Variable pressure reducing device

a technology of pressure reducing device and variable pressure, which is applied in the direction of mechanical equipment, process and machine control, instruments, etc., can solve the problems of loss of function, capillary tubing, blockage, etc., and achieve the effect of improving the adjustability of the device, eliminating turbulence, and improving the flow through the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

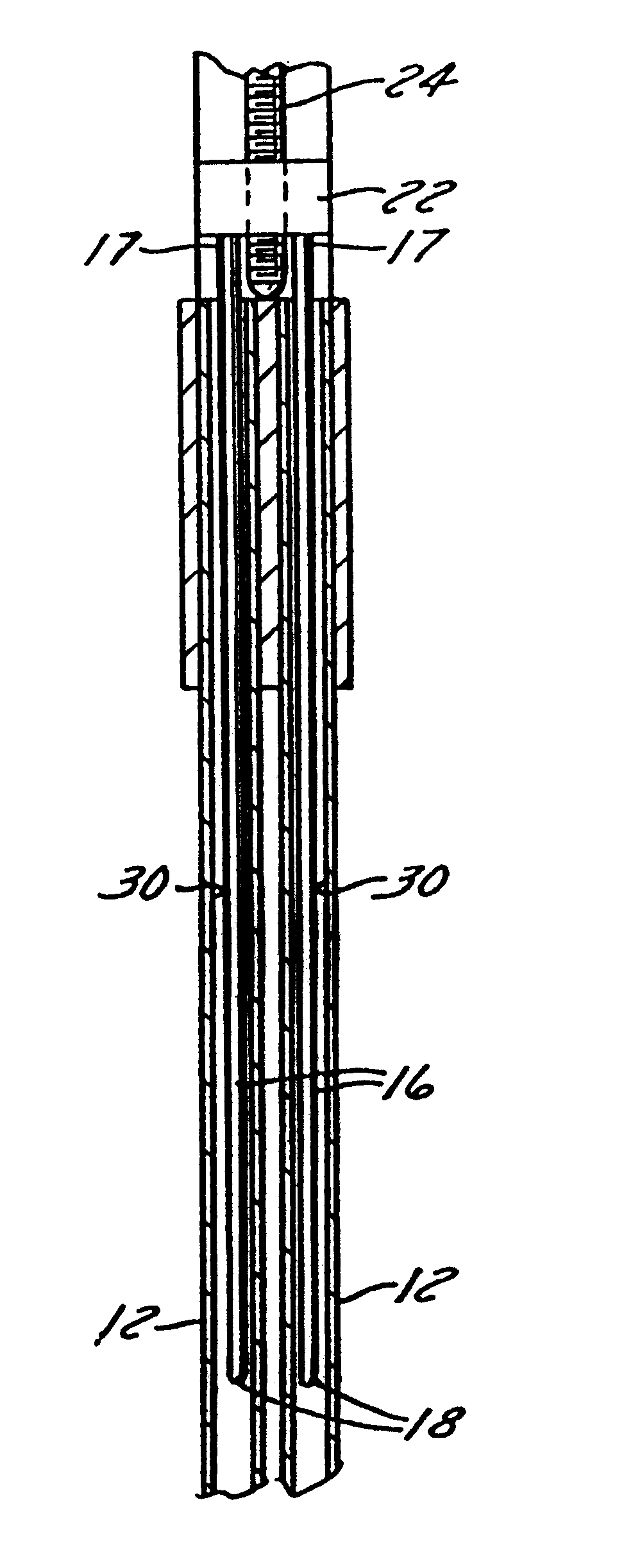

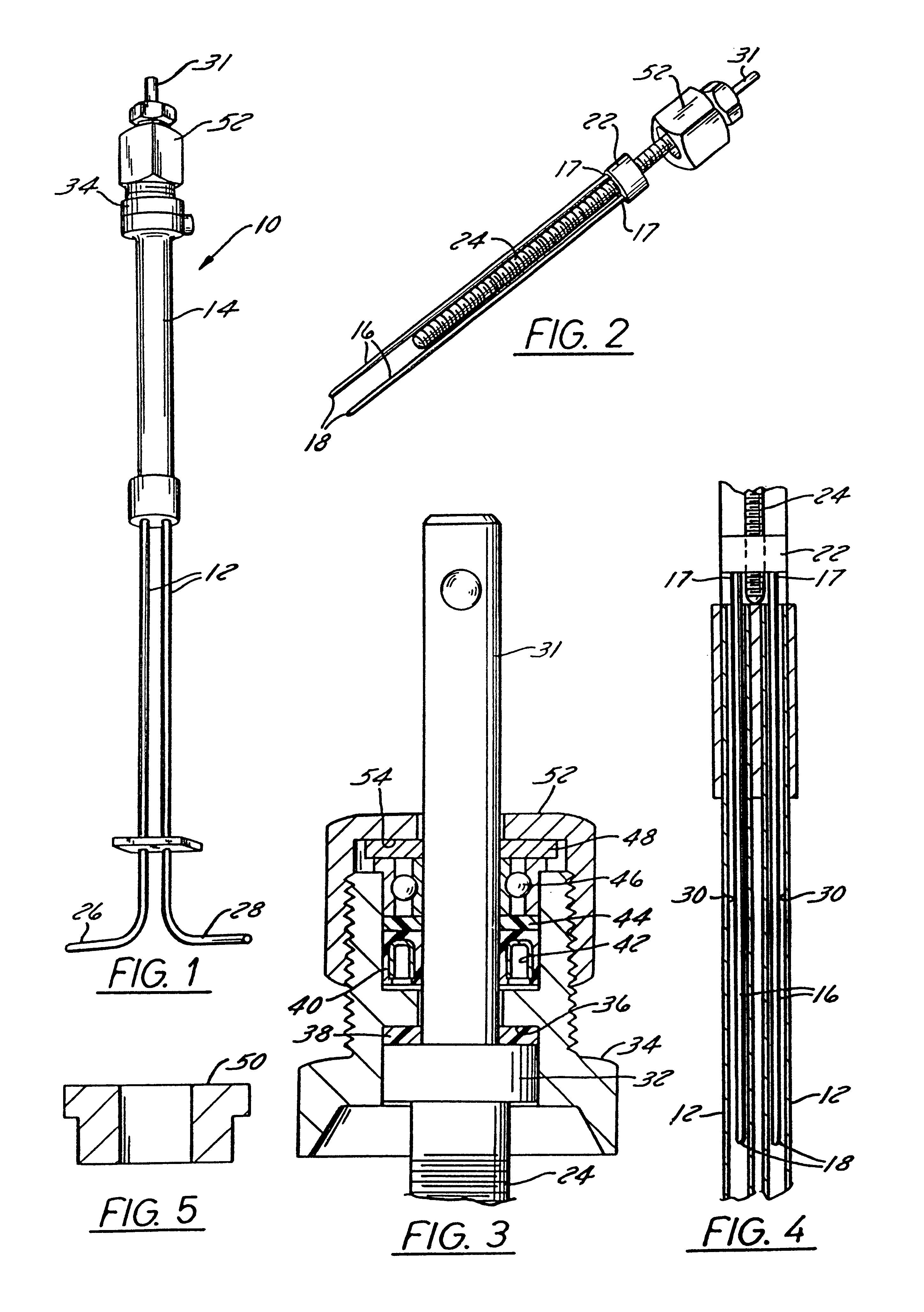

