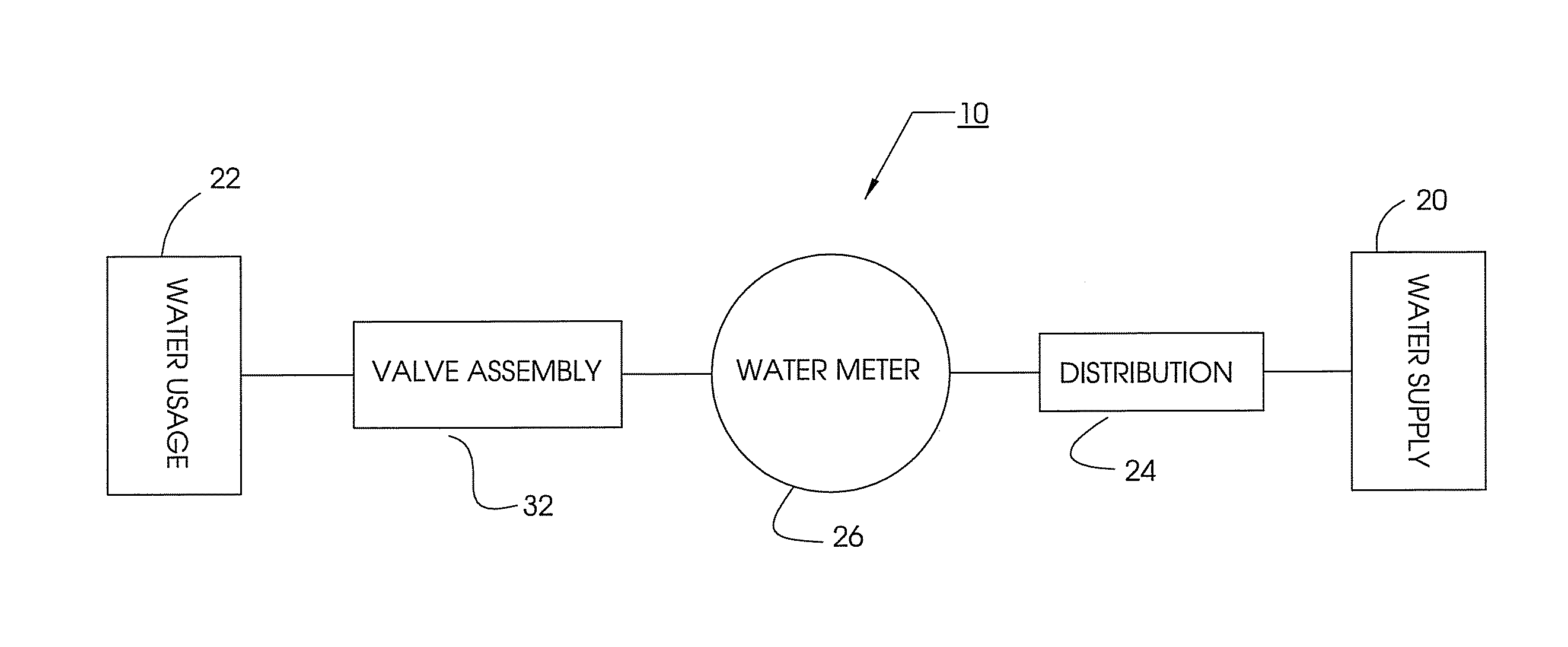

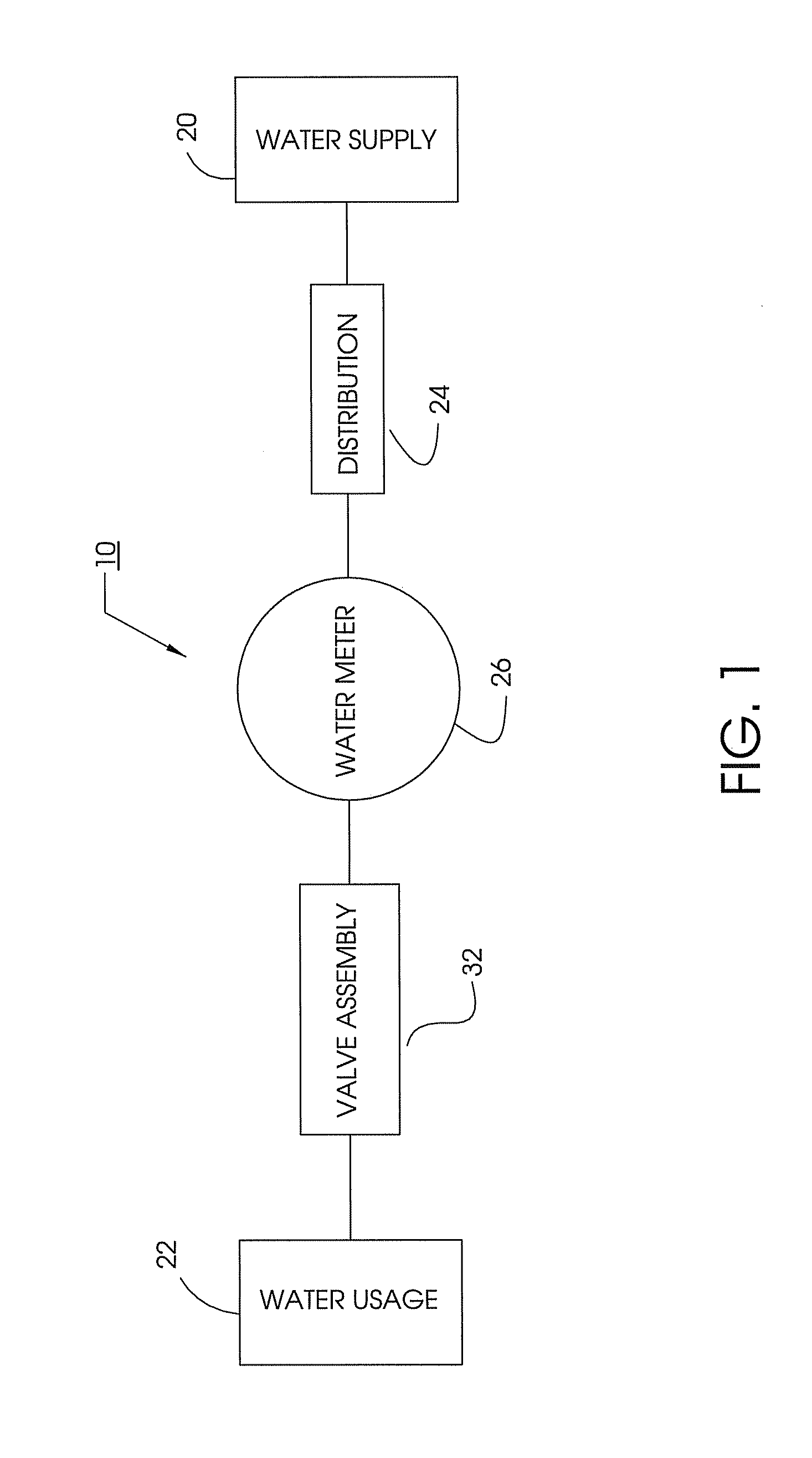

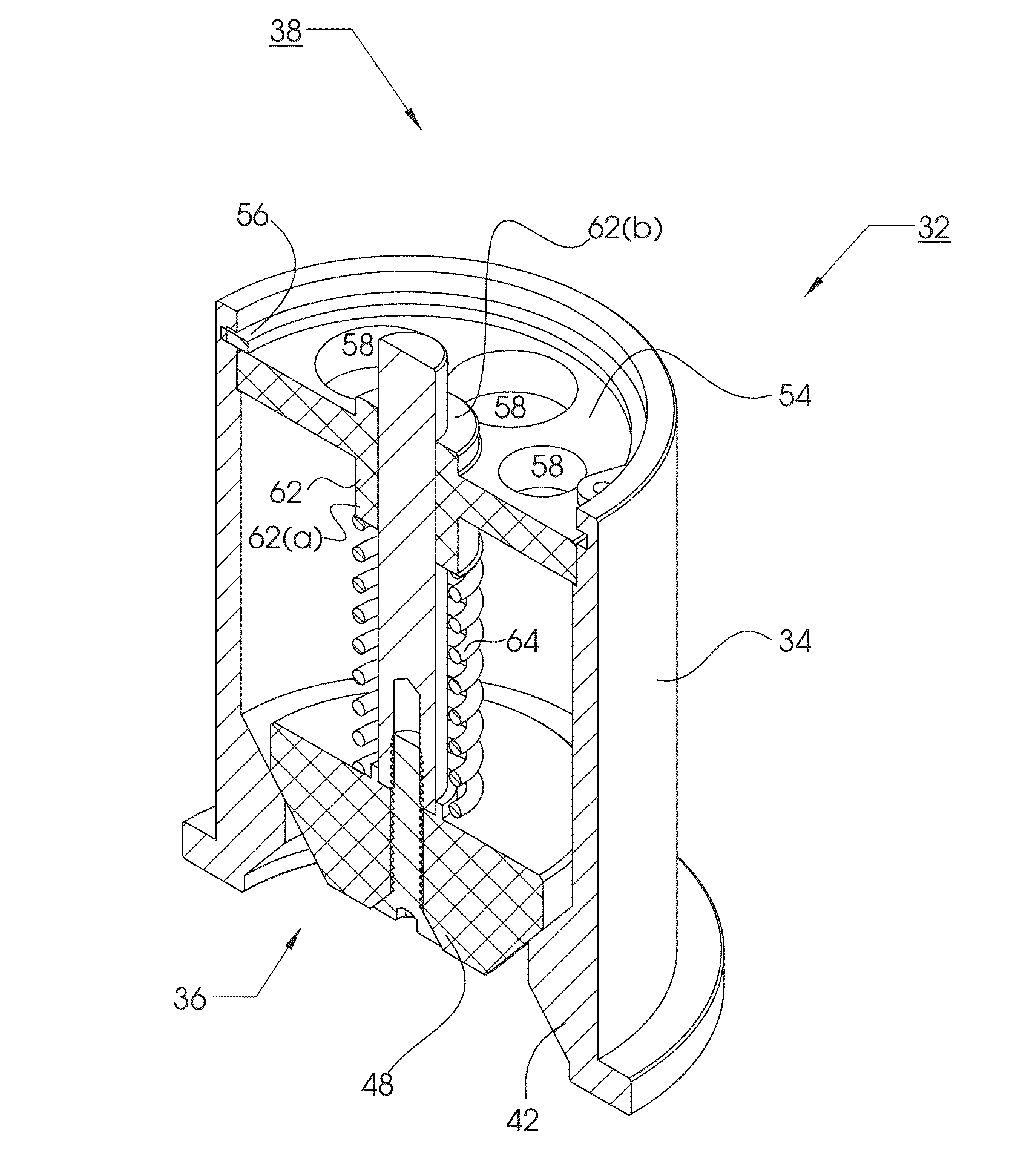

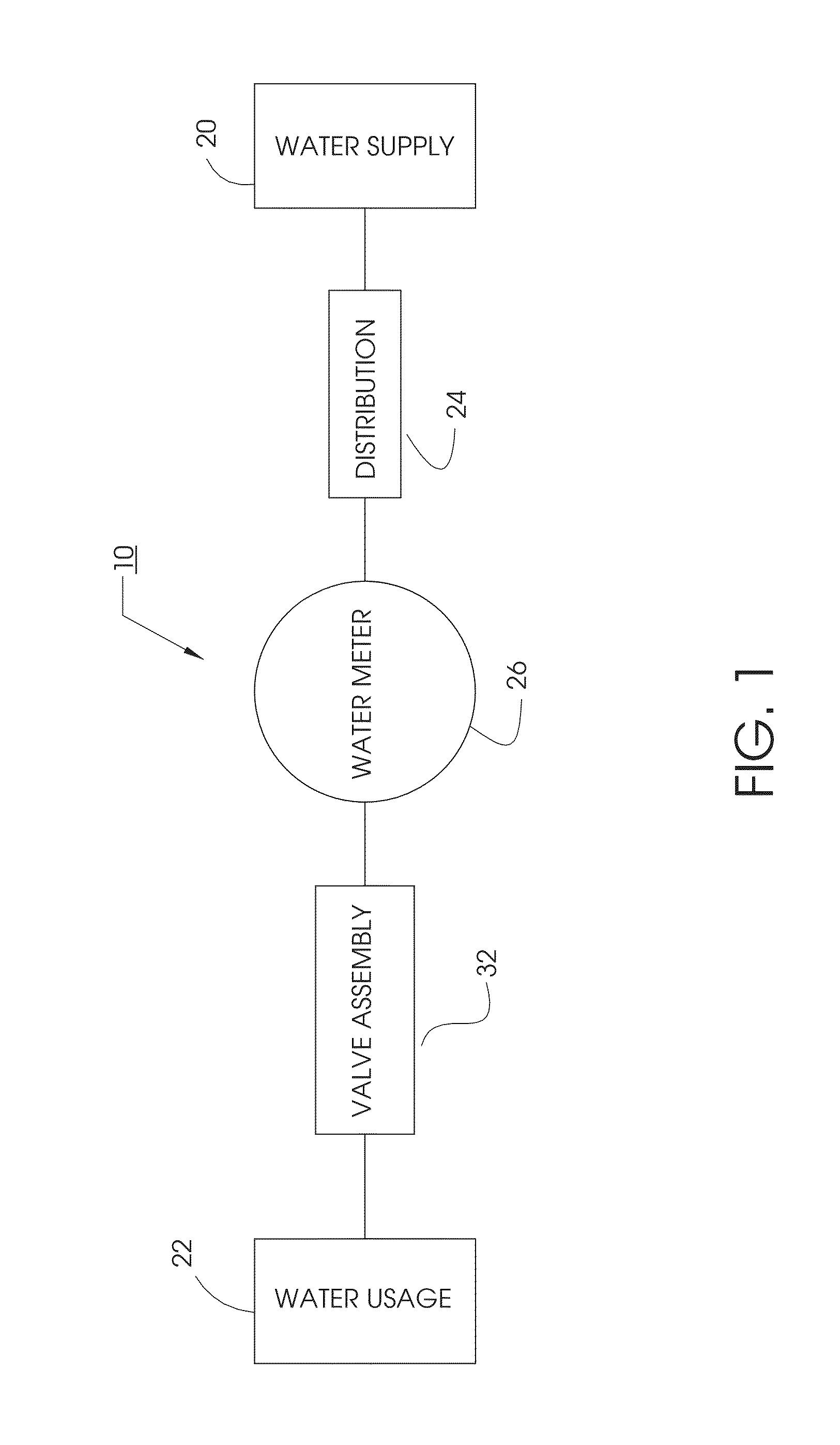

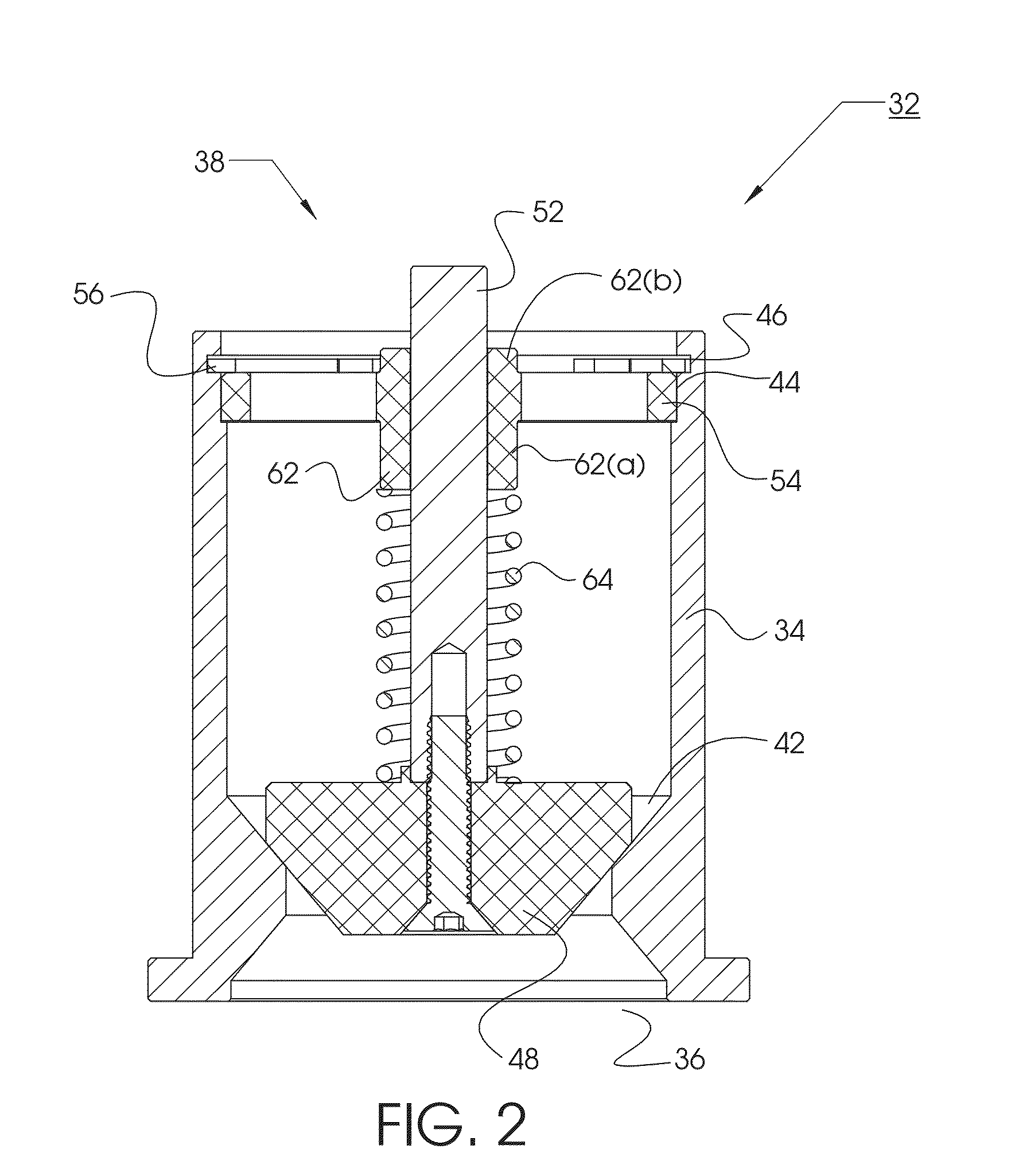

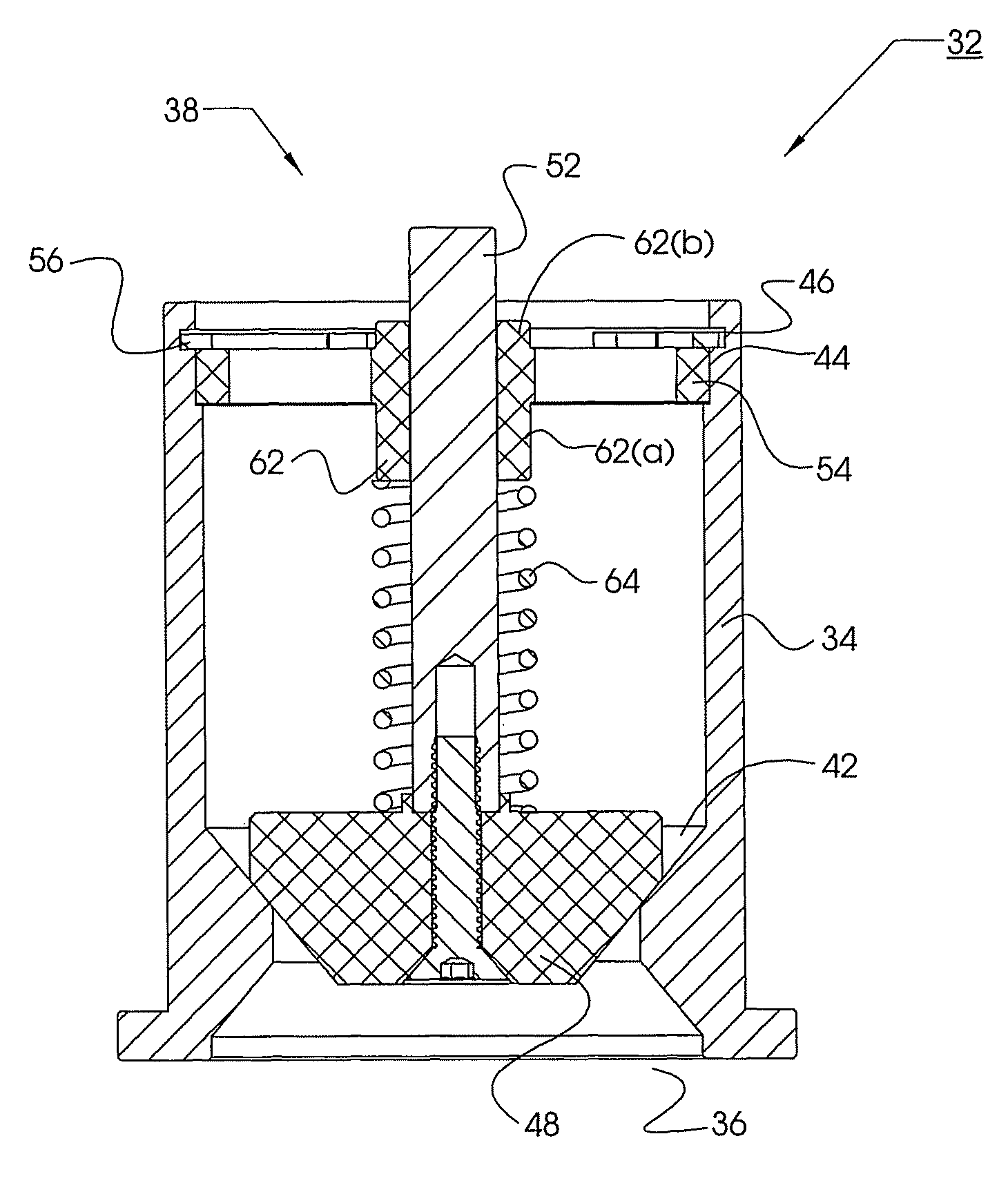

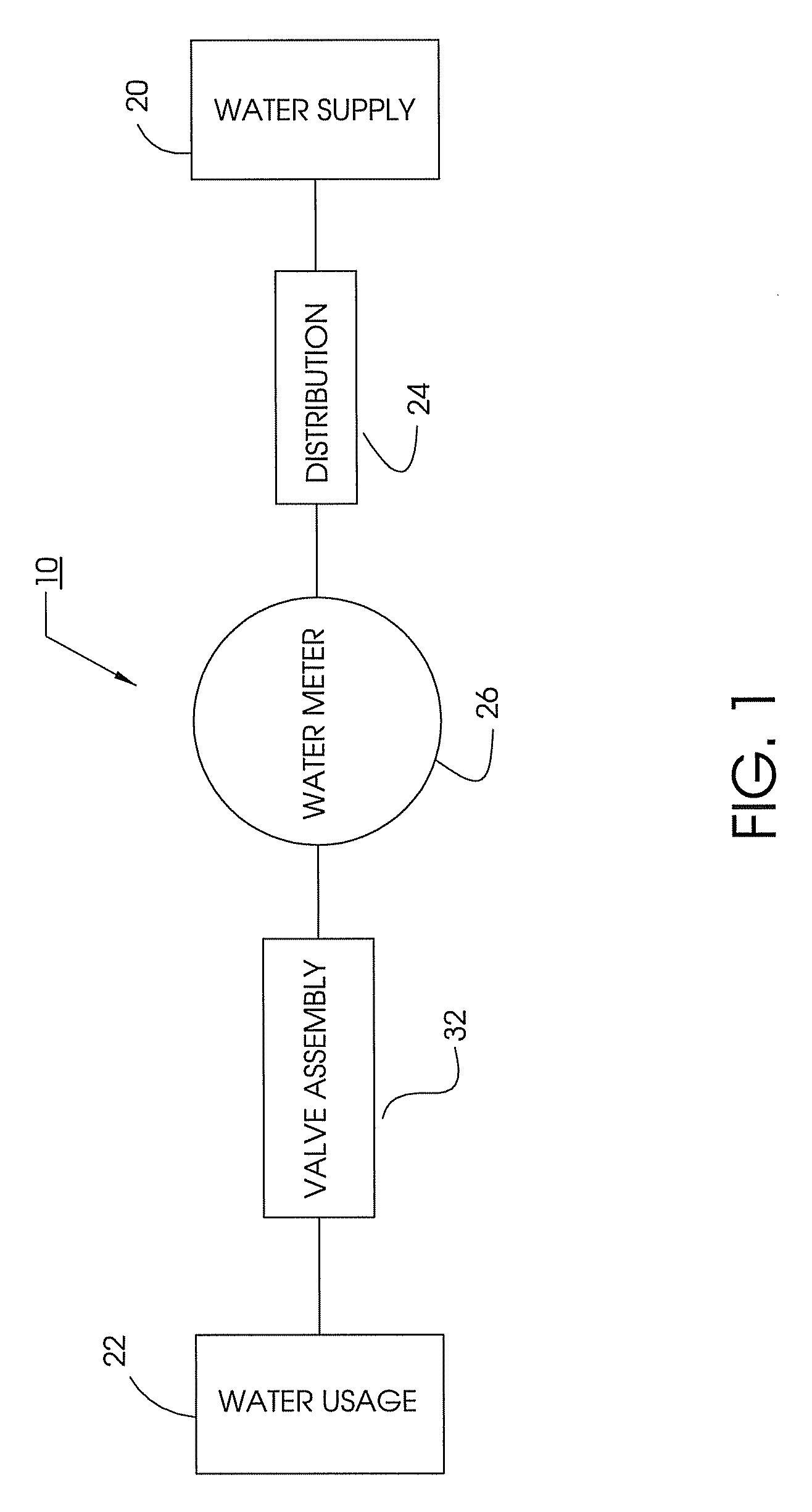

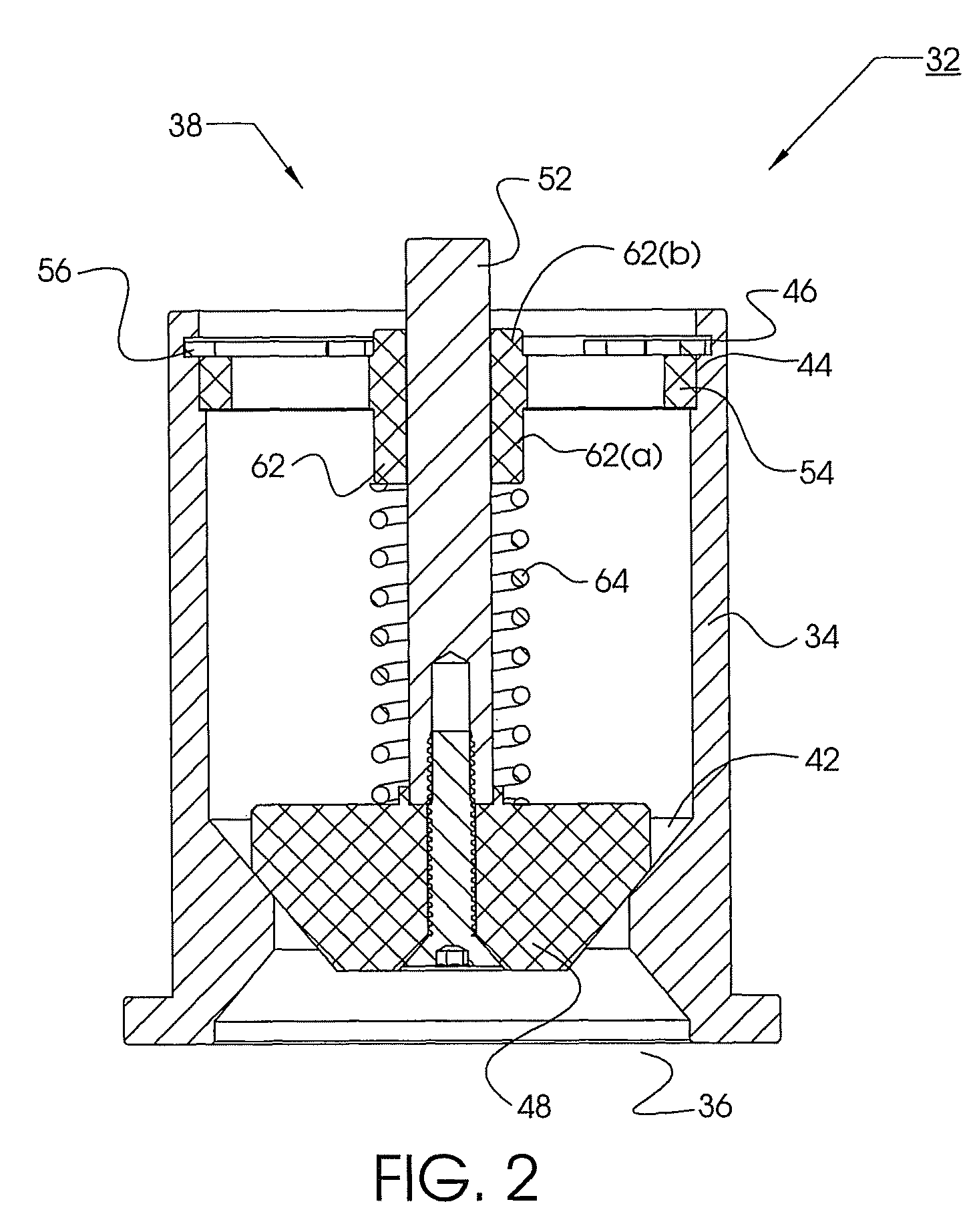

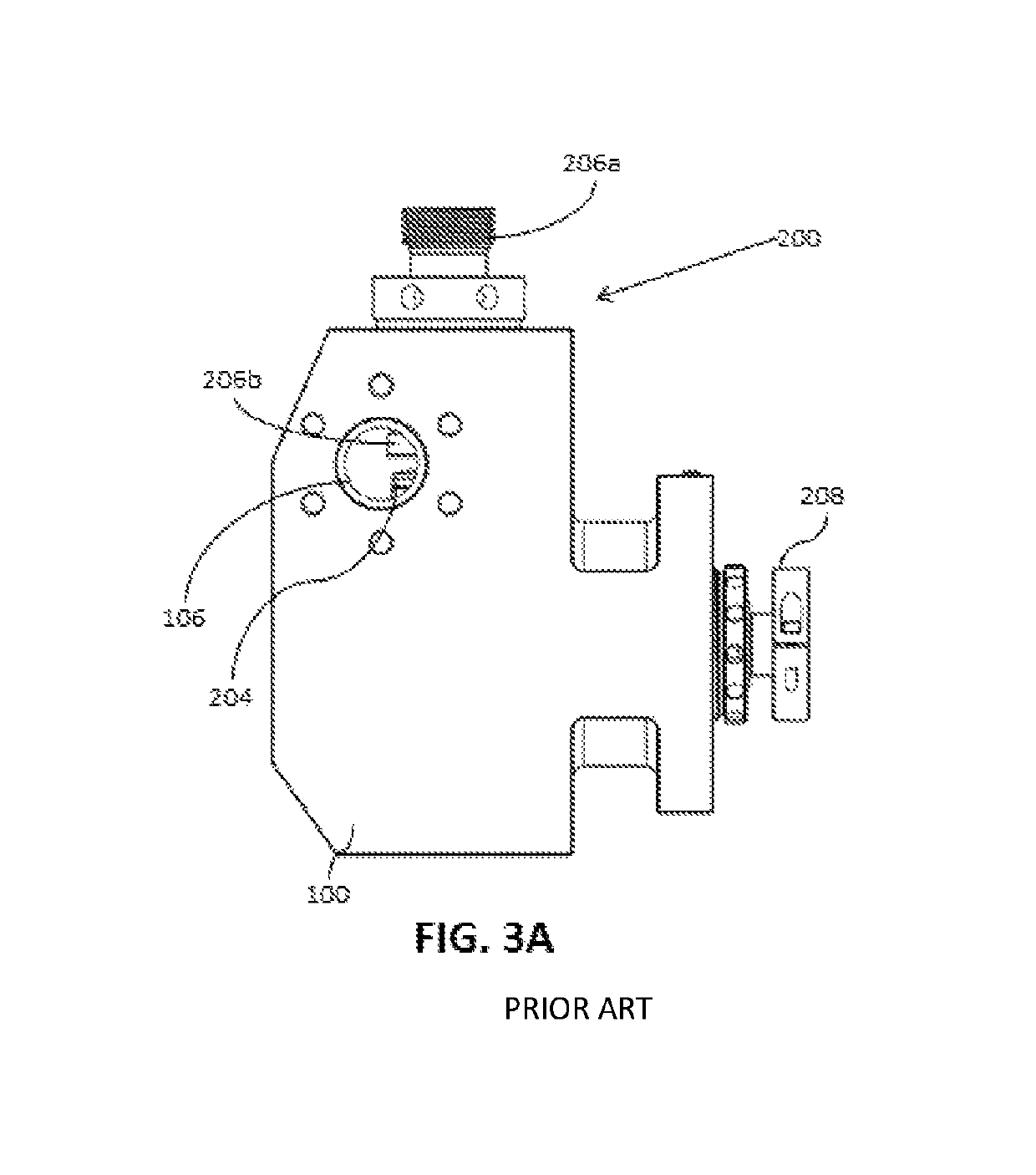

System for Increasing the Efficiency of a Water Meter

InactiveUS20120118406A1High densityHigh measurement accuracyVolume/mass flow measurementCheck valvesAir entrainmentEngineering

Disclosed is a system and an associated valve assembly that are adapted to increase the efficiency of an upstream water meter. By way of the valve assembly entrained water bubbles can be removed from a water supply. This, in turn, increases the density of the water running through the water meter. This ensures that the water meter is not inaccurately including entrained air as metered water. The result is more accurate water readings and reduced utility bills.

Owner:FLOW DYNAMICS LLC

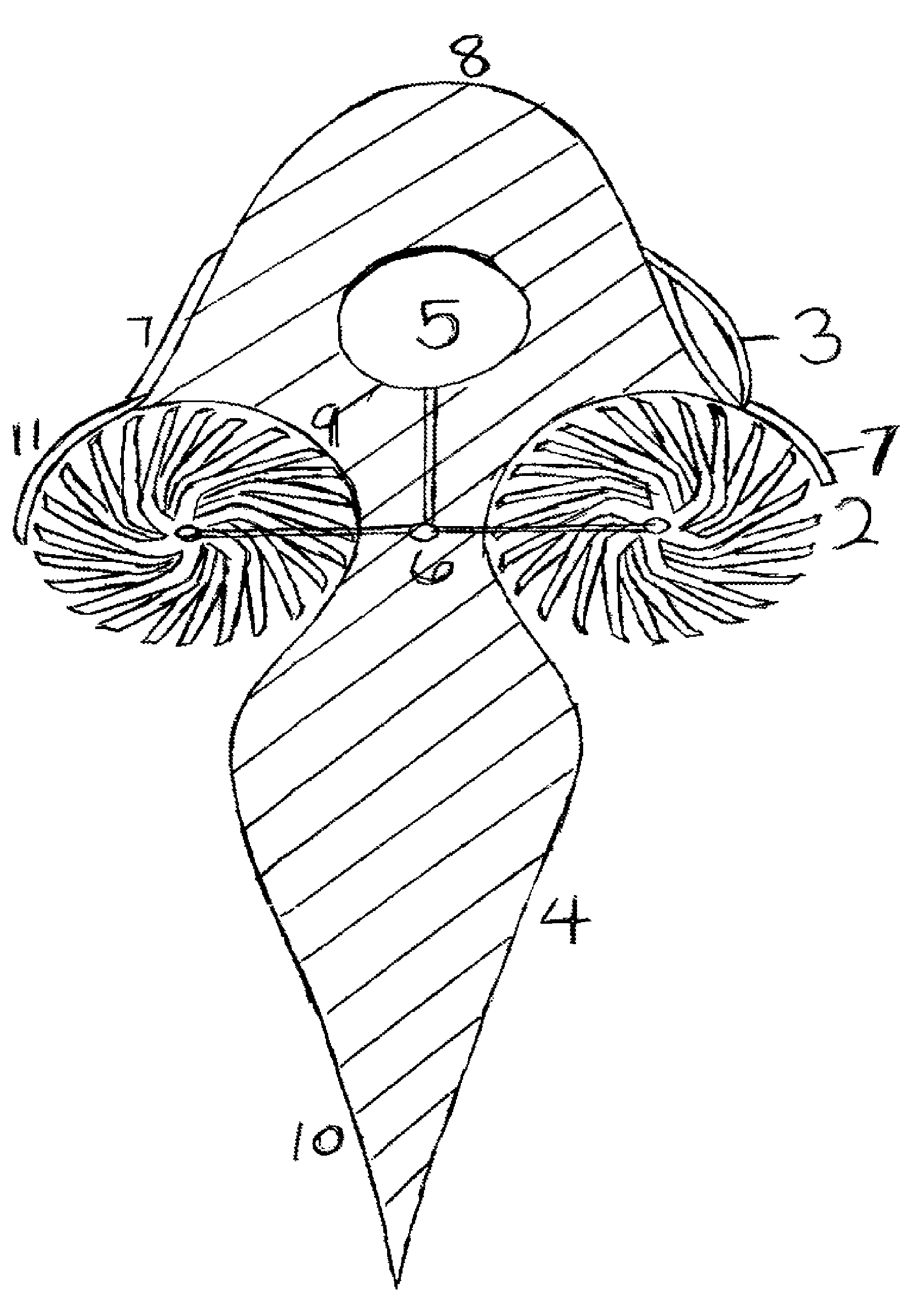

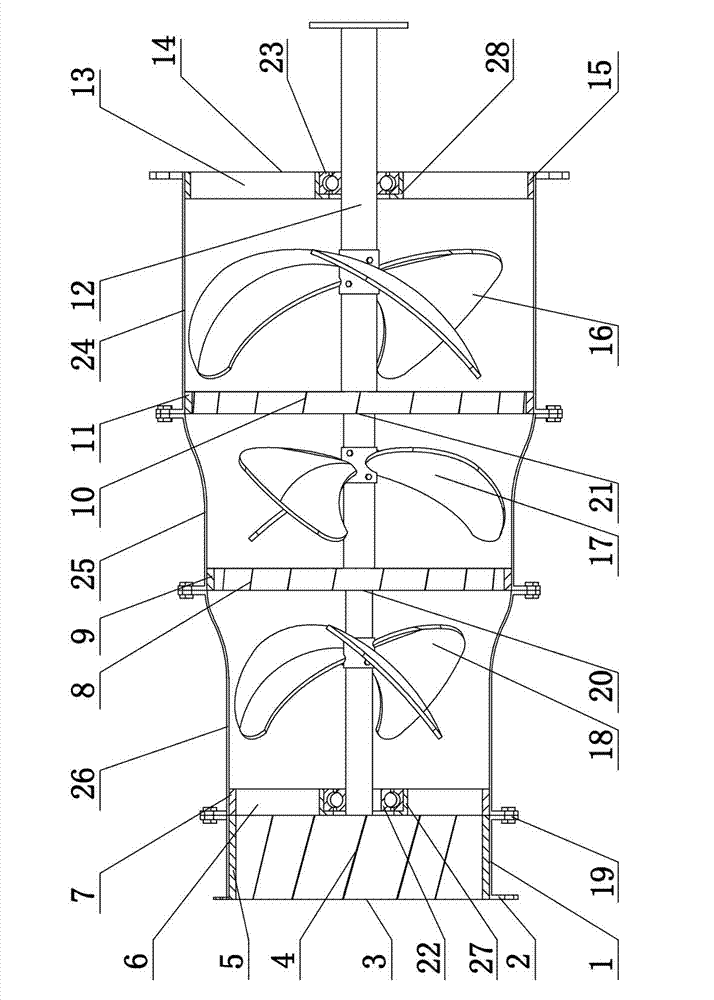

Shrouded vertical axis dual-turbine generator

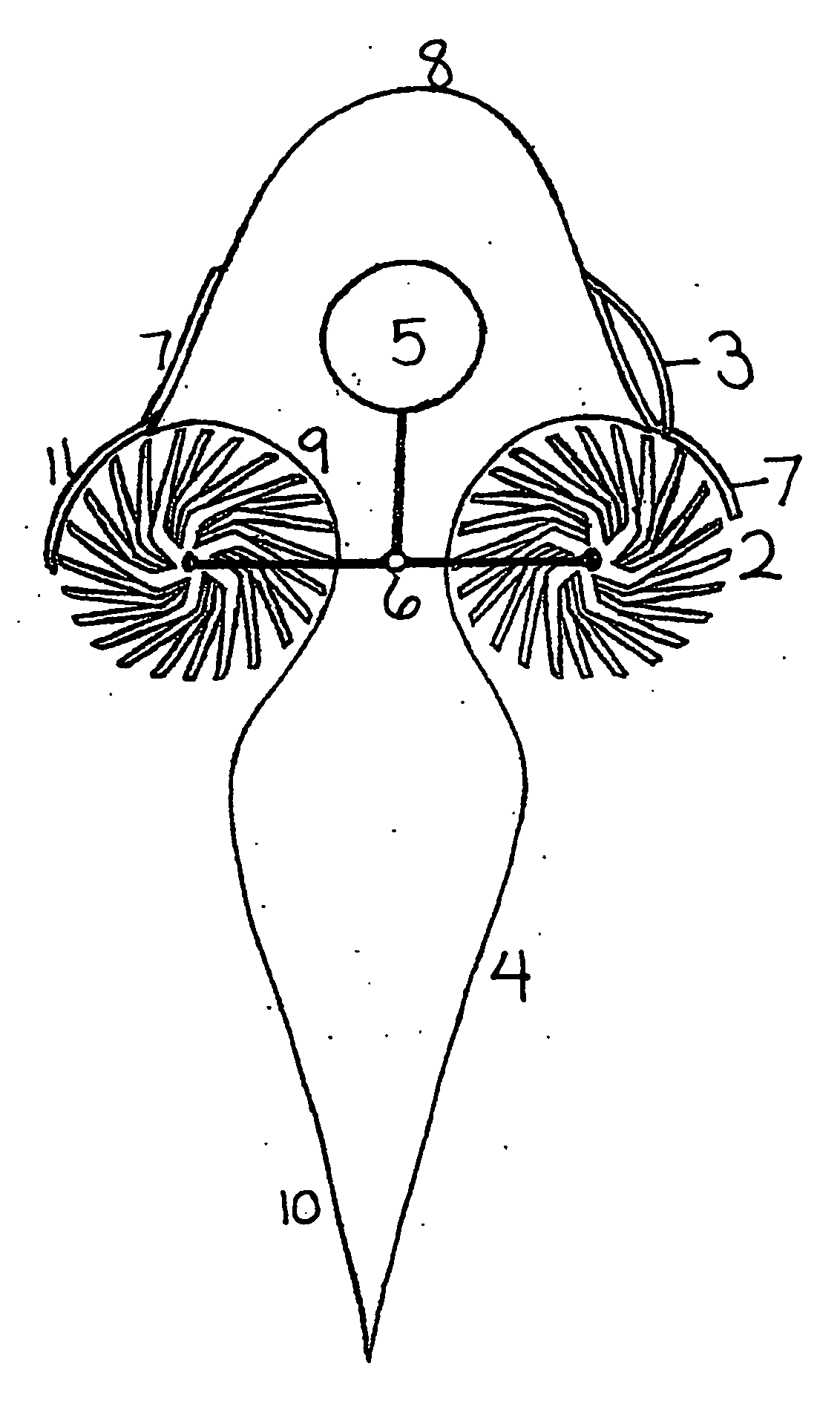

InactiveUS20100213720A1Increase speedEliminate energy-robbing turbulenceWind motor controlWind motor combinationsLeading edgeWater flow

