Patents

Literature

38results about How to "Increased drive torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

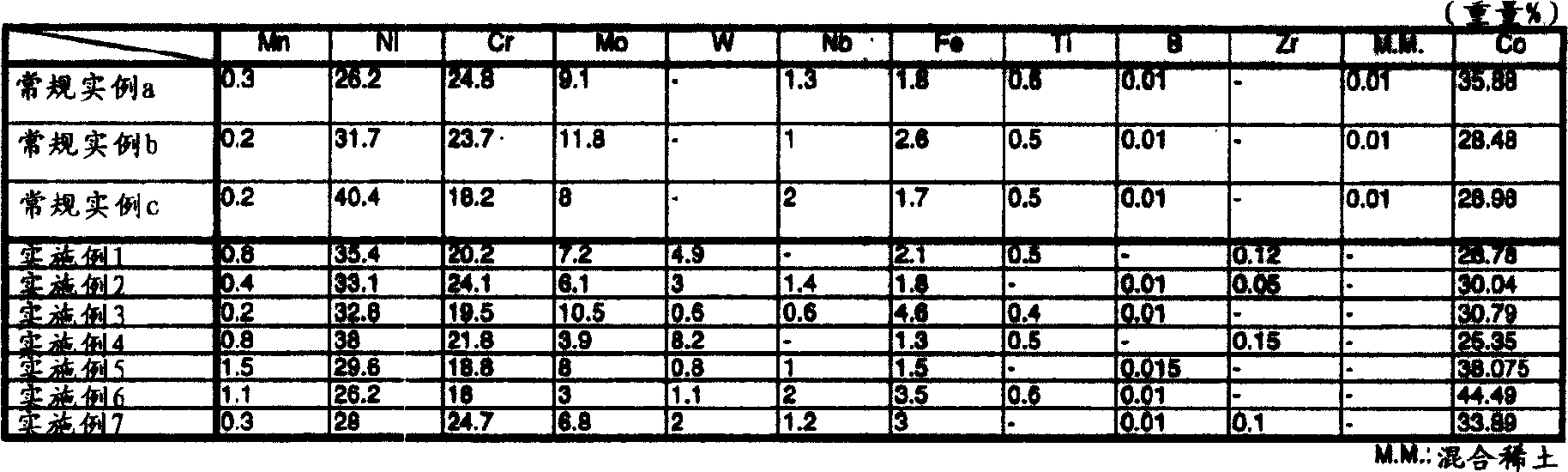

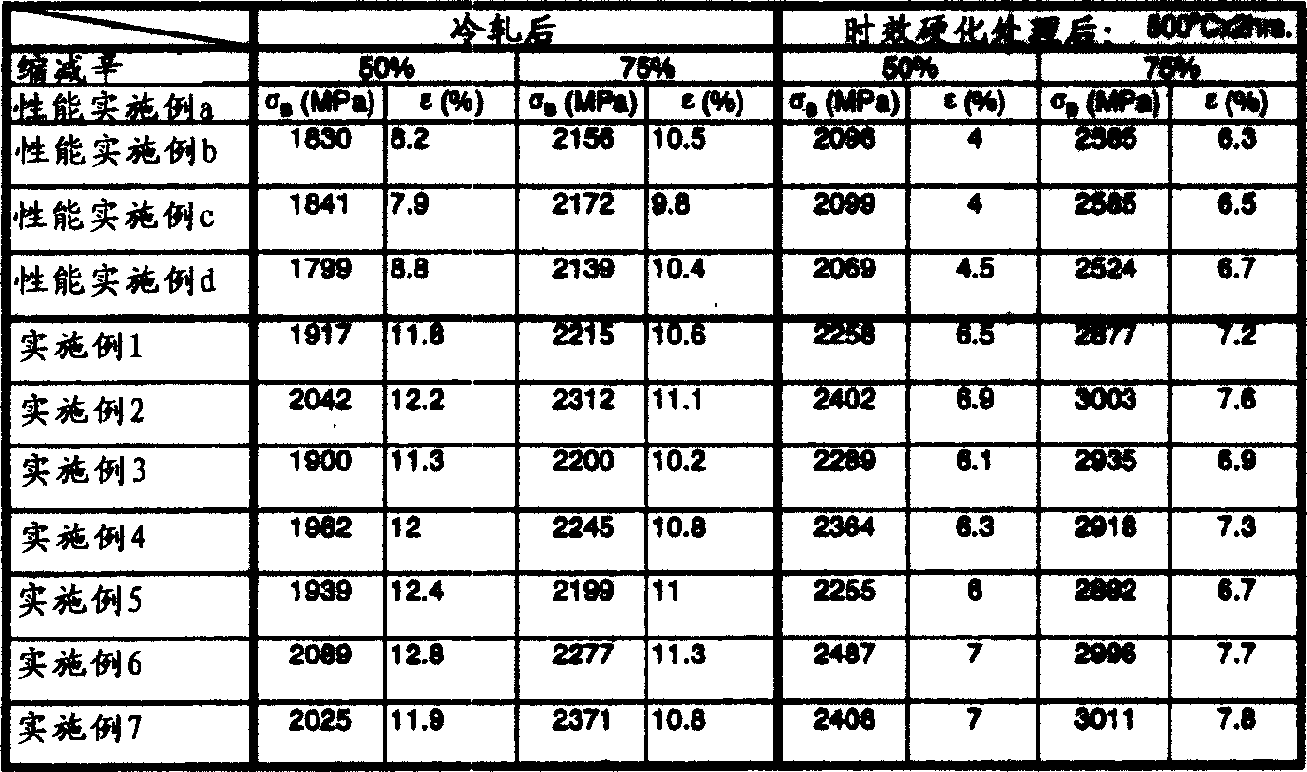

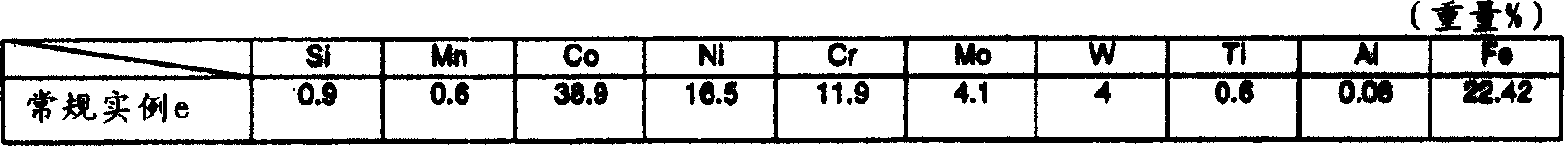

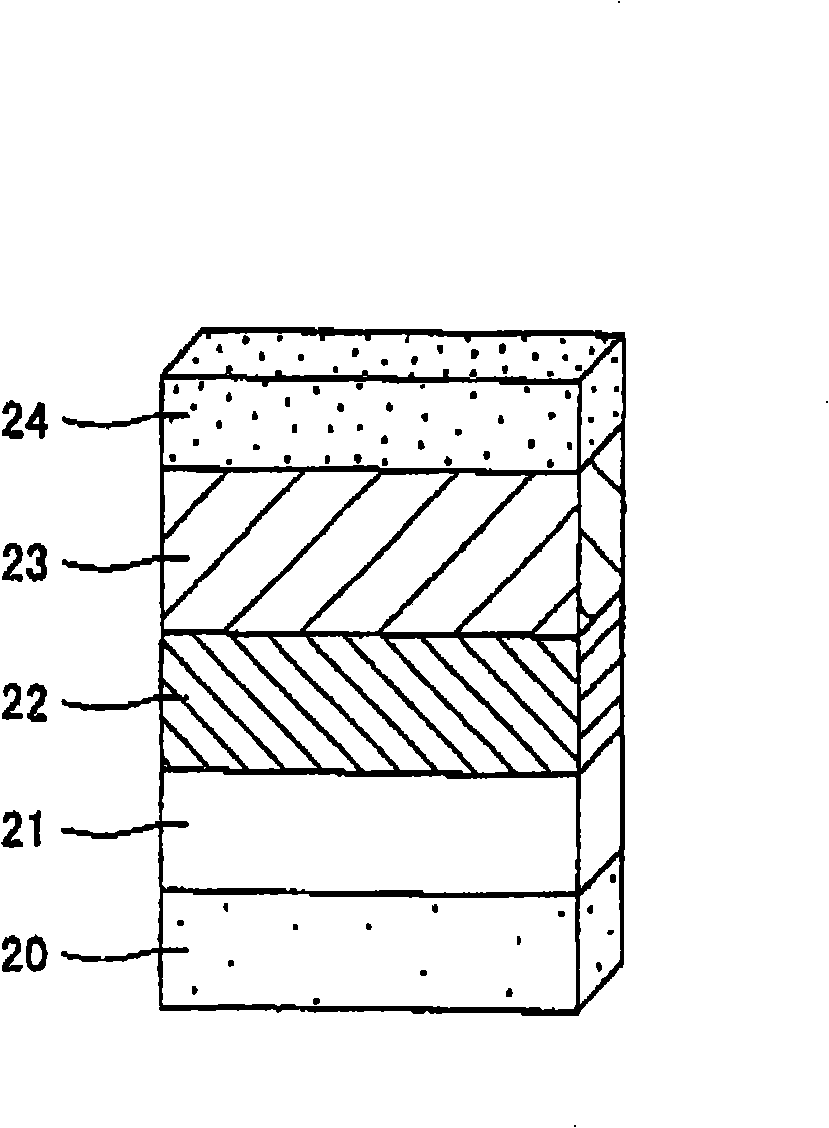

Co-Ni-base alloy

A Co-Ni-base alloy, being characterized in that a composition of the alloy comprises at least Co, Ni, Cr, Mo, W and Fe, and percentages by weight of the composition are from 25% to 45% of Co, from 25% to 40% of Ni, from 18% to 26% of Cr, from 3% to 11% of Mo, from 0.5% to 9% of W, wherein a sum of Mo and W is from 4% to 13% by weight, and from 1.1% to 5% of Fe.

