Miniature pump for liquid cooling system

a liquid cooling system and miniature pump technology, applied in the field of pumps, can solve the problems of reducing affecting the cooling efficiency of the whole system, so as to eliminate the flow turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

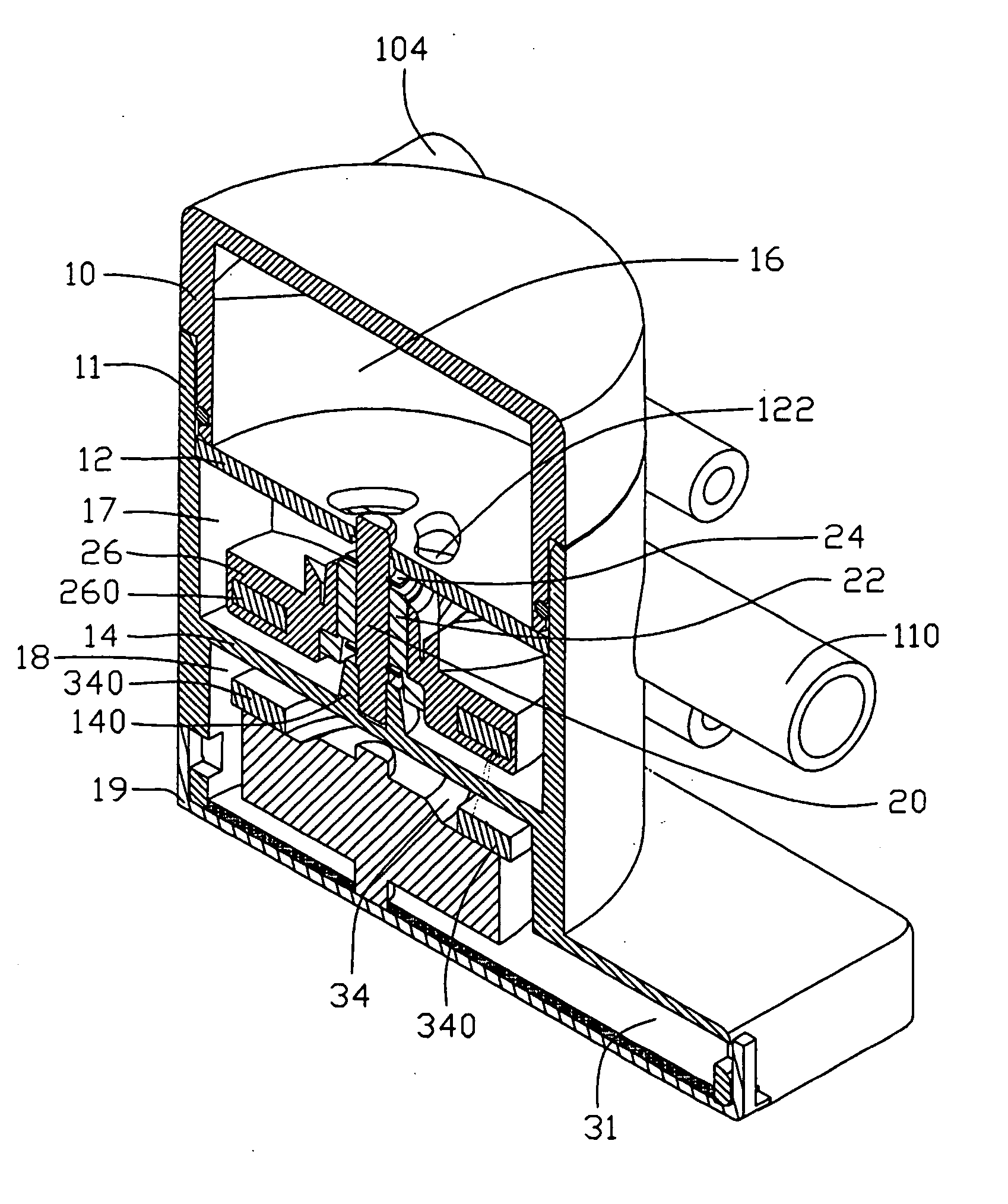

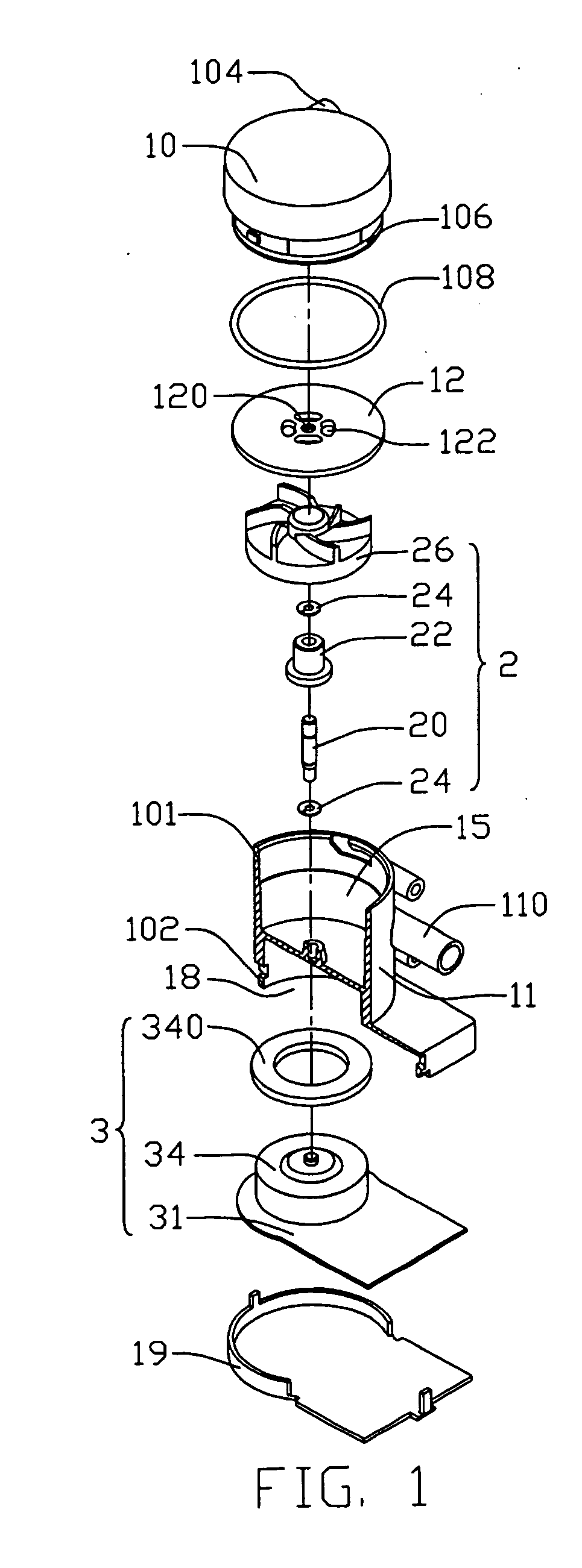

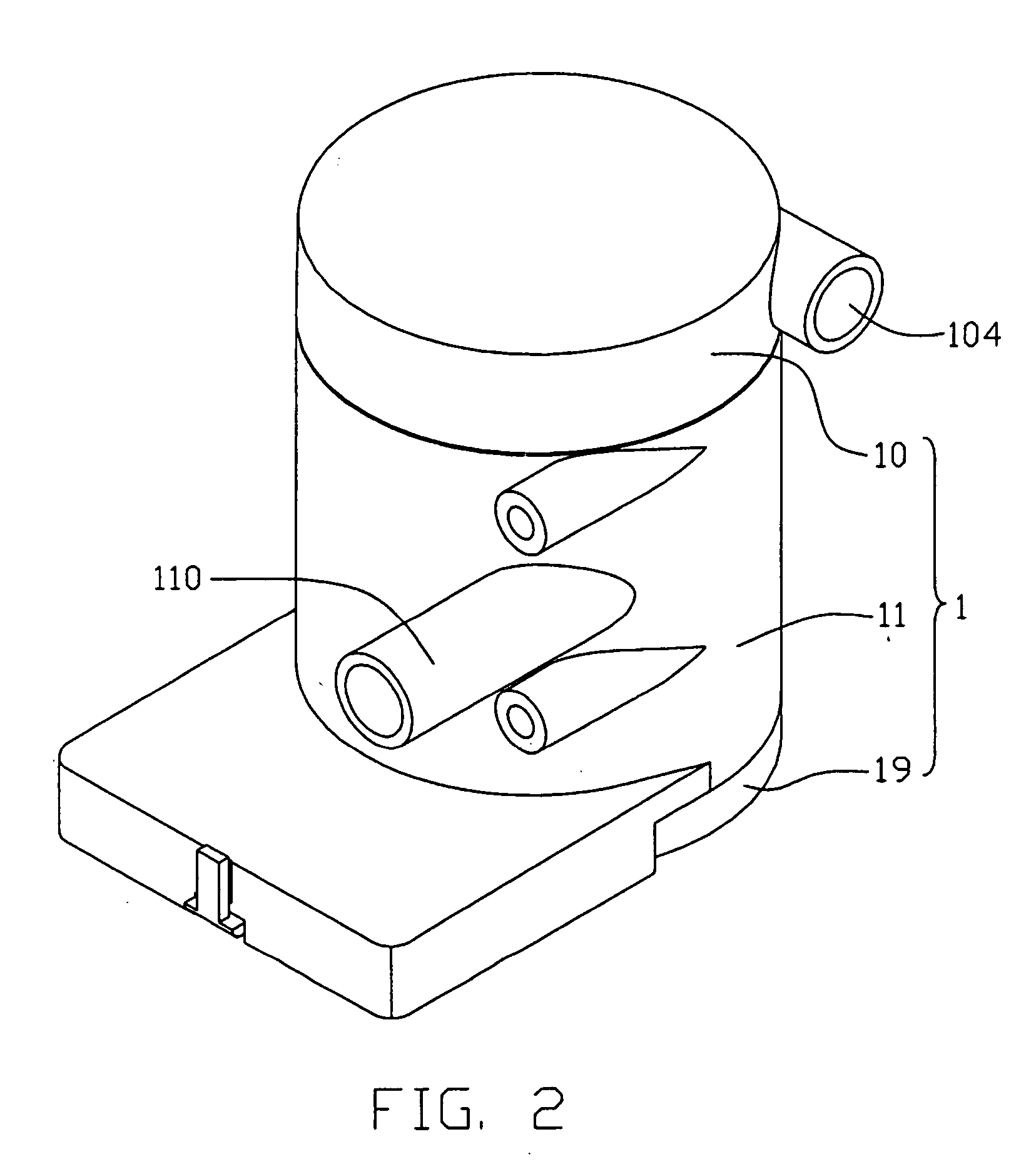

[0014] Referring to FIGS. 1 and 2, a miniature pump in accordance with a preferred embodiment of the present invention comprises a pump casing 1 having an inner space, and a liquid circulating unit 2 and a motor driving unit 3 received in the inner space of the pump casing 1.

[0015] The pump casing 1 comprises a hollow main body 11, a top cover 10 hermetically attached to a top end 101 of the main body 11, and a bottom cover 19 attached to a bottom end 102 of the main body 11. A sealing ring 108 is disposed between the main body 11 and the top cover 10 to prevent liquid leakage. The top cover 10 forms an annular groove 106 at a bottom edge thereof for receiving a sealing ring 108 therein. An inlet 104 is formed on the top cover 10 for allowing liquid to enter the pump casing 1. An outlet 110 is formed on the main body 11 for allowing the liquid to exit the pump casing 1.

[0016] The main body 11 transversely forms an inner partition wall 14. This partition wall 14 effectively divides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com