The Shrouded Vertical Axis Dual-Turbine Generator is a system consisting of a superstructure in the shape of a symmetrical foil, with a vertical axis turbine set into the camber of each side. The leading edge of the superstructure increases the speed of the water or air current passing around the generator. The trailing edge creates a slip stream which reduces turbulence. Shutters on each side of the superstructure control the amount of current in contact with the turbines by sliding forward or rearward to increase or decrease flow to the turbines. The turbines are modular in design and can be customized into longer or shorter turbines, depending on application.

Owner:BAILEY LAURA J +1

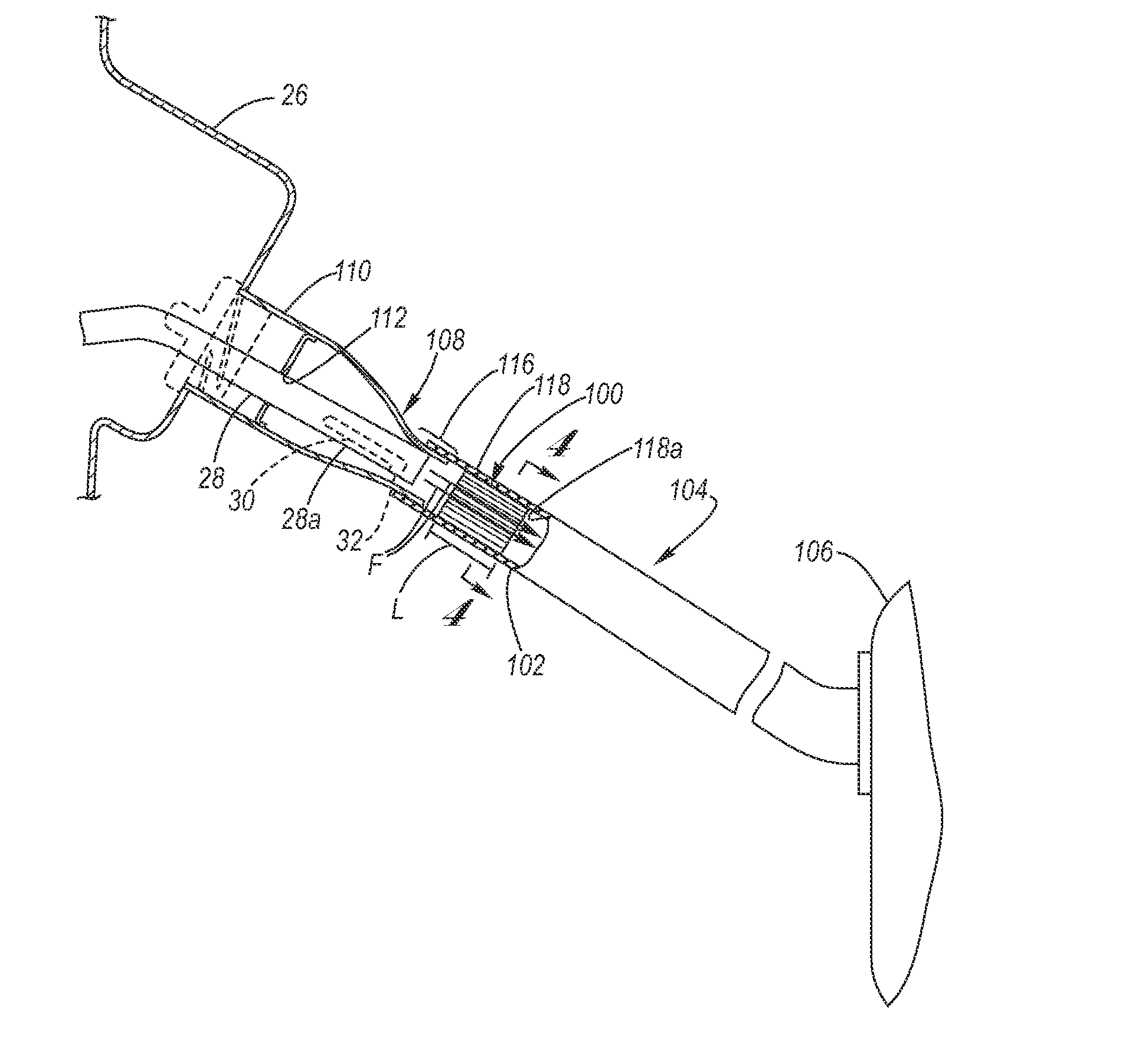

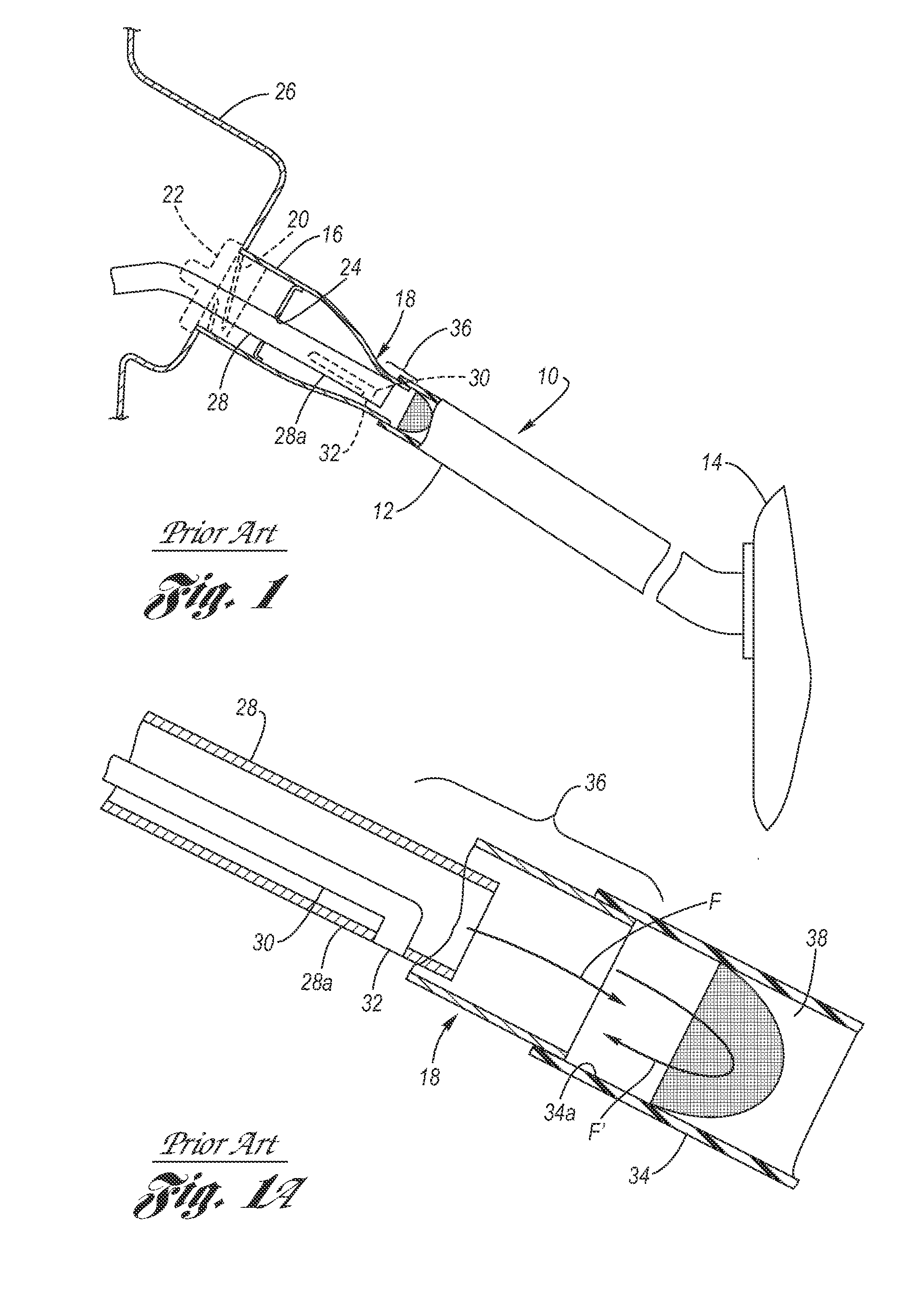

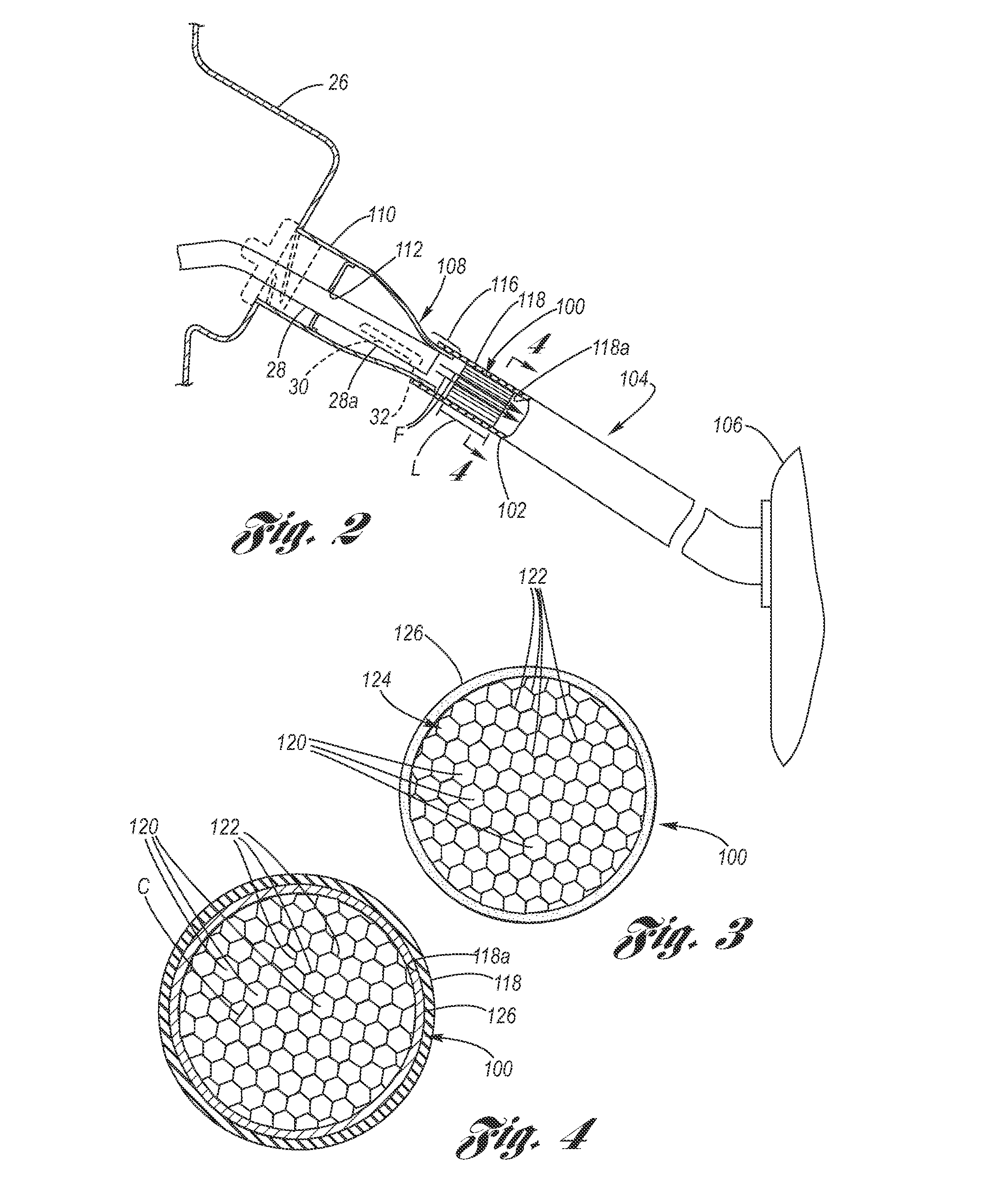

Honeycomb Flame Arrester and Flow Straightener for a Fuel System Fuel Fill Pipe

InactiveUS20080271814A1Ensure efficient flowSpeed up the flowFire rescueLiquid transferring devicesFlame arresterEngineering

A motor vehicle filler pipe flame arrester and fuel flow straightener configured to effectively quench a moving flame front, while providing laminar fuel flow therethrough. A multi-channel (or multi-cell) configuration, most preferably a honeycomb configuration, provides effective flame arresting due to its heat sink capacity and large effective surface area for flame arrestment, while attendantly limiting availability of fuel and oxygen to the flame, thereby providing quenching of a flame wave as it propagates through the channels. Service station pump nozzle shut-off sensor disruption is avoided because the channels encourage laminar flow of the fuel through the multi-channel filler pipe flame arrester and fuel flow straightener.

