Mixed combustion visual combustor

A mixed combustion and burner technology, which is applied in combustion chambers, combustion methods, and combustion equipment, can solve problems such as unfavorable combustion diagnosis, disrupted ignition sequence, and difficult-to-ignite fuel grains, so as to avoid serious backflow of gas outlet and reduce Disturbance of combustion environment, effect of good flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

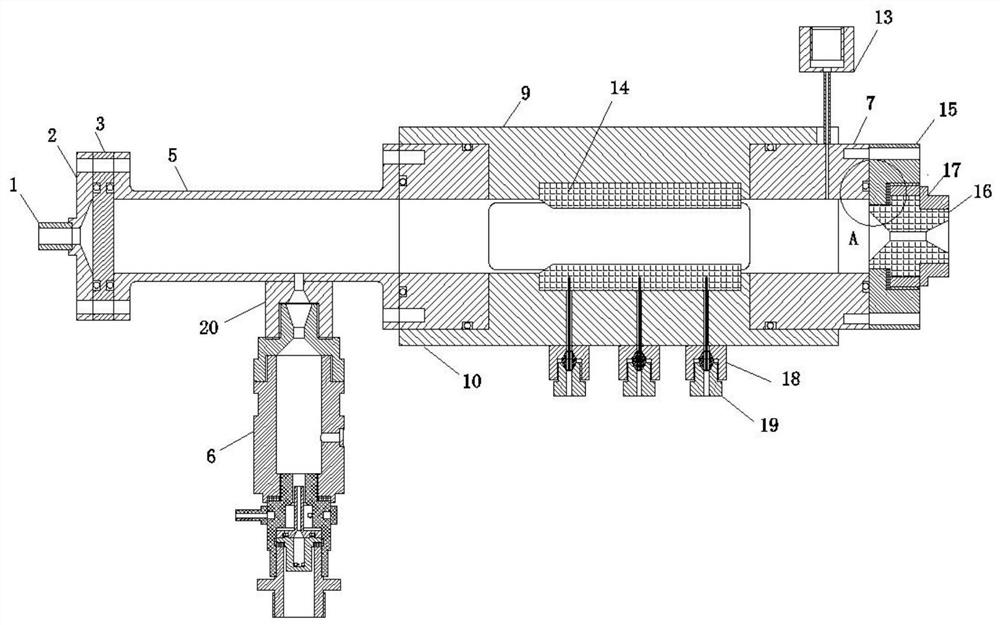

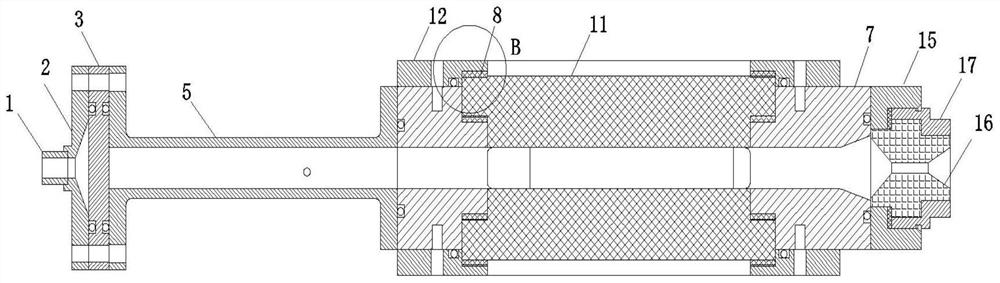

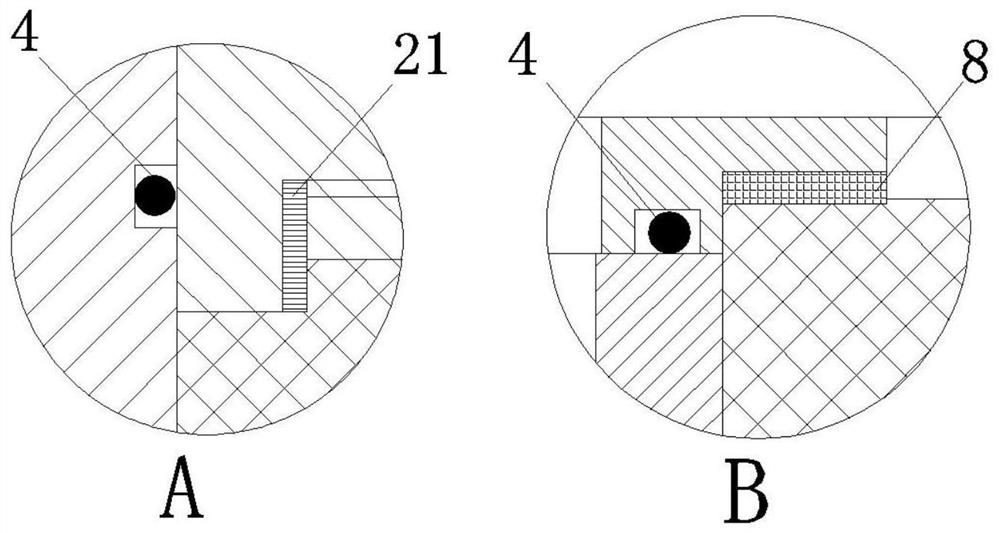

Embodiment 1

[0082] Embodiment 1: The fuel is cut into several long strips with an end surface size of 20mm×20mm and a length of 150mm, and the grains are finely trimmed to have a forward angle of 30°. Weigh absolute ethanol and polyvinyl butyral according to the mass fraction of 92% and 8% to configure the coating solution, slowly add polyvinyl butyral to absolute ethanol, place it in a water bath at 50°C, and use a glass rod to Stir continuously until the polyvinyl butyral is completely dissolved, and use the prepared coating solution to evenly coat the side of the solid fuel 14 to ensure that the charges burn in parallel layers. Use a twist drill bit with a diameter of 0.5mm in one of the solid fuel 14 rods, the depth of the fuel inner hole is 2 / 3 of the height of the fuel, and the drilling position is coaxial with the through hole at the bottom of the lower top cover 10 of the combustion chamber. Weigh epoxy resin (A glue) and curing agent (B glue) according to the mass ratio of 5:3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com