Efficient gas compressor vane wheel

A compressor, high-efficiency technology, applied in the direction of mechanical equipment, combustion engines, machines/engines, etc., can solve the problems of increasing gas temperature, unable to flow, gas pressure temperature, uneven speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

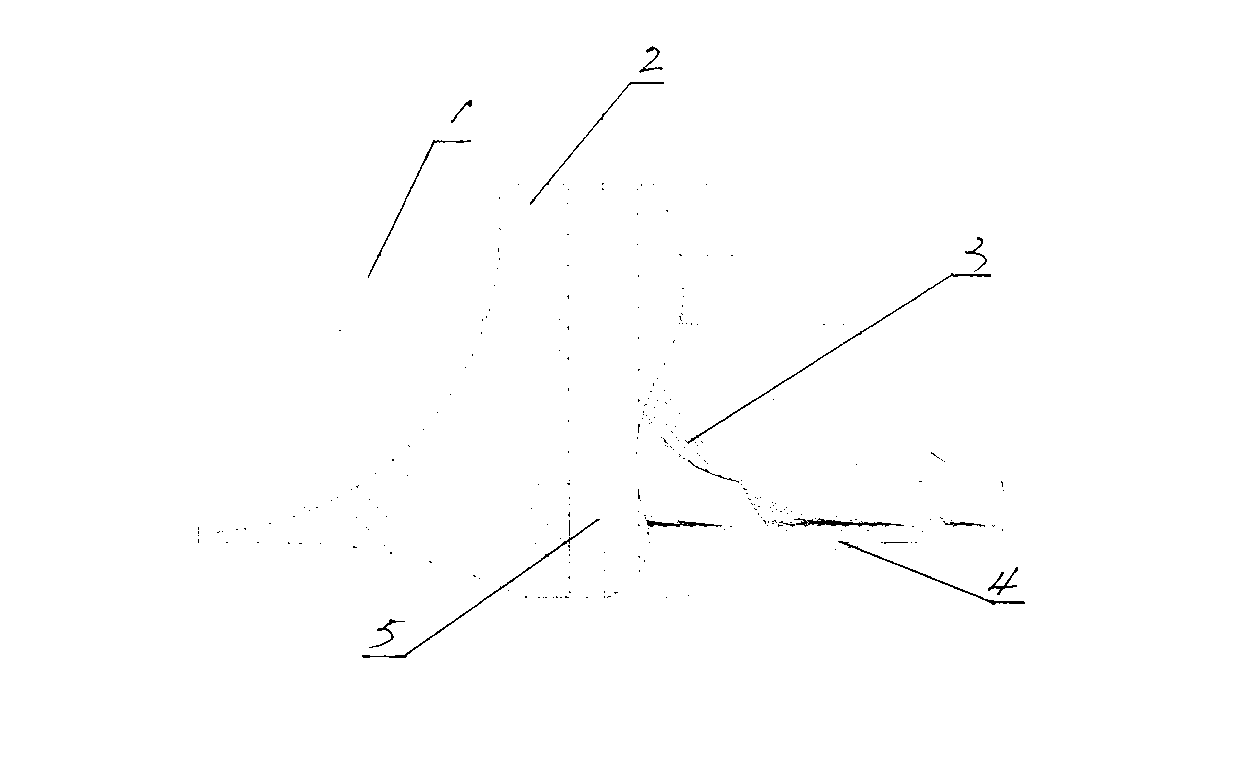

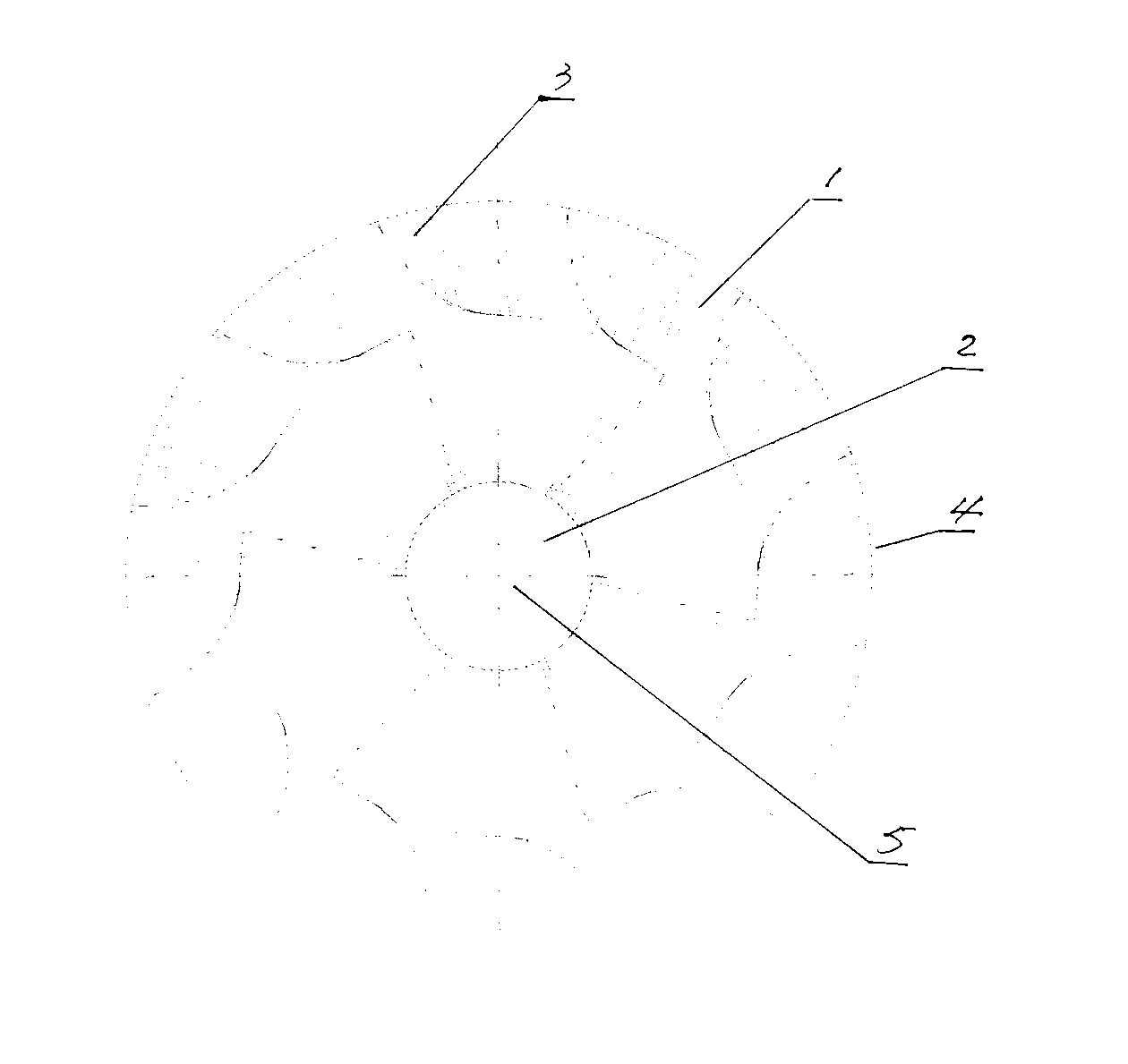

[0013] Such as figure 1 and figure 2 As shown, the high-efficiency compressor impeller of the present invention includes a hub, and the hub includes an axle 2, and a bottom plate 4 is fixed at the inner end of the axle 2. The base plate 4 is circular, and its plate surface is perpendicular to the wheel shaft, and the outer surface of the wheel shaft 2 and the plate surface of the base plate 4 are smooth surfaces, so that the hub is in the radial direction from the axial direction of the wheel shaft 2 to the base plate 4. Streamlined horn shape with excessive arc. Blades 1 are evenly distributed in the circumferential direction of the hub, and the blades are helical. Flow guide grooves 3 are processed on the hub between adjacent blades 1, and the flow guide grooves 3 are evenly arranged on the hub along the streamline direction. When the gas enters the meridian channel between two adjacent blades 1, the turbulence and eddy current generated by the gas can be eliminated thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com