Owner:GM GLOBAL TECH OPERATIONS LLC

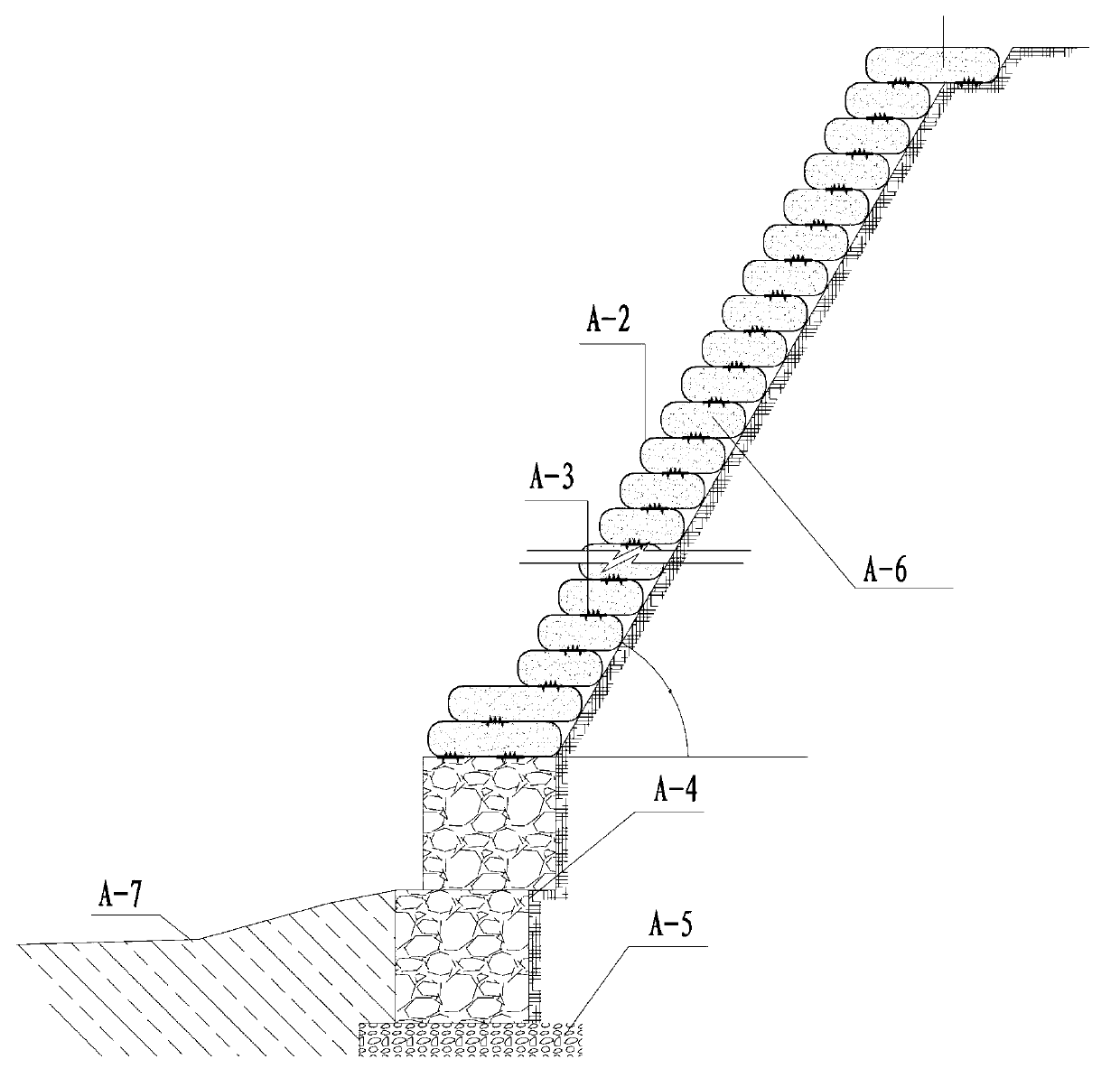

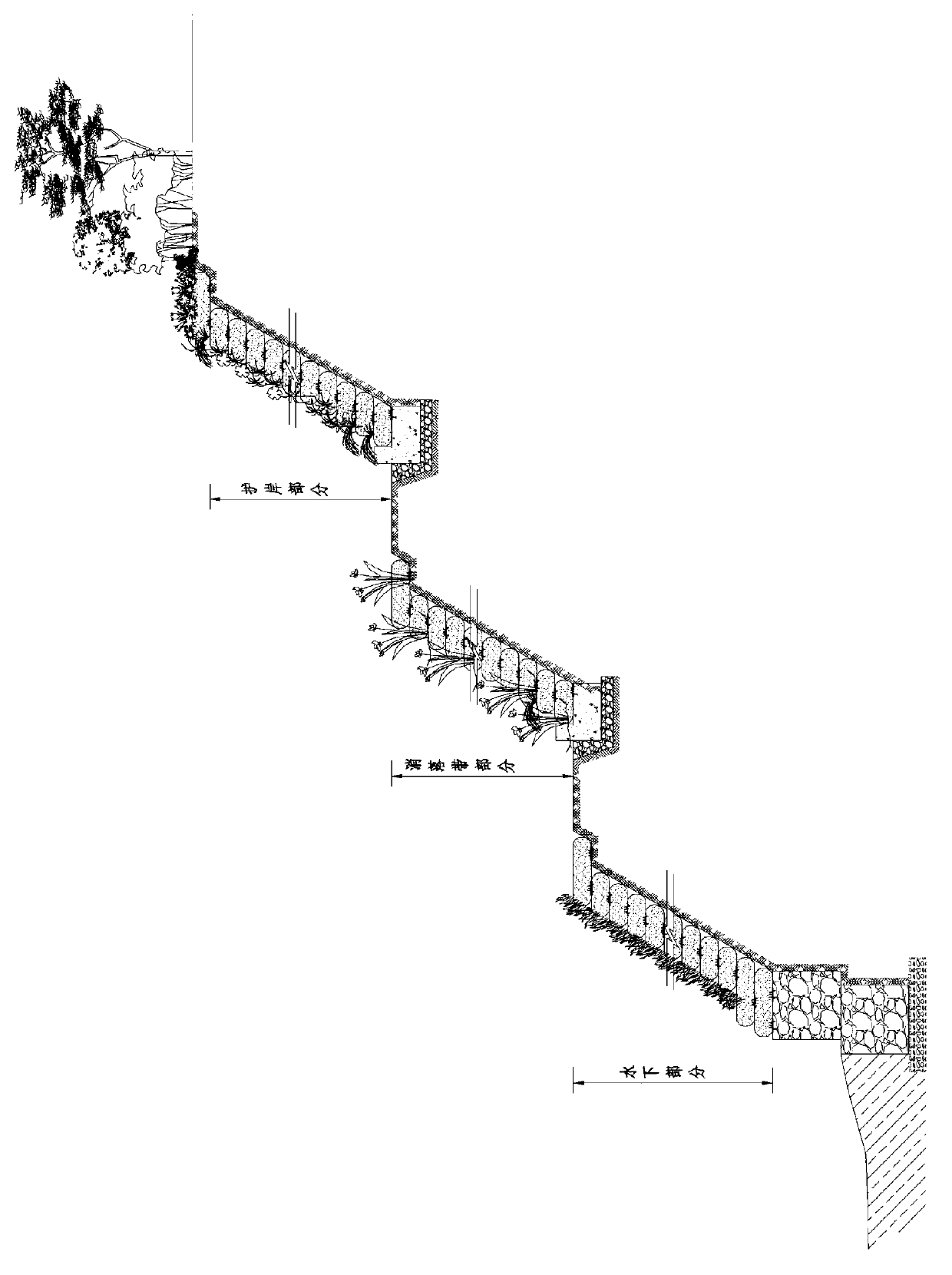

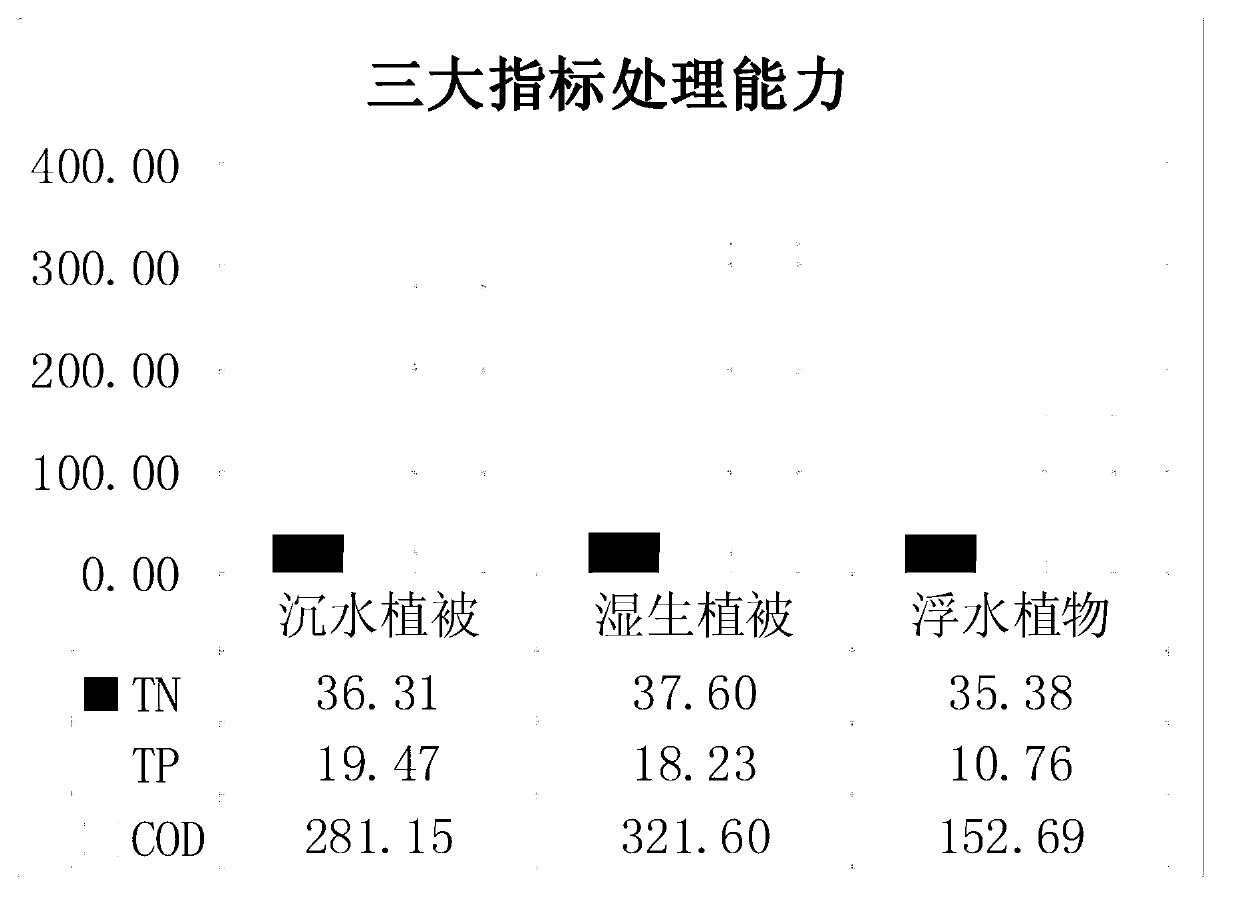

Underwater revetment based on ecological bags and water body ecological management method

InactiveCN103276696AWon't breakWill not deformCoastlines protectionSustainable biological treatmentFilter feederShrimp

The invention relates to an underwater revetment based on ecological bags and a water body ecological management method. The method comprises a first step of dredging and solidifying, a second step of establishing a water bottom foundation, a third step of clearing up the revetment surface, a fourth step of paving the ecological bags in a step-shaped lamination dislocation mode from the top of the water bottom foundation, a fifth step of planting submerged plants on the ecological bags, a sixth step of stopping river closure or beginning to coffer after the water quality conforms to or superior to the fourth scale of the national surface water environment criterion GB / 3838-2002, wherein when the water quality does not conform to or inferior to the fifth scale of the GB / 3838-2002, microbial preparation is added into the water according to the water quality measuring result, and a seventh step adding filter feeder fishes or / and herbivorous fishes, shrimps and demersal mussel animals. The method guarantees that floodwater can be drawn off based on the fact that the underwater revetment structure of rivers and lakes is safe, and the cooperative management capacity for the water body is improved through ecological restoration of the underwater revetment.

Owner:CHONGQING DANHAI IND

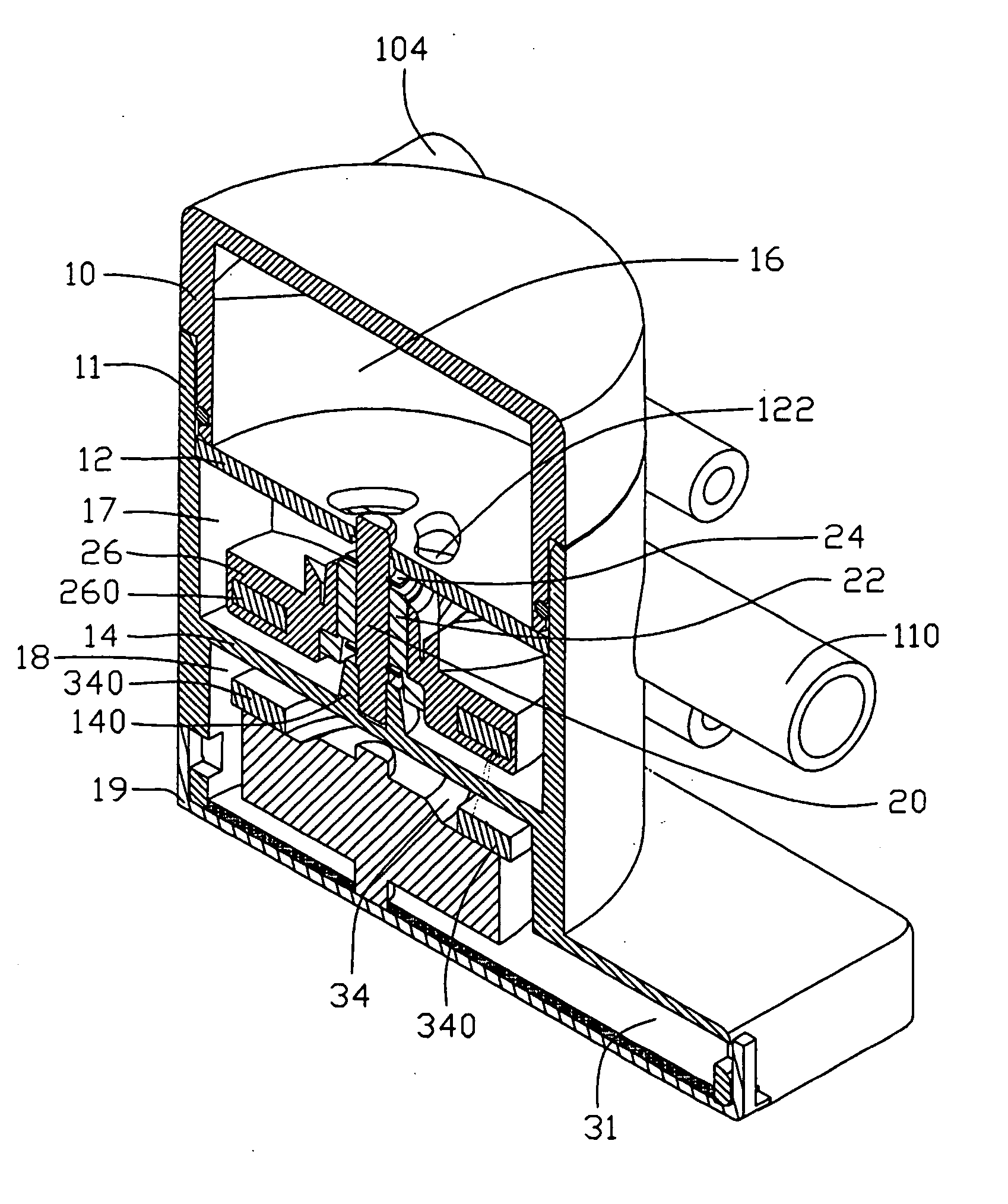

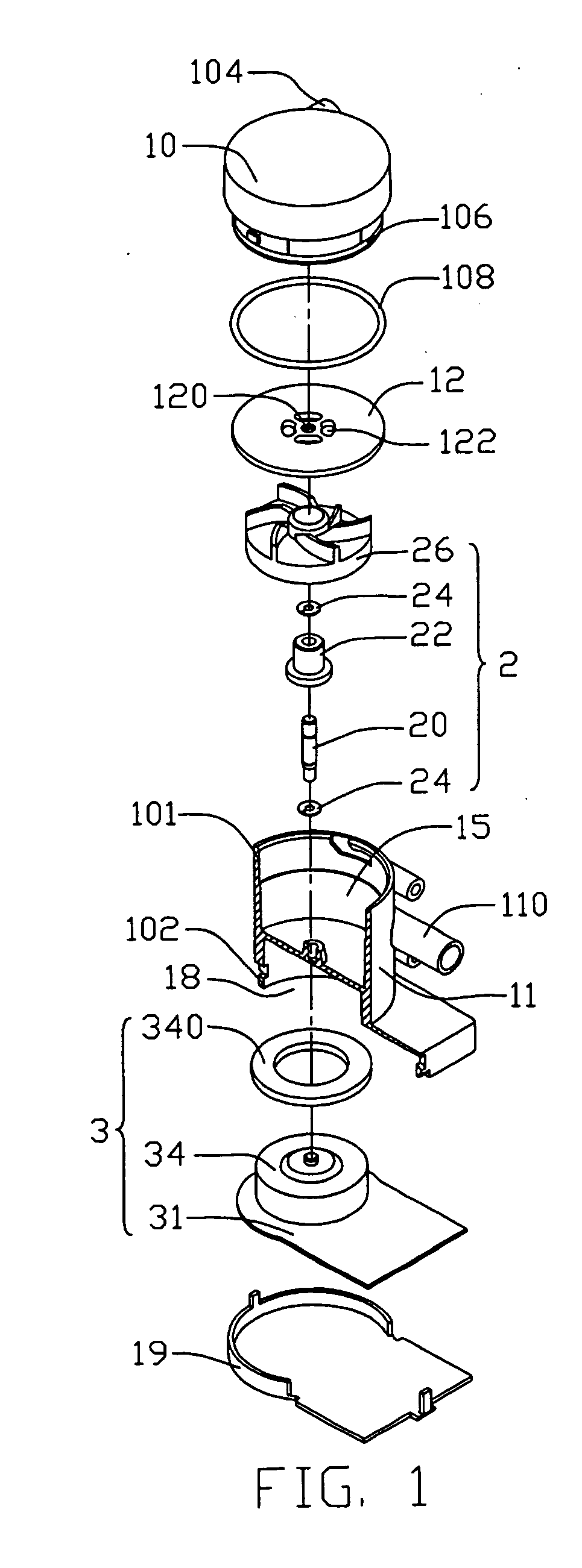

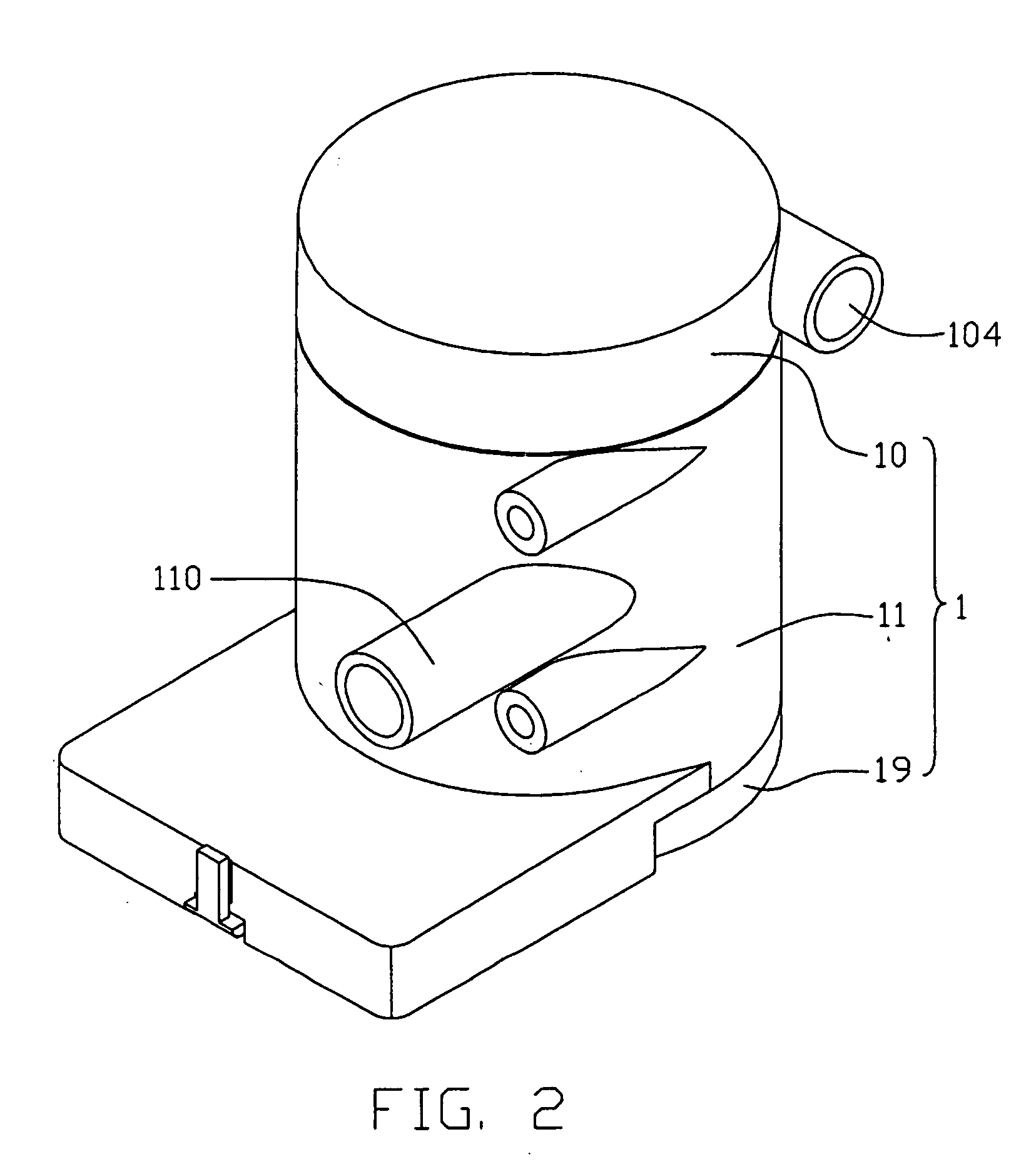

Miniature pump for liquid cooling system

InactiveUS20060051222A1Eliminate turbulencePiston pumpsPump installationsLiquid cooling systemEngineering

A miniature pump in accordance with the present invention comprises a pump casing (1) and a liquid circulating unit (2) received in the pump casing. The pump casing defines an enclosed space (15) for storing liquid therein. A spacing plate (12) is arranged in the pump casing to divide the enclosed space into a first chamber (16) and a second chamber. The spacing plate defines a through opening (122) at a center portion thereof to make the first and second chambers communicate with each other. An inlet (104) and an outlet (110) are formed on the pump casing respectively communicating with the first and second chambers. The liquid circulating unit is mounted in the second chamber for circulating the liquid in a liquid cooling system.