Owner:SEIKO INSTR INC +1

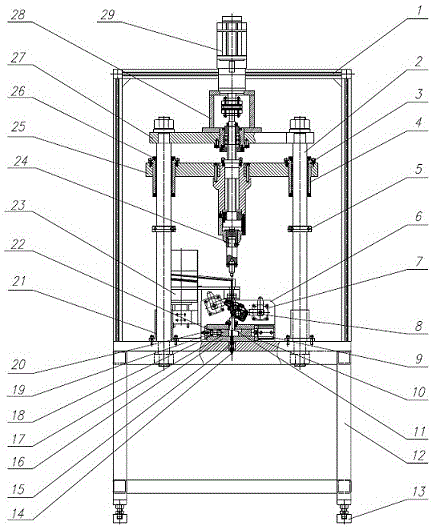

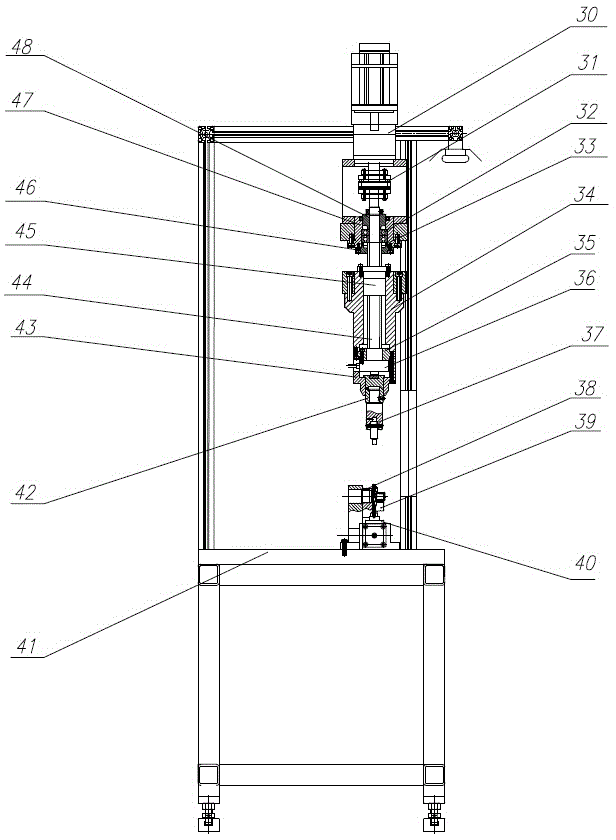

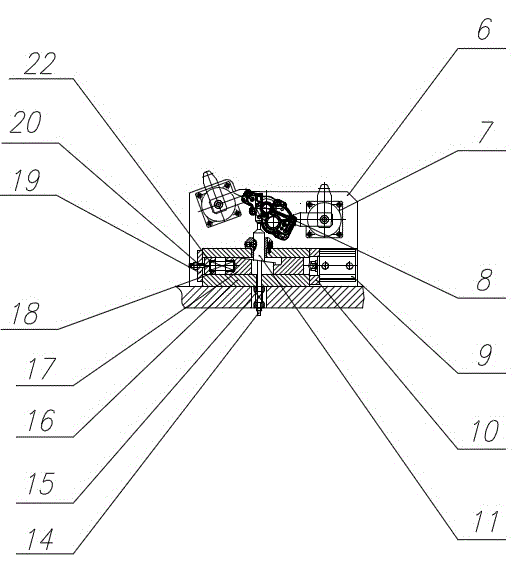

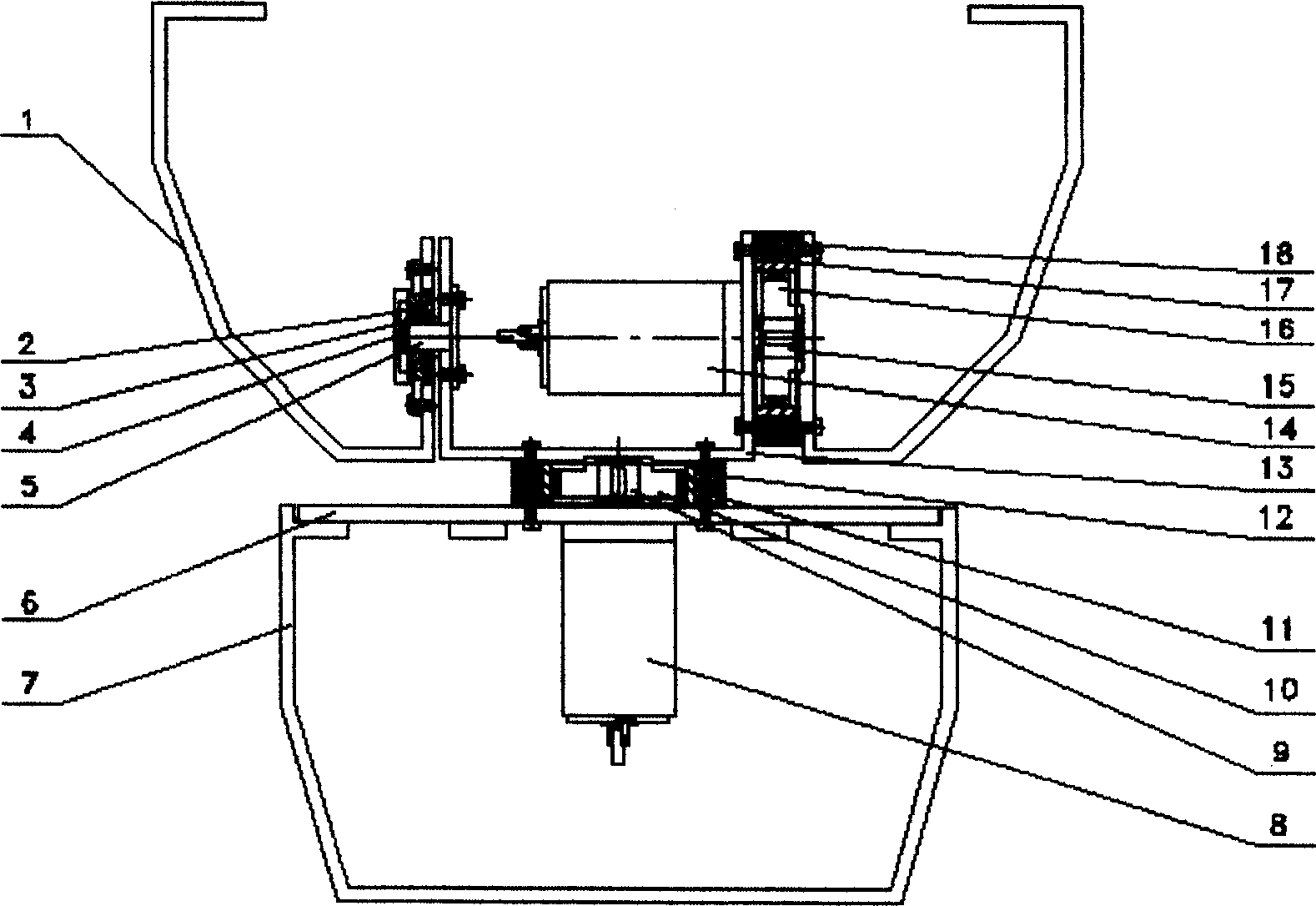

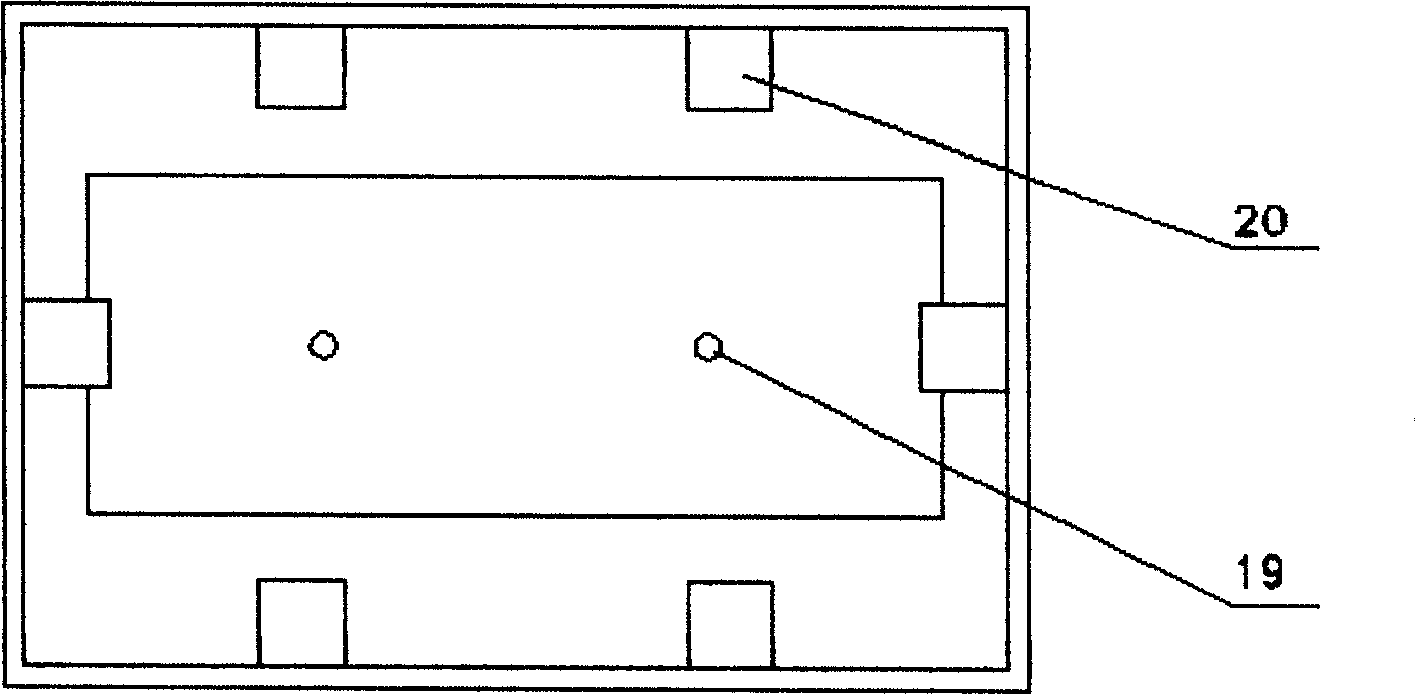

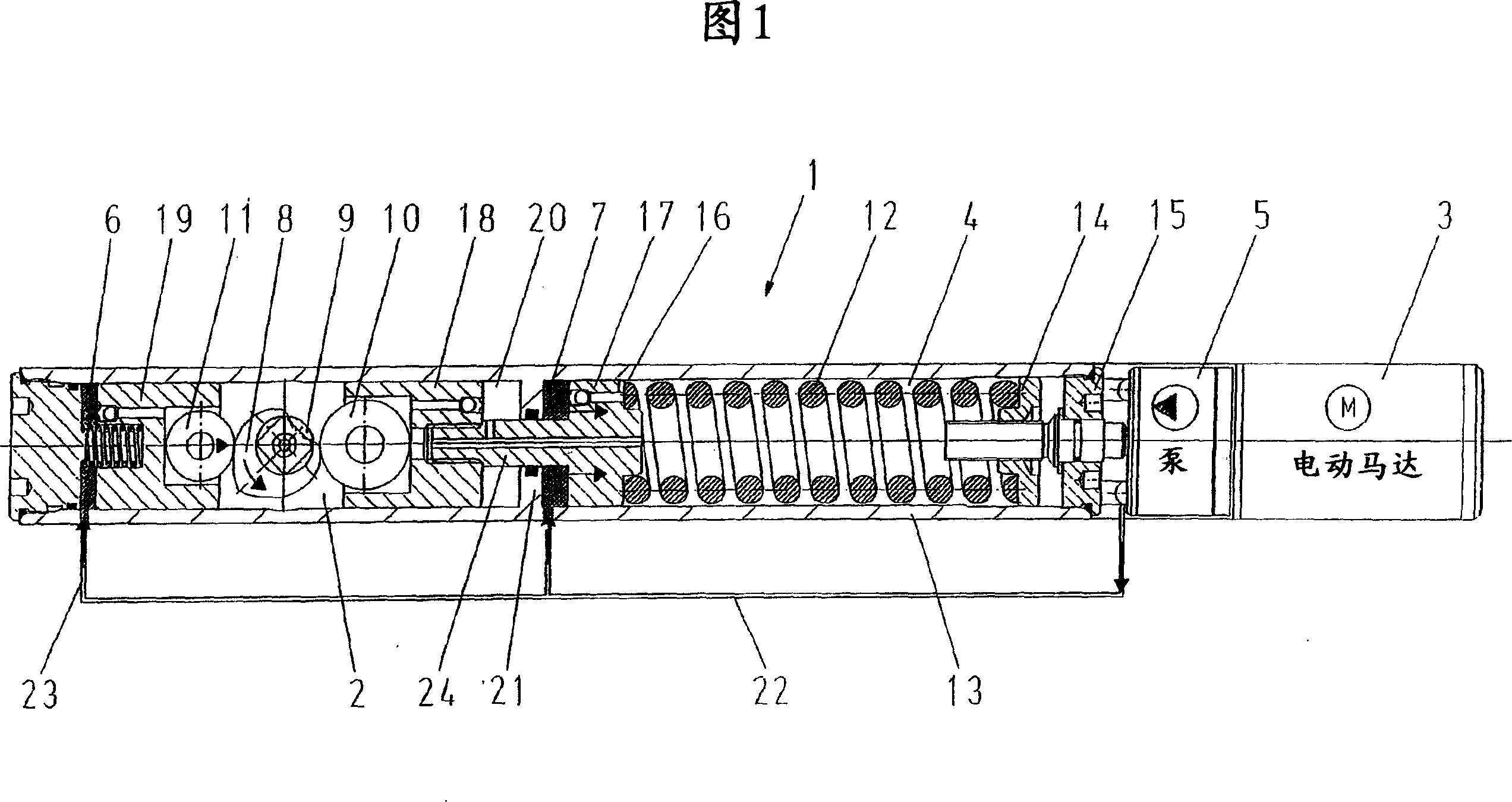

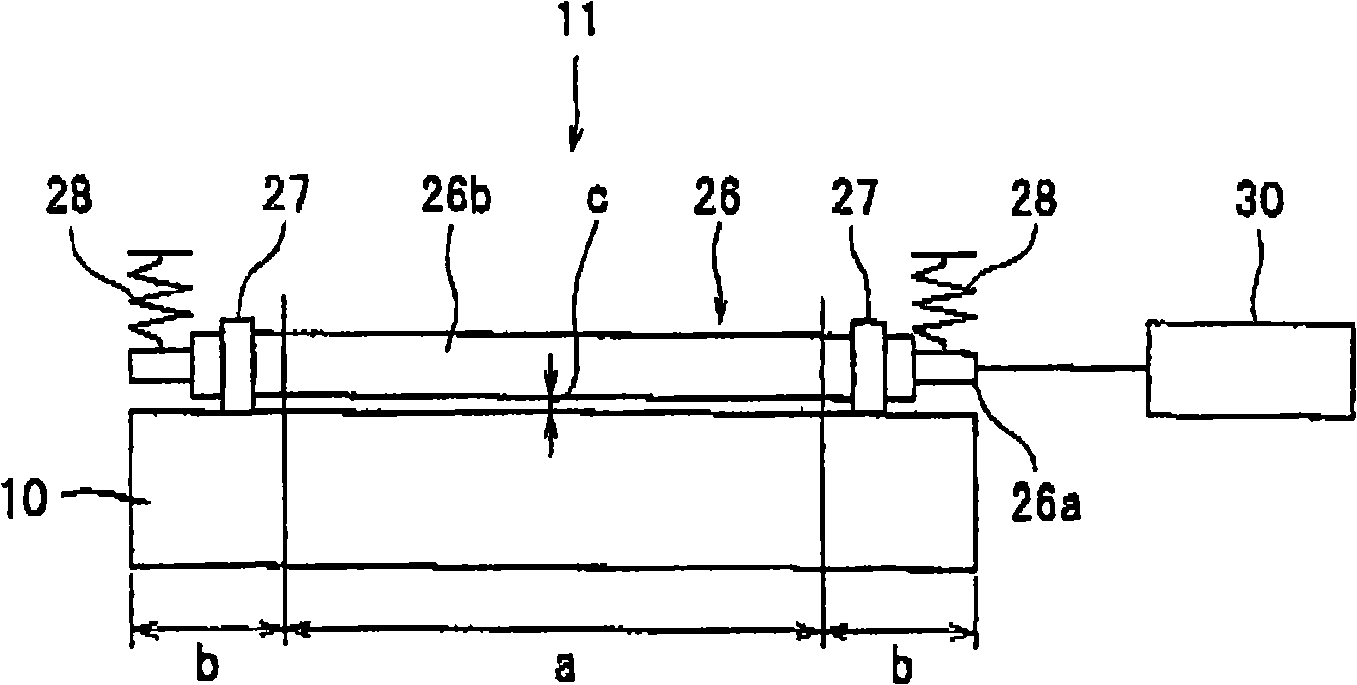

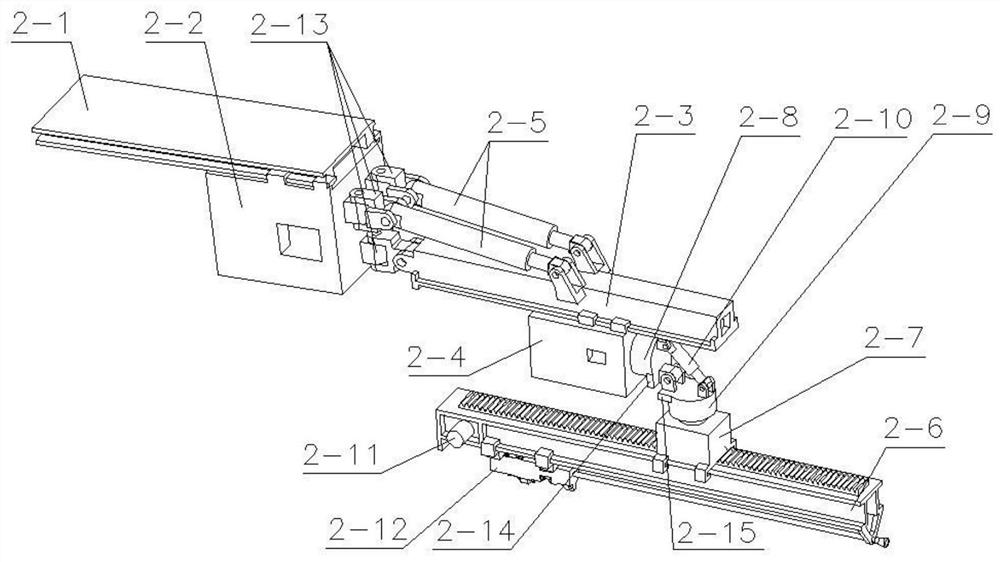

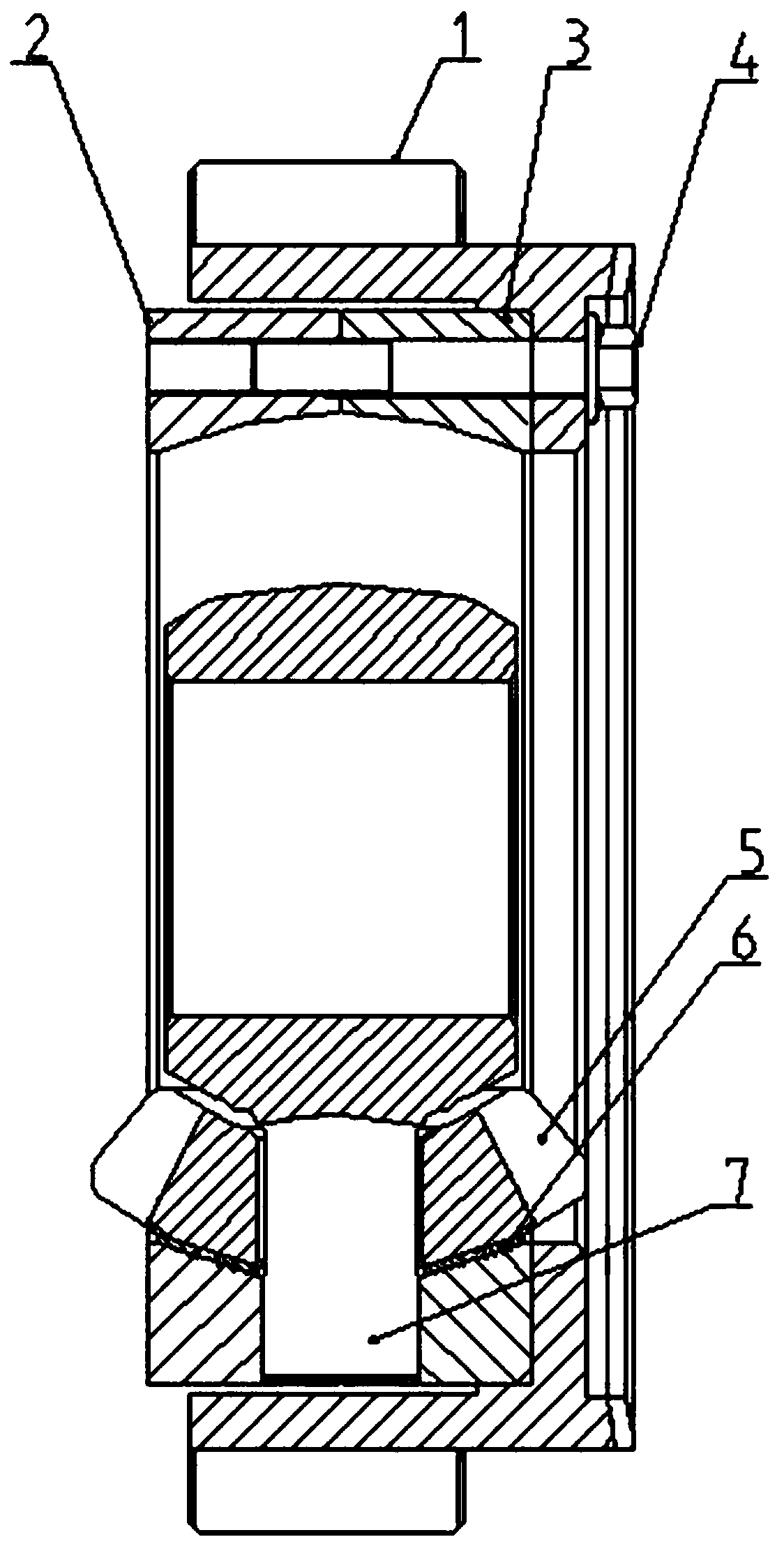

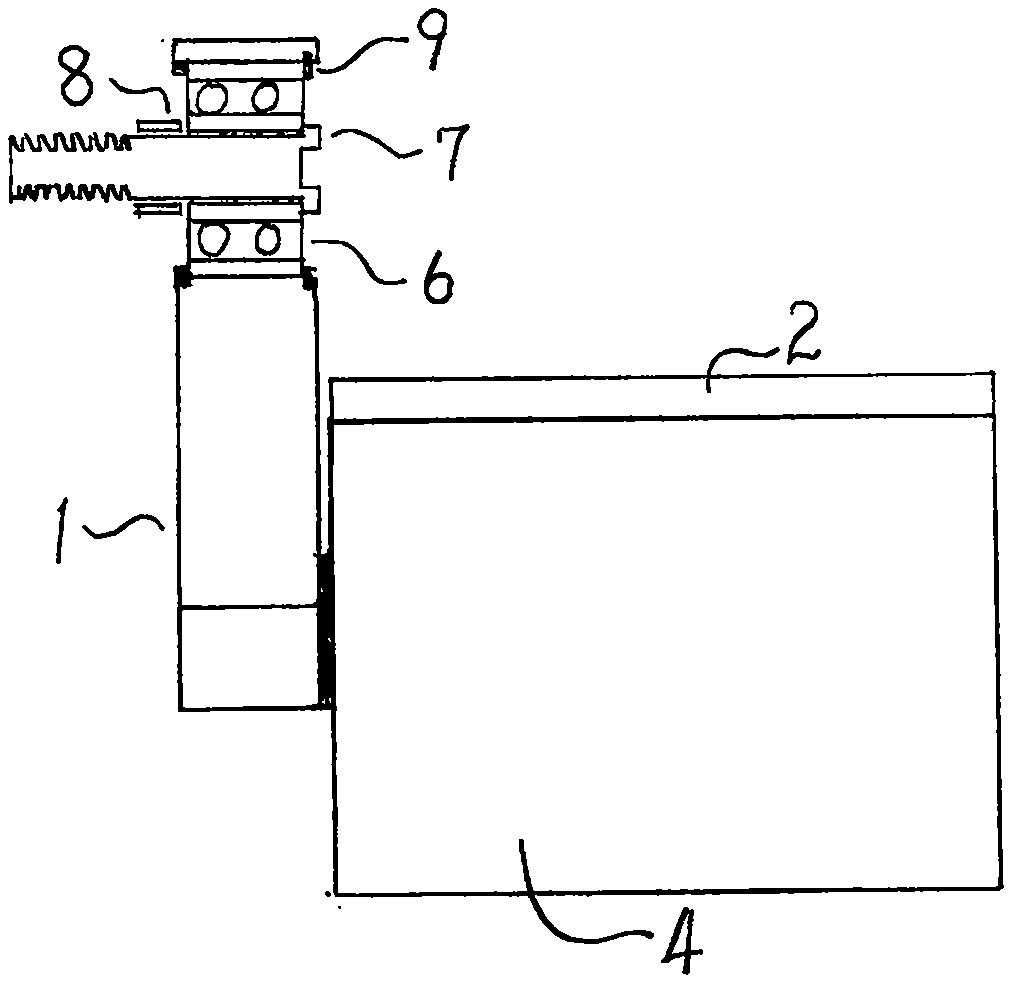

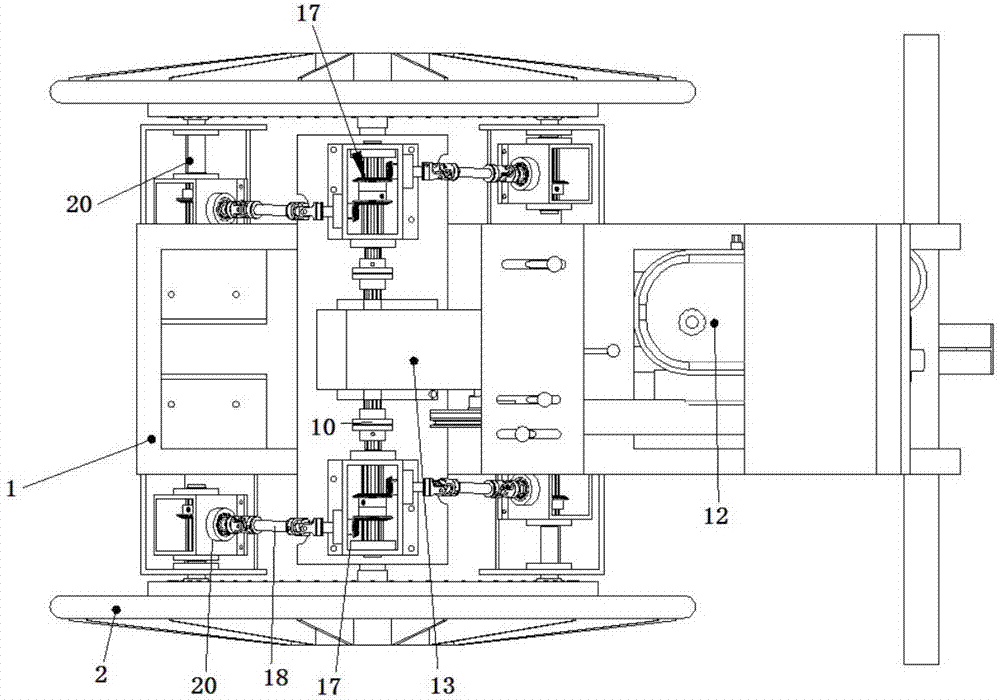

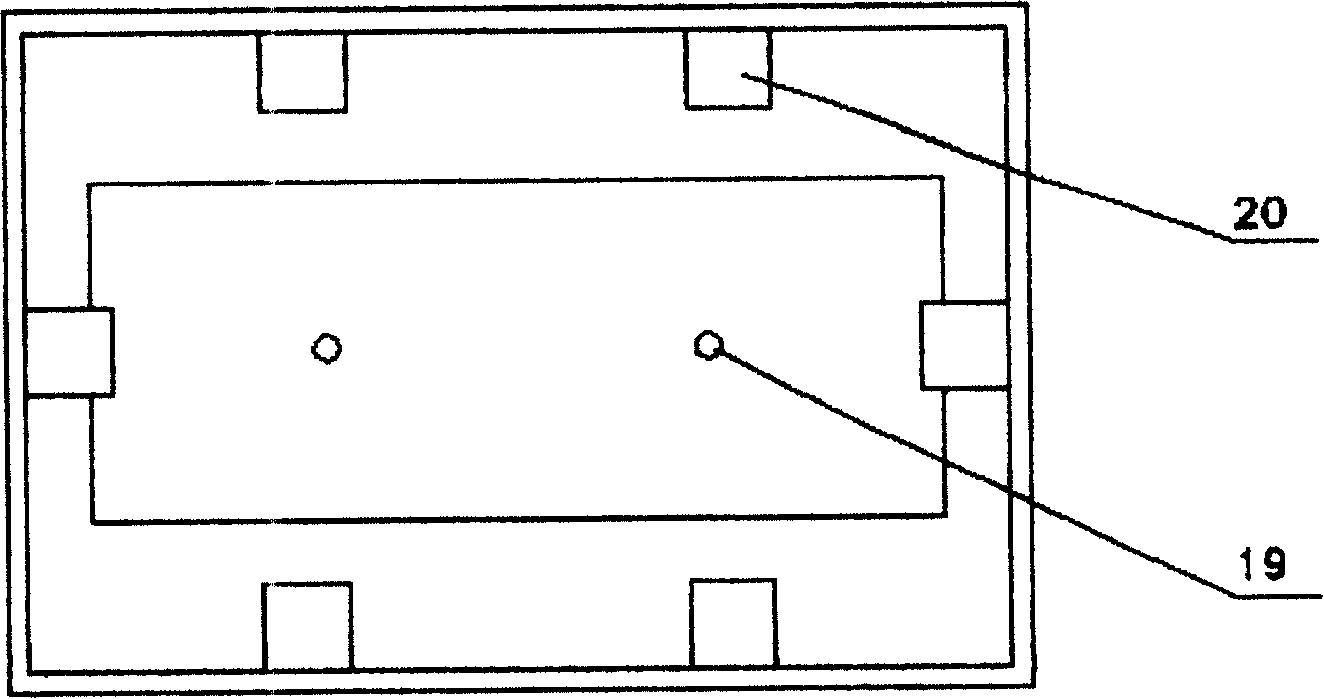

Pump body steel ball pressing fitting machine

InactiveCN104526313ASatisfy the pressing speedIncreased drive torqueMetal working apparatusProduction rateSteel ball

The invention discloses a pump body steel ball pressing fitting machine. The pump body steel ball pressing fitting machine is of a vertical structure, and is composed of a machine tool table, a steel ball automatic feeding device, a pressing fitting device and an oil pump clamp. Pressing fitting is driven through a servo motor so that it can be guaranteed that the pump body steel ball pressing fitting machine has the good accuracy, the good rigidity and the good operation stability. A pressure sensor is installed on a pressing head, and changes of displacement and pressure in the pressing fitting process can be monitored in real time. One-face-two-pin positioning is adopted in the clamp, and clamping through an air cylinder is achieved. Pressing fitting process automation is achieved, automatic feeding of a steel ball is achieved through the steel ball automatic feeding device, and the labor production rate is improved.