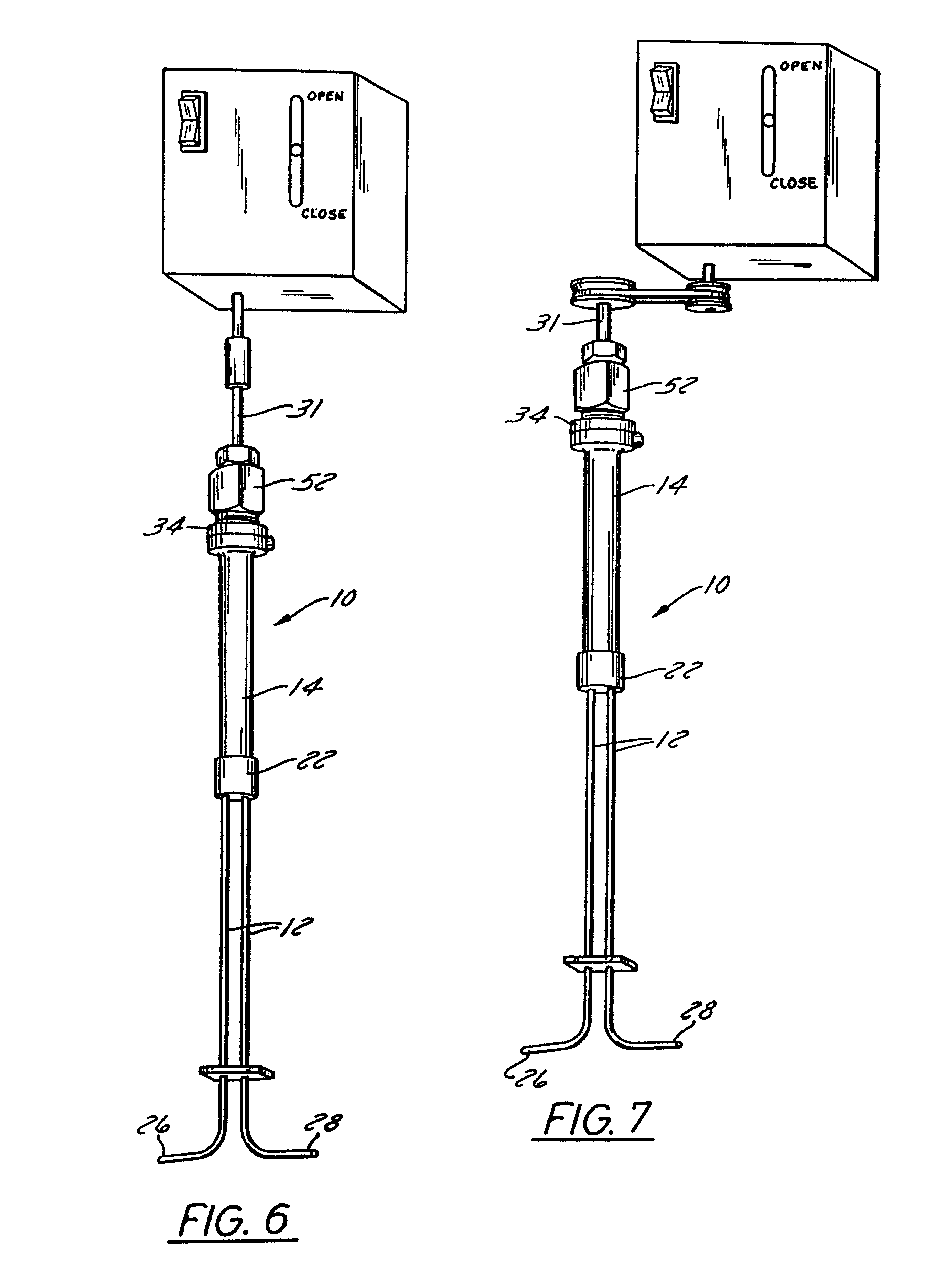

A variable pressure reducing element (VREL .TM.) 10 is used to reduce the pressure and control the flow of high pressure liquids. The device 10 is especially useful for reducing the pressure of steam and hot water samples in a power plant front as high as 5000 psi down to about 50 psi so that the liquid can be safely piped to an analyzer instrument or handled manually for a grab sample.

The VREL 10 is a rod-in-tube pressure reducing, flow control device comprising two stainless steel tubes 12 joined to one end of a larger tube or barrel 14. A pair of tapered rods 16 .[.is.]. .Iadd.are .Iaddend.inserted into the two tubes 12. One end 17 of each rod 16 is connected to a threaded ring 22 on a threaded guide screw 24 within the barrel 14. The other end 18 of each rod 16 is rounded. Between the ends 17 and 18, the rod 16 is smoothly tapered from a relatively wide diameter at the end 17 which is connected to the threaded ring 22 down to a relatively narrow diameter at the rounded end 18 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com