Owner:HON HAI PRECISION IND CO LTD

Shrouded vertical axis dual-turbine generator

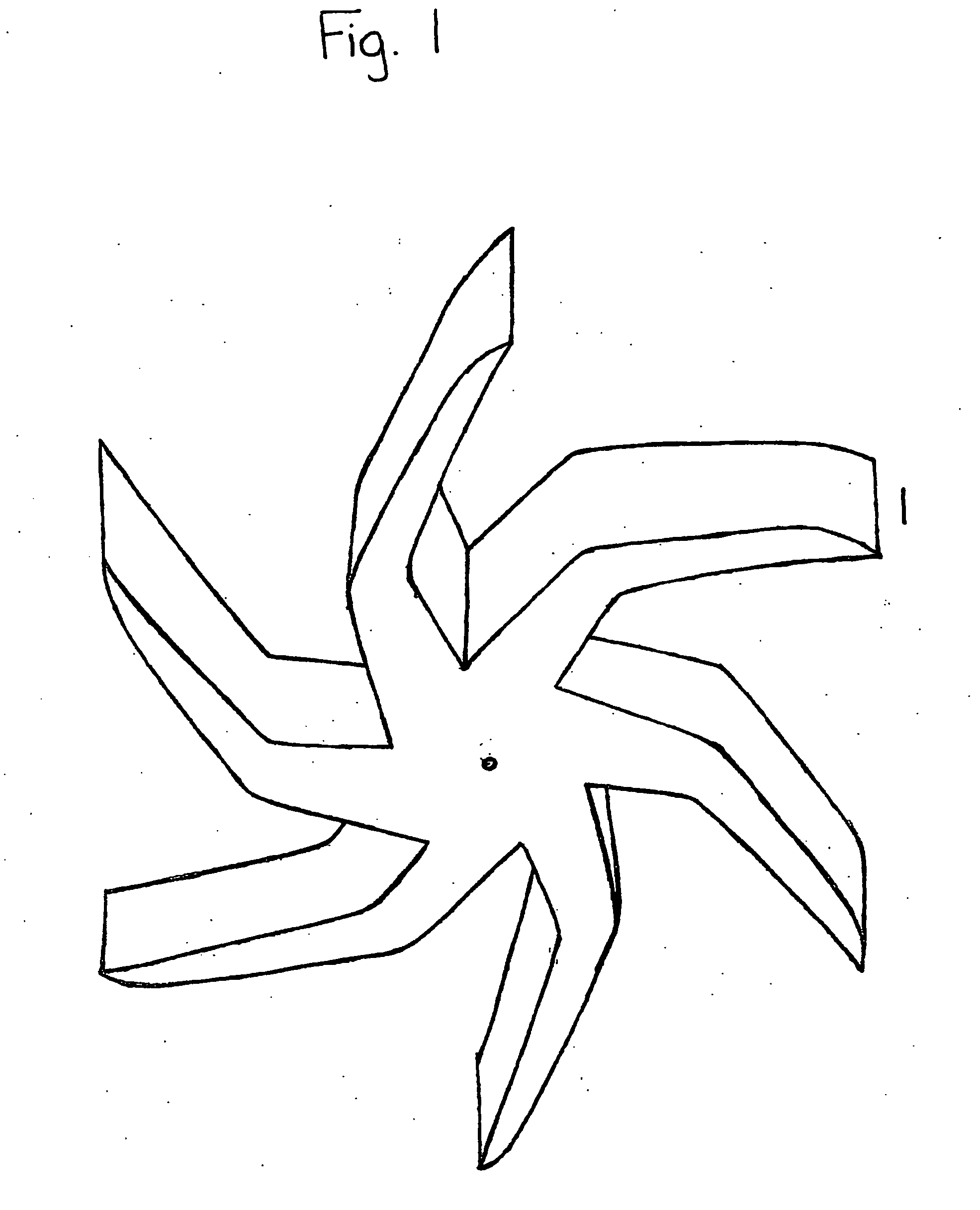

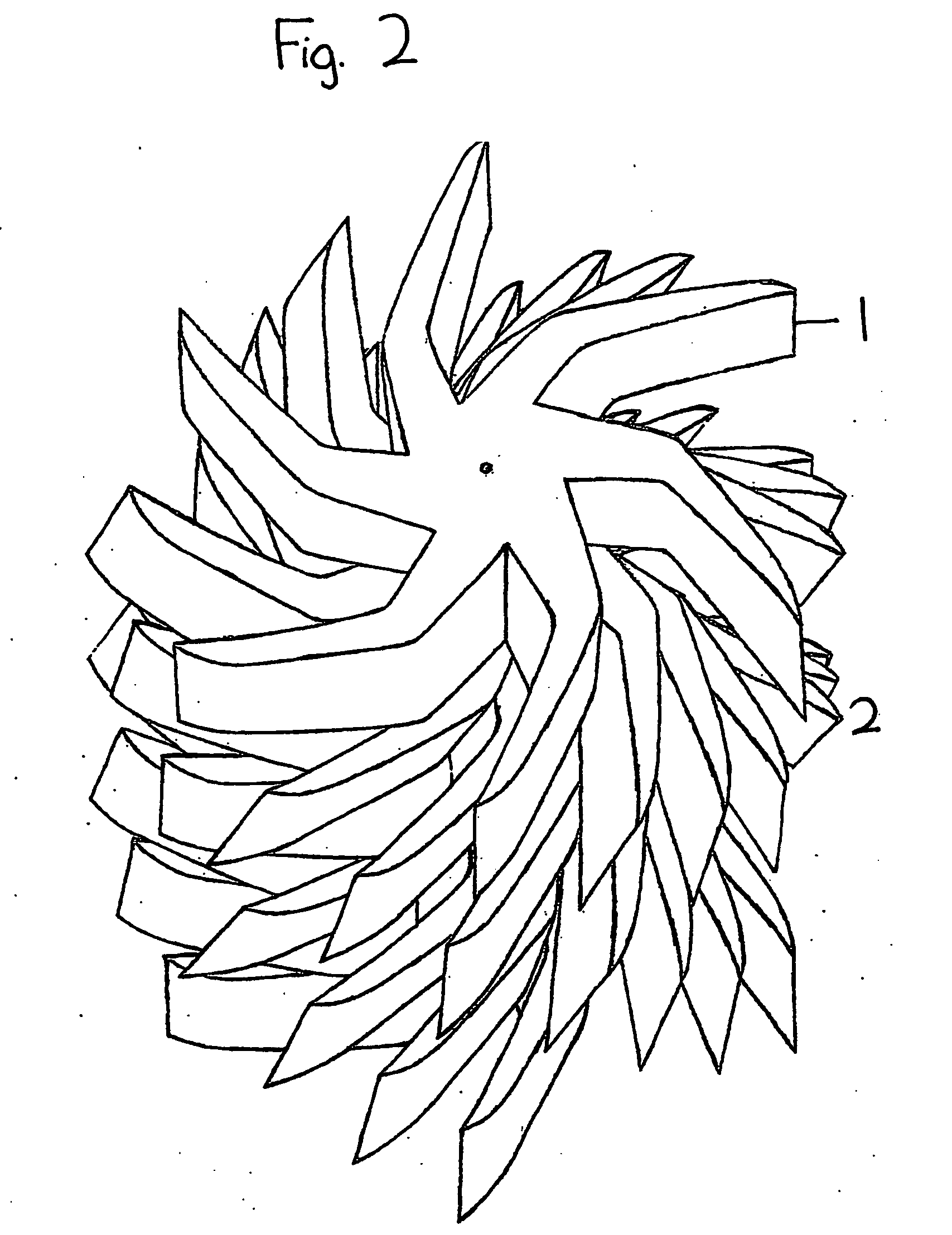

InactiveUS8432056B2Increase speedImprove efficiencyWind motor controlWind motor combinationsLeading edgeModular design

The shrouded vertical axis dual-turbine generator is a system comprising a structure in the shape of a double airplane wings symmetrical foil, having a vertical axis turbine set into each camber at each side of the foil. The aerodynamic shape of the leading edge of the foil increases the speed of the water or air current incoming toward the generator. The trailing edge of the foil creates a slip stream which reduces turbulence. Movable shutters on each side of the foil structure control the amount of current to the turbines and sheltering them from storm and debris. The turbines have a modular design and can be made of a stacked number of blades.

Owner:BAILEY LAURA J +1

Aerodynamic airflow deflector for aircraft landing gear

An aerodynamic airflow deflecting device for a landing gear retracting into a housing of an aircraft, comprising at least one element for closing the housing that is, through the action of a control device, able to occupy a position for shielding at least a part of the landing gear against the aerodynamic airflow, thus constituting a noise reducing aerodynamic device. The closing element can in particular include at least one trap door element that is, through the action of the control device, movable between a first position for closing the housing, a second position allowing the landing gear to exit and a third position constituting said shielding position.

Owner:AIRBUS OPERATIONS (SAS)

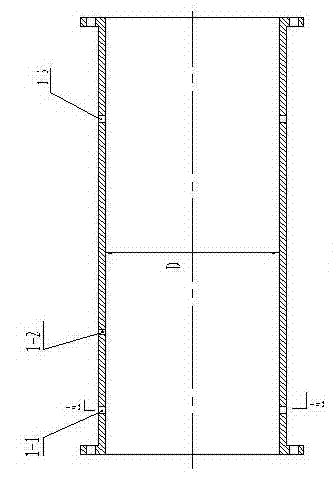

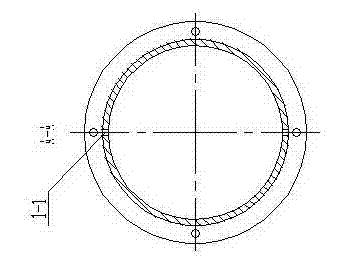

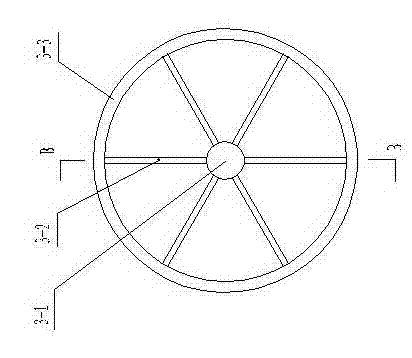

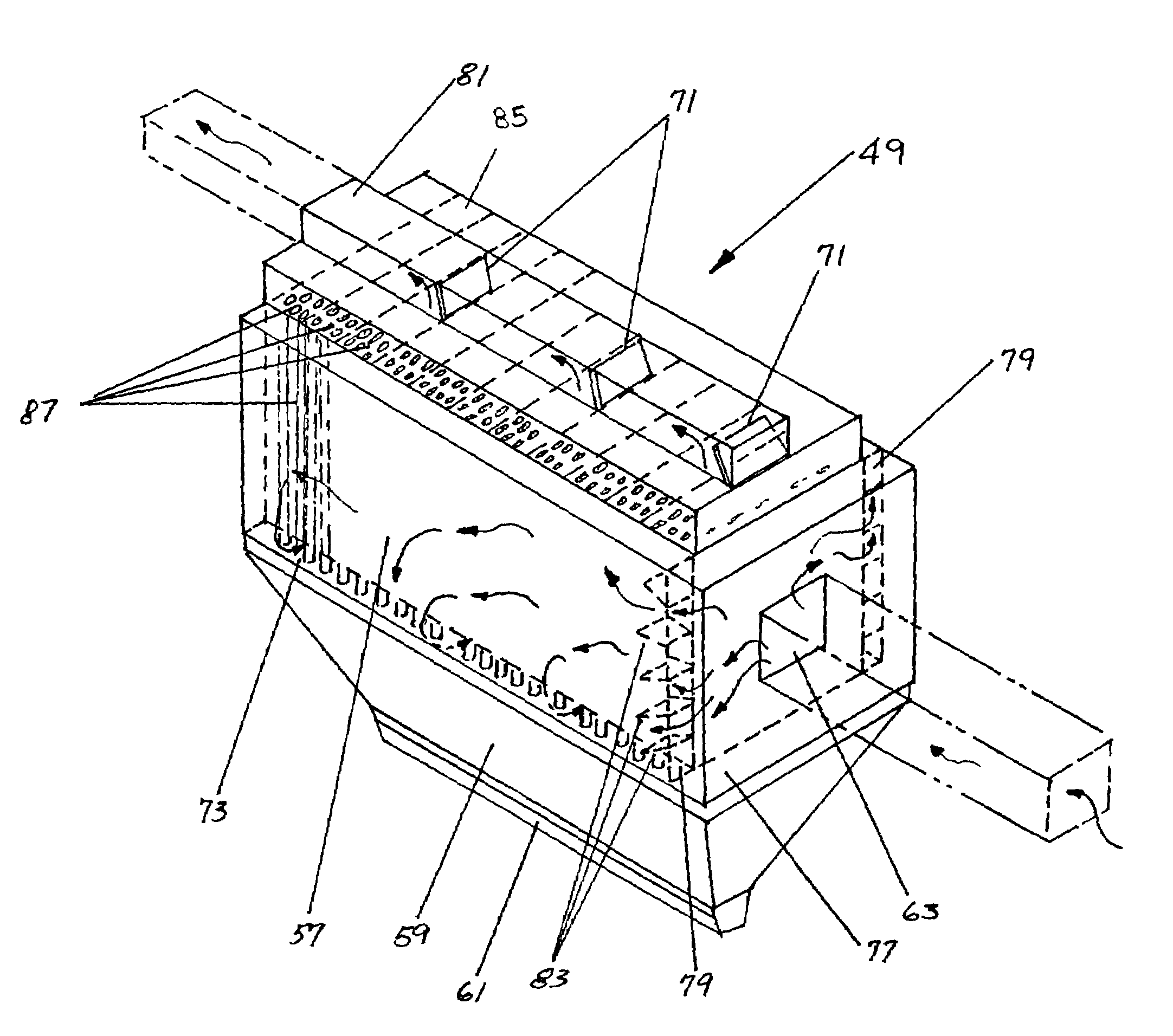

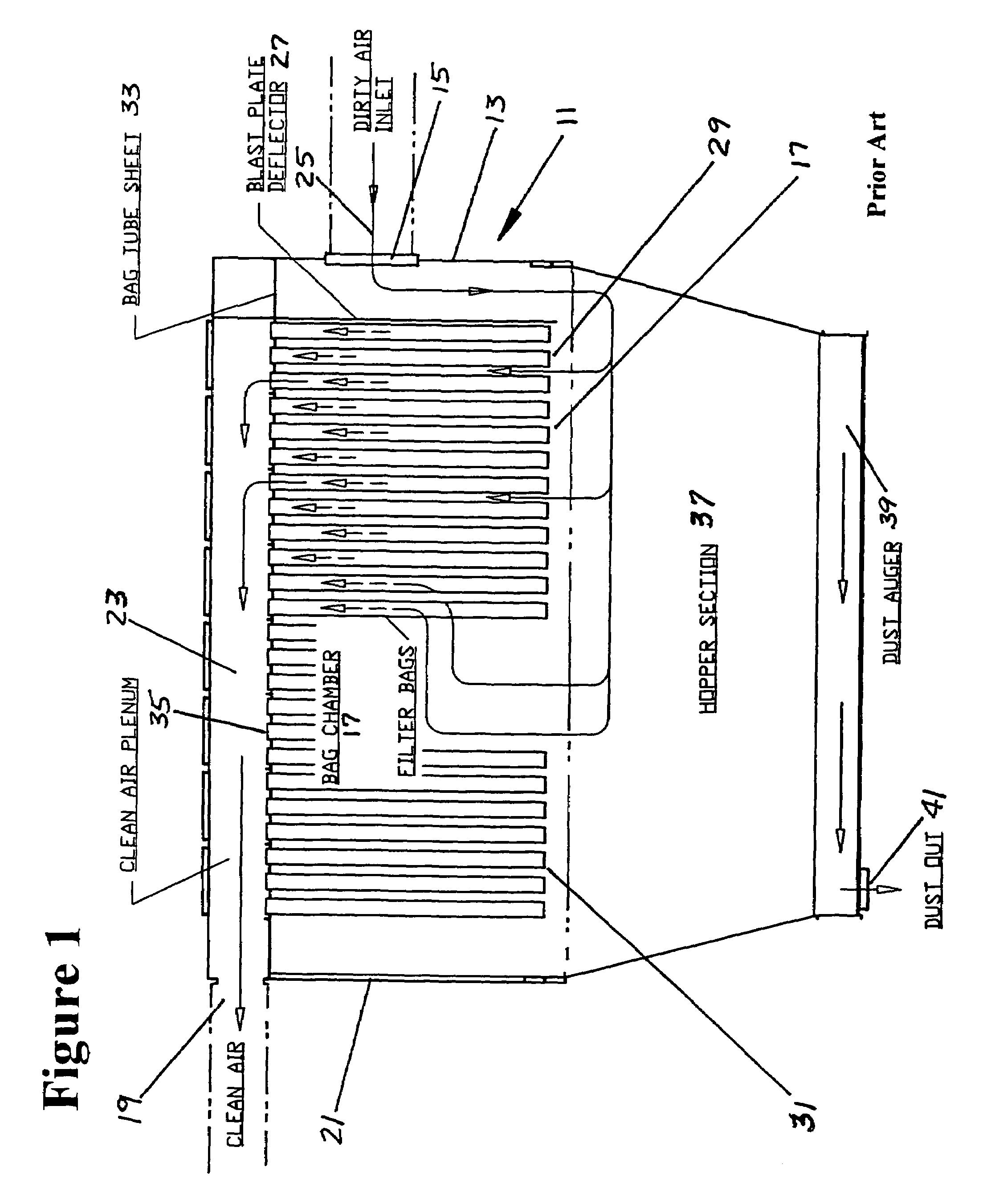

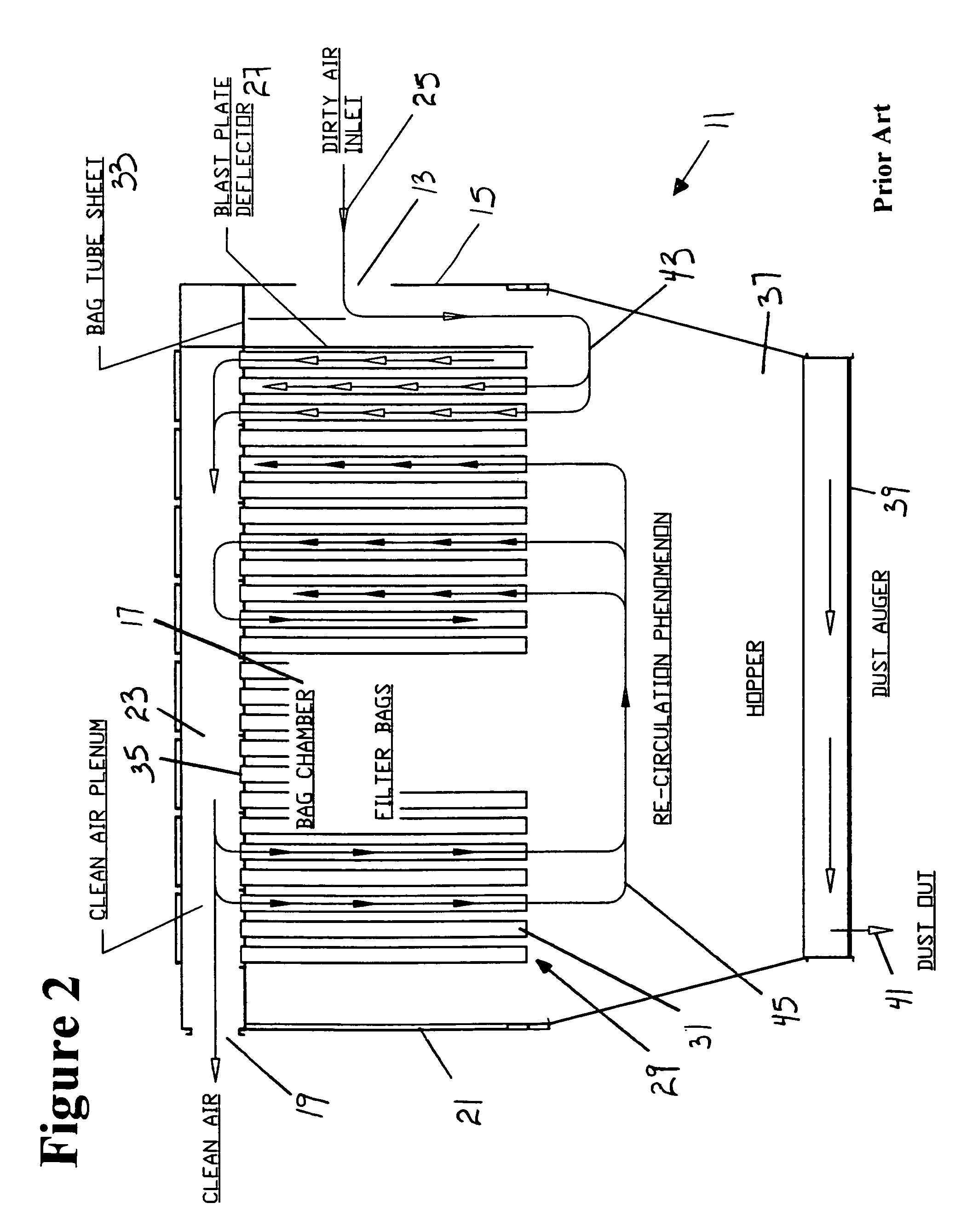

Modular up-draft pressure pulse bag house

InactiveUS7479170B1Simplifies bag cleaning operationIncrease pressureCombination devicesAuxillary pretreatmentAir filtrationAutomatic control

A bag house air filtration system with minimal recirculation uses new inlet airflow patterns and cleaning processes. Inlet air enters the bag house. An input plenum changes the velocity profile. Dirty inlet air is split into two plenums, and then passed through guide vanes. A clean air plenum contains a series of individual compartments with a pre-set number of filter bags that are effectively cleaned during a single cleaning cycle. Each individual compartment has a door or louver mounted above the bag openings that is opened and closed during the cleaning cycle. An automatic control system continuously senses bag house pressure drop and activates the cycle when needed. The doors open and close in a pre-set pattern to drop the dust cakes from the bags and restore air flow to normal pressures. Closing a door mounted above the bags creates a reversal of pressure that removes the dust cake.

Owner:COLLETTE JERRY R

System for Increasing the Efficiency of a Water Meter

InactiveUS20140182717A1High densityHigh measurement accuracyVolume/mass flow measurementCheck valvesAir entrainmentEngineering

Disclosed is a system and an associated valve assembly that are adapted to increase the efficiency of an upstream water meter. By way of the valve assembly entrained water bubbles can be removed from a water supply. This, in turn, increases the density of the water running through the water meter. This ensures that the water meter is not inaccurately including entrained air as metered water. The result is more accurate water readings and reduced utility bills.

Owner:FLOW DYNAMICS LLC

System for increasing the efficiency of a water meter

InactiveUS8707981B2High densityHigh measurement accuracyVolume/mass flow measurementCheck valvesAir entrainmentEngineering

Disclosed is a system and an associated valve assembly that are adapted to increase the efficiency of an upstream water meter. By way of the valve assembly entrained water bubbles can be removed from a water supply. This, in turn, increases the density of the water running through the water meter. This ensures that the water meter is not inaccurately including entrained air as metered water. The result is more accurate water readings and reduced utility bills.

Owner:FLOW DYNAMICS LLC

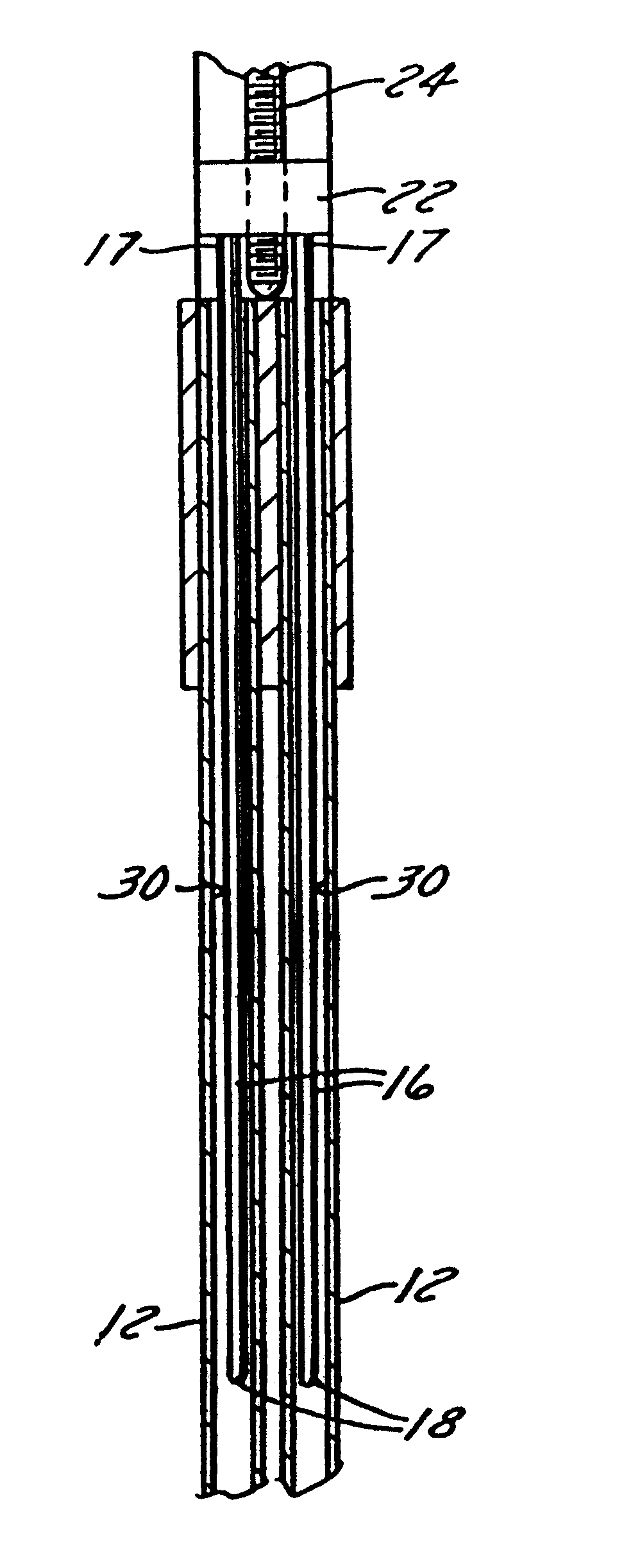

Hemispherical Wedge Valve with Laminar Flow

InactiveUS20110073792A1Laminar flowEliminate turbulencePlug valvesValve members for absorbing fluid energyHollow coreEngineering

A valve having a hemispherical wedge closure member and including structure for maintaining laminar fluid flow through the valve body. The laminar fluid flow structure may include a solid core member with a plurality of discrete bores therethrough or a plurality of baffles extending longitudinal through a hollow core member. The laminar flow reduces noise, structural failure, erosion, cavitation, and premature wearing of valve seals and seats.