Owner:CHANGCHUN UNIV OF TECH

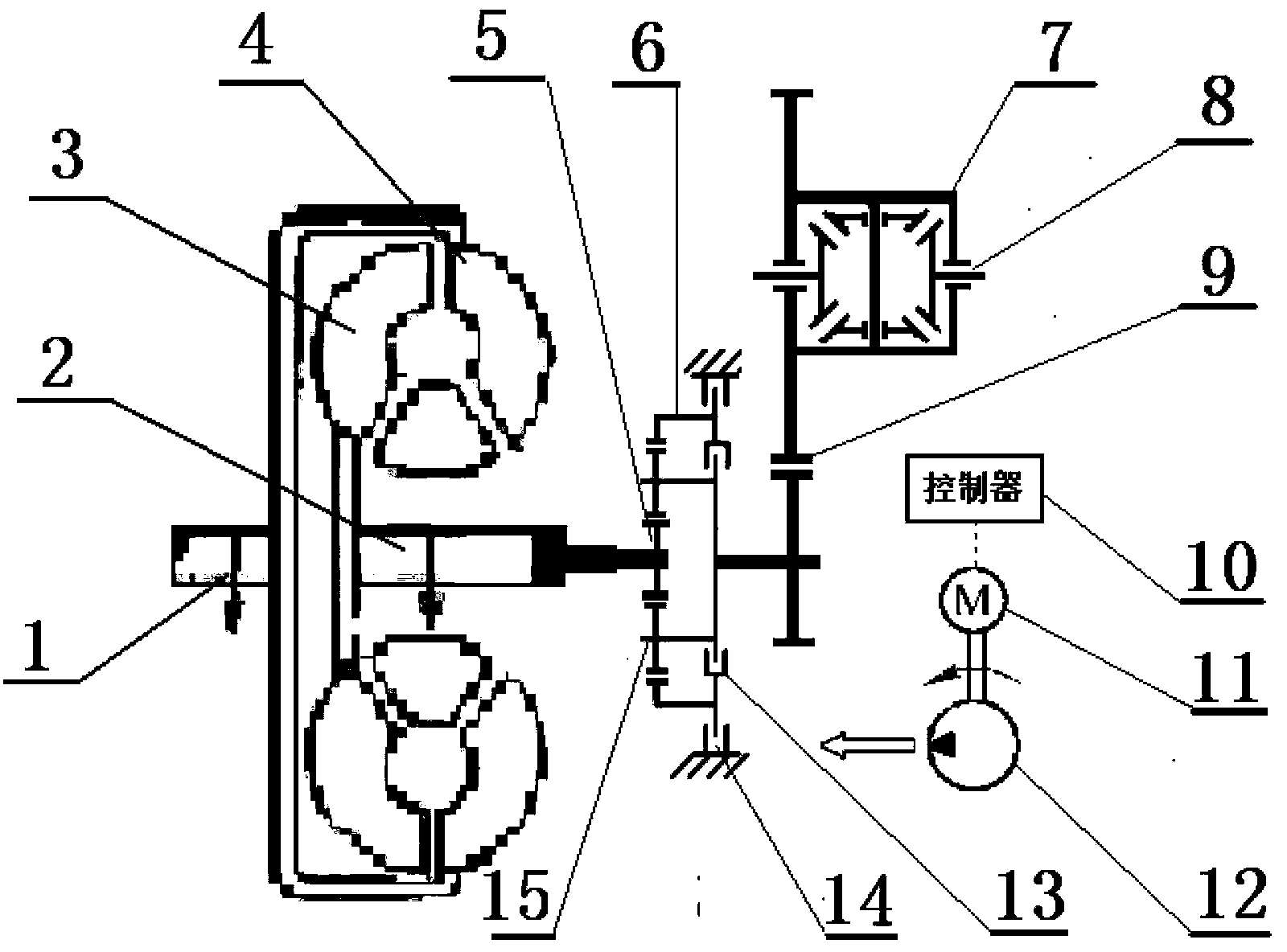

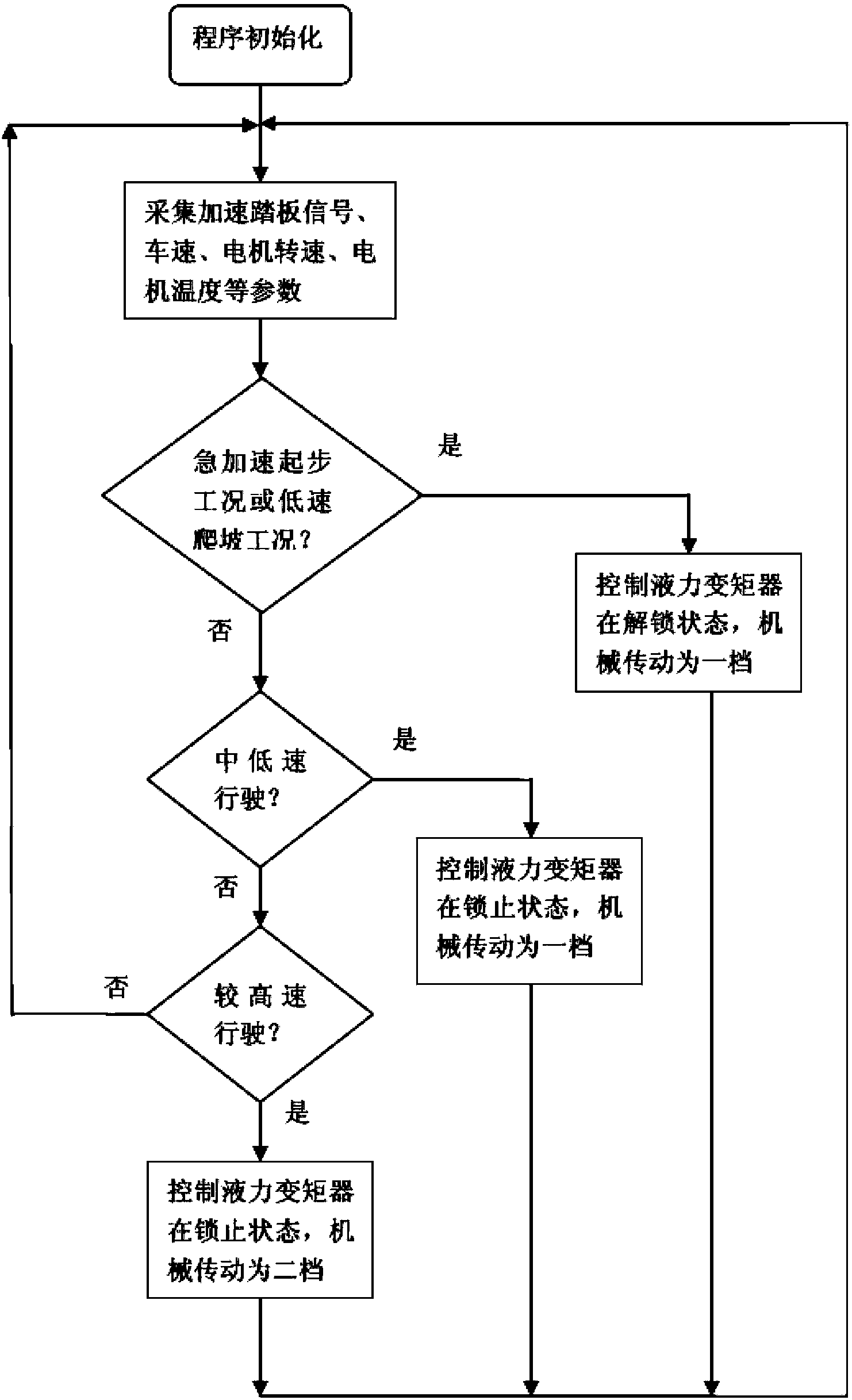

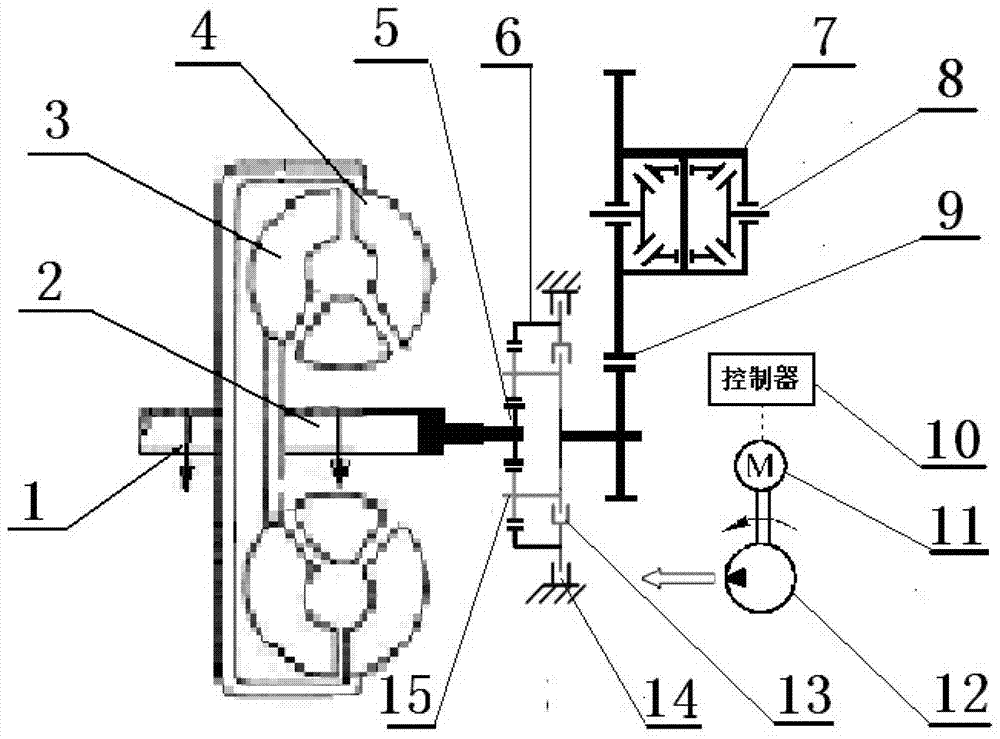

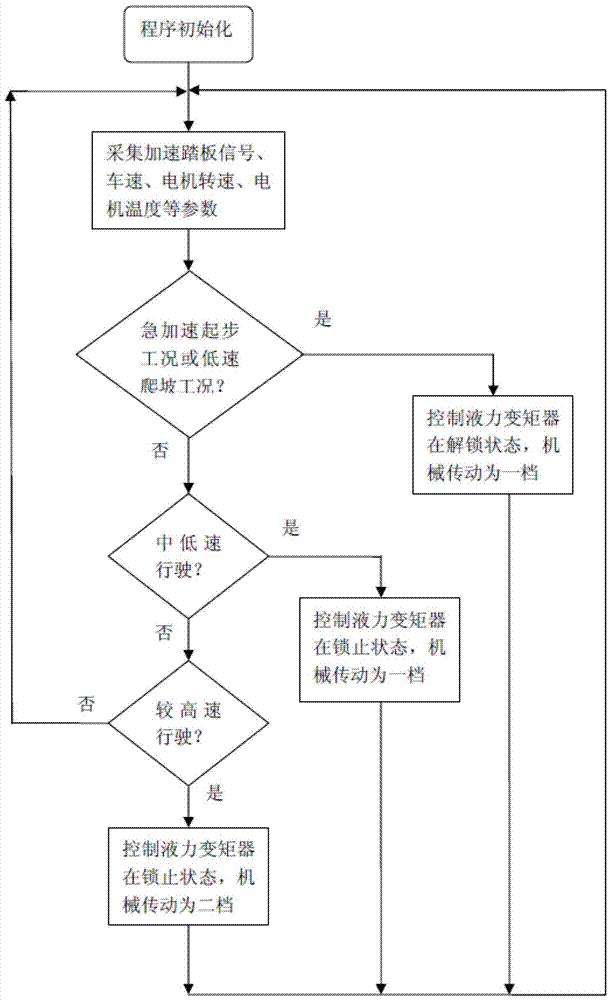

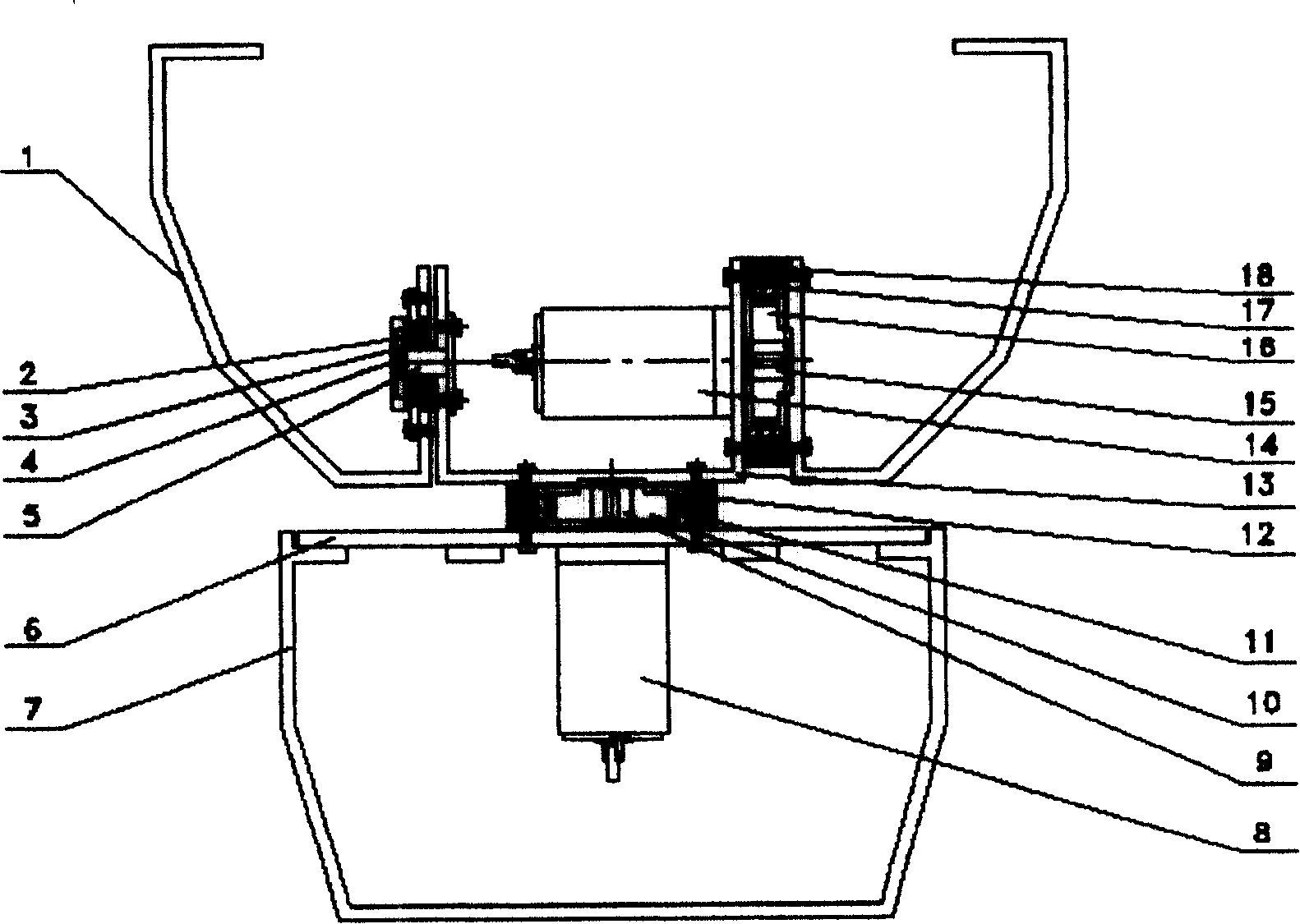

Electric automobile transmission and speed change method

The invention discloses an electric automobile transmission and a speed change method of the electric automobile transmission. The electric automobile transmission comprises a hydraulic torque converter with the locking function, a planet gear mechanism, an oil pump, an oil pump motor, a controller, a speed reducing mechanism and a differential mechanism. The hydraulic torque converter with the locking function comprises a pump impeller, a turbine, an input shaft, an output shaft and other components. A driving motor is connected with the pump impeller through the input shaft, and the turbine is connected with the output shaft. The torque of the output shaft is transmitted to the planet gear mechanism. The planet gear mechanism comprises a sun gear, a planet carrier, a big gear ring, a clutch, a brake and other components. Torque is output from the planet carrier through the planet gear mechanism and drives an automobile to run after passing through the speed reducing mechanism and the differential mechanism. The transmission can have two mechanical transmission gears and one hydraulic torque conversion gear. The oil pump is used for providing pressure for a hydraulic system of the transmission. Due to the electric automobile transmission, the climbing performance and the acceleration performance of the electric automobile can be improved, and the reliability of the automobile can be enhanced.

