Fan-shaped material distributor

A distributing device and fan-shaped technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of magnetic separator processing volume fluctuation, process control influence, and service cycle decline, so as to improve the equalization effect and detect Accurate results and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

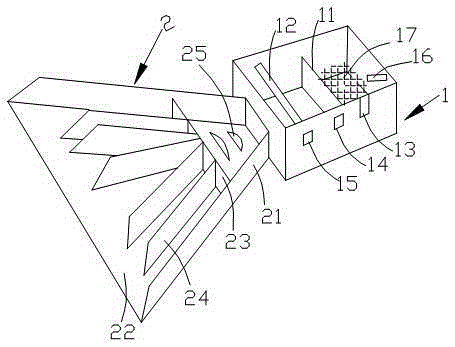

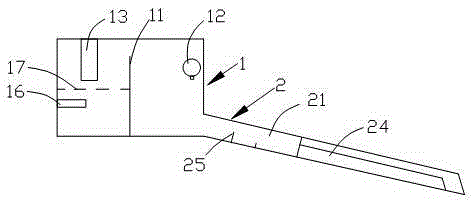

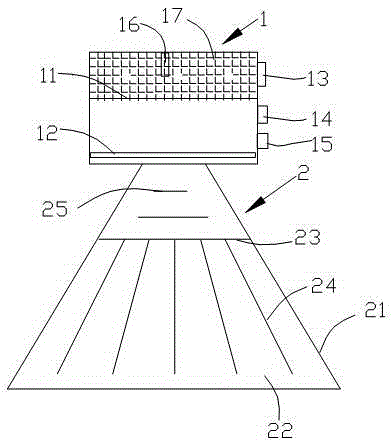

[0032] Such as Figure 1~3 The fan-shaped distributor shown includes a box body 1 and a distribution tank 2; the box body 1 is divided into a slurry inlet tank and a slurry outlet tank by an overflow plate 11. A valve 13 and an online pulp concentration meter 16 are arranged on the inner wall of the slurry inlet tank; a dilution water pipe 12 is arranged on the upper part of the slurry outlet tank parallel to the slurry outlet; a controller 14 and a controller 14 are arranged on the outer wall of the tank. A pump 15 that supplies water to the dilution water pipe 12; a controller 14 is connected to an online slurry concentration meter 16, a valve 13, and a pump 15;

[0033] The distribution trough 2 is fan-shaped and includes side plates 21 , bottom plates 22 , one baffle plate 23 , six deflector plates 24 , and two buffer plates 25 . The baffle plate 23 is parallel to the pulp outlet and connected with the bottom plate 22 and the side plate 21 . The deflector 24 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com