Owner:PROSERV OFFSHORE INC +1

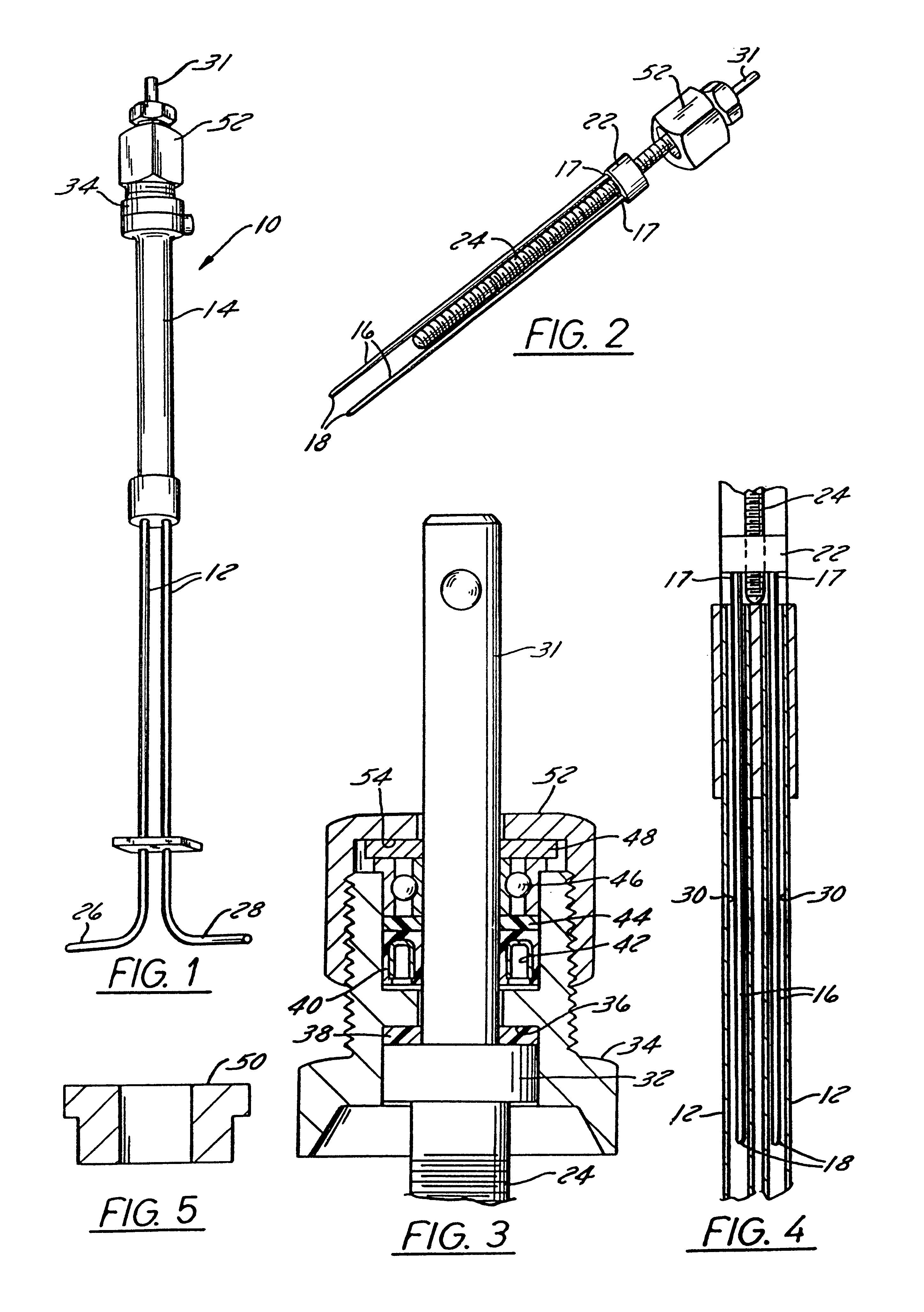

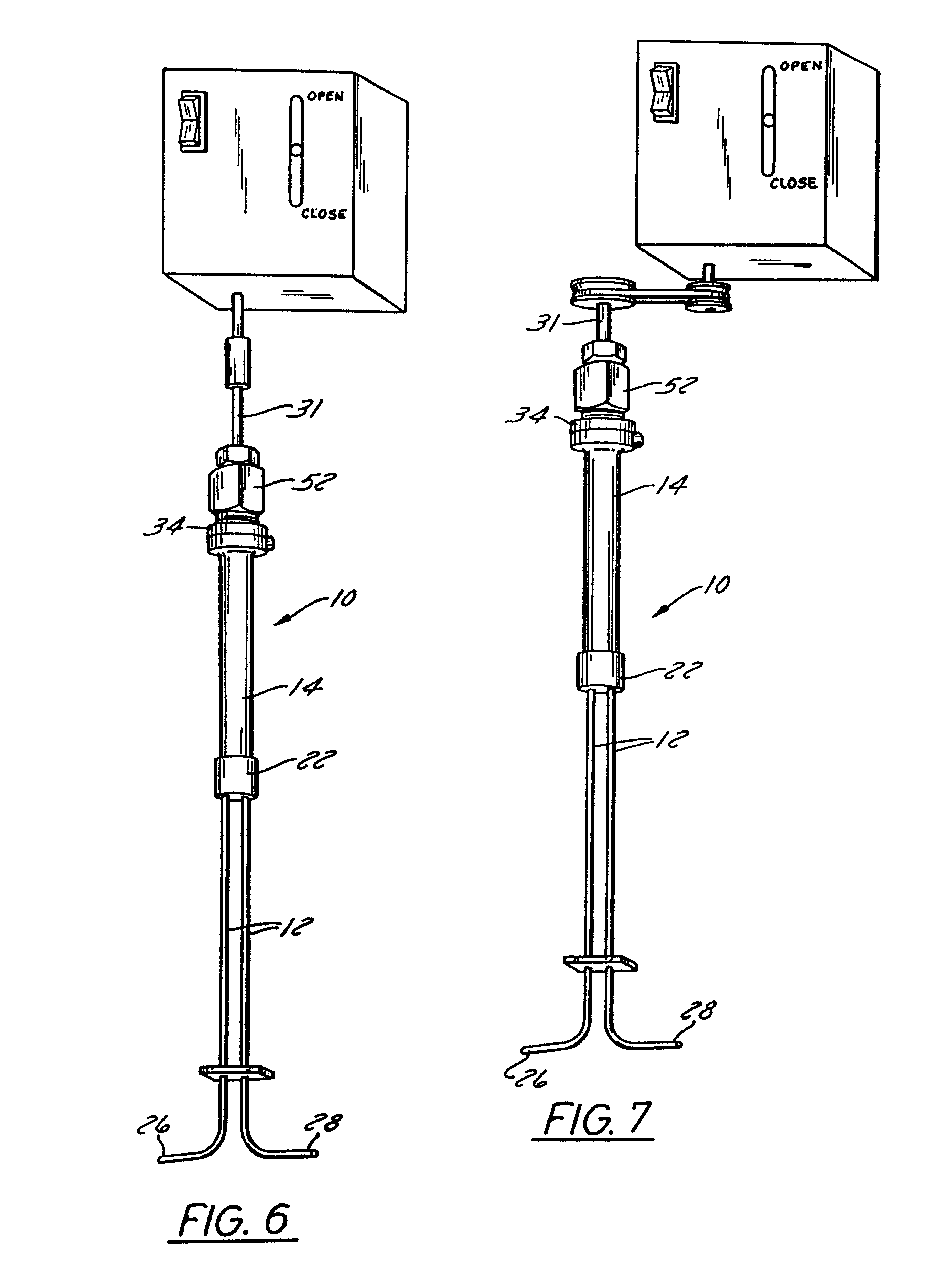

Variable pressure reducing device

InactiveUSRE37153E1Eliminate turbulenceImprove sealing propertiesEngine sealsWithdrawing sample devicesComplementary pairEngineering

A variable pressure reducing device for reducing high pressure in steam and hot water samples forces the liquid through an annular passageway between a pair of rods within a complementary pair of tubes. The flow rate through the rod-in-tube device, or the pressure drop across the device, is adjustable by means of a rotatable guide screw for adjusting the position of the rods within the tubes. The rods are tapered to provide a smooth flow of liquid through the device. The seal around the guide screw is self energized by means of a seal jacket between a valve gland and a stem portion of the guide screw constructed so that the biasing force of a spring on the seal jacket is supplemented by pressure from liquid flowing through the device The guide screw is centered within the valve gland to keep the guide screw properly aligned, particularly when the device is used with a motor for rotating the guide screw to adjust the position of the rods.