Owner:HUNAN UNIV

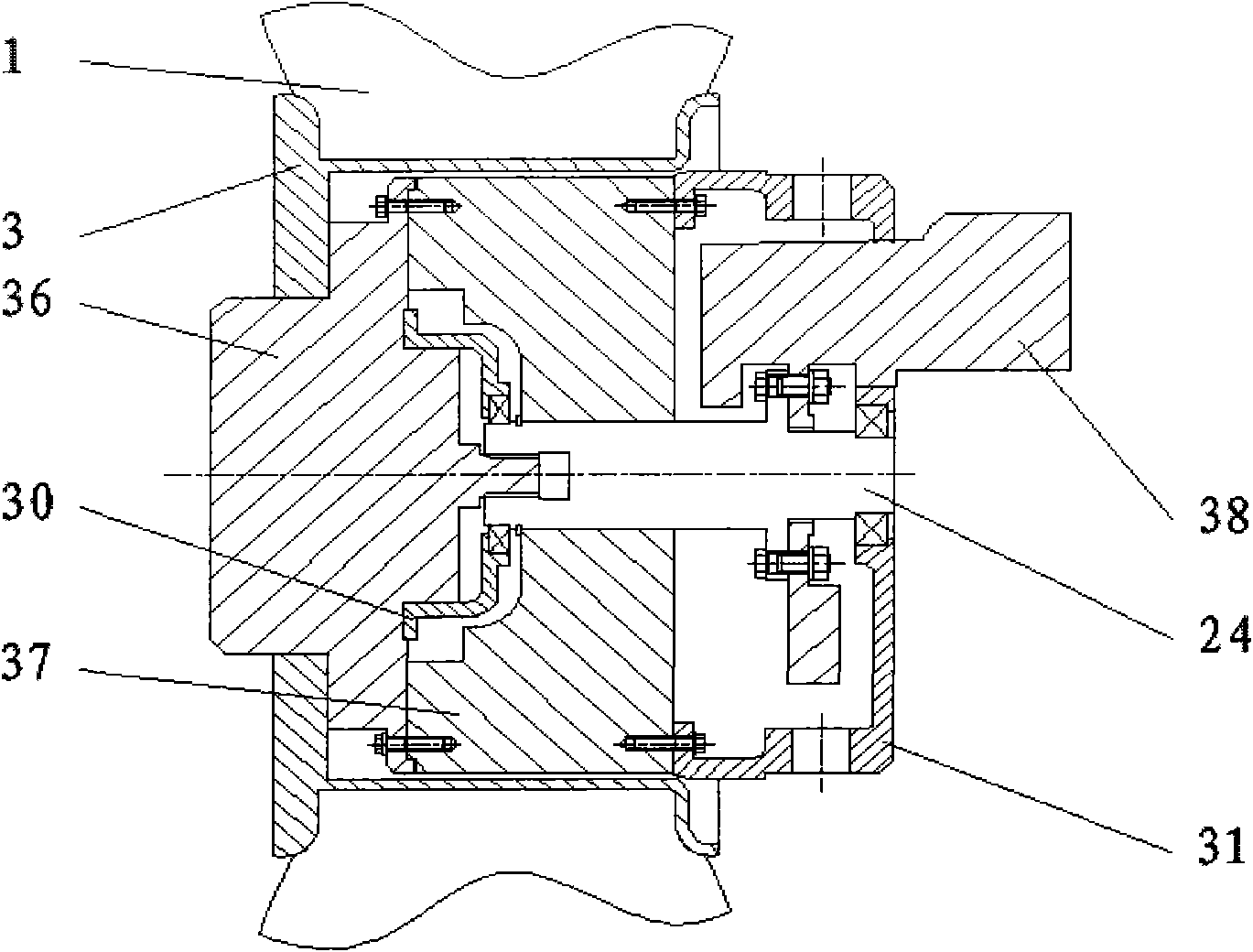

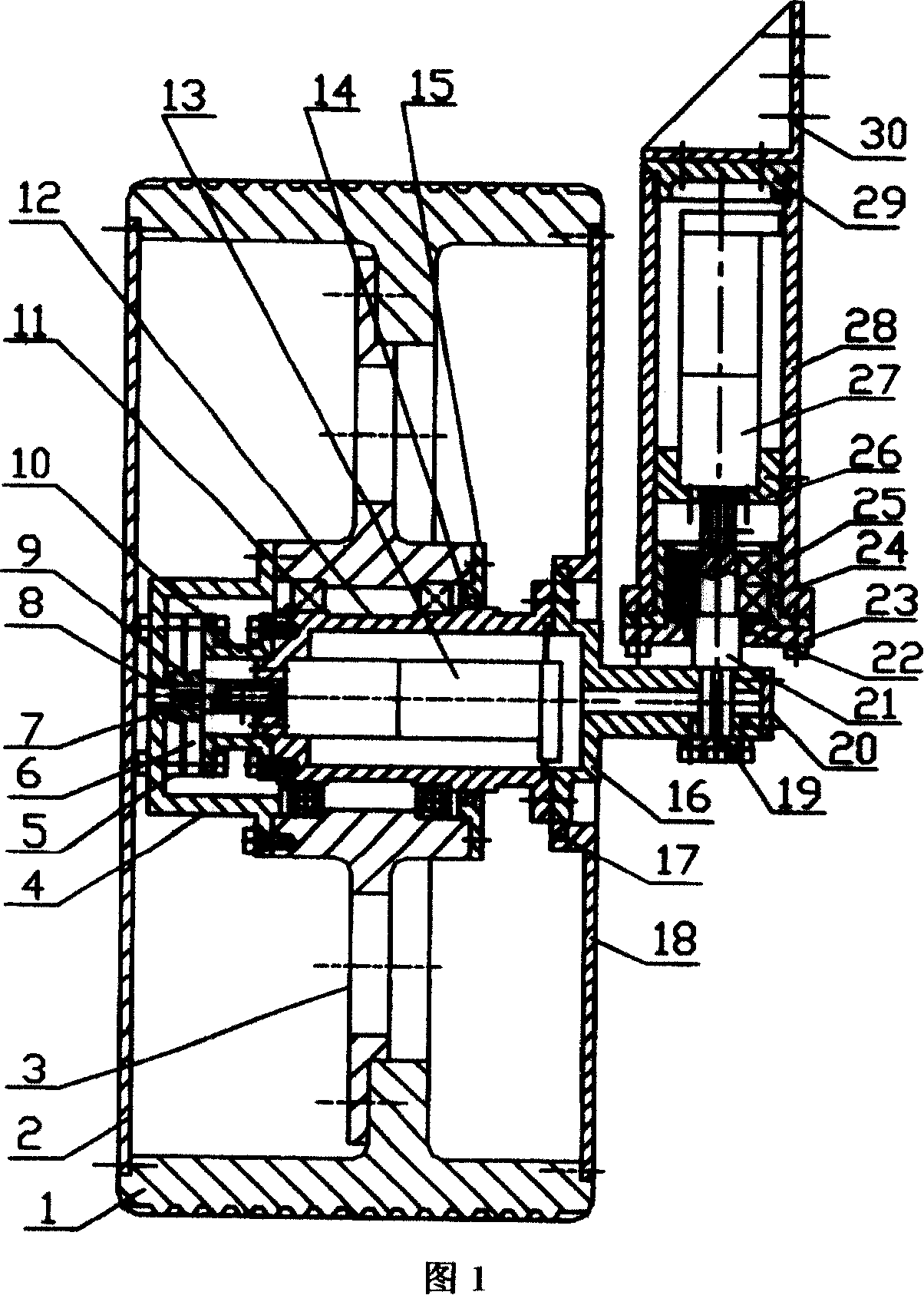

Pitching transferring integrated waist structure of human-like robot

The invention relates to a waist structure of robot whose pitching and turning motions are integrated, belonging to the robot technique. Wherein, the angle contact ball bearing is inside the end cover, to be fixed via binding ring and end cover axle; the left part of thorax plate and the left part of connecting plate are connected by the end cover axle; the stable wheel of second harmonic reducer is connected to the right part of connecting plate; the movable wheel of second harmonic reducer is connected to the right upright plate of thorax plate; the input axle sleeve of second harmonic reducer is sheathed on the output axle of pitching driving motor; the stable wheel of first harmonic reducer is fixed to the cover plate of abdominal cavity; the movable wheel of first harmonic reducer is connected to the connecting plate; the input axle of first harmonic reducer is sheathed on the output axle of transfer driving motor. The invention uses integrated structure, while the pitching driving motor and the transfer driving motor are serially connected to themselves harmonic reducers coaxially, with large motion range. Said waist structure can meet the pitching and transfer demands in wide range.

Owner:SHANGHAI JIAO TONG UNIV

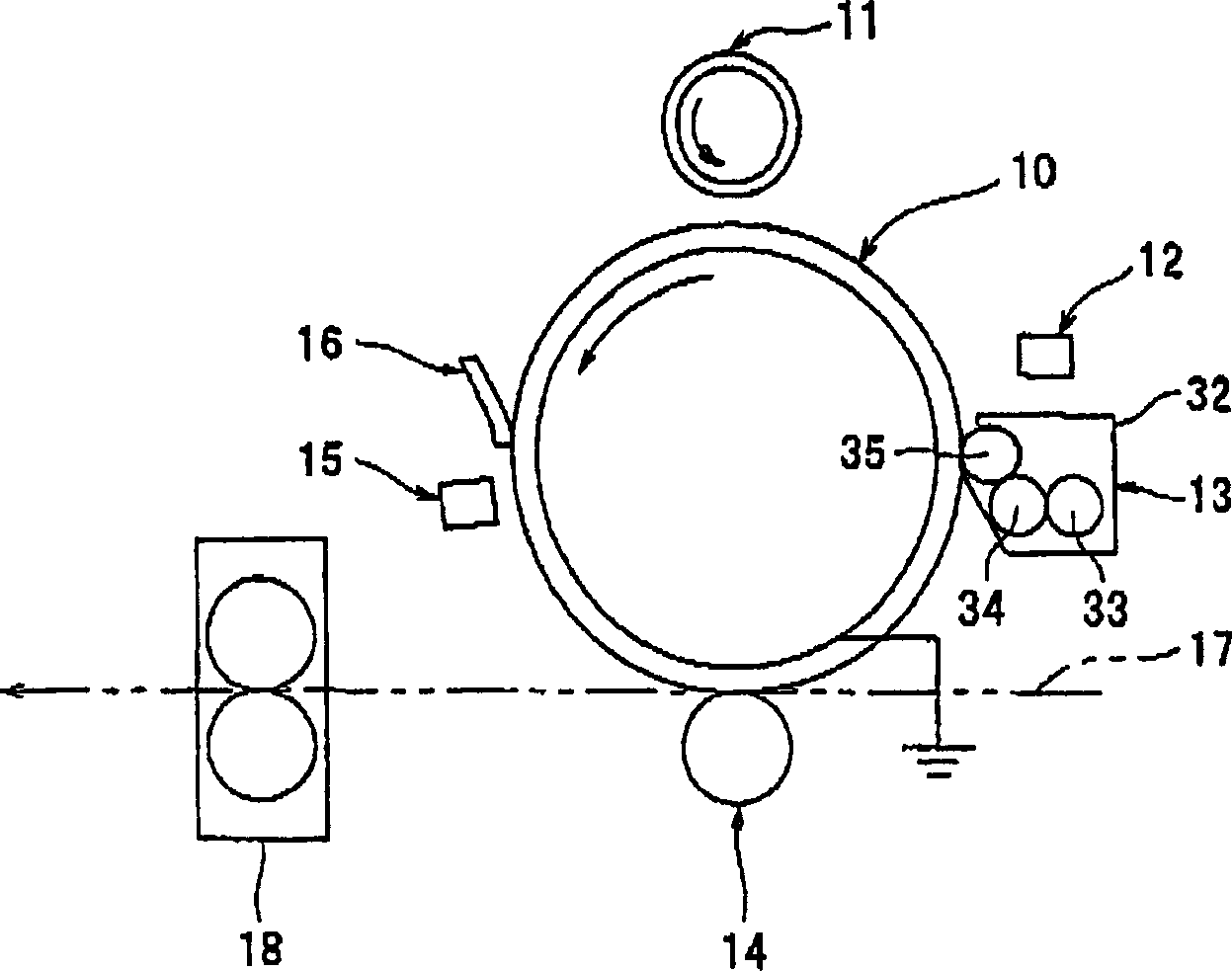

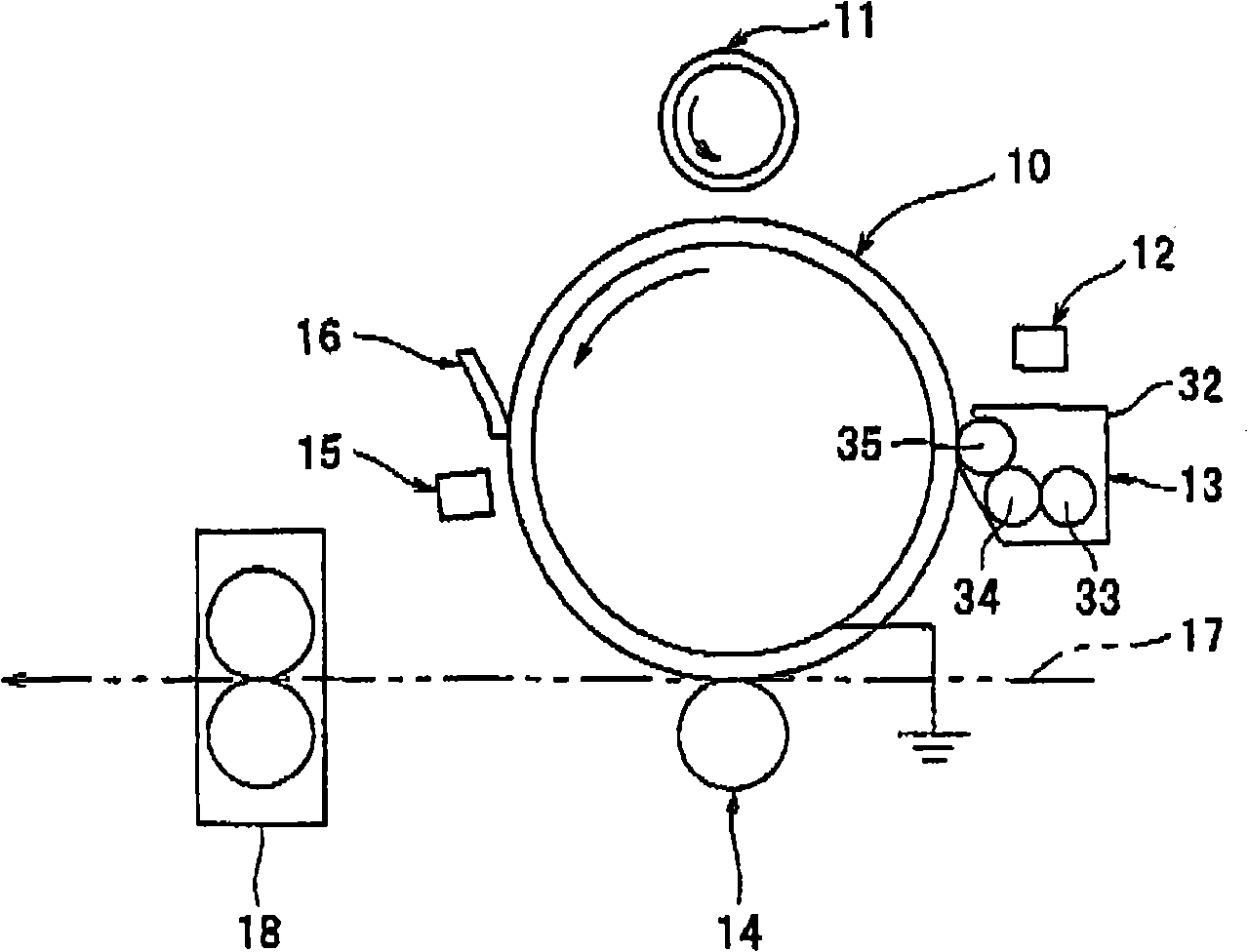

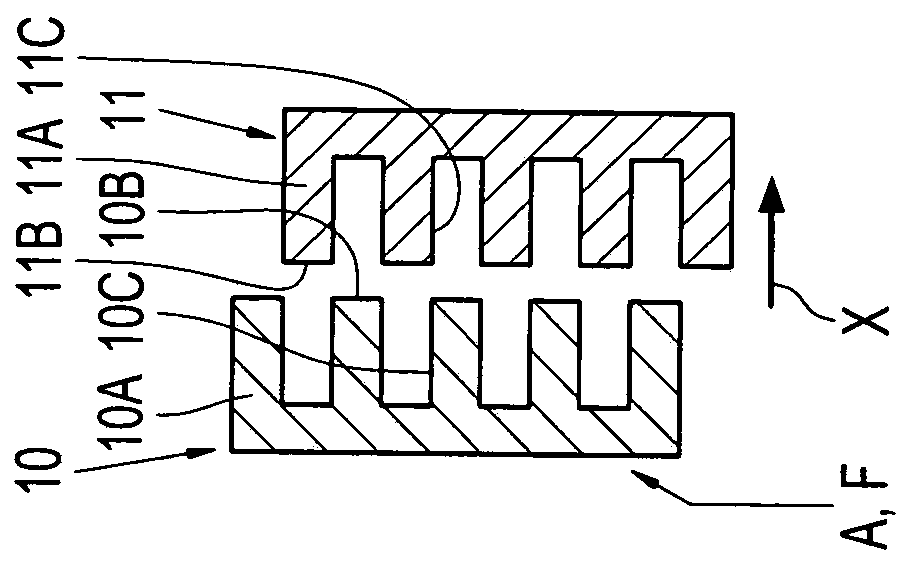

Cleaning device, process cartridge, and image forming apparatus

ActiveCN1770041ANo reduction in contact widthIncrease line pressureElectrography/magnetographyBand shapeImage formation

In cleaning devices, process cartridges and image forming devices, a cleaning structure with low linear pressure and high surface pressure can be obtained by specifying the material, shape and support structure of the cleaning blade. Press the front end corners of the elastic cleaning blade (38) supported by the so-called sheet holder, that is, the supporting member (37), on the roller-shaped and belt-shaped image carrier (10), and remove the residue remaining on the image carrier after image transfer. body toner. In such a cleaning device (16), the angle (θ) forming the front end corner line portion (36) of the cleaning blade is formed as an obtuse angle, and the front end corner line portion is formed at a surface pressure greater than or equal to 2.0 g / mm2. Press on the image carrier. The so-called surface pressure refers to the value obtained by dividing the total load applied to the cleaning blade by the contact area of the cleaning blade with respect to the member to be cleaned.

Owner:RICOH KK

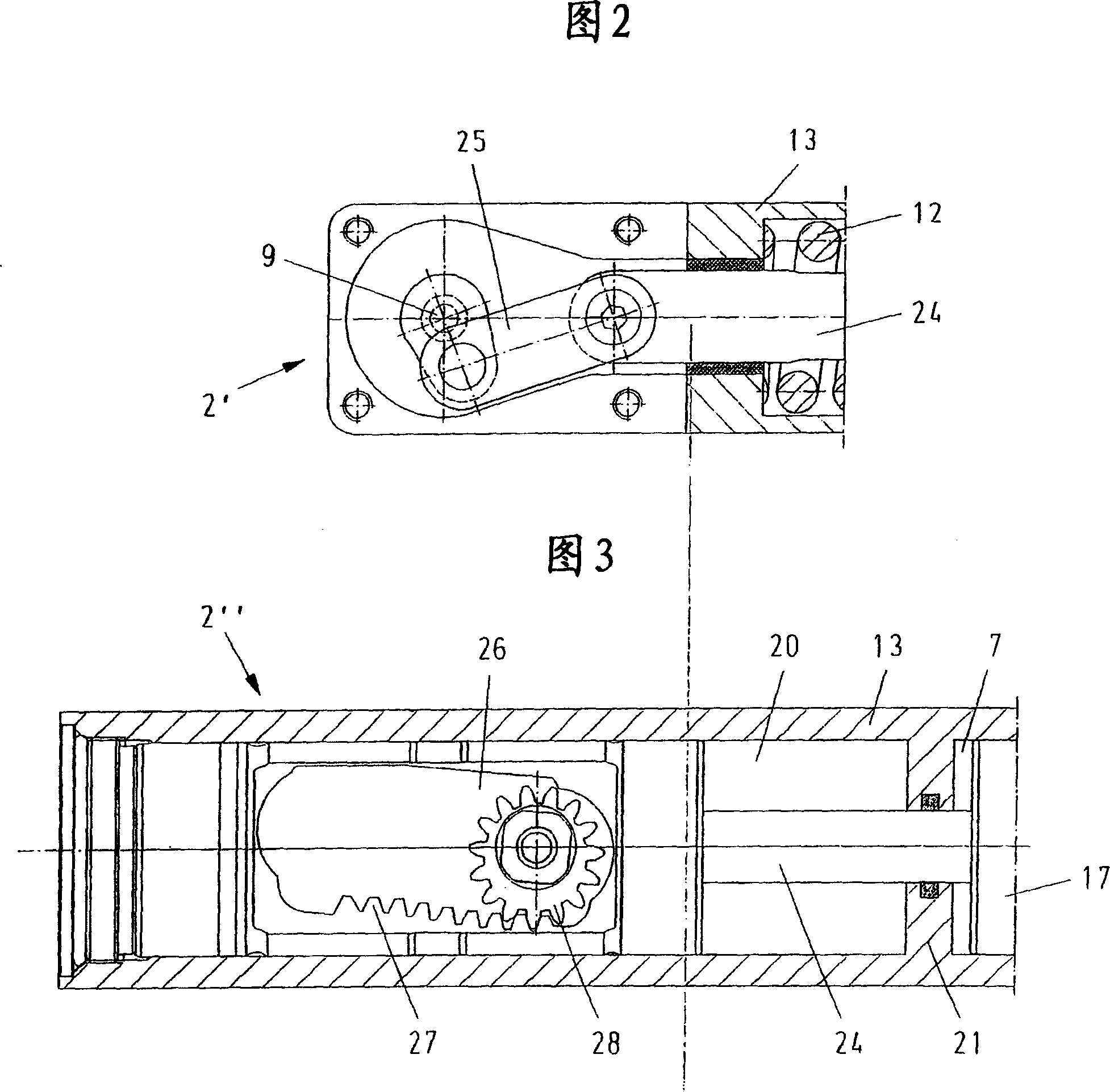

Door drive, in particular a revolving door drive

ActiveCN101068998AReduce work stressIncrease the areaBuilding braking devicesPower-operated mechanismHydraulic pumpElectrical and Electronics engineering