Owner:SENTRY EQUIP

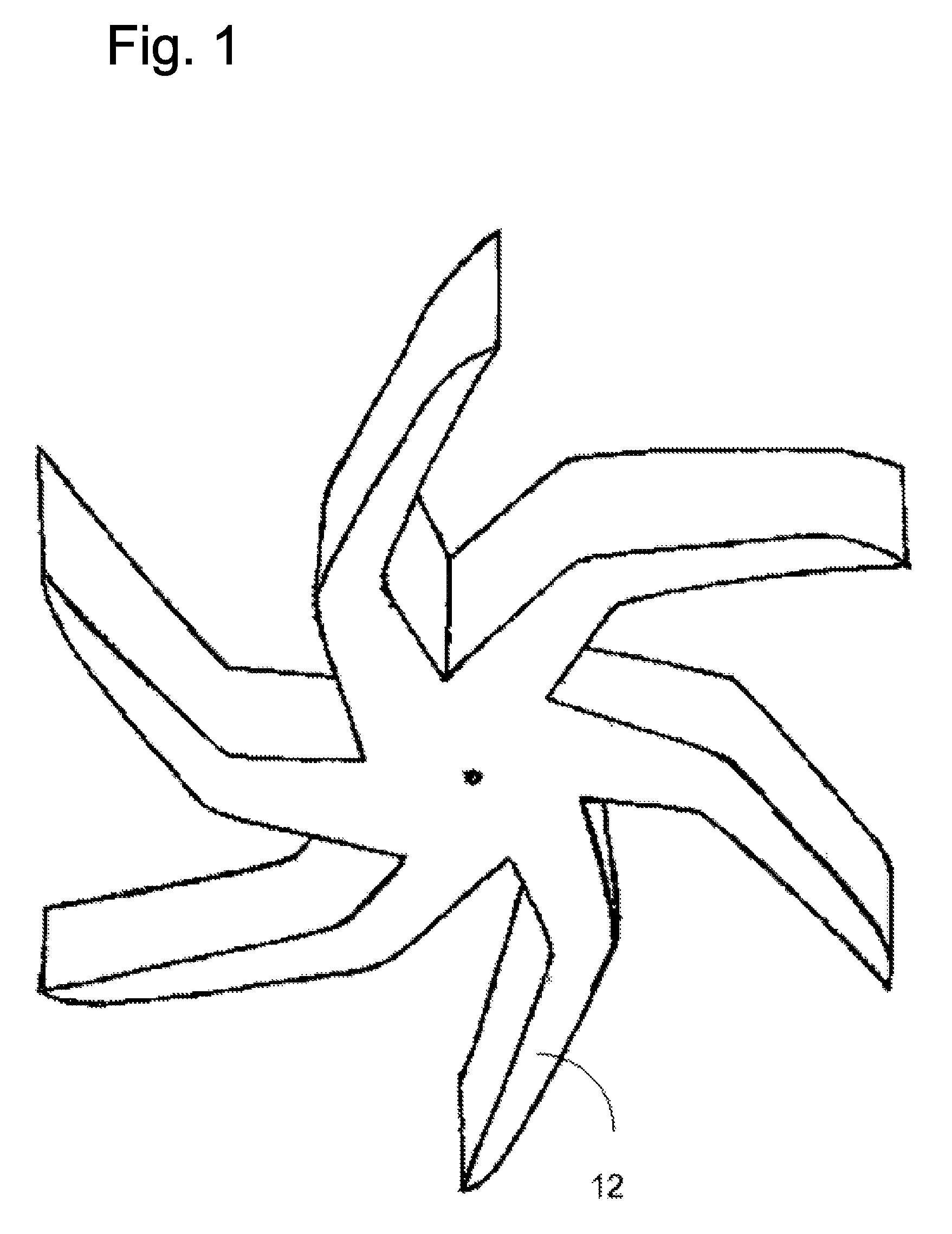

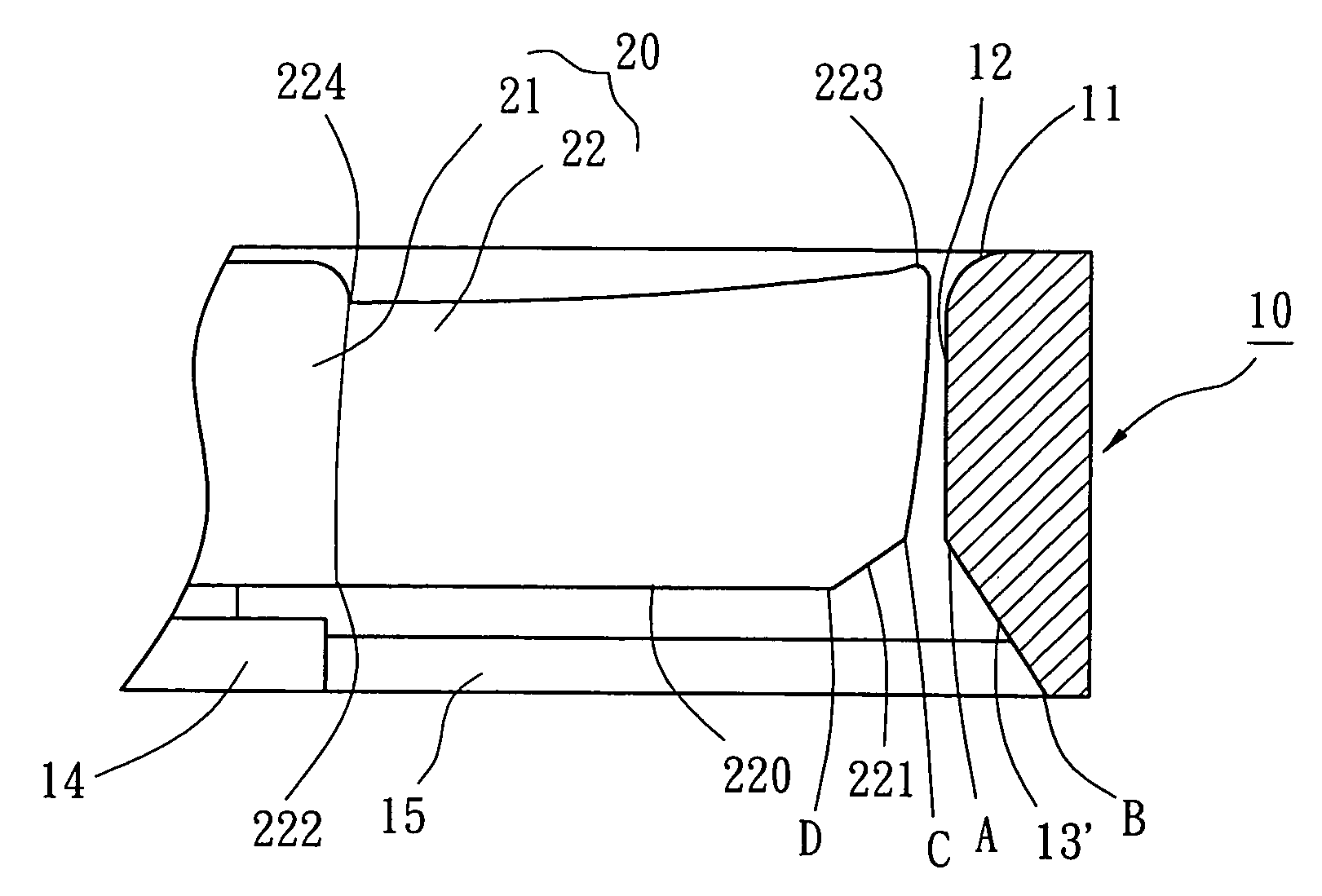

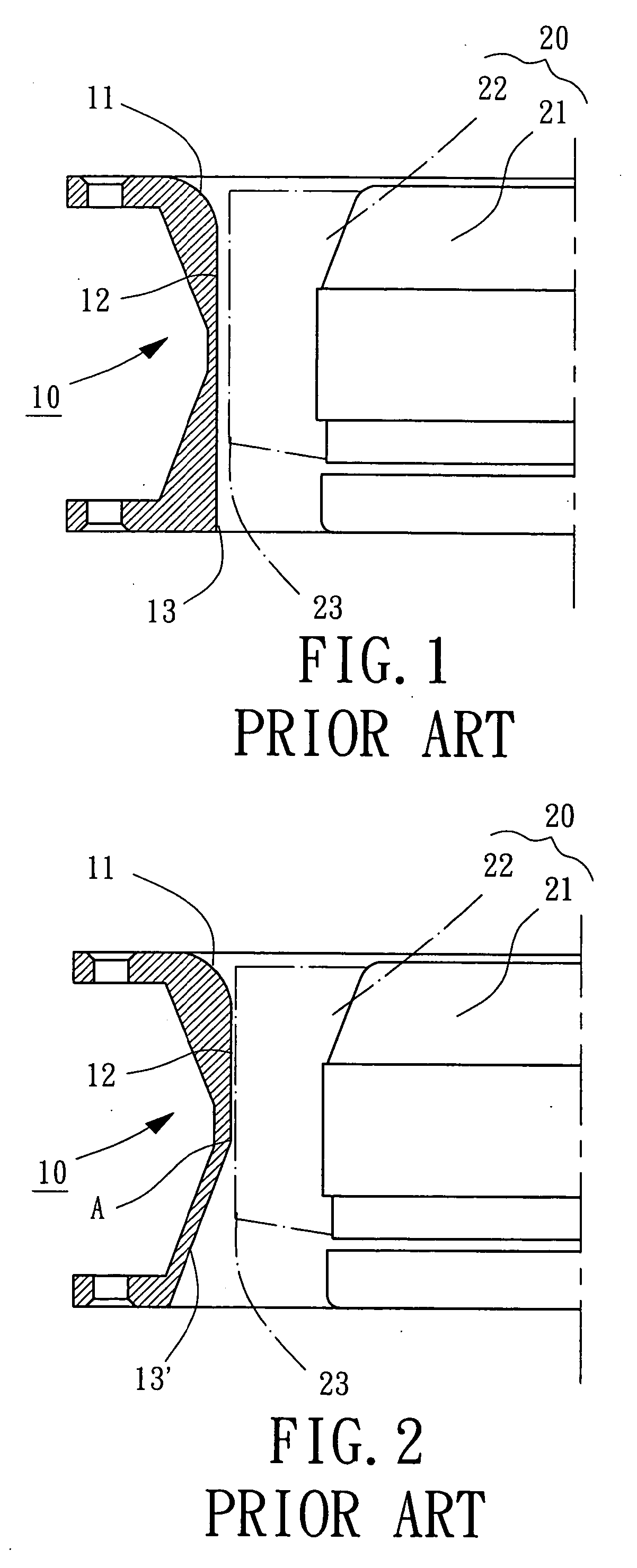

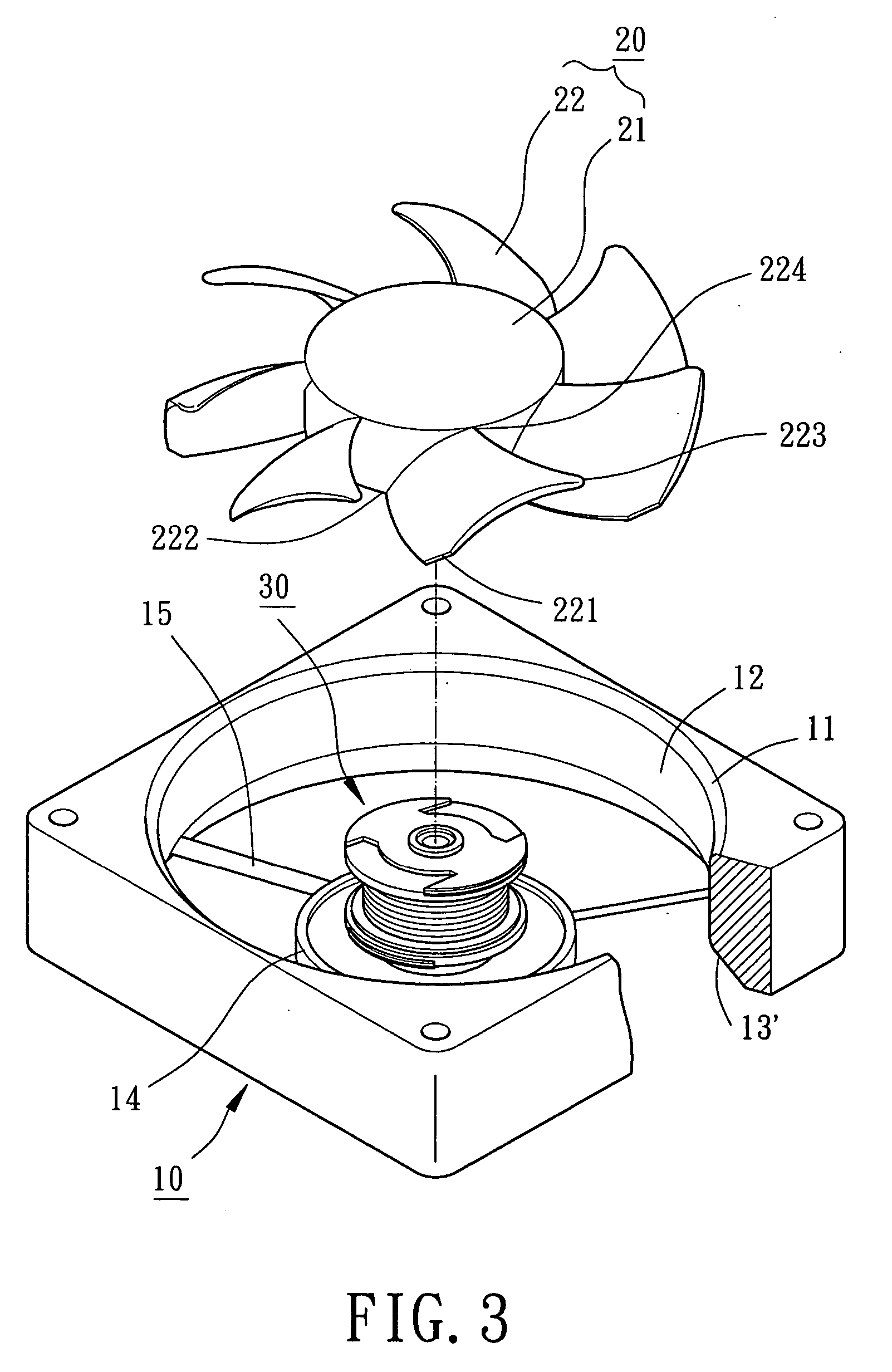

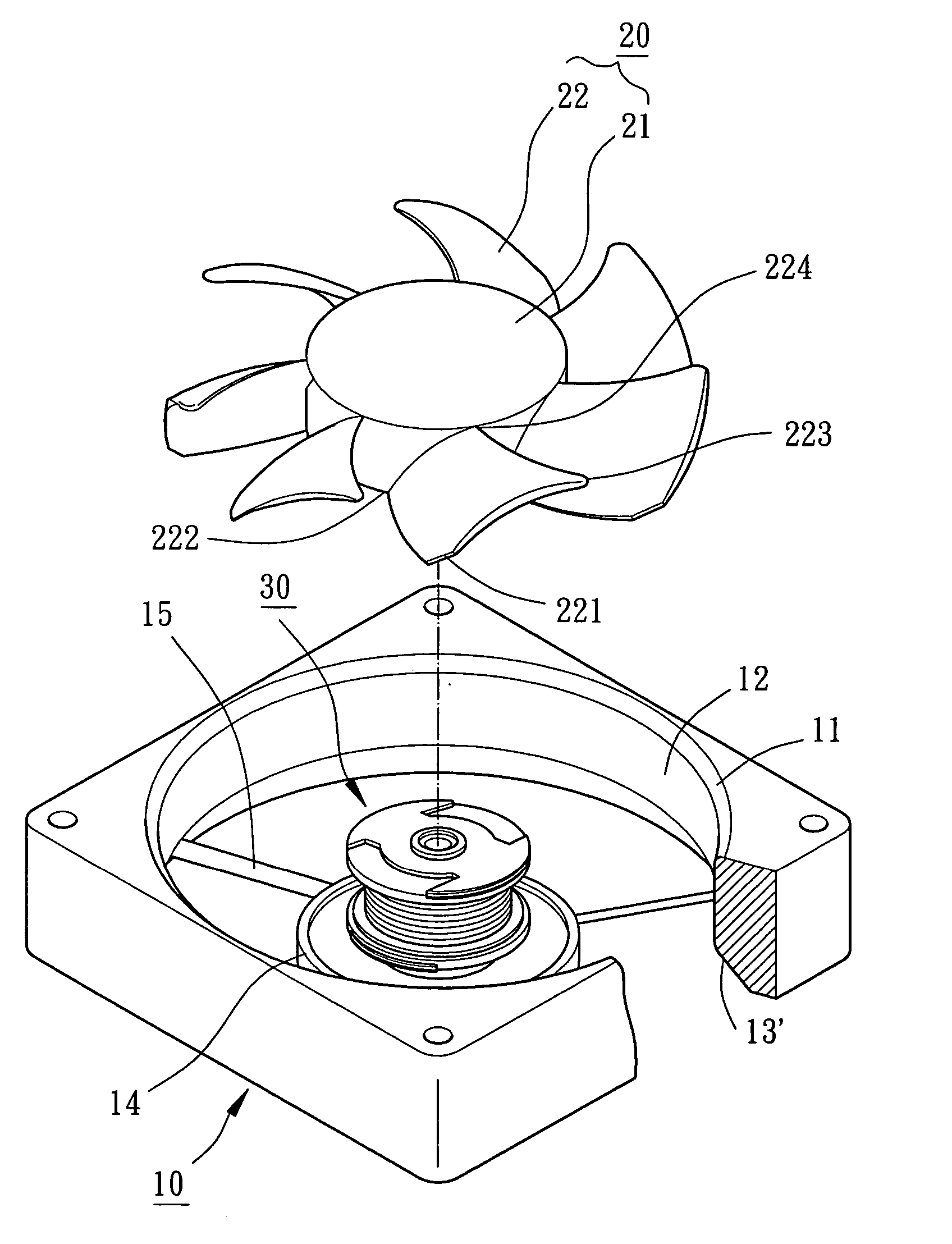

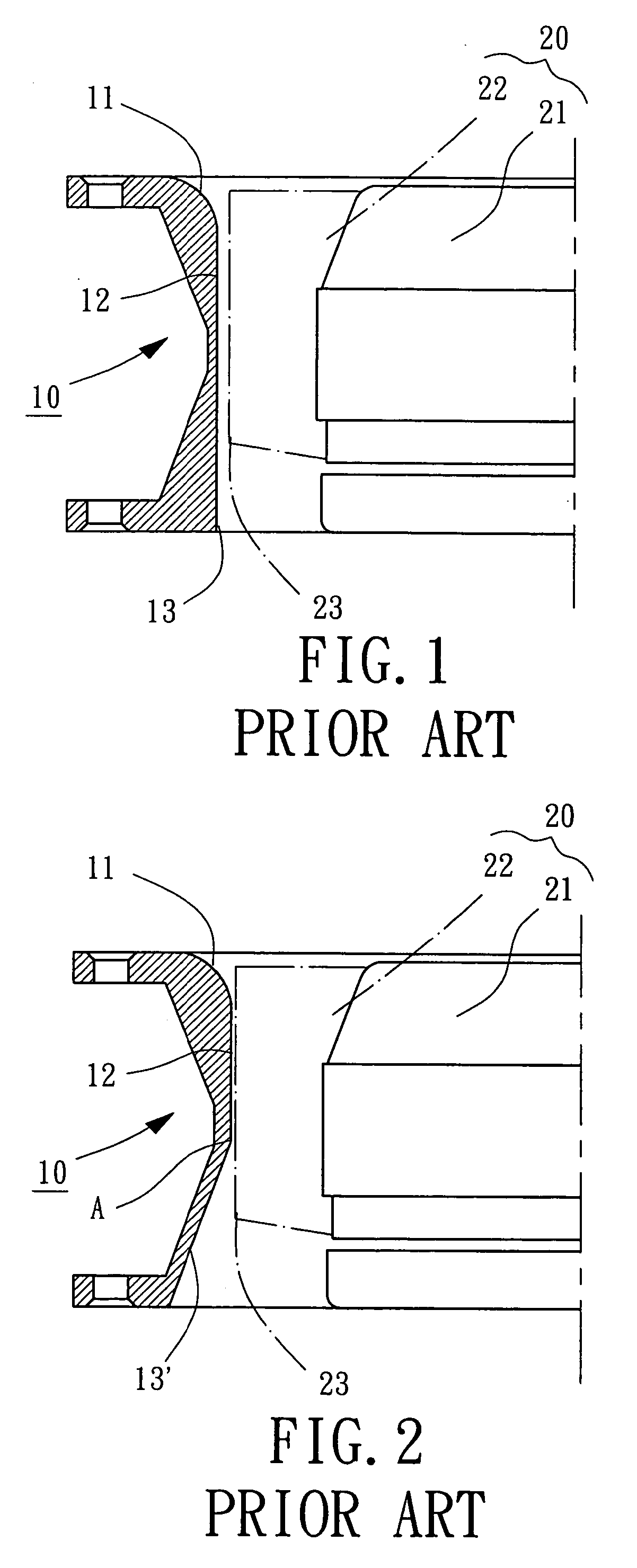

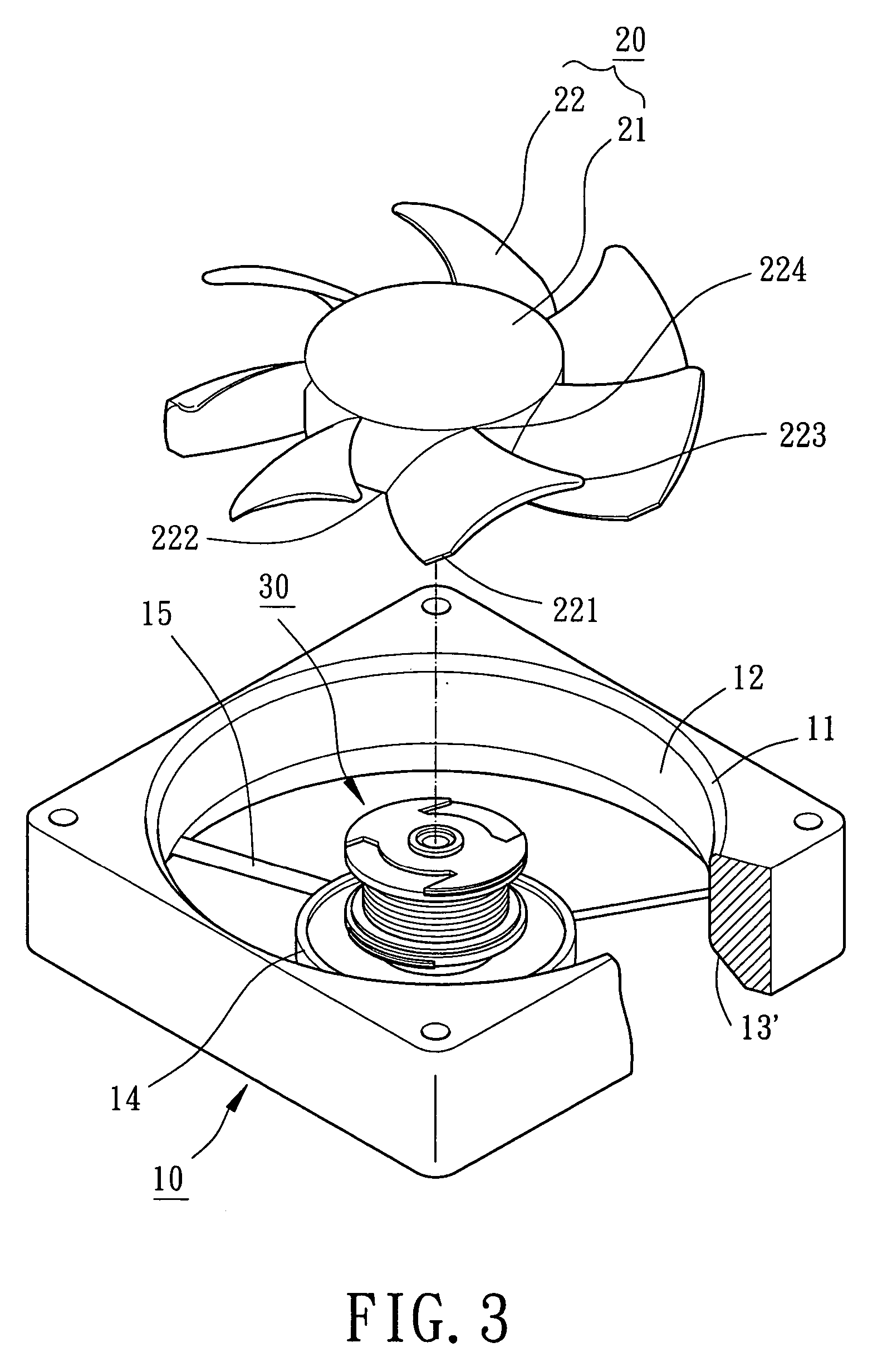

Axial-flow type fan having an air outlet blade structure

InactiveUS20050249585A1Eliminate air noiseRemove noisePump componentsBlade accessoriesImpellerFan blade

An axial-flow type fan includes a fan housing consisting of an air inlet, an air outlet and an air channel, and a fan wheel consisting of a hub and fan blades. The air channel of the fan housing accommodates the fan wheel which has end-cornered cutting blades proximate the air outlet of the fan housing. When the fan wheel is rotated, the end-cornered cutting blades are able to eliminate air turbulence and air noise in the air outlet of the fan housing.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Axial-flow type fan having an air outlet blade structure

InactiveUS7125220B2Remove noiseEliminate turbulencePump componentsBlade accessoriesImpellerFan blade

An axial-flow type fan includes a fan housing consisting of an air inlet, an air outlet and an air channel, and a fan wheel consisting of a hub and fan blades. The air channel of the fan housing accommodates the fan wheel which has end-cornered cutting blades proximate the air outlet of the fan housing. When the fan wheel is rotated, the end-cornered cutting blades are able to eliminate air turbulence and air noise in the air outlet of the fan housing.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

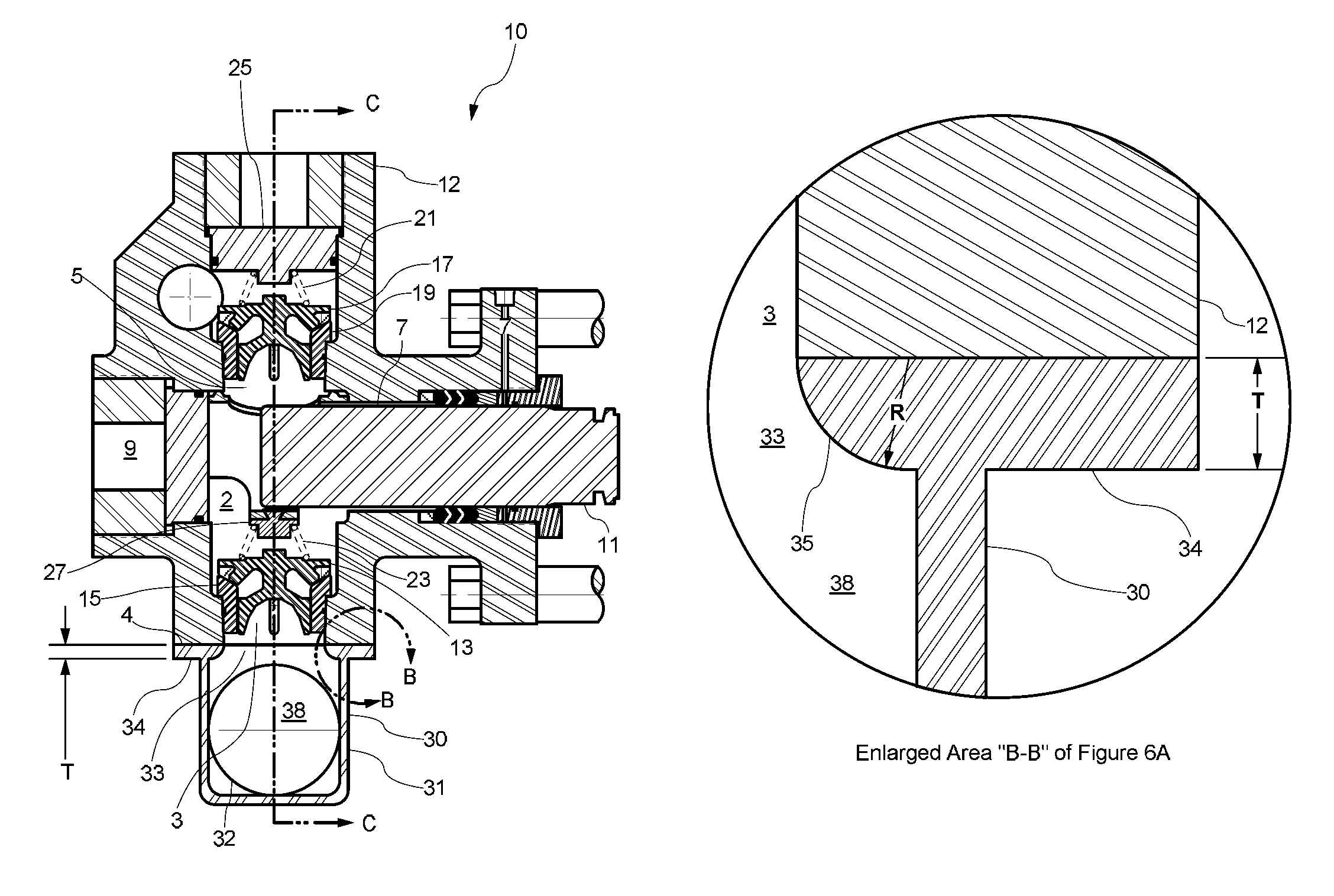

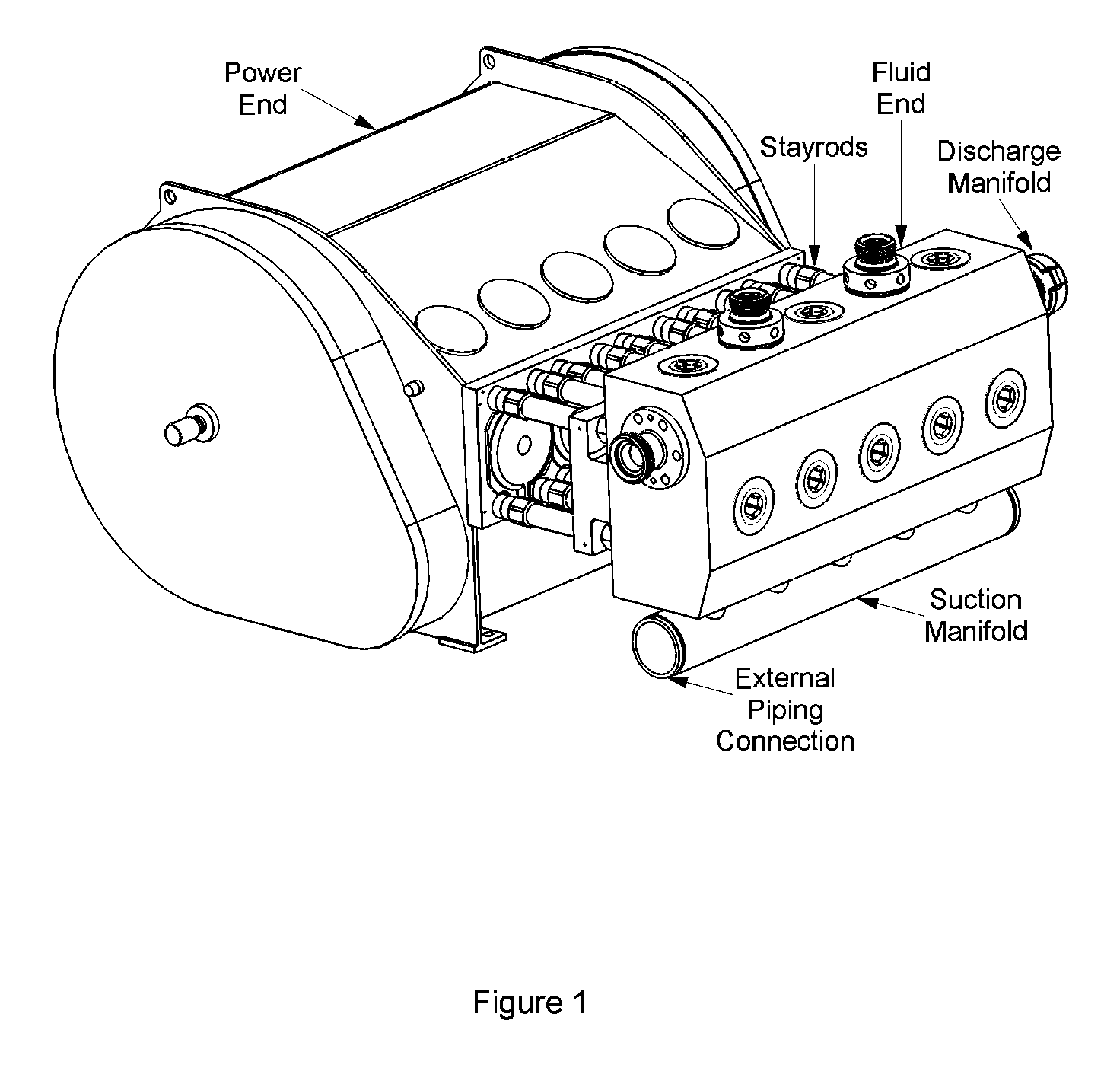

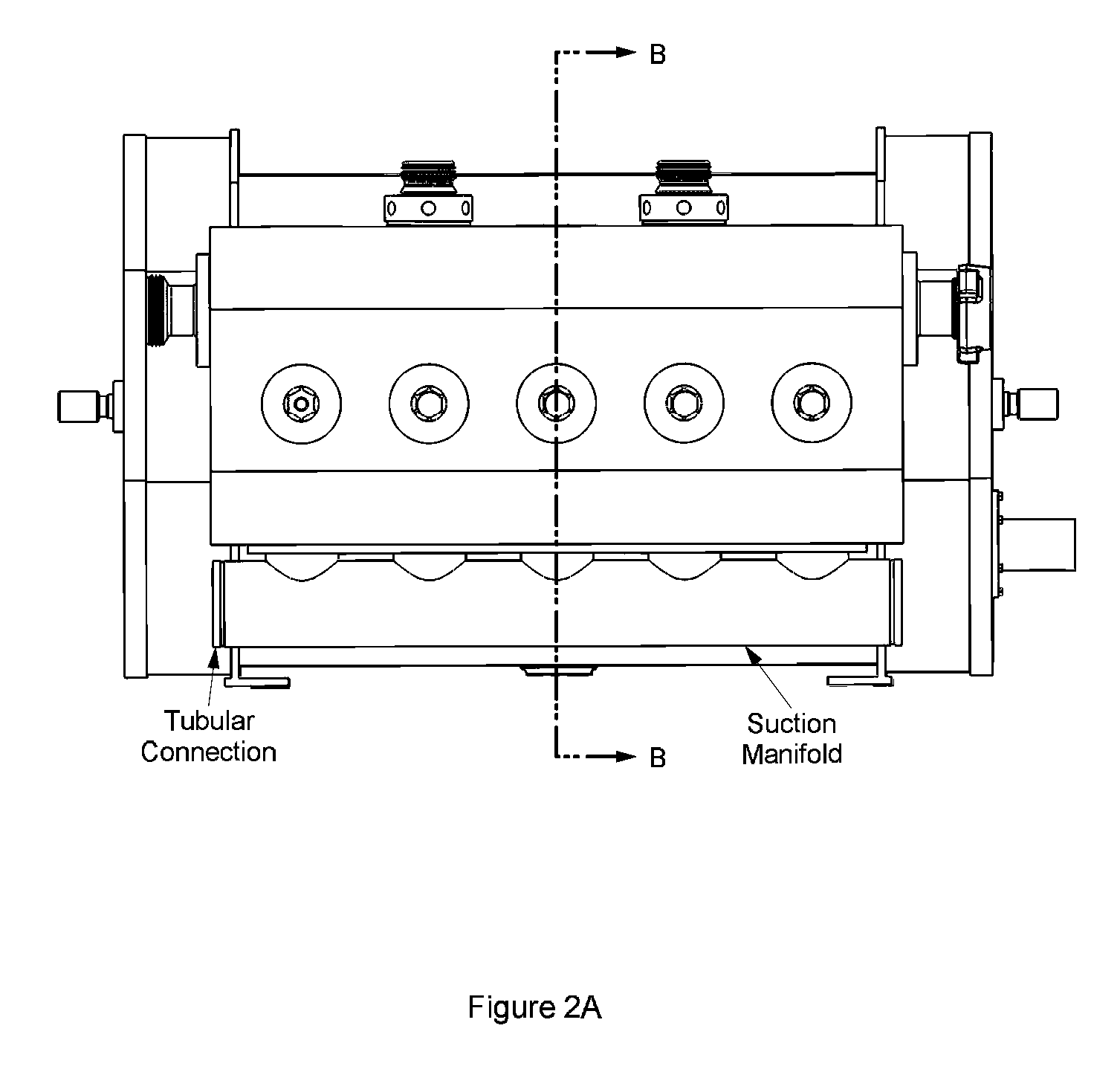

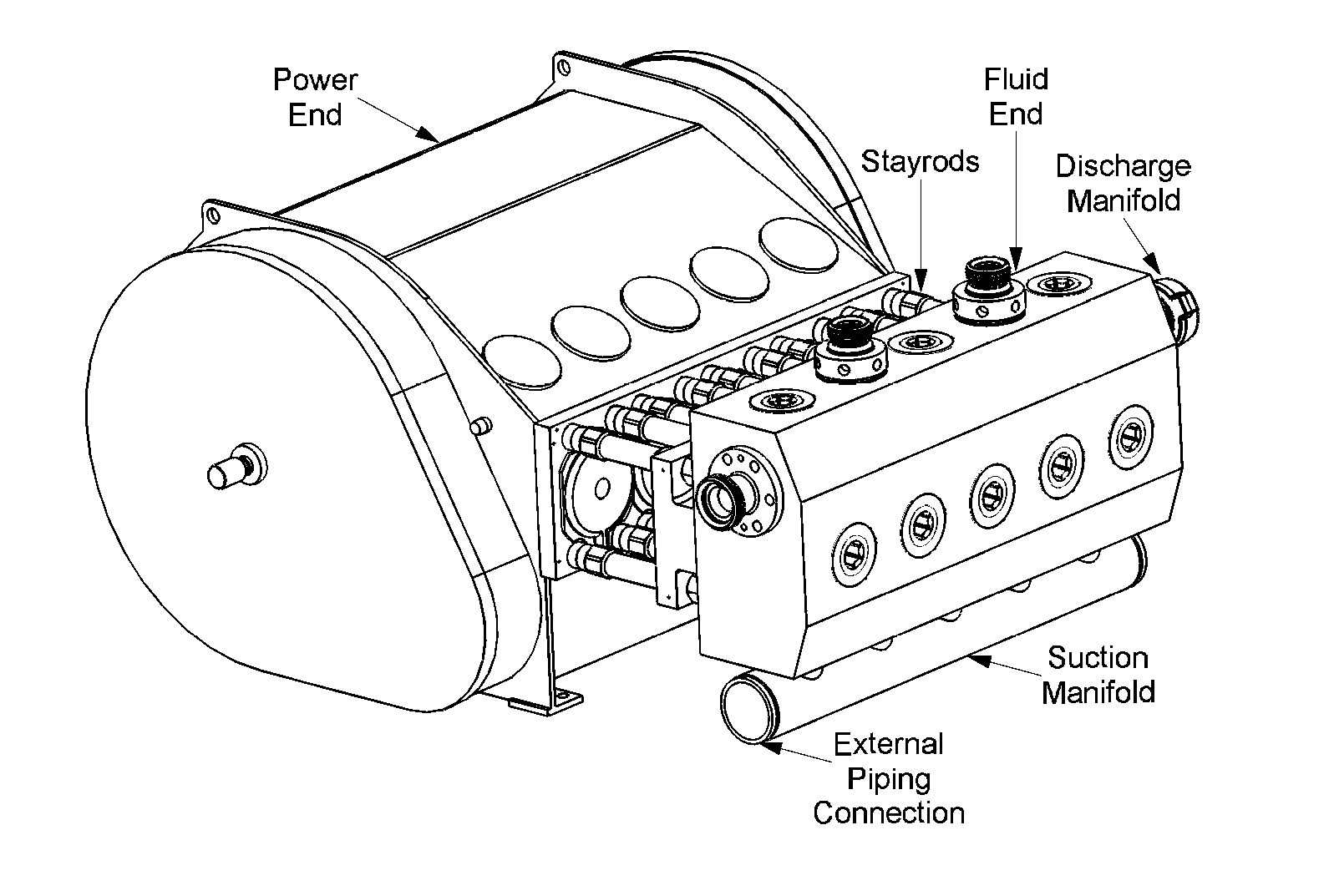

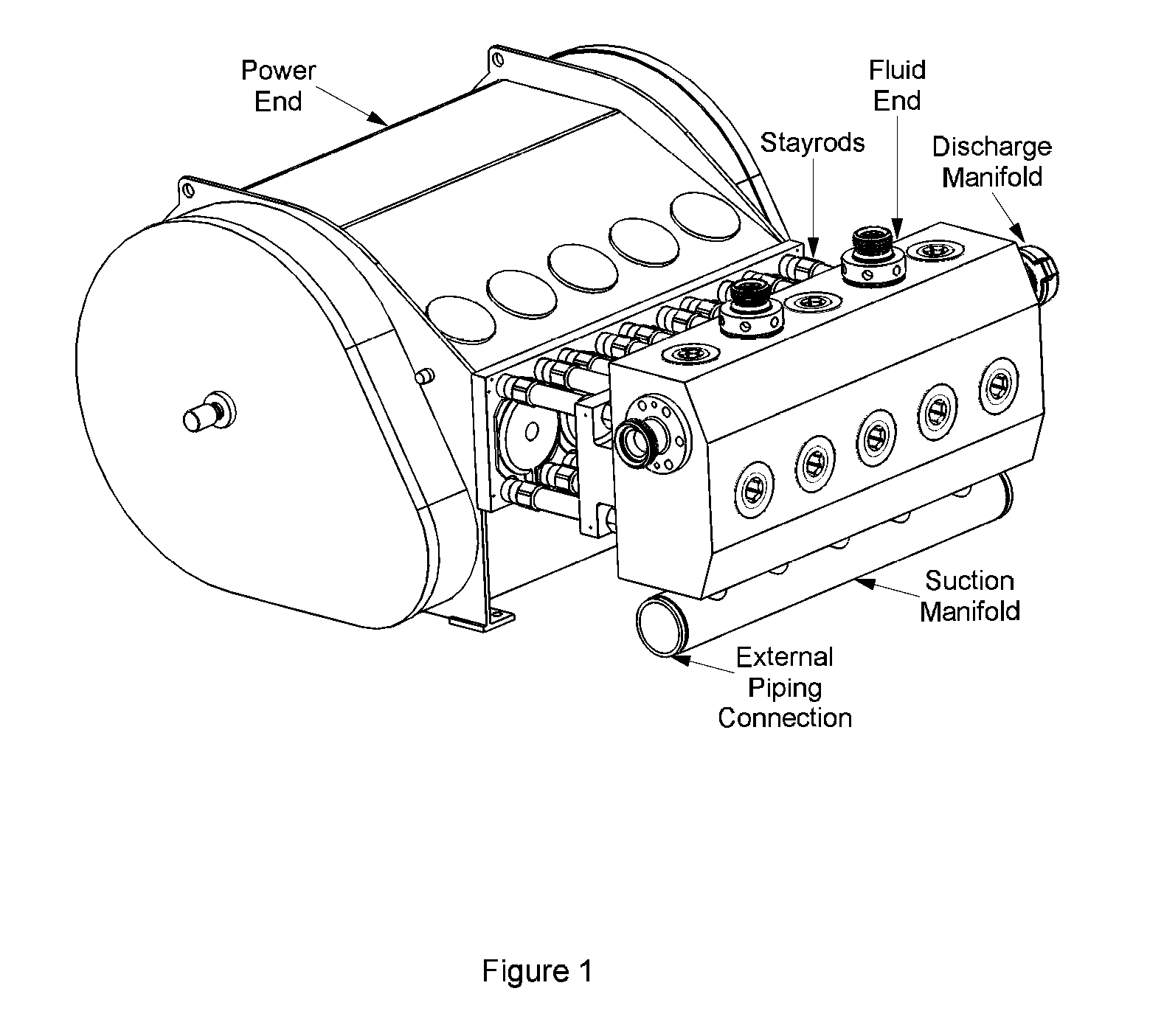

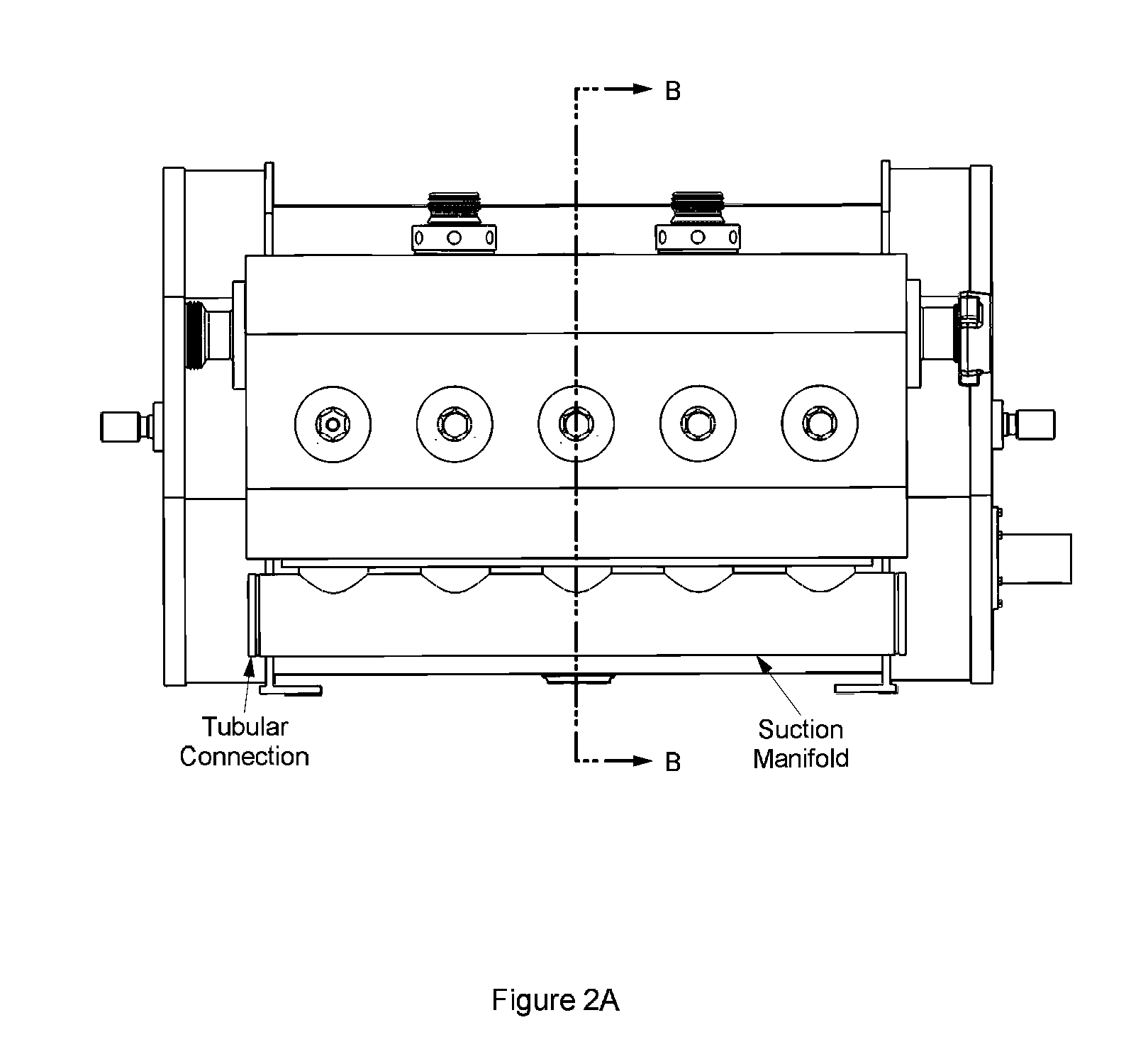

Integrated design fluid end suction manifold

InactiveUS9500195B2Reduce frictionReduce turbulencePositive displacement pump componentsPiston pumpsIntegrated designCatheter

A fluid end assembly comprising a housing, valve bodies, seals, seats, springs, and other associated parts, paired with a suction manifold that facilitates bi-directional fluid flow. The suction manifold of this invention is designed to preserve fluid energy that will ensure complete filling of the cylinder in extreme pumping conditions. The suction manifold utilizes a chamber design positioned immediately below the suction valves, eliminating all connecting ducts. Alternate embodiments of this invention include a suction manifold with an integral fluid dampeners or stabilizers.

Owner:ALTIS INVESTMENTS LLC

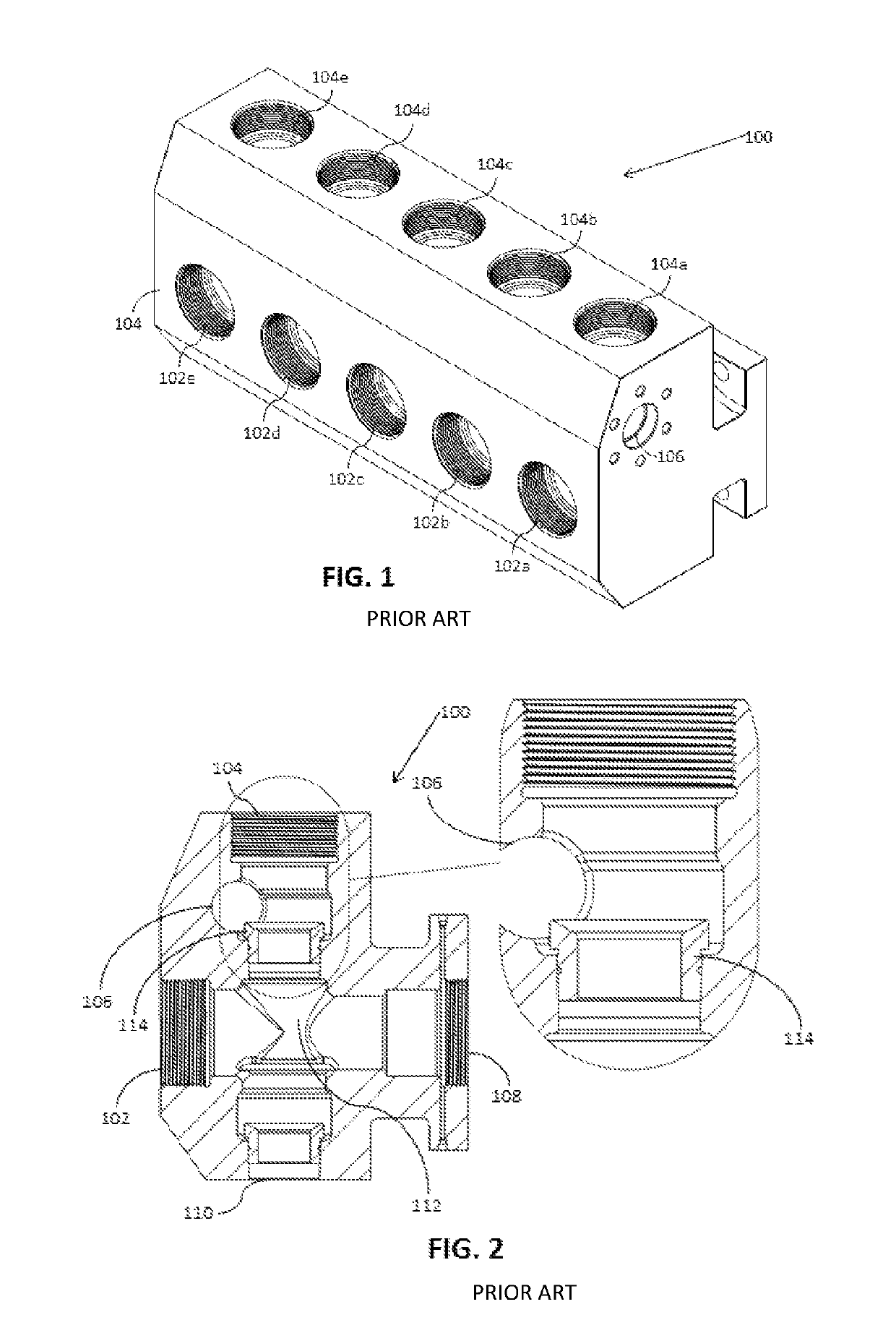

Discharge cap and block for a fluid end assembly

ActiveUS10465680B1Eliminate turbulenceIncrease usagePositive displacement pump componentsPositive-displacement liquid enginesEngineeringMechanical engineering

Disclosed herein is an improved fluid end discharge cap and bore to minimize or avoid cavitation during use of a reciprocating fluid end pump and hence prolong the use and life of the fluid end assembly. The improved design included modifying the current cylindrical discharge cover or cap to a tapered, conical or convex design, enlarging the discharge bore, and recessing seat decks into the suction and discharge bores, to avoid fluid flow obstructions and increase volume flow. The pump outlet bore was enlarged and the bore height and diameter were increased to further increase flow. The conventional design has edges and ninety-degree angles which tended to allow for fluid media to remain in the bore and trigger pump cavitation. The current inventive design has eliminated restrictions, in particular 90° angles, to allow uninterrupted fluid flow therein.

Owner:VP SALES & COMPANY

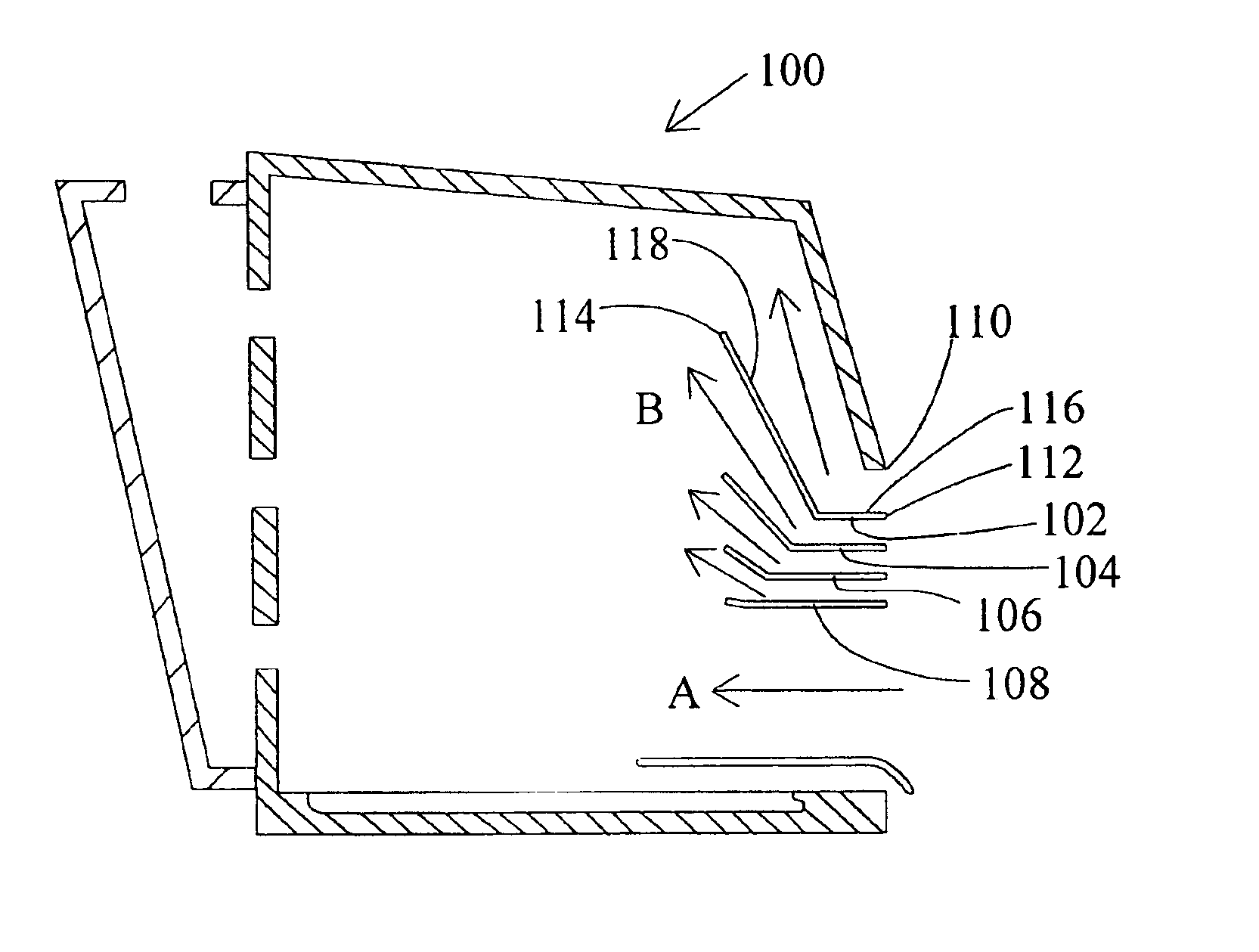

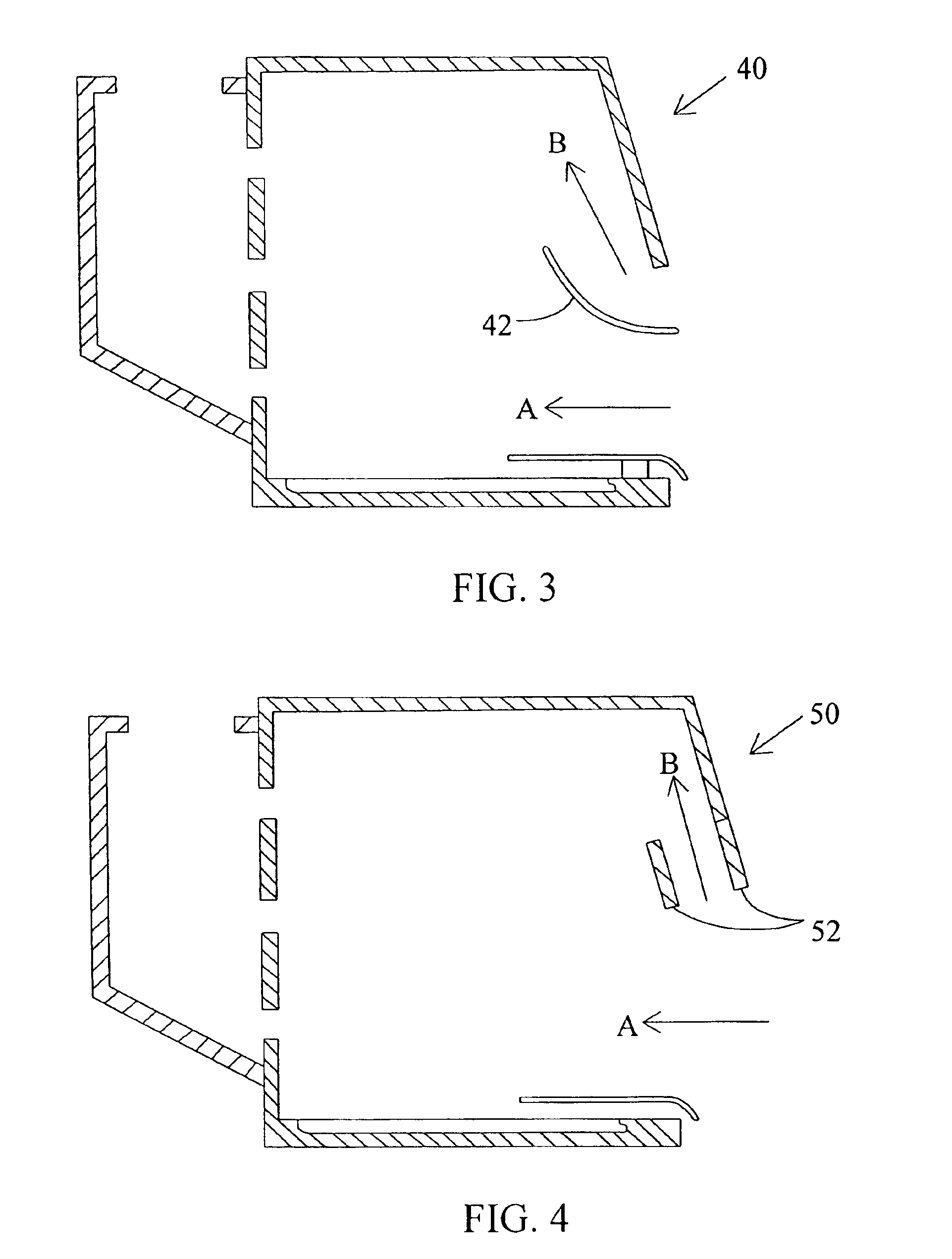

Turbulence-free laboratory safety enclosure

InactiveUS6871170B2Most efficientIncreased turbulenceMechanical apparatusDomestic stoves or rangesEddy currentFume hood

The present invention relates to controlled airflow and air distribution within a laboratory safety enclosure and in particular, to turbulence-free airflow within a laboratory fume hood. The fume hood of the present invention has a work chamber and an access opening having an upper edge. A horizontal air deflector structure is positioned adjacent to the upper edge of the access opening to divert a portion of air entering the access opening upwardly within the chamber, whereby the diverted air eliminates an airflow eddy current.

Owner:FLOW SCI INC

Integrated Design Fluid End Suction Manifold

InactiveUS20140137963A1Easy to placeReduce frictionPositive displacement pump componentsPressure pumpsEngineeringIntegrated design

A fluid end assembly comprising a housing, valve bodies, seals, seats, springs, and other associated parts, paired with a suction manifold that facilitates bi-directional fluid flow. The suction manifold of this invention is designed to preserve fluid energy that will ensure complete filling of the cylinder in extreme pumping conditions. The suction manifold utilizes a chamber design positioned immediately below the suction valves, eliminating all connecting ducts. Alternate embodiments of this invention include a suction manifold with an integral fluid dampeners or stabilizers.

Owner:ALTIS INVESTMENTS LLC

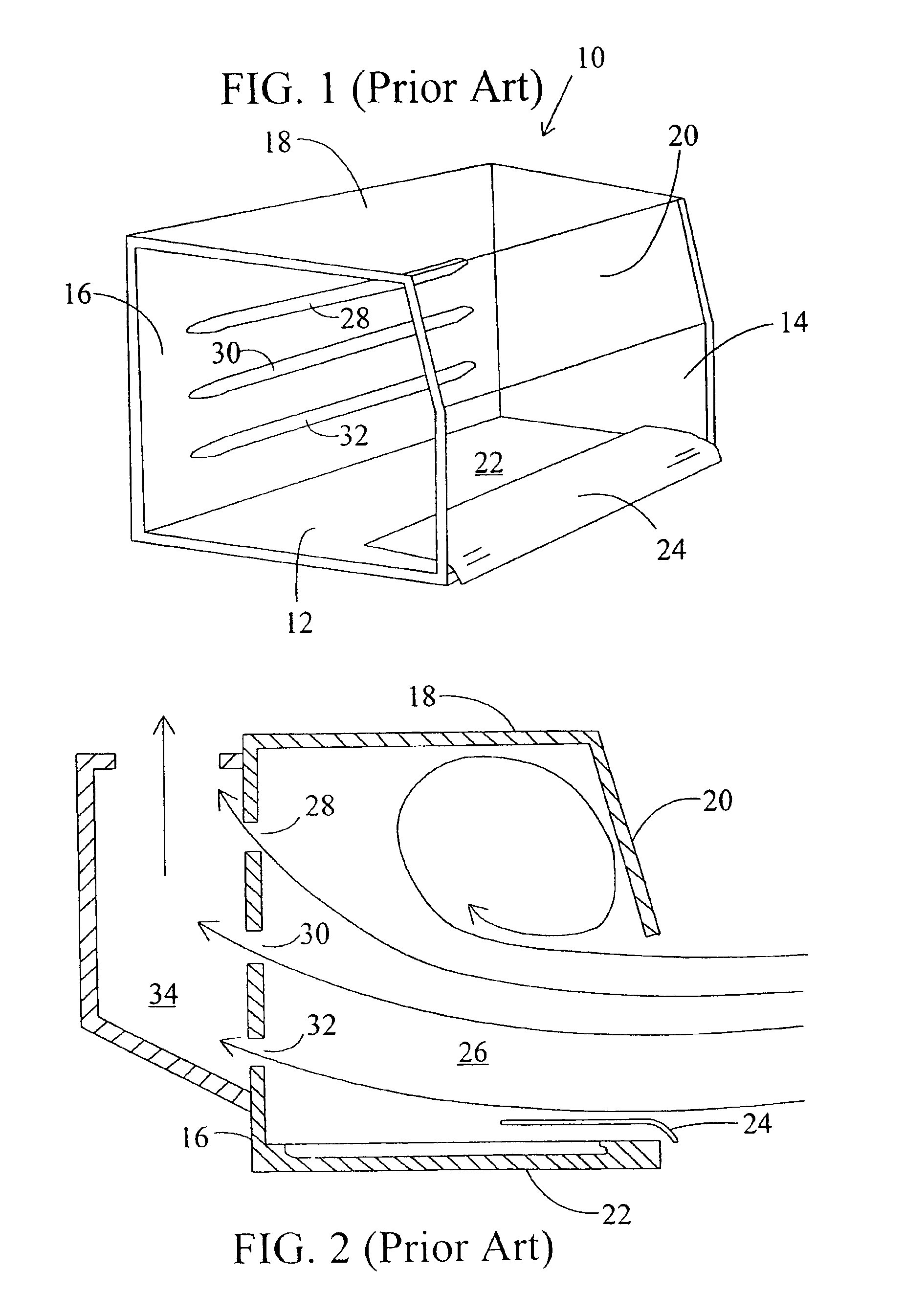

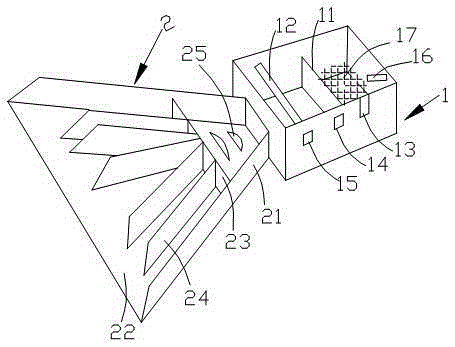

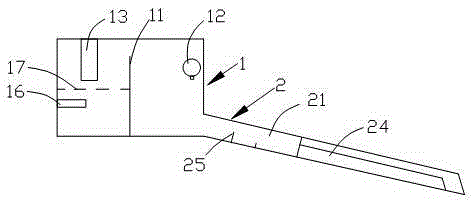

Narrow tube wind gathering power generation centrifugal wind power engine

InactiveCN102808723AImprove playbackEliminate turbulenceMachines/enginesWind energy generationPressure-gradient forceDynamic balance

The invention discloses a narrow tube wind gathering power generation centrifugal wind power engine which relates to a comprehensive discipline theory of inertial centrifugal effects, centripetal force, dynamic balance, pressure gradient force, viscous force, blade molding, spiral wind attitude causes, turbine effects and the like and a major core technology and belongs to the technical field of the narrow tube wind gathering power generation centrifugal wind power engine. The narrow tube wind gathering power generation centrifugal wind power engine comprises a butt barrel, a front flange, a fluid inlet, a regulating plate A, a fixing ring A, a strutting piece A, an annular ring A, a regulating plate B, a fixing ring B, a regulating plate C, a fixing ring C, a stepped shaft, a strutting piece B, a wind drain channel, an annular ring B, a blade C, a blade B, a blade A, a butt flange, a radial ring A, a radial ring B, a bearing A, a bearing B, a shell A, a shell B, a shell C, a shaft seat A, and a shaft seat B.

Owner:WUXI C SOLAR NEW ENERGY TECH

Mixed combustion visual combustor

ActiveCN112303665AEliminate vortex irregular pulsationQuality improvementContinuous combustion chamberCombustion chamberCombustor

The invention discloses a mixed combustion visual combustor, and belongs to the technical field of rocket engines. The combustor comprises an air inlet assembly, a rectification section, a combustionchamber and a coaxial ignition torch; the rectification section is coaxially installed between the air inlet assembly and the combustion chamber; the coaxial ignition torch is installed on the outer circumferential face of the rectification section in the radial direction of the rectification section; the rectifying section is of a columnar structure with a rectangular through hole in the axial direction; a round flange plate and a square flange plate are arranged at the two ends of the rectifying section respectively; the rectifying section is coaxially and hermetically connected with the airinlet assembly through the round flange plate and coaxially and hermetically connected with the combustor inlet end through the square flange plate; a circular hole is formed in the peripheral wall of the rectifying section; the rectifying section is communicated with the coaxial ignition torch through an assembly ignition base; the rectification section is additionally arranged to be matched with the porous injection plate, so that irregular vortex pulsation of airflow is eliminated, and the airflow is stably introduced into the combustion chamber; the section of a flow channel in the rectification section is kept consistent with the section of a flow channel of the combustion chamber, so that a backflow area, namely a vortex structure, is effectively avoided; and therefore a high-quality flow field structure can be obtained in an experiment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