Owner:DORMAKABA DEUT GMBH

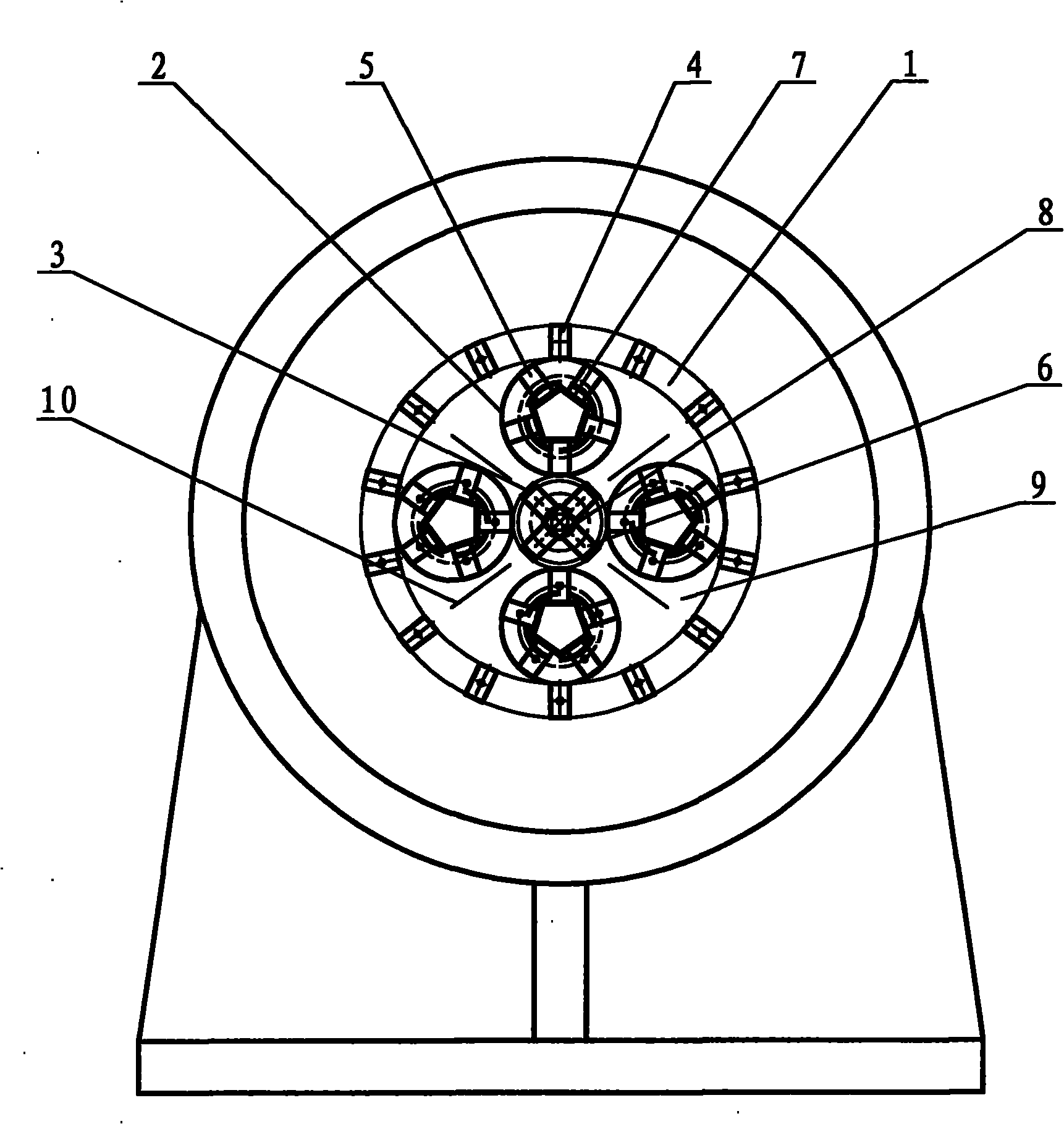

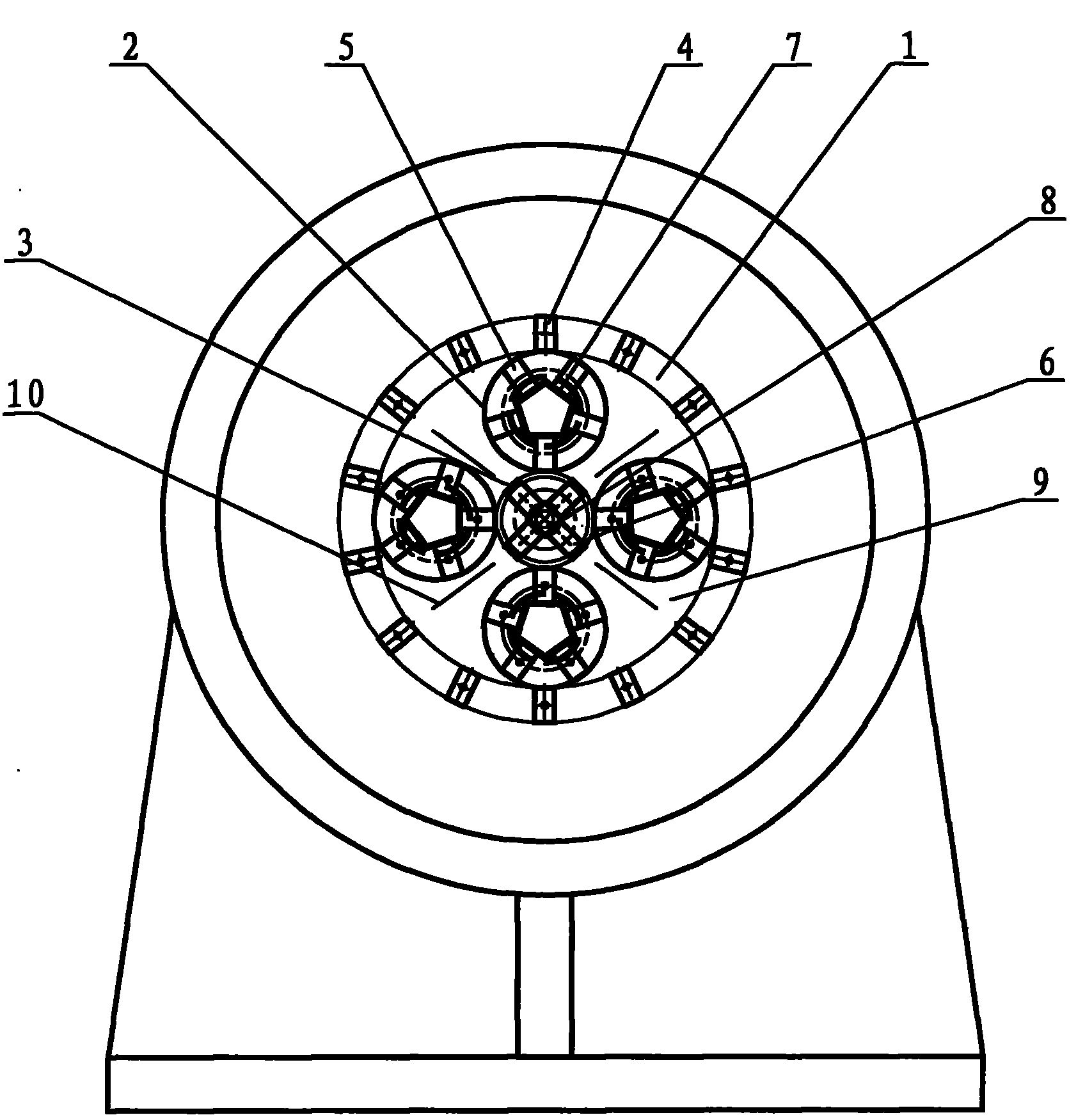

Magnetic suspension planetary gear variable-speed motor

The invention relates to a magnetic suspension planetary gear variable-speed motor which comprises a ring gear, a sun gear and a plurality of planet gears arranged between the ring gear and the sun gear. The ring gear, the sun gear and the planet gears are respectively provided at least one magnetic block along the radial direction of circumferential direction of an excircle per se, homopolarities of the magnetic blocks on the ring gear and the planet gears are opposite to generate repulsion so that the ring gear drives the planet gears to rotate, and the homopolarities of the magnetic blocks on the planet gears and the sun gear are opposite to generate repulsion so that the planet gears drive the sun gear to rotate. By transmitting a torque between the magnetic block on the ring gear and the magnetic block on the sun gear through the planet gears with the magnetic blocks, the overall volume of a magnetic suspension transmission mechanism is effectively reduced, meanwhile, an air gap between the ring gear as a drive body and the sun gear as a driven body is reduced, the transmission of the magnetic torque is ensured to be stable, and the variable-speed motor has the advantages of safe use, stable torque transmission and long service life.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD +1

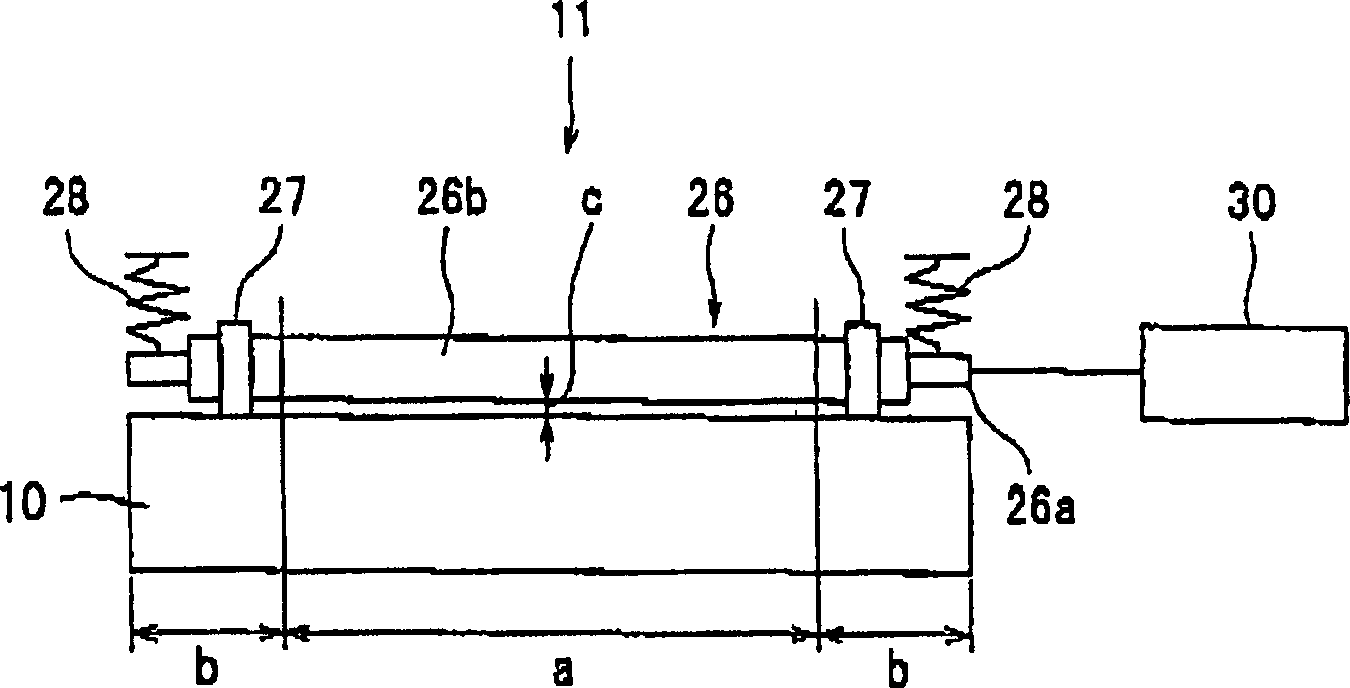

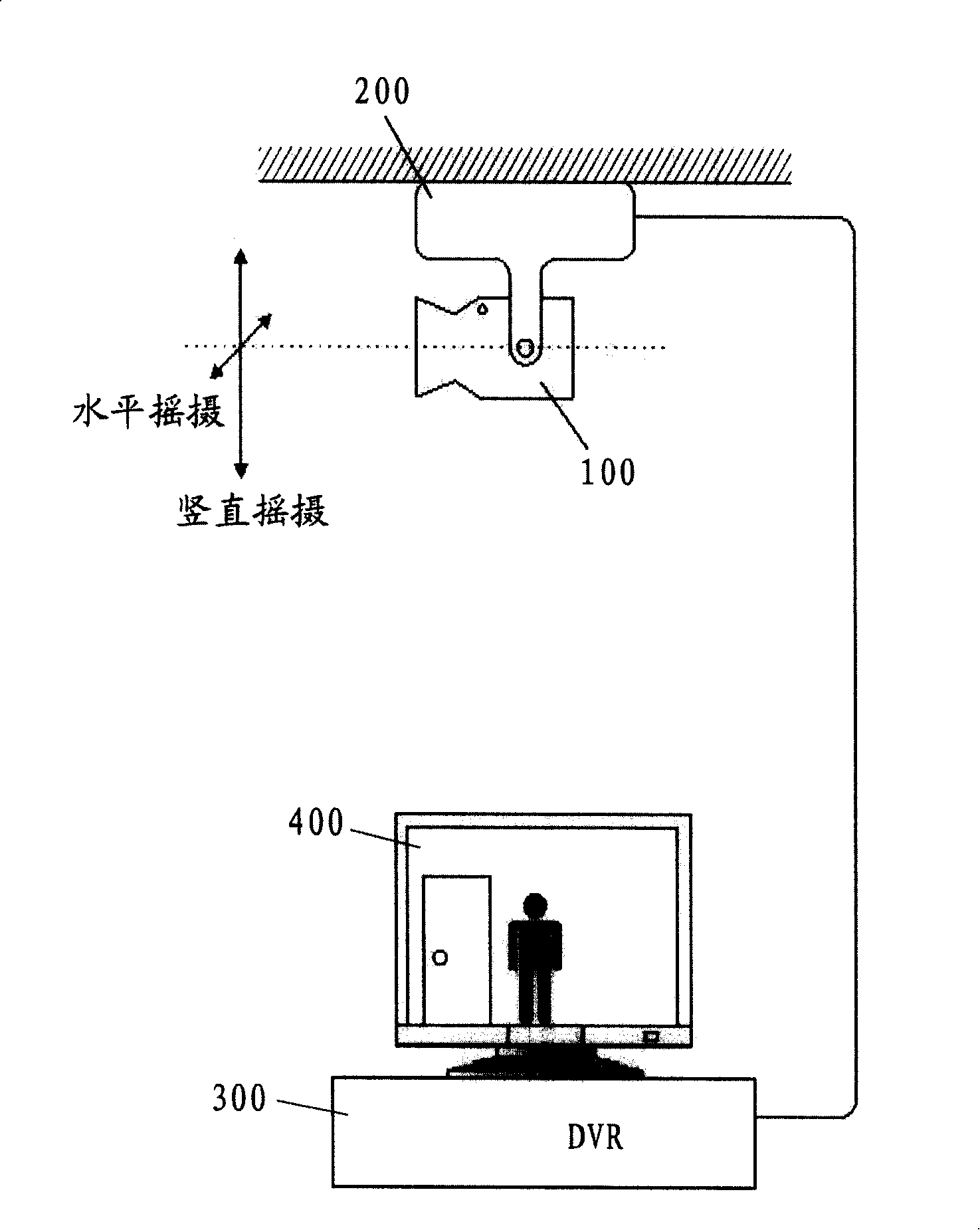

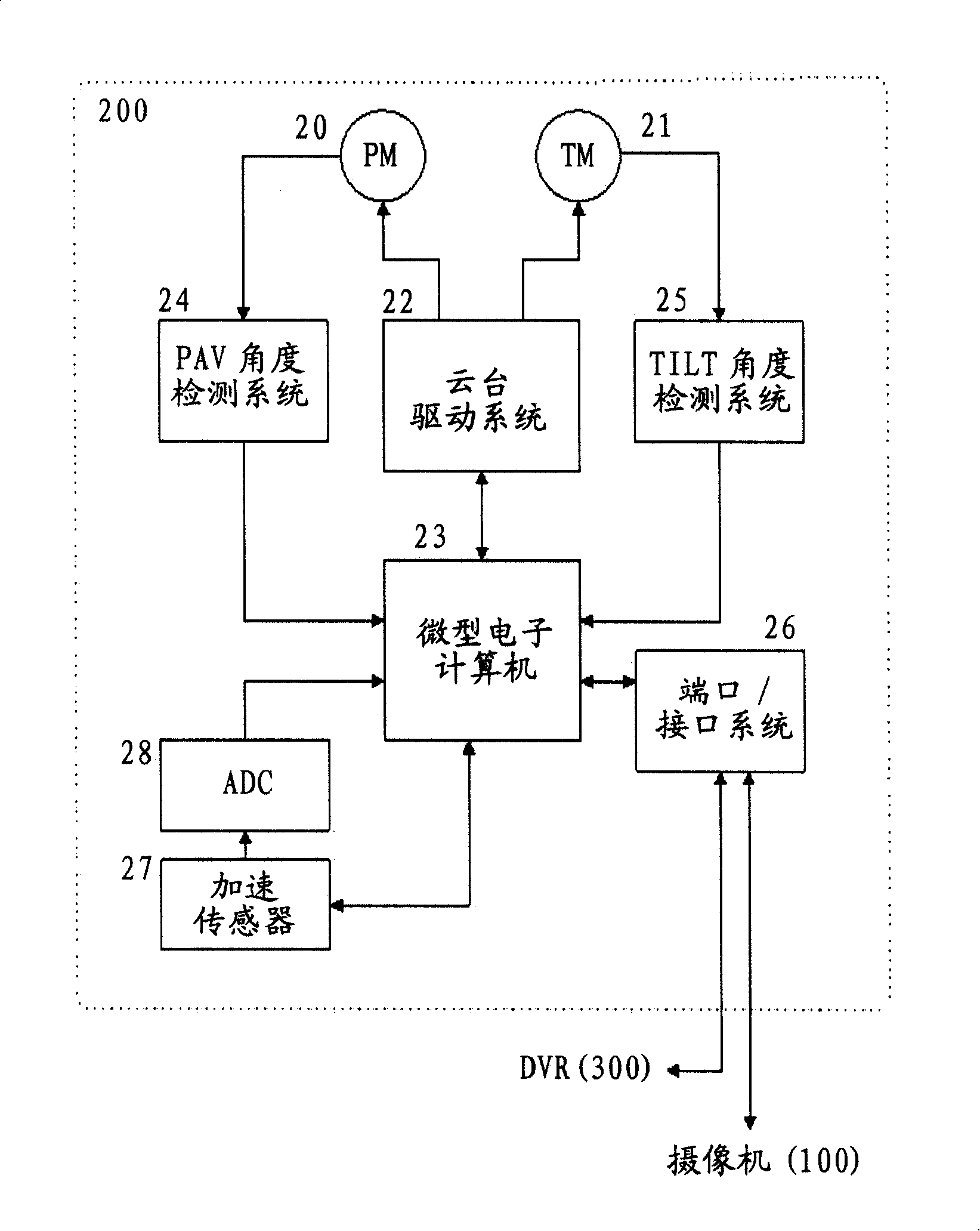

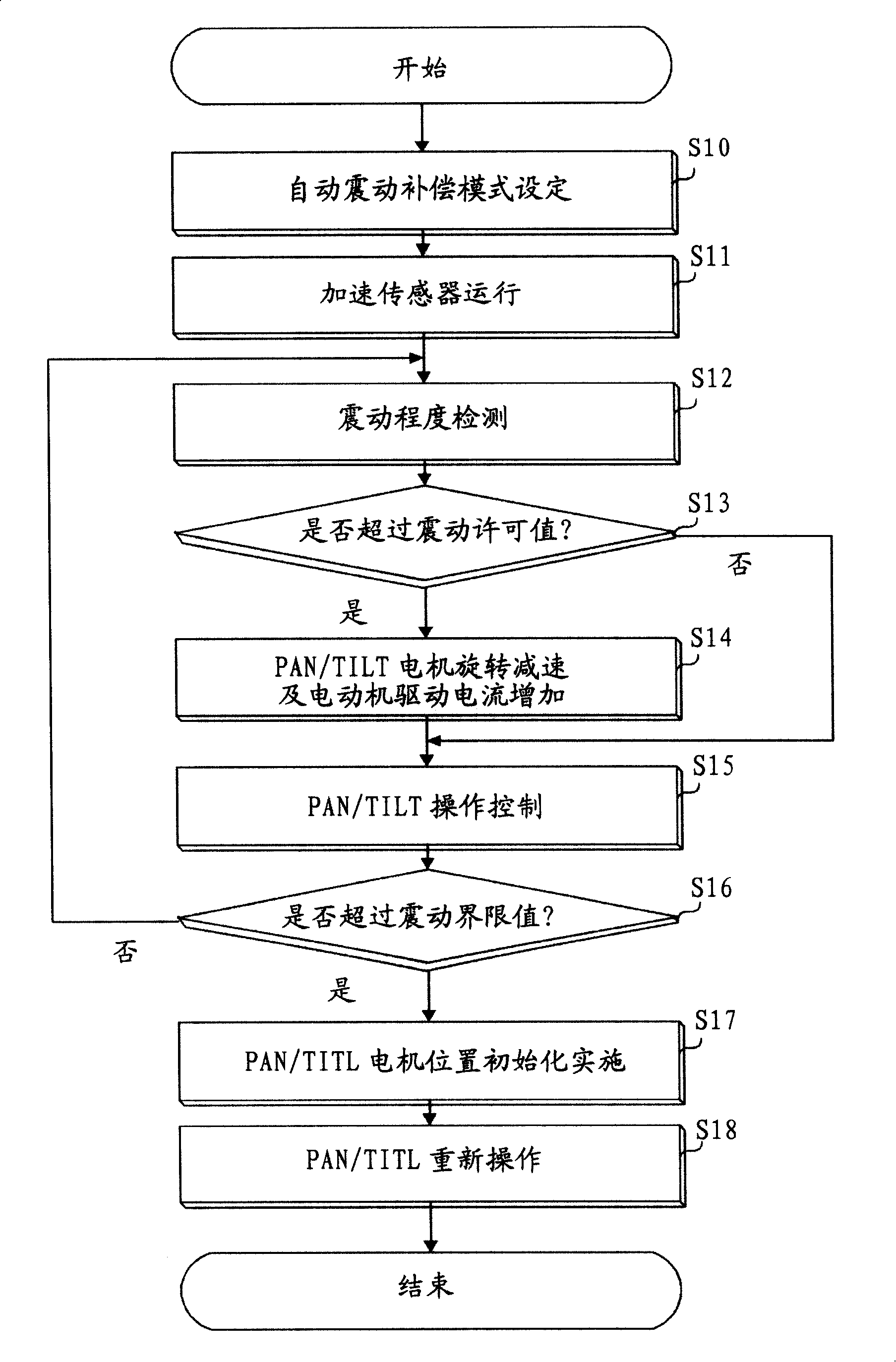

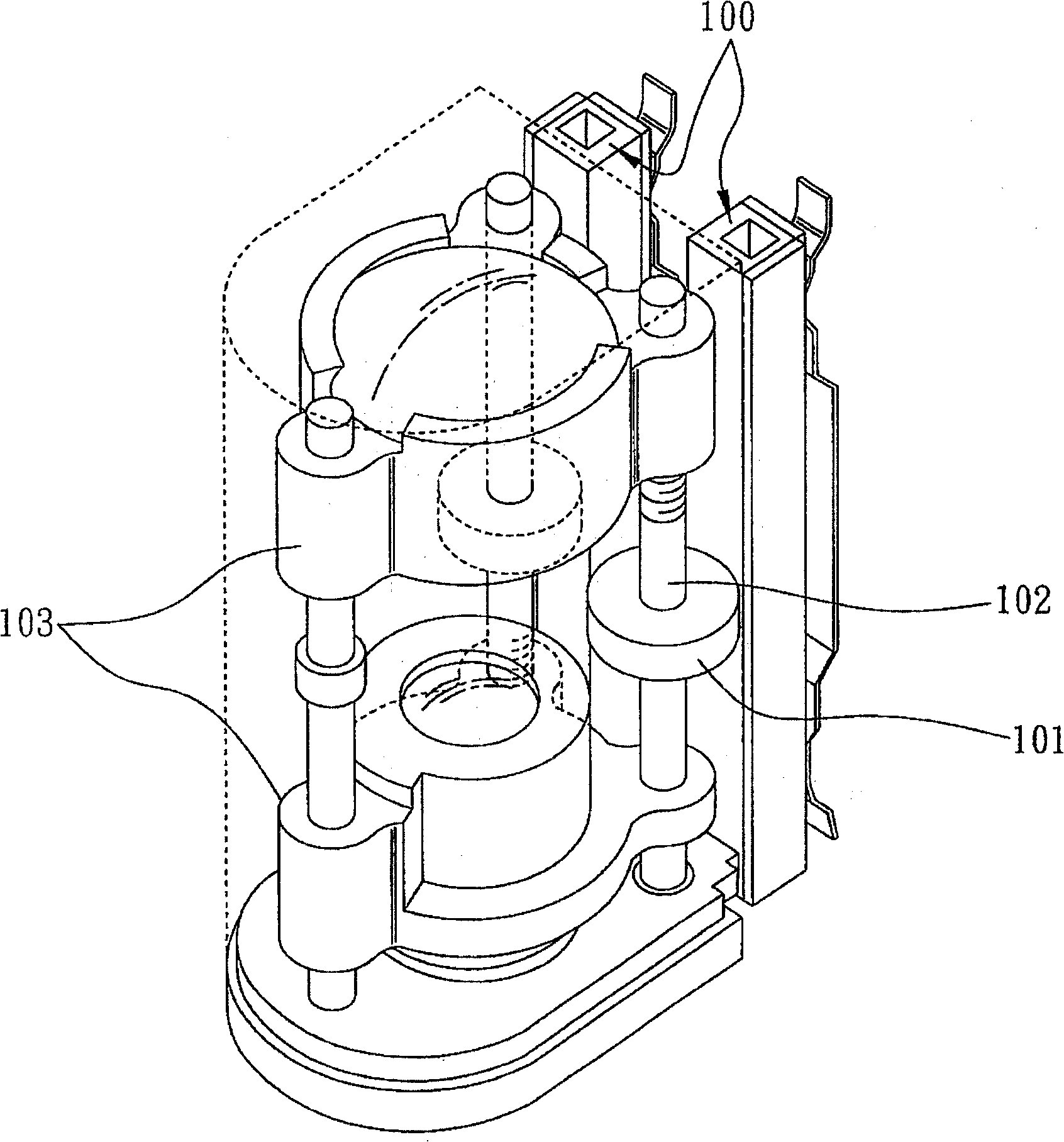

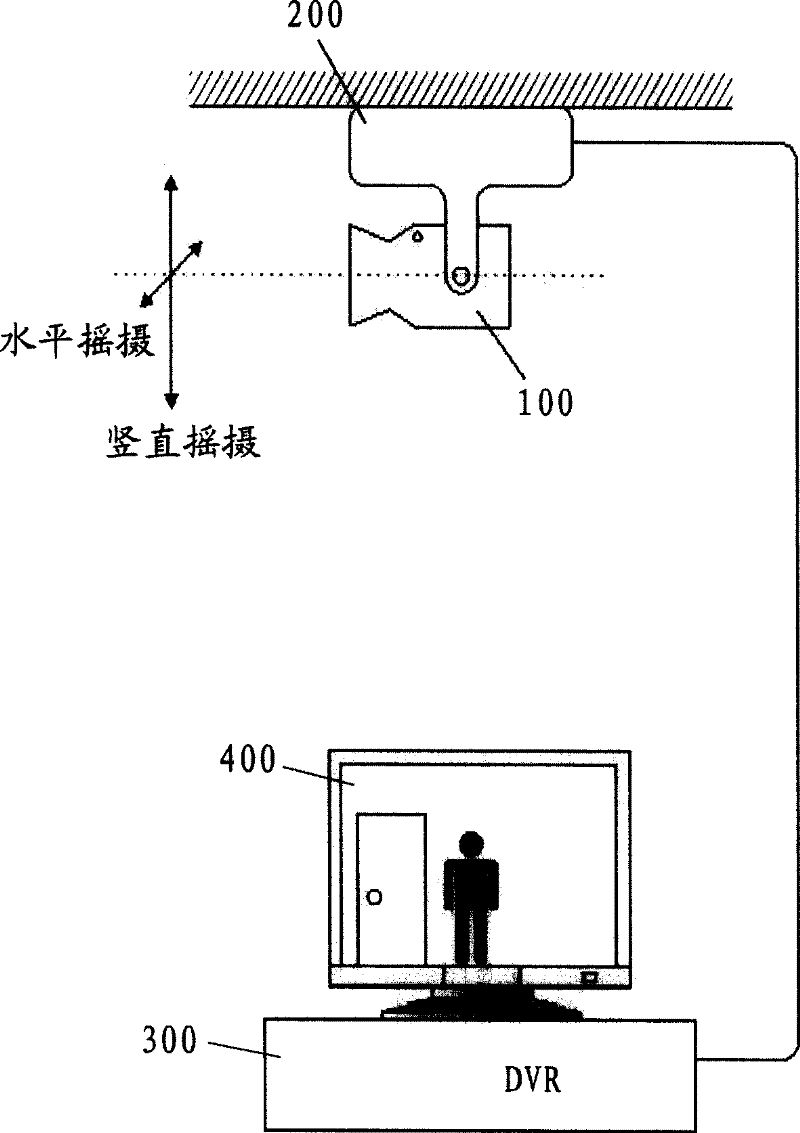

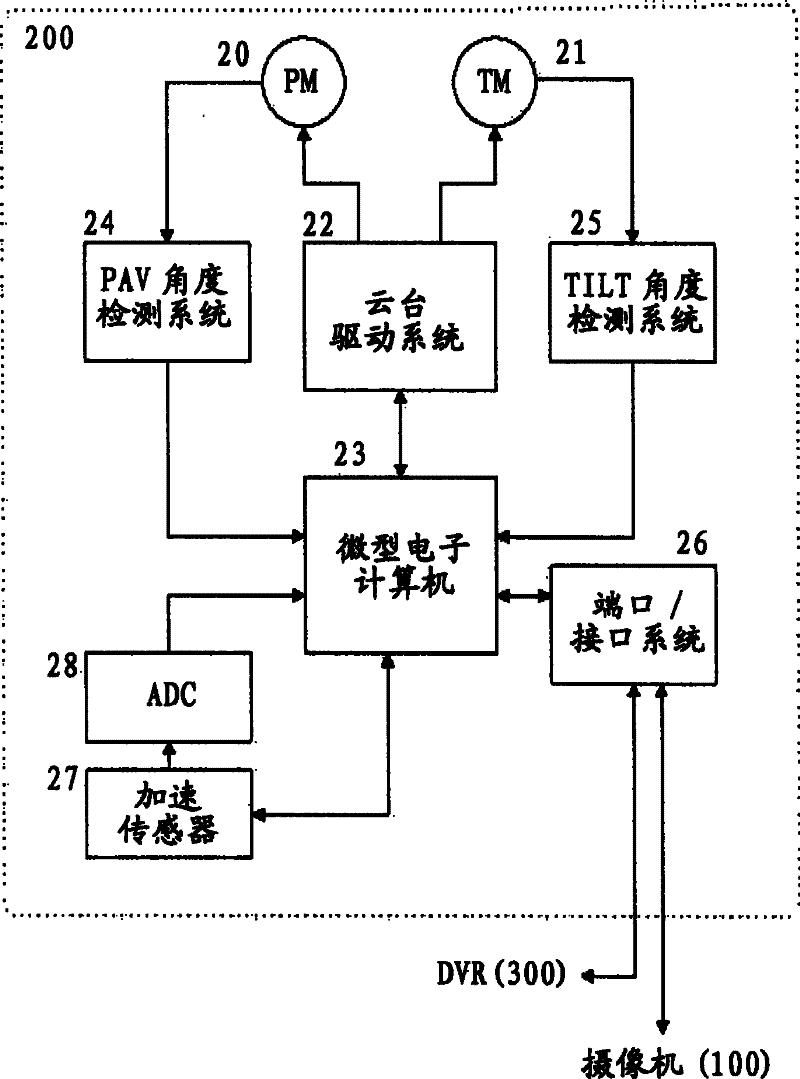

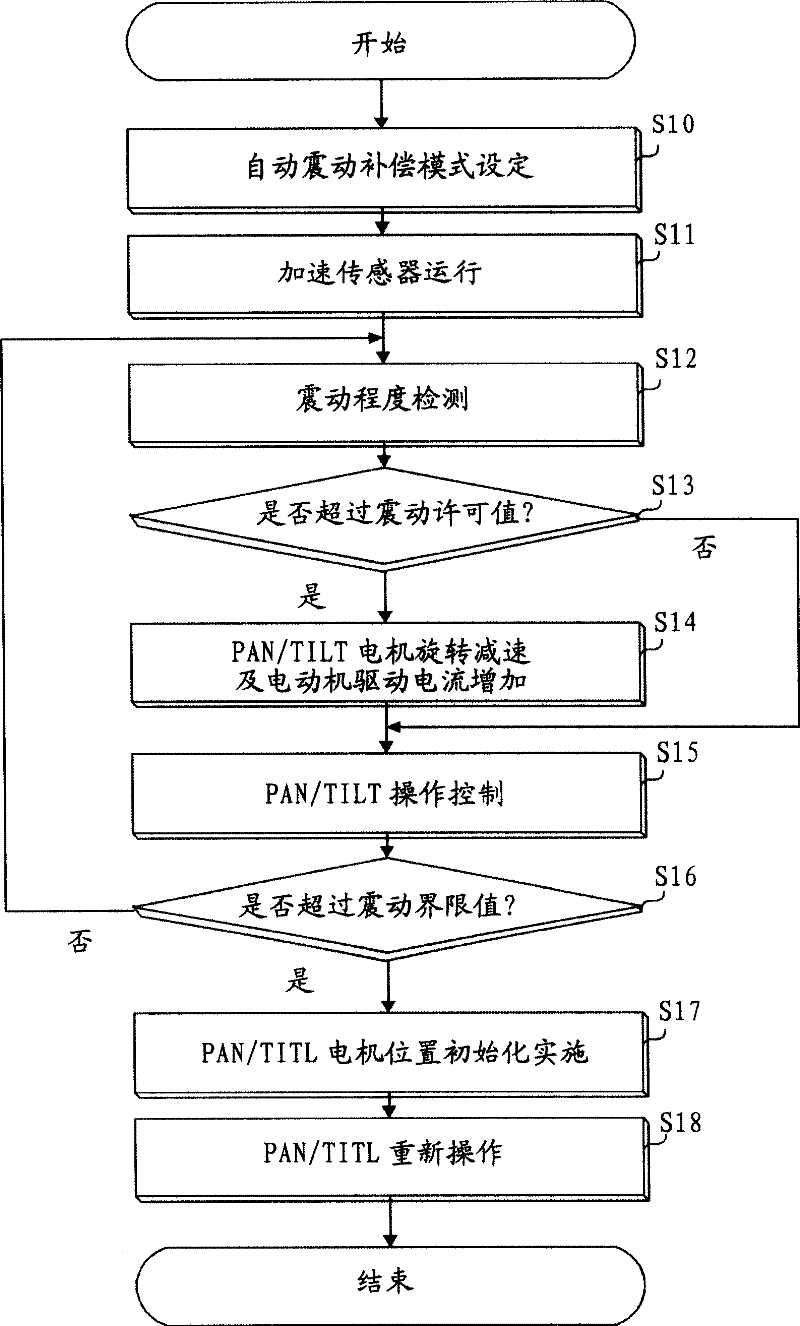

Method for compensation of vibration of horizontal stage electric machine

InactiveCN101230887AEasy to controlIncreased drive torqueNon-rotating vibration suppressionStands/trestlesValue setElectric machine

The invention relates to a vibration compensation method of a tripod head electric motor, which comprises the first step of utilizing a sensor in the tripod head to detect the present vibration values and the second step of causing the driving interference of the tripod head electric motor to be increased if the vibration values detected exceed the vibration permit values set by a machine. Under the circumstances that a camera for monitoring vibrates on a boarded pan / tilter, the invention utilizes an acceleration sensor, etc. to detect the corresponding vibration values, simultaneously, causes the torque of the tripod head electric motor to increase or the position of the cloud platform electric motor to initialize. For errors of the control and the operation of the tripod head, because prevention can be carried out before the errors happen, even if the vibration happens, the right tripod head control can be carried out.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