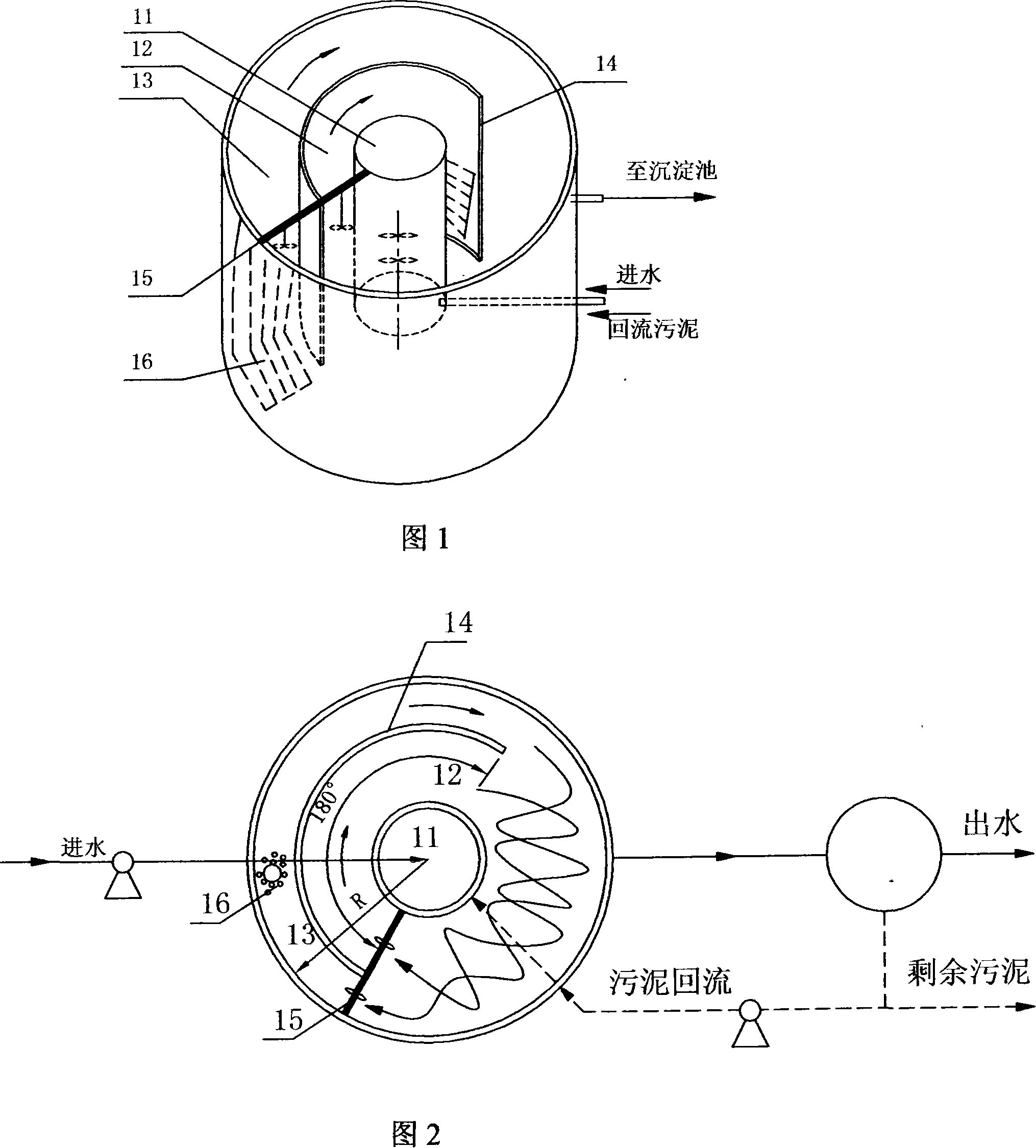

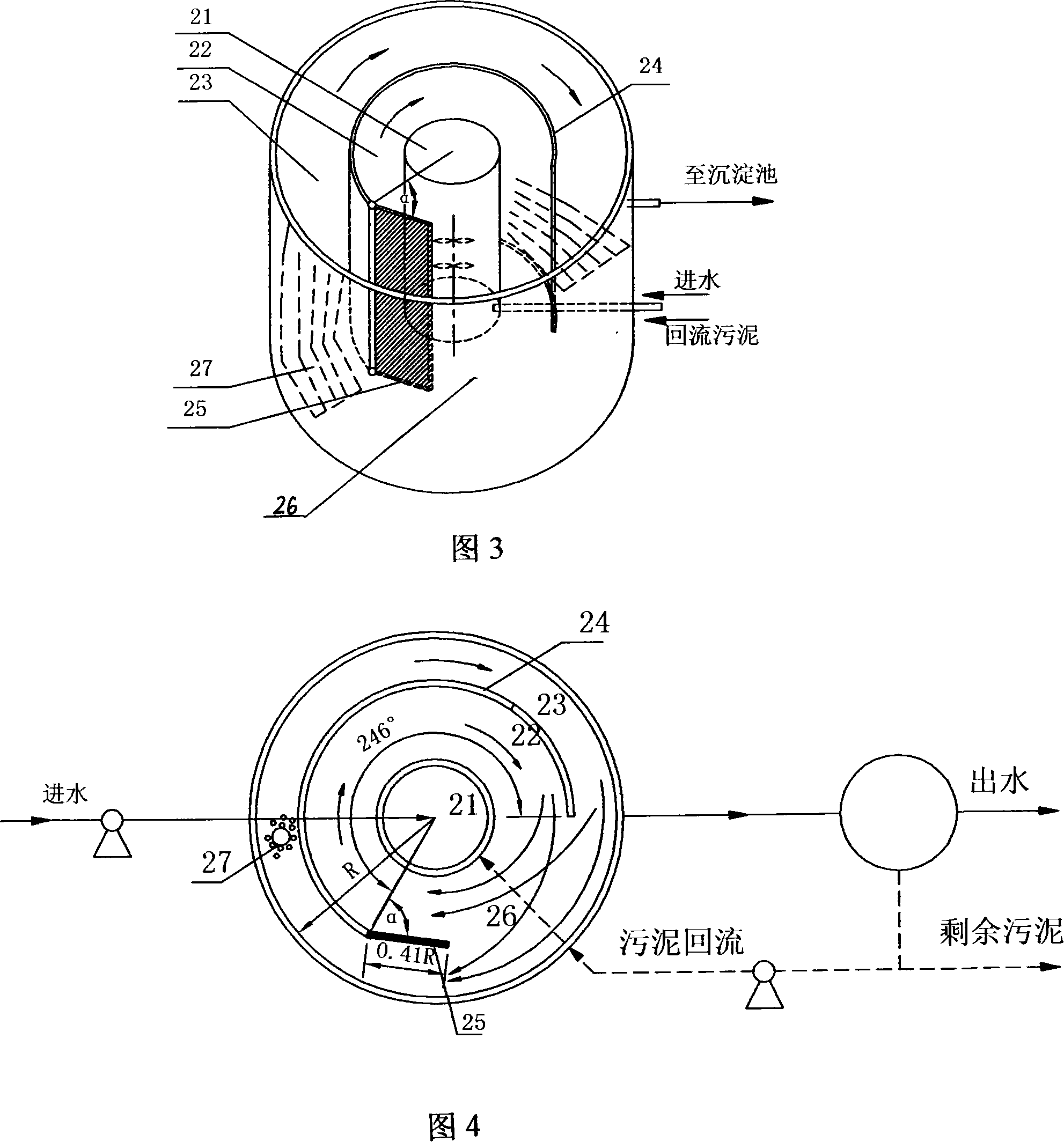

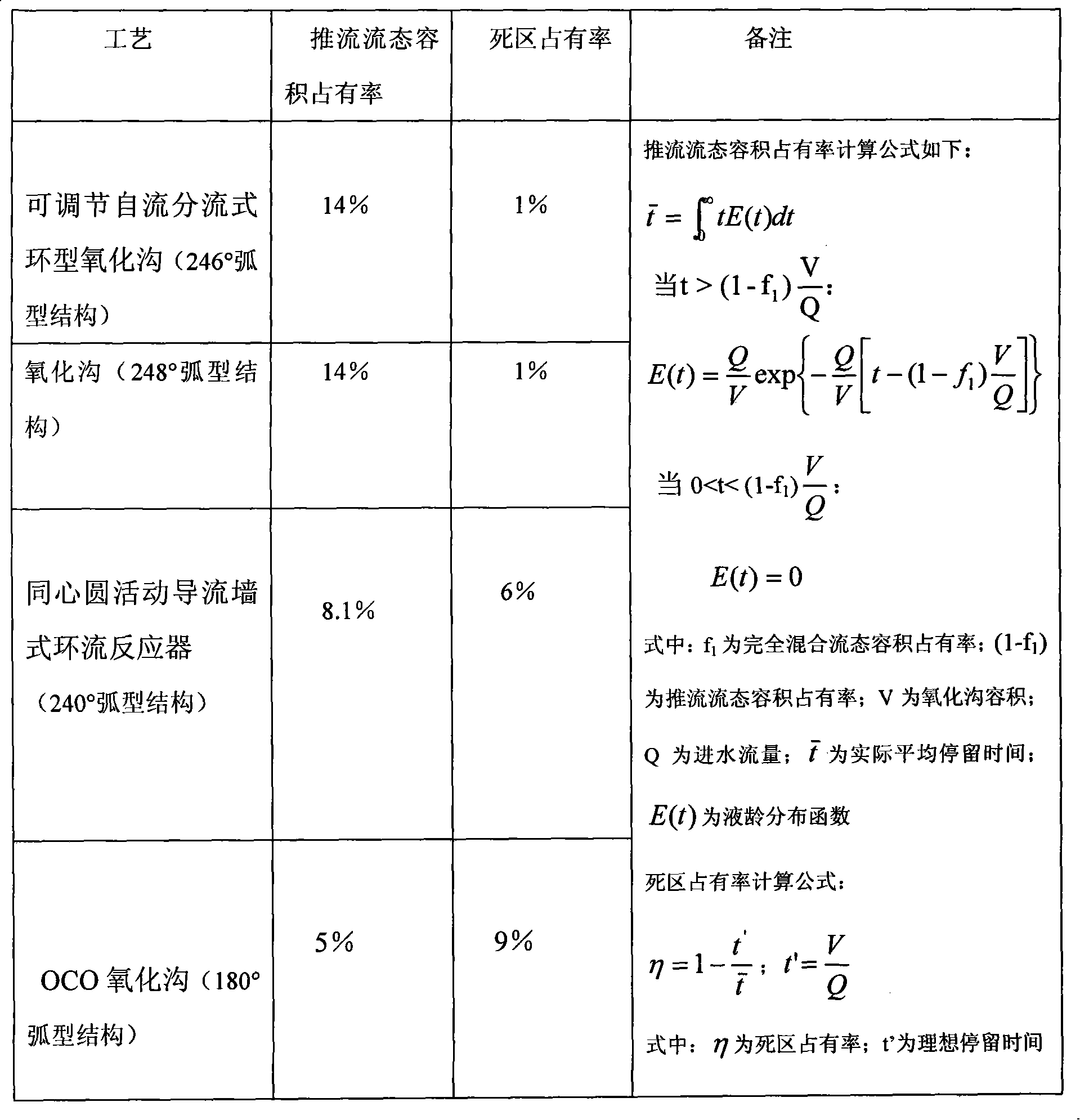

Adjustable self-flowing diffluence type ring-shape oxidization trench

InactiveCN101125710AExtended stayEasy to shareTreatment with aerobic and anaerobic processesWater qualityGravity flow

The invention provides a branching ring type oxidation ditch with adjustable gravity flow. The interior of the invention is an O type anaerobic zone, the exterior is an O type aerobic zone and the middle part is a C type anoxic zone. The intersection zone of a C type nick and the O type aerobic zone is a mixing zone, wherein, the radian of a C type circular arc separating wall that forms the anaerobic zone is 246 degrees, the length of the C type circular arc separating wall that stretches into the mixing zone is 0.41R and the R is the radius of a concentric circle separating wall of the aerobic zone, the angle Alpha at a starting end point of the C type circular arc separating wall that can be adjusted is equal to 10 degrees- 107 degrees and the alpha is an included angle formed by a line connecting the starting end point and the center of the C type circular arc separating wall and an adjustable branching wall. The structure can weaken the turbulence in the ditch, increase the volume occupancy of the plug-flow fluid in the ditch, promote the efficiency of a reactor, prolong the stopping time at the aerobic zone and the anoxic zone, decrease the stopping time at the mixing zone and the occupancy of a dead zone and leave out the energy consumption caused by a mechanical stirrer. Besides, the returning flow that enters into the aerobic zone and the anoxic zone can be flexibly adjusted and controlled based on different water quality, so as to gain stable nitrogen and phosphors removal effect that fully meets the discharge standards of the state.

Owner:CHONGQING UNIV

Turbulence-free laboratory safety enclosure

InactiveUS20050164622A1Maintains turbulence-free operationEasy to liftMechanical apparatusDomestic stoves or rangesEddy currentFume hood

The present invention relates to controlled airflow and air distribution within a laboratory safety enclosure and in particular, to turbulence-free airflow within a laboratory fume hood. The fume hood of the present invention has a work chamber and an access opening having an upper edge. A horizontal air deflector structure is positioned adjacent to the upper edge of the access opening to divert a portion of air entering the access opening upwardly within the chamber, whereby the diverted air eliminates an airflow eddy current.

Owner:FLOW SCI INC

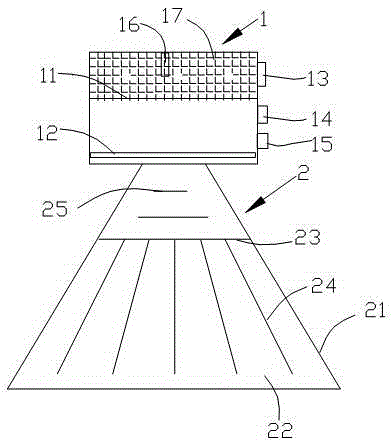

Fan-shaped material distributor

ActiveCN105381872AEliminate turbulenceUniform overflowMagnetic separationMagnetic separatorPulp and paper industry

The invention relates to the technical field of mineral separation equipment and discloses a fan-shaped material distributor. The fan-shaped material distributor comprises a box body and a material distribution chute, wherein the box body is divided into pulp inlet trough and a pulp outlet trough by an overflow plate; a valve and a plurality of on-line ore pulp concentration meters are arranged on the inner wall of the pulp inlet trough; a diluting water pipe is arranged at the upper part, parallel to a pulp outlet, of the pulp outlet trough; a controller and a pump for supplying water to the diluting water pipe are arranged on the outer wall of the box body; the controller is connected with the on-line ore pulp concentration meters, the valve and the pump respectively; the material distribution chute is shaped like a fan and comprises side plates, a bottom plate, a baffle plate, flow guiding plates and a plurality of buffer plates; and a flow stabilizing grate is arranged in the pulp inlet trough. The controller of the fan-shaped material distributor can carry out adjustment through the valve and the pump according to the treatment capacity of a downstream magnetic separator to obtain appropriate ore pulp. The ore pulp is mixed and guided by the material distribution chute to uniformly flow to a bottom box along a cylinder of the magnetic separator.

Owner:江苏紫润建设有限公司

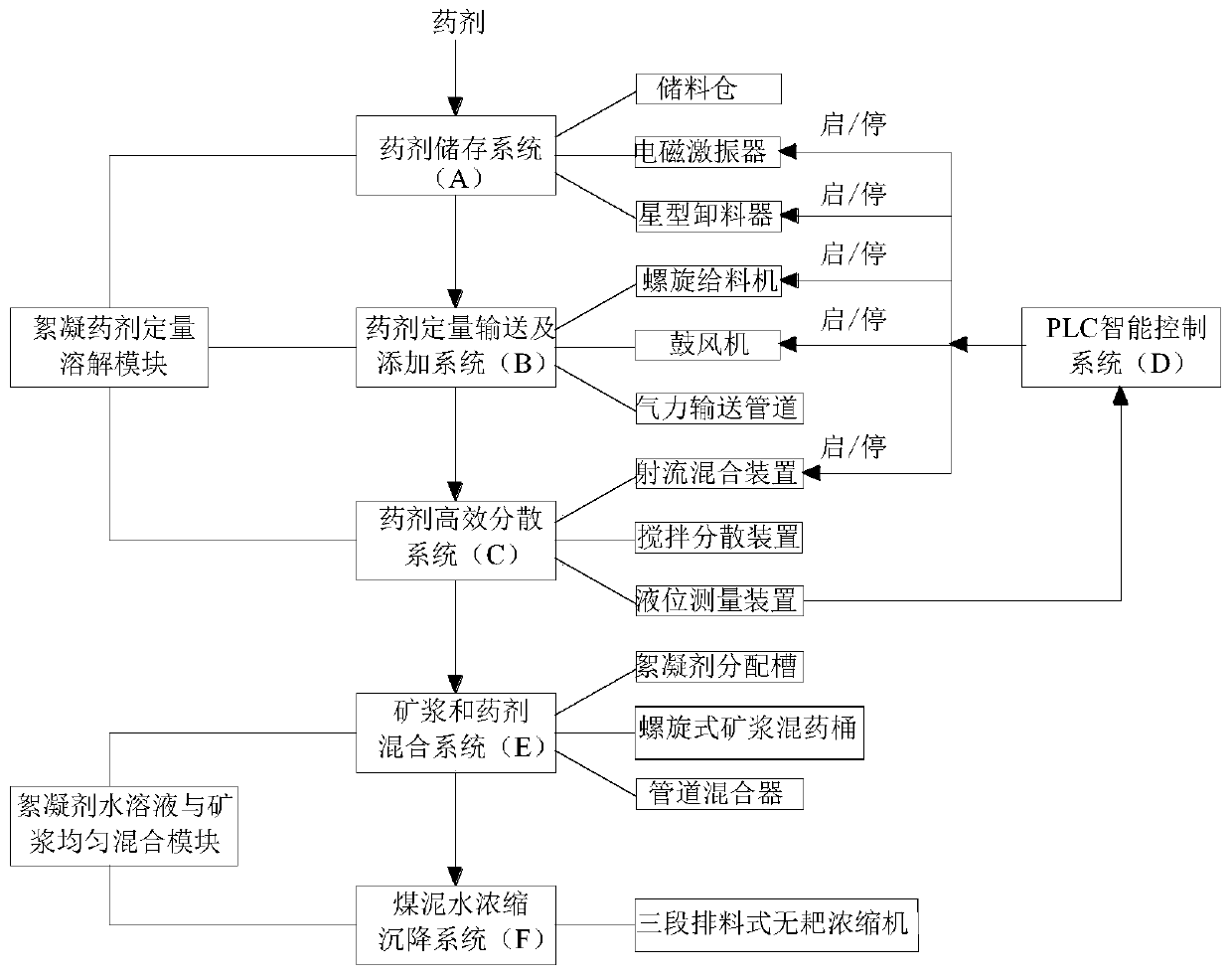

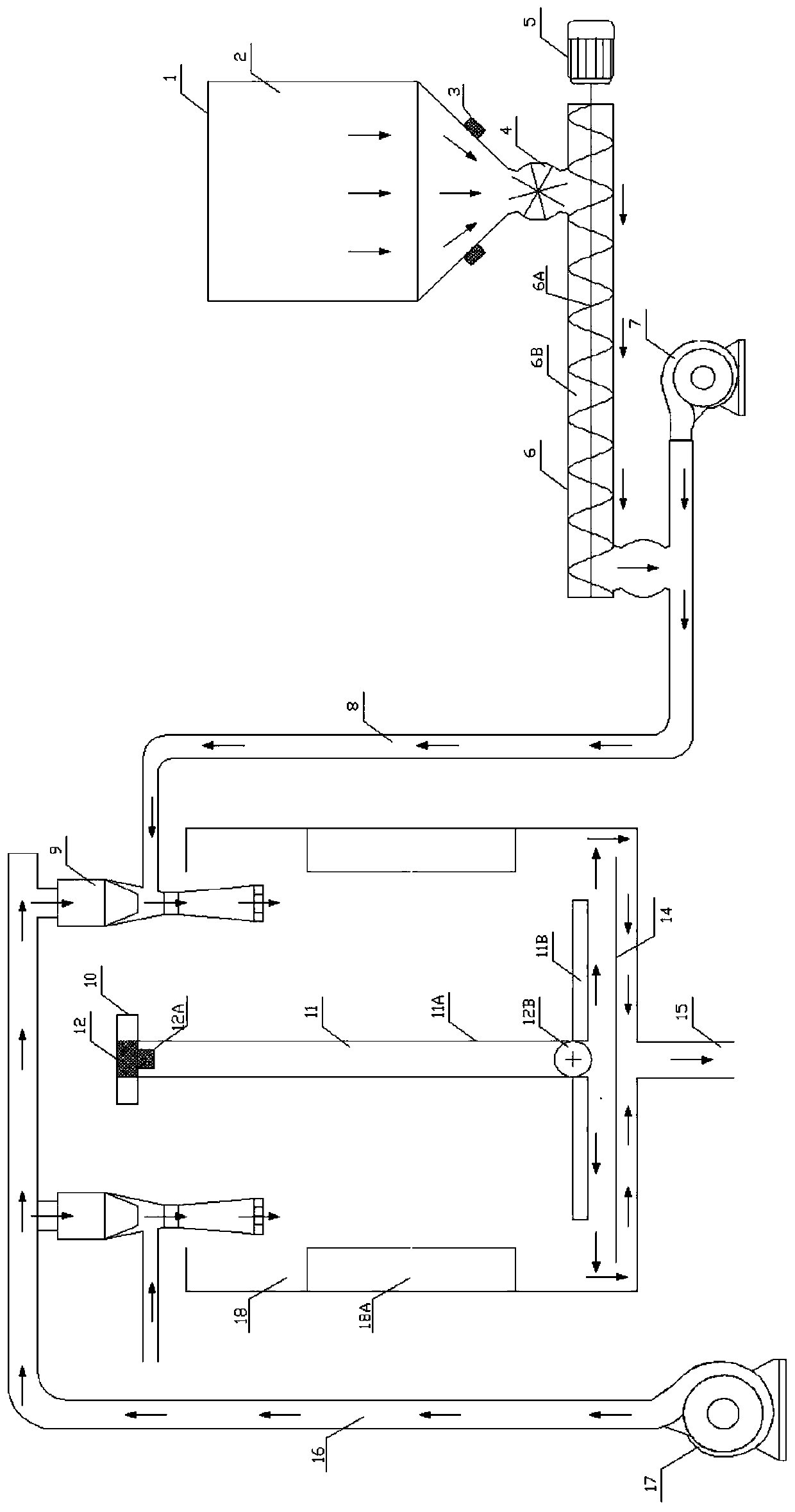

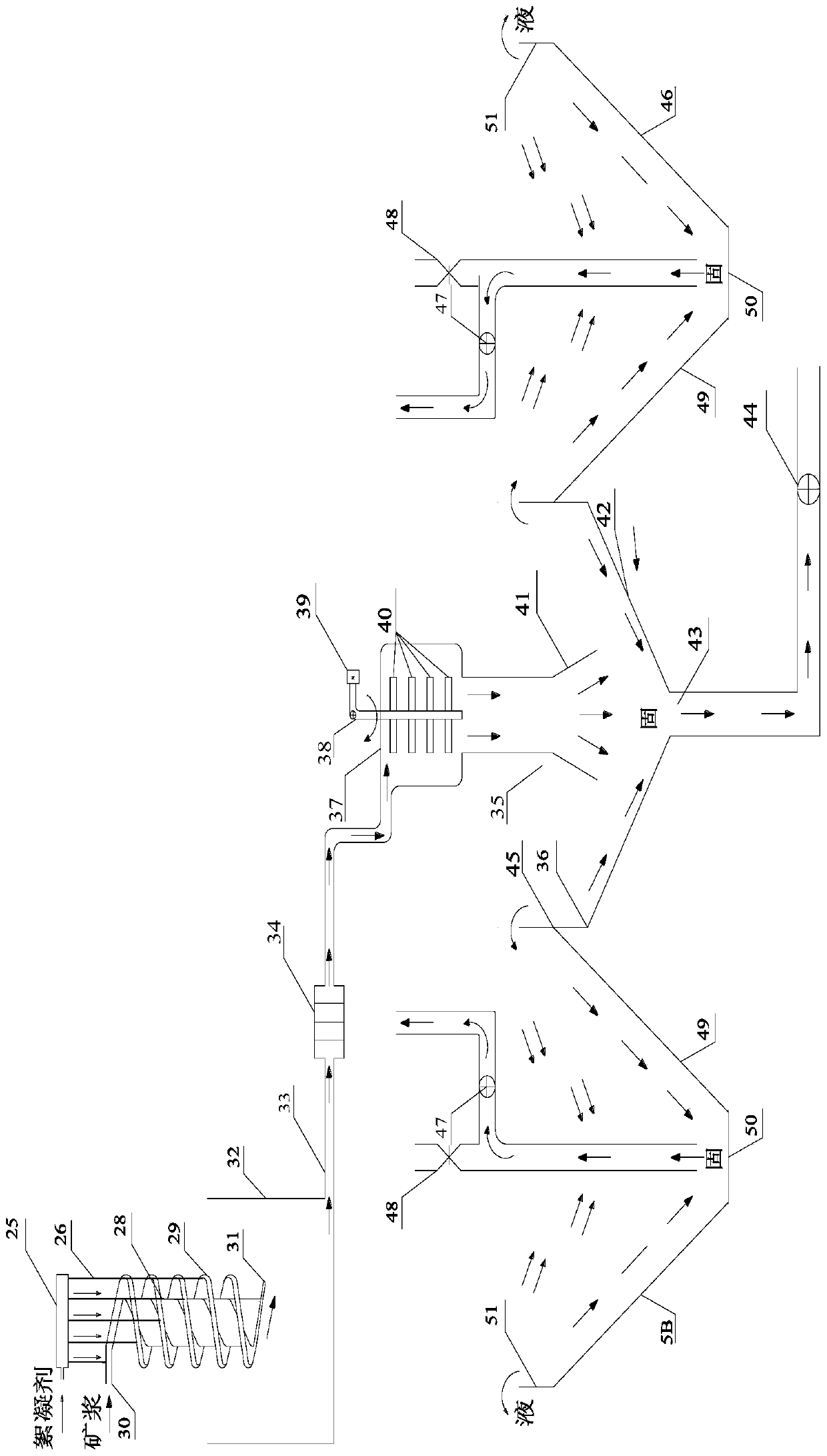

Quantitative dissolution and uniform mixing addition system of flocculation agent

InactiveCN110026123AReasonable system structureHigh degree of automationTransportation and packagingSettling tanks feed/dischargeSettling timeIntelligent control system

The invention relates to the field of concentration treatment of coal slurry water, in particular to a quantitative dissolution and uniform mixing addition system of a flocculation agent. The system comprises an agent storage system, a quantitative agent conveying and addition system, an efficient agent dispersion system, a PLC (programmable logic controller) intelligent control system, an ore pulp and agent mixing system and a coal slurry water concentration and settling system, wherein the agent storage system and the quantitative agent conveying and addition system ensures addition of the powdered agent according to required dose; the efficient agent dispersion system achieves uniform dispersion and quick dissolution of the powdered agent in an aqueous solution; and the ore pulp and agent mixing system promotes uniform mixing of the aqueous solution in which the flocculation agent is dissolved, and the coal slurry water and has a good flocculation settling initial condition. A coredevice of the coal slurry water concentration and settling system is a three-section discharge harrow-less concentrator; the concentrator adopts a 'one-middle and two-sides' discharge mode; thick particles and fine particles are discharged and recovered through different ports; the fine particles have longer settling time; and a whole concentration task has higher concentration efficiency.

Owner:ANHUI UNIV OF SCI & TECH

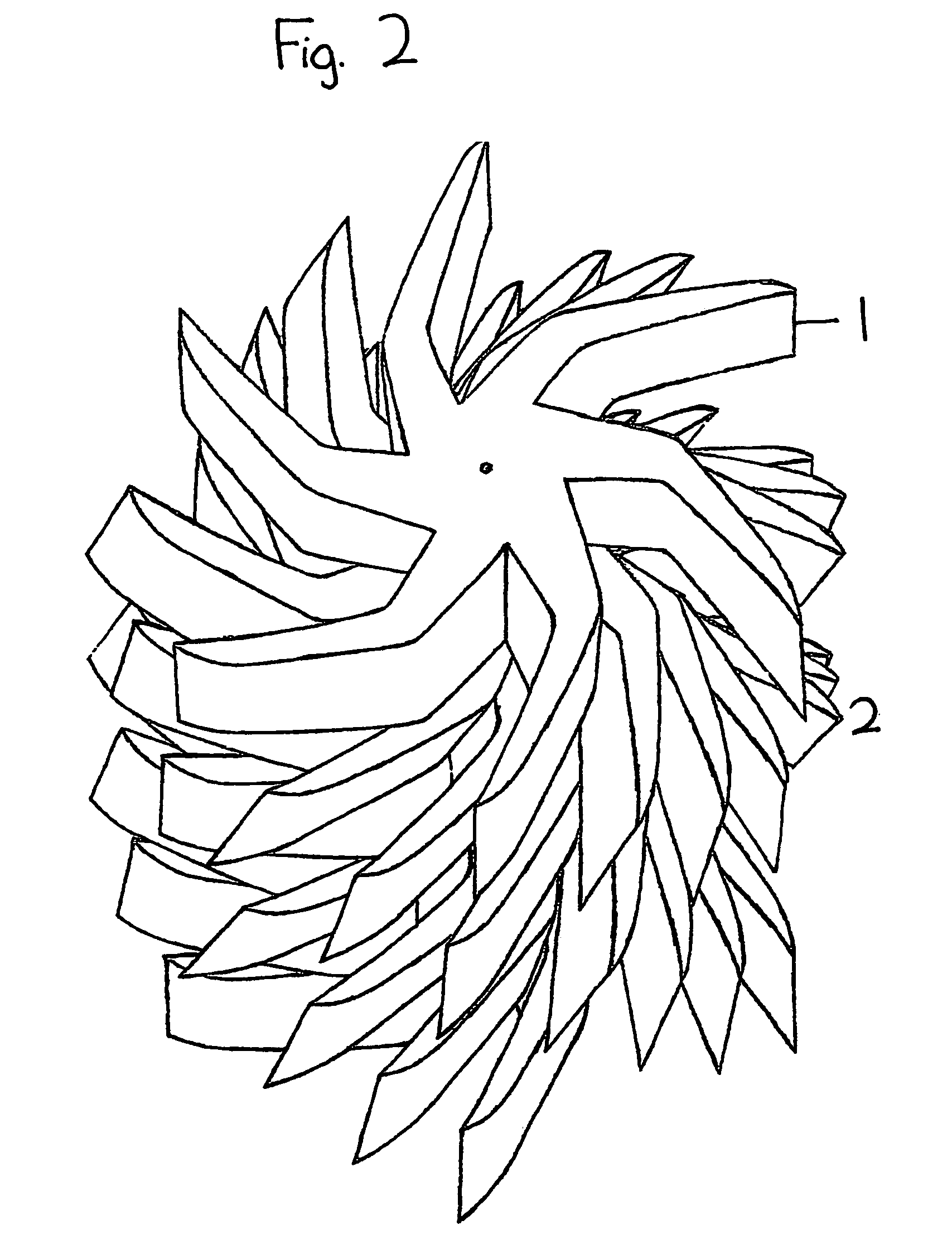

Efficient gas compressor vane wheel

InactiveCN103195750AEliminate turbulenceEliminate vortexPump componentsCombustion enginesImpellerTurbocharger

The invention relates to an efficient gas compressor vane wheel, in particular to a gas compressor vane wheel on a turbocharger. The vane wheel comprises hubs, the hubs are of an axial-to-radial streamline-typed arc-turning trumpet shape, and blades are evenly distributed outside the hubs. The gas compressor vane wheel is characterized in that each hub arranged between two adjacent blades is provided with one diversion trench, and the diversion trenches are distributed in a streamline direction on each vane wheel. With the efficient gas compressor vane wheel, collision and friction between gases can be reduced, gas temperature can be reduced and efficiency of the vane wheel can be improved. The efficient gas compressor vane wheel is applicable to superchargers with high-pressure ratio and high-efficiency.

Owner:无锡科博增压器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com