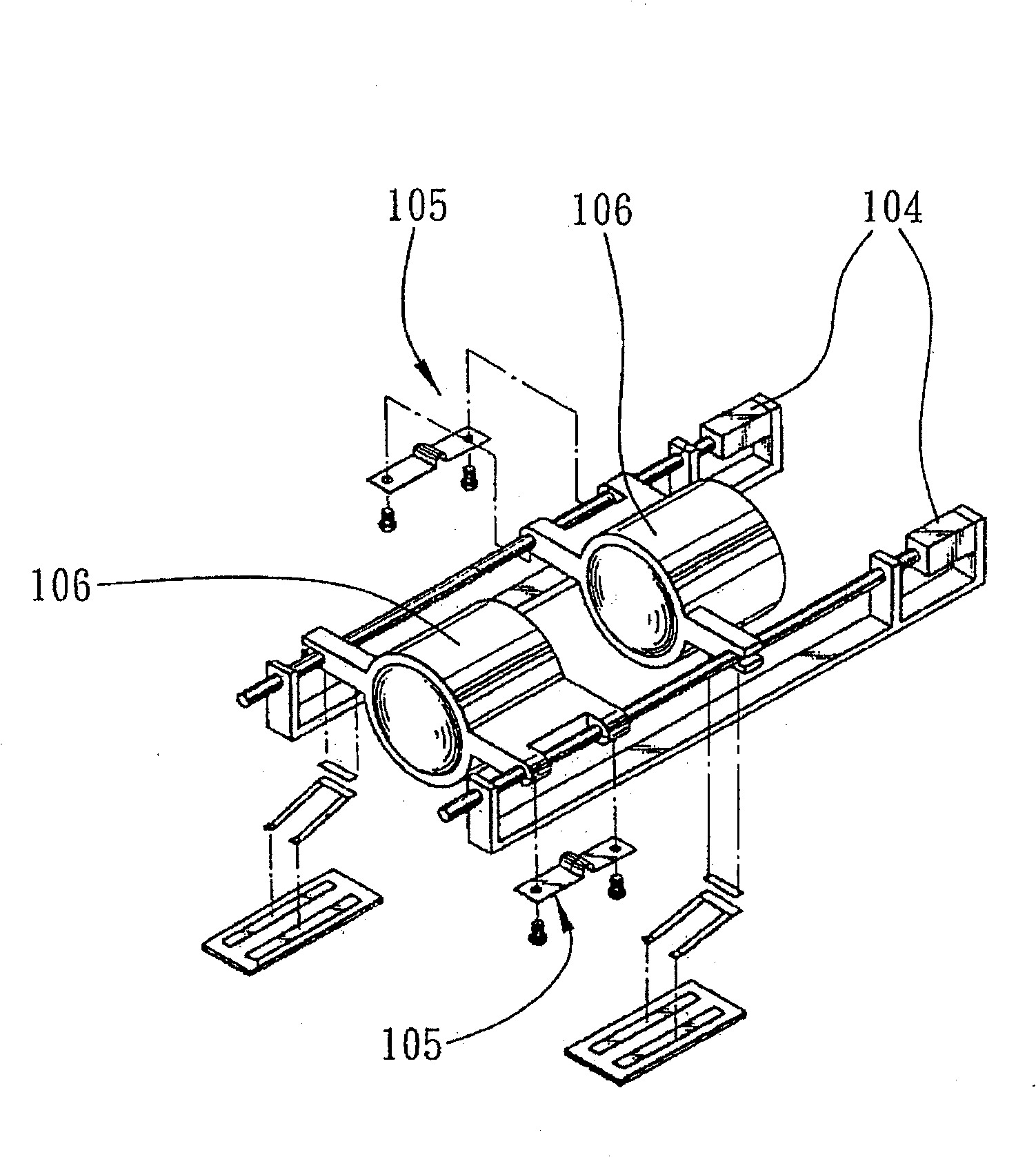

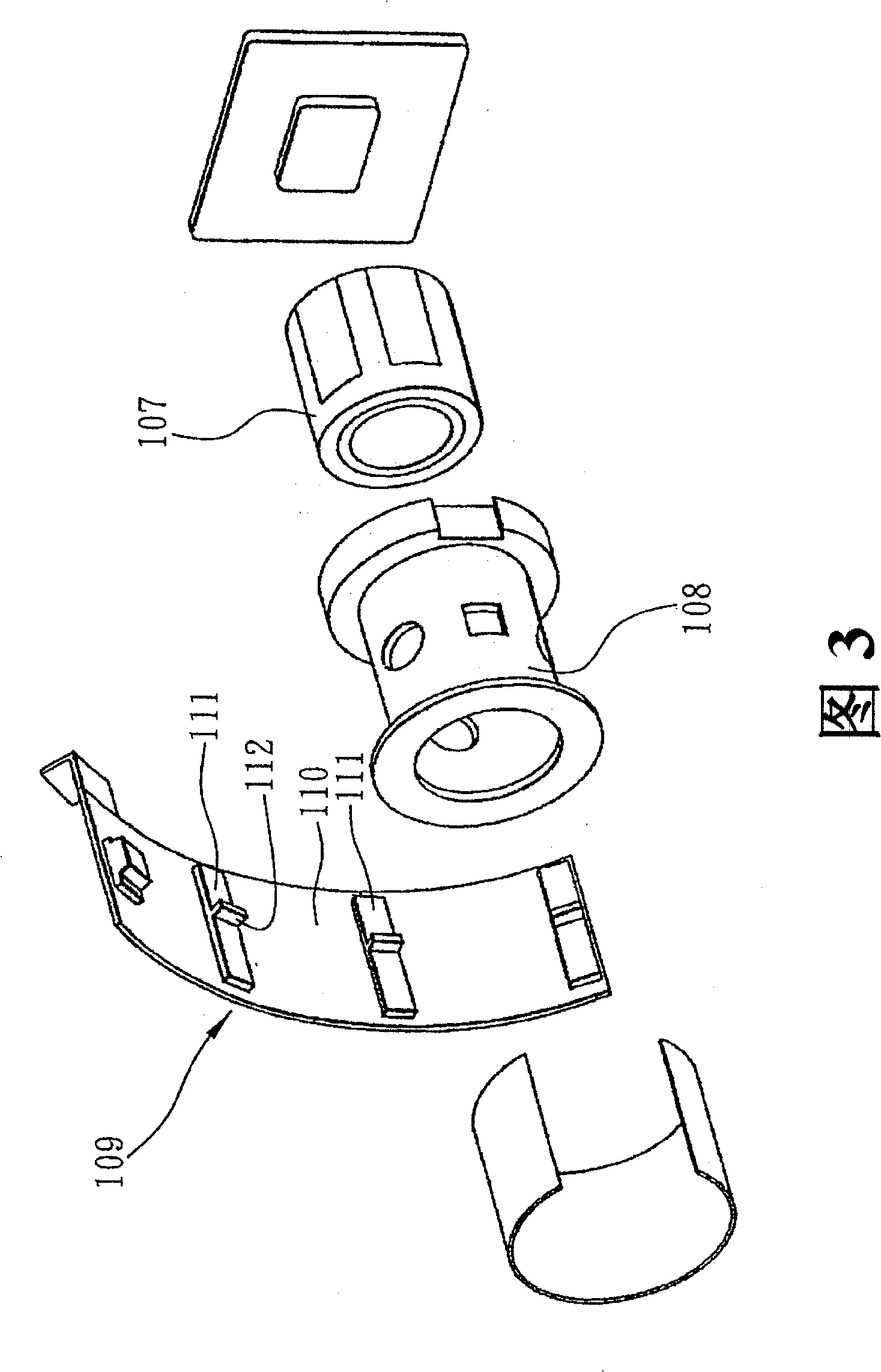

Optical focusing mechanism

InactiveCN101246243AIncreased drive torqueReduce volumeMountingsPiezoelectric/electrostrictive devicesCamera lensEngineering

The invention provides an optical focusing device, including base, sleeve which is coupled with the base, screw thread is connected with lens of the sleeve, and piezoelectric actuator which is fixed in the base for contiguously driving sleeve rotating, the base and the lens are respectively equipped with corresponding locating sliding first guiding part and second guiding part, then the sleeve is driven to rotate for converting and forcing the lens to focus. So the optical focusing device having simple components improves the driving force and overcomes the defects that the component with prior art is complex.

Owner:IND TECH RES INST

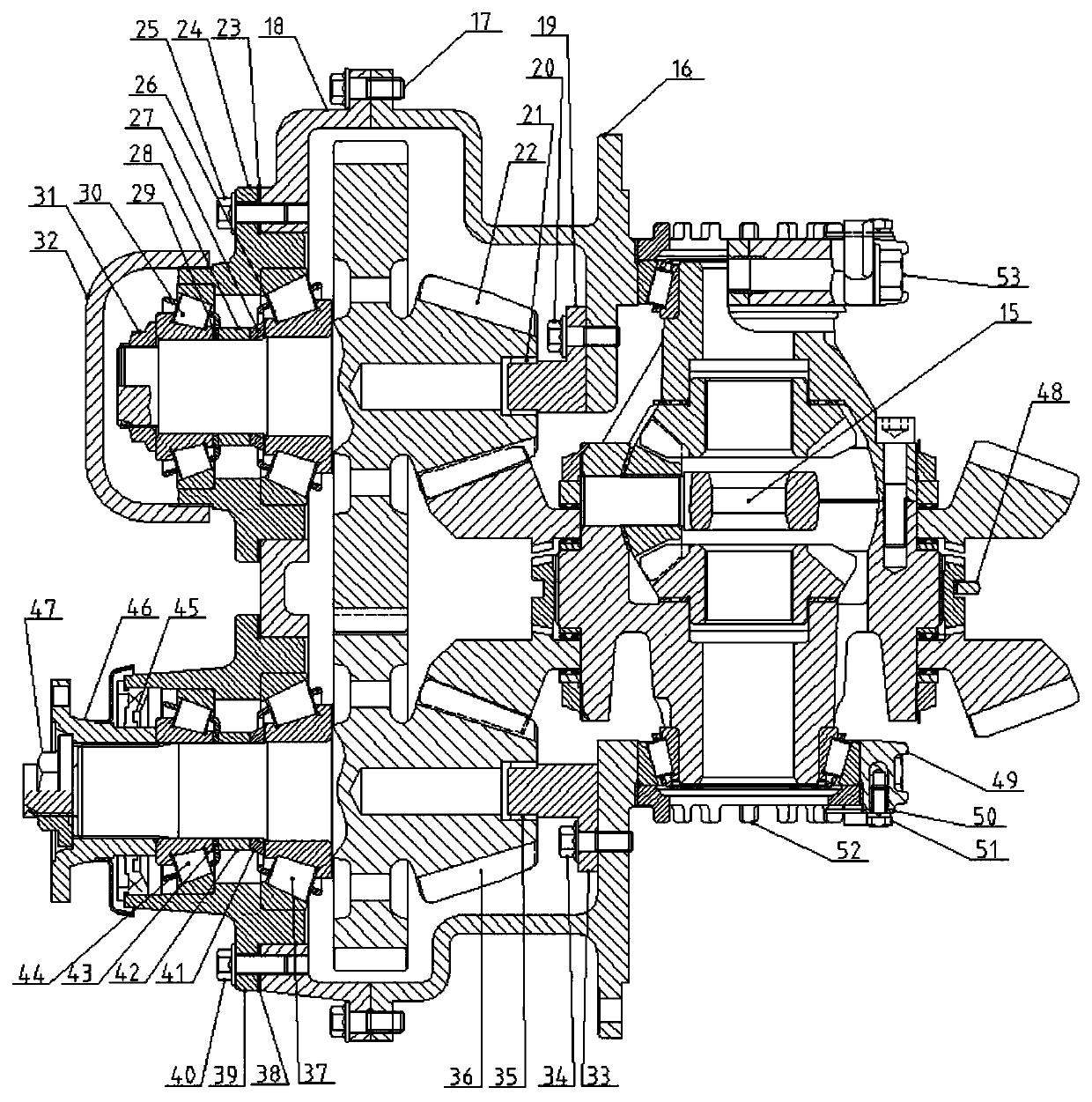

Double-bevel gear drive axle double-speed reducer structure

PendingCN109695686AReduce weightIncreased drive torqueControlled membersGearingGear wheelReduction drive

The invention belongs to the field of automobile drive axles, and relates to a double-bevel gear drive axle double-speed reducer structure. The device mainly comprises a differential mechanism assembly, a first shaft driving bevel gear, a second shaft driving bevel gear, a first shaft driven bevel gear and a second shaft driven bevel gear; the first shaft driving bevel gear adopts an integrated structure with driving bevel gears and a driving cylindrical gear, the driving bevel gears of the end face is meshed with the first shaft driven bevel gear, and the driving cylindrical gear structure ismeshed with a driven cylindrical gear structure of the second shaft driving bevel gear; the second shaft driving bevel gear adopts an integrated structure with driving bevel gears and a driven cylindrical gear, the driving bevel gear of the end face is meshed with the second shaft driven bevel gear, and the driven cylindrical gear structure is meshed with the driving cylindrical gear structure ofthe first shaft driving bevel gear. According to the device, the double-speed reducer structure is adopted, when a commercial vehicle is fully loaded, a large speed ratio is adopted, and driving torque is increased; when no-load is carried out, a small speed ratio is adopted, and the driving speed is increased; through reasonable arrangement of the speed and the torque, the oil consumption is reduced, and the efficiency is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Cleaning device, process cartridge, and image forming apparatus

ActiveCN101339396ANo reduction in contact widthIncrease line pressureElectrographic process apparatusBand shapeImage transfer

A low linear pressure and high surface pressure cleaning structure by specifying the material, shape and support structure of a cleaning blade in a cleaning device, a process cartridge and an image forming apparatus is obtained. A tip portion of an elastic cleaning blade 38 supported by a support member 37 which is a so-called blade holder is pressed against a drum-shaped or belt-like image bearing member 10 to remove a residual toner remaining on the image bearing member after image transfer. In such a cleaning device 16, an angle [theta] forming a front edge portion 36 of the cleaning blade is made obtuse and the front edge portion is pressed against the image bearing member at a surface pressure of 2.0g / mm<2> or larger. The surface pressure is a value given by dividing total load applied on the cleaning blade by a contact area of the cleaning blade to the image bearing member.

Owner:RICOH KK

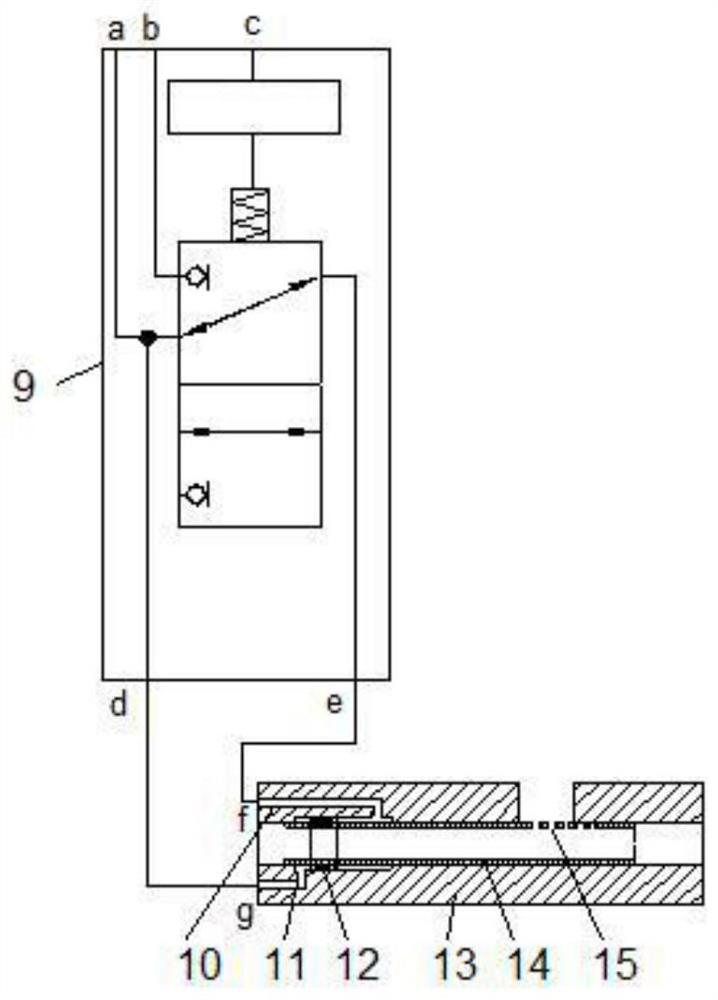

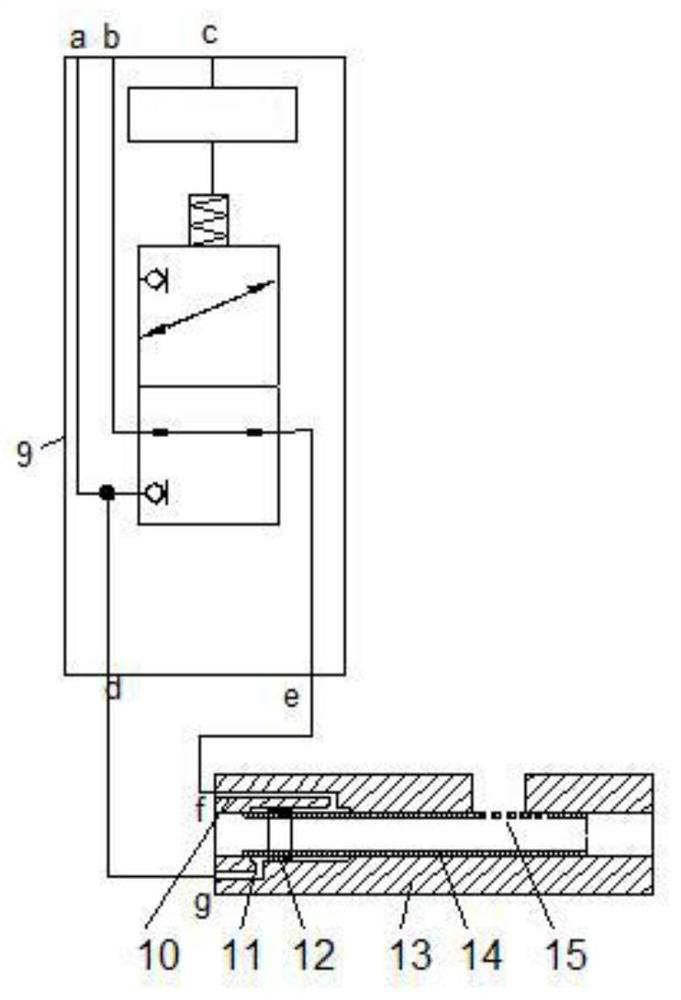

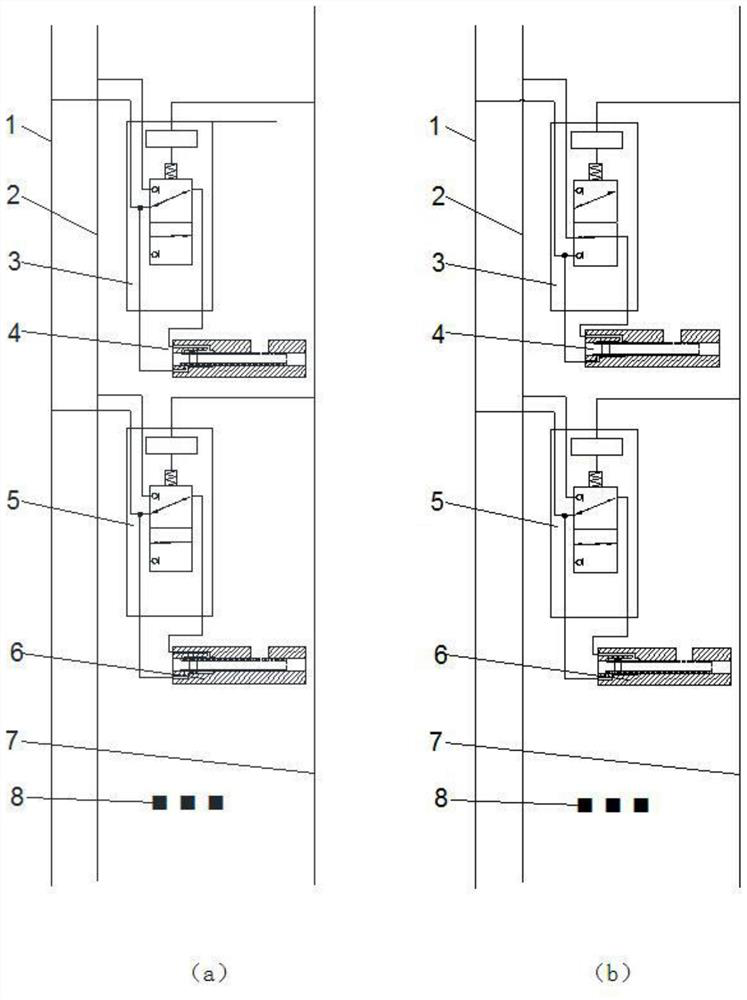

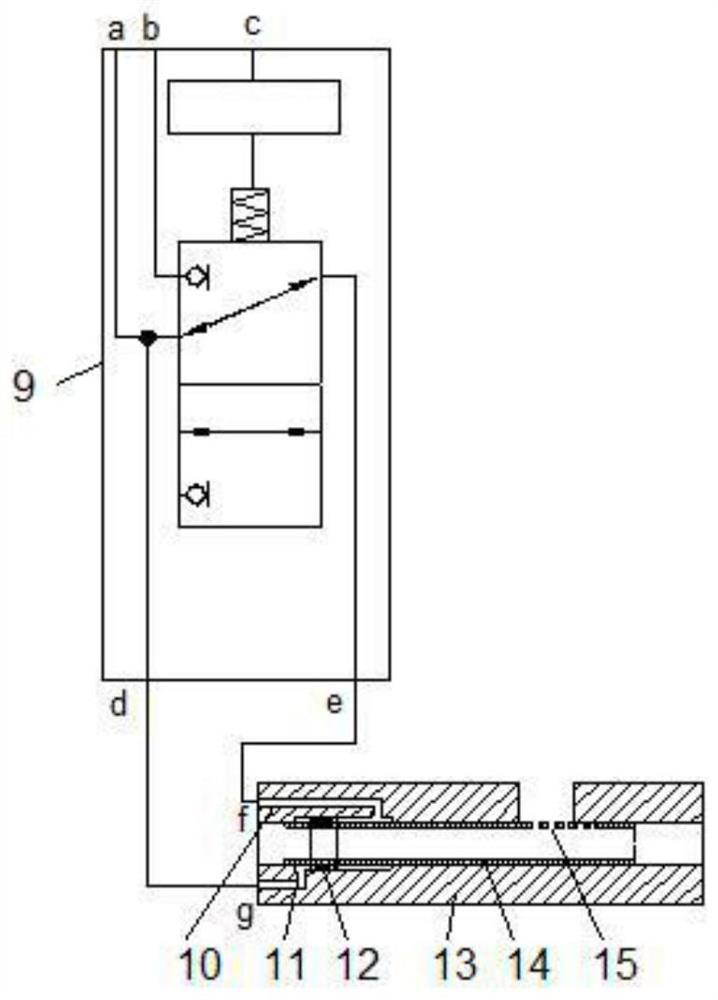

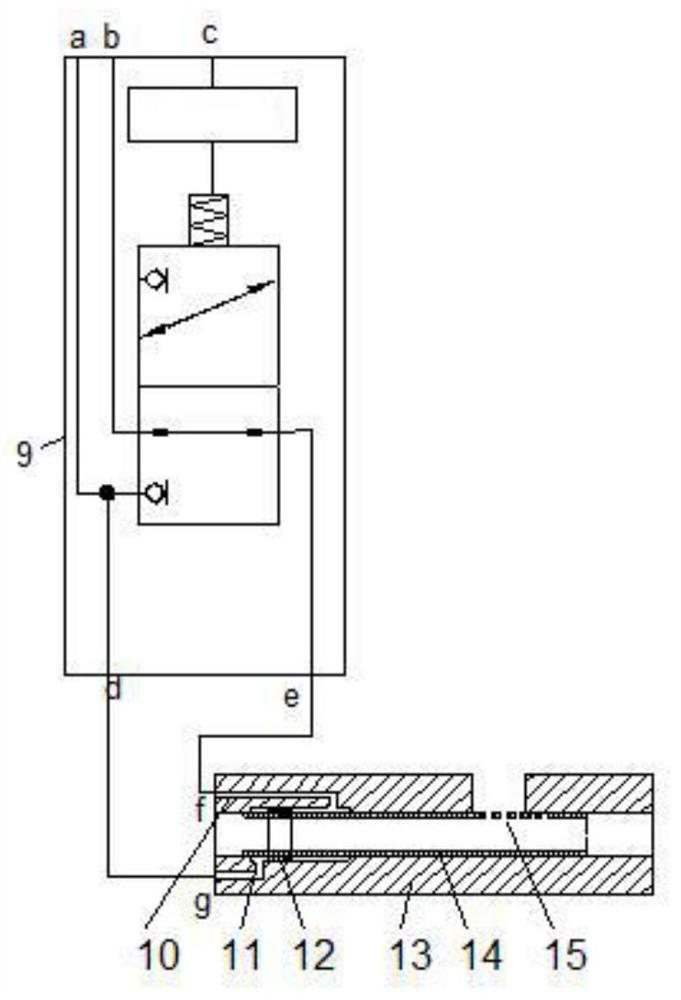

Electro-hydraulic compound control underground decoding device and decoding method thereof

ActiveCN112696172AResolve delayReduce decreaseWell/borehole valve arrangementsSealing/packingControl systemControl engineering

The invention provides an electro-hydraulic compound control underground decoding device and a decoding method thereof. A first hydraulic control pipeline and a second hydraulic control pipeline are respectively connected with an electro-hydraulic compound control device and are connected with ground control equipment through a signal control cable of an electro-hydraulic compound control decoder; a lower electro-hydraulic compound control system is arranged below the electro-hydraulic compound control device located at the bottommost end of a well. Horizon identification is realized by utilizing a circuit system, so that the action of a two-position three-way electromagnetic valve is realized, pressure liquid is guided, the horizon identification efficiency is improved, the problem of delay of a hydraulic decoding system is solved, and the identification precision is improved; and a hydraulic control sliding sleeve is driven through the two hydraulic control pipelines, and compared with a full electric control mode, the number of motors and electronic components is reduced and the driving torque is increased, so therefore the overall process reliability is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

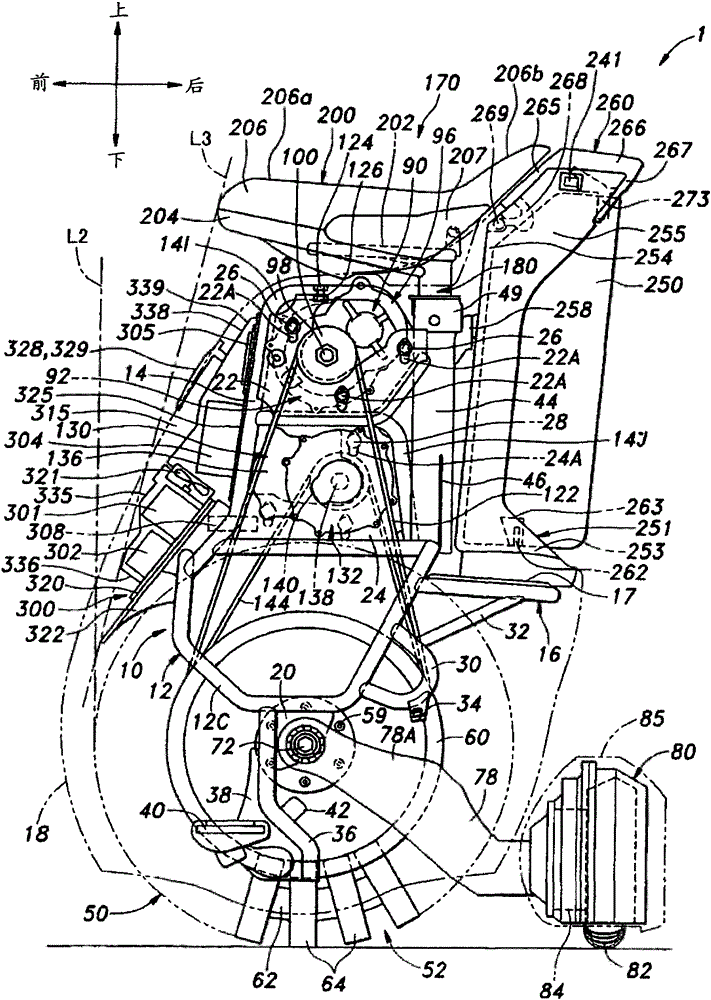

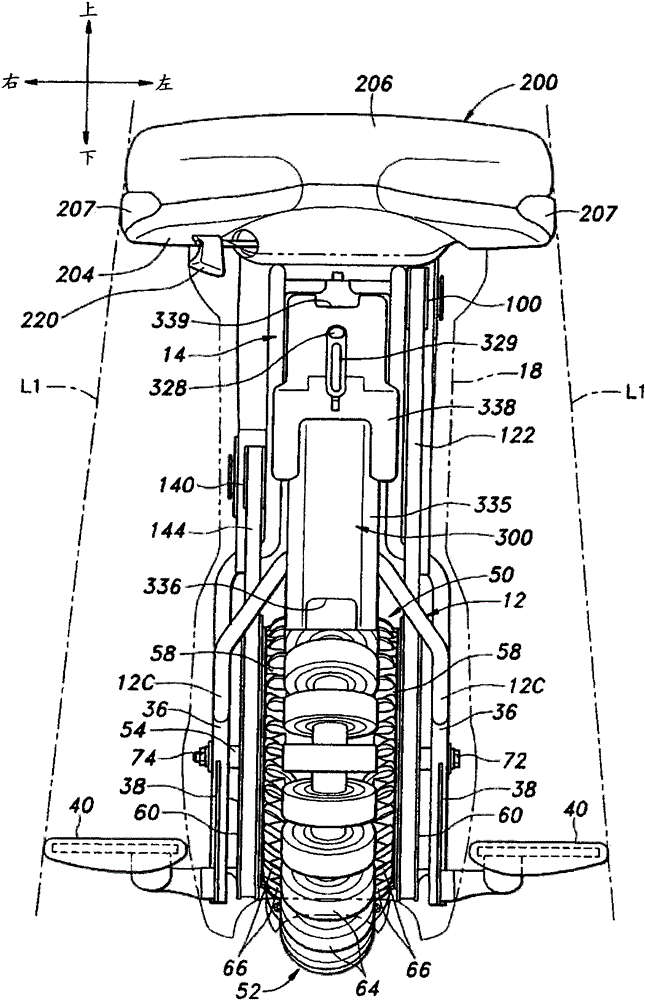

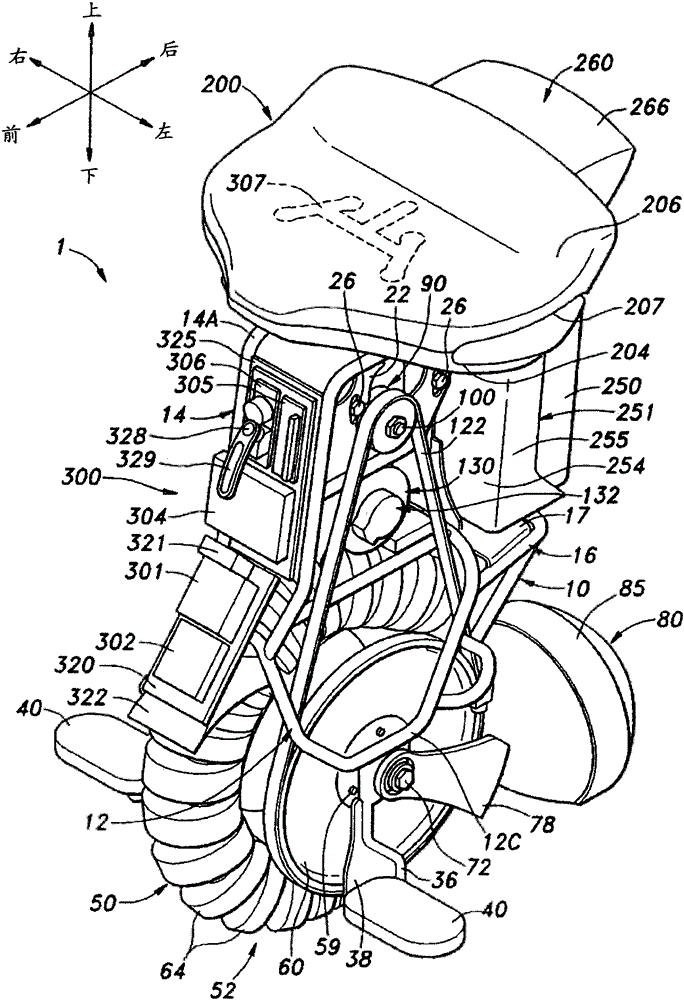

inverted swing vehicle

ActiveCN103419875BHigh torqueDo not change classificationUnicyclesCycle standsInverted pendulumPulley

An inverted swing vehicle includes: a vehicle body frame; a main wheel including a plurality of rotatable driven rollers configured to form a ring; and a pair of left and right drive plates supported for rotation on the vehicle body frame. Each drive plate includes a plurality of rotatable drive rollers arranged in twisted relationship in contact with the driven rollers. The vehicle also includes a pair of left and right driven pulleys provided on the outer sides of the drive plate, and a pair of left and right drive units attached to the vehicle body frame above the main wheels and including motors having output power shafts attached to the drive pulleys. An endless transmission member interconnects the drive and driven pulleys. The left and right drive units are arranged in a vertically offset relationship to each other.

Owner:HONDA MOTOR CO LTD

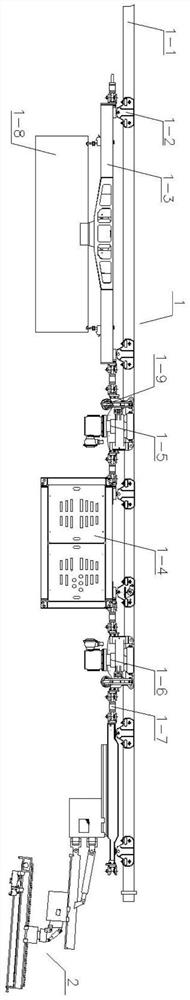

Monorail crane hydraulic rock drilling machine

PendingCN112431556AFast constructionIncreased drive torqueDrilling rodsDerricks/mastsRock cuttingMonorail

The invention discloses a monorail crane hydraulic rock drilling machine. The monorail crane hydraulic rock drilling machine comprises a monorail crane system and a hydraulic rock drilling system arranged at the front end of the monorail crane system; a hoisting beam, a first driving part, a control box, a second driving part and the hydraulic rock drilling system are sequentially connected through connecting rods, and a storage battery is in circuit connection with the control box; the control box is correspondingly connected with the first driving part, the second driving part and an oil path of the hydraulic rock drilling system; and the hydraulic rock drilling system comprises an upper adjusting mechanism, a middle adjusting mechanism, a lower adjusting mechanism and a hydraulic rock drilling machine. According to the monorail crane hydraulic rock drilling machine, the hydraulic rock drilling machine can be dragged through a monorail crane, other to-be-transported equipment can bedirectly connected to the monorail crane, the problem of underground upper-layer space utilization can be solved, the roadway construction time is shortened, and the construction efficiency is improved.

Owner:XUZHOU LIREN MONORAIL TRANSPORTATION EQUIP CO LTD

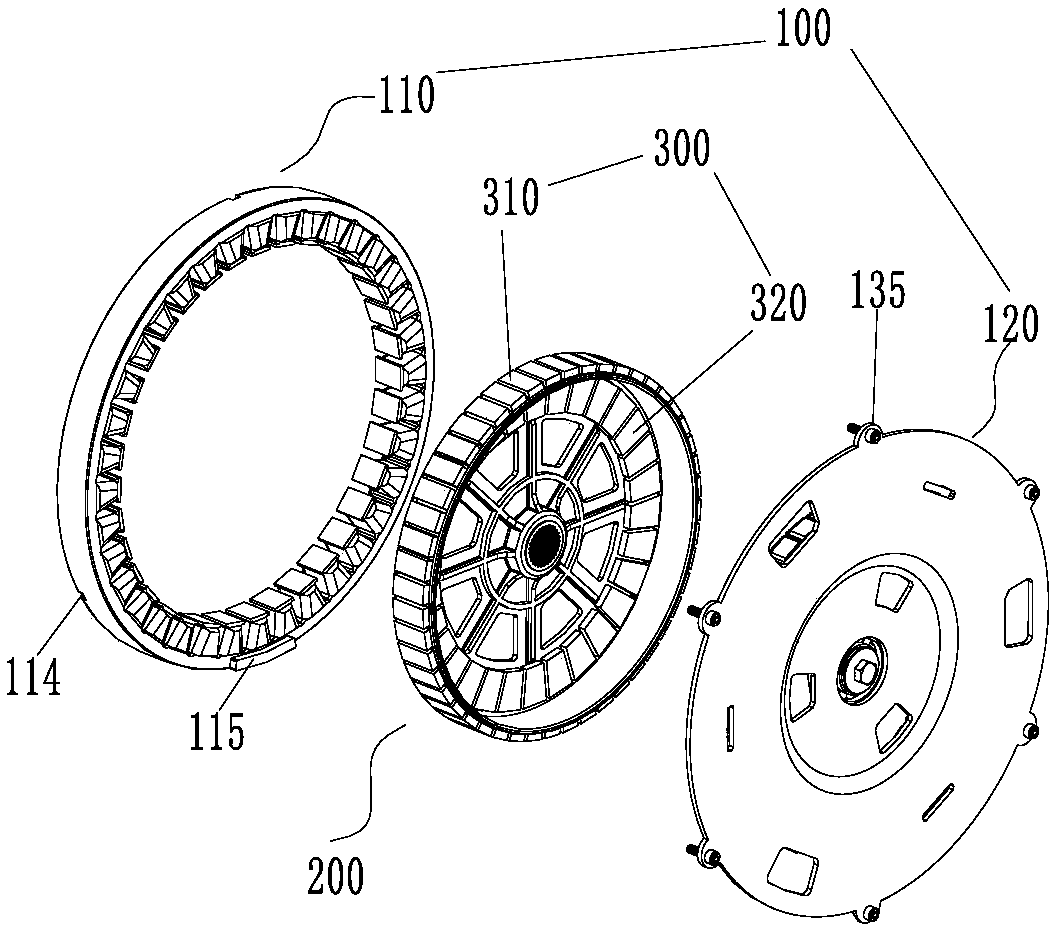

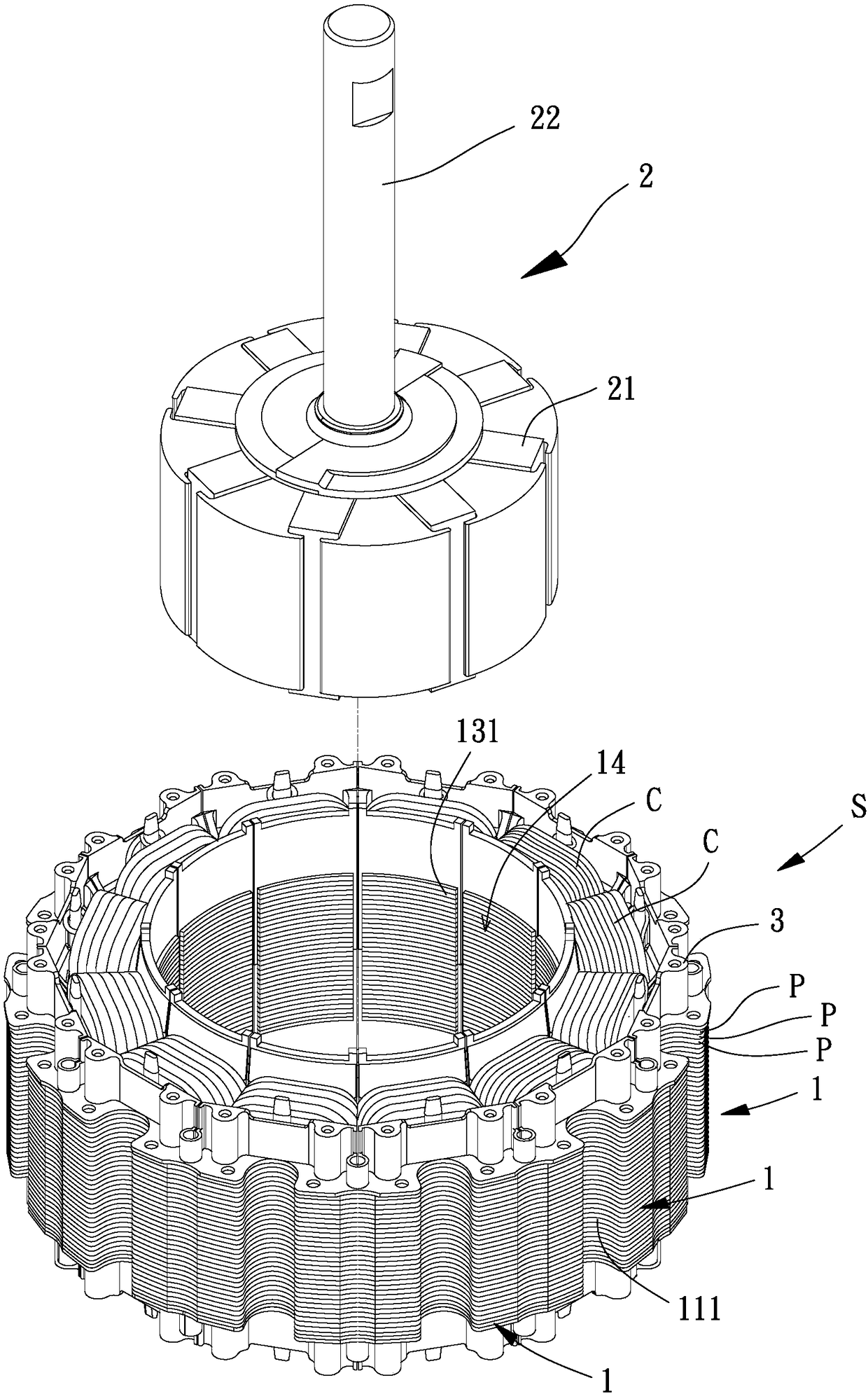

Motor and washing machine with same

PendingCN107896039AIncreased drive torqueEnhanced magnetic fieldSupports/enclosures/casingsElectric machineEngineering

The invention relates to a motor and a washing machine with the same. The motor includes two or more stator sets and at least one rotor set. The rotor is provided with steel magnets respectively corresponding to two or more stator sets. The washing machine includes a casing; and a water cylinder, a roller and the above motor that are disposed in the casing. The water cylinder is a fixed part, andthe roller is a rotating part. The rotor of the motor and the roller are connected through a rotating shaft. The stators of the motor are fixed on the water cylinder. The rotating shaft is provided with at least two bearings, and a portion, which cooperates with the rotating shaft, of the rotor of the motor is located between the two bearings. The technical scheme of the invention can not only improve the driving torque of the motor, thereby increasing the capacity of washing clothes in the washing machine, but also reduce the noise and prolong the service life of the washing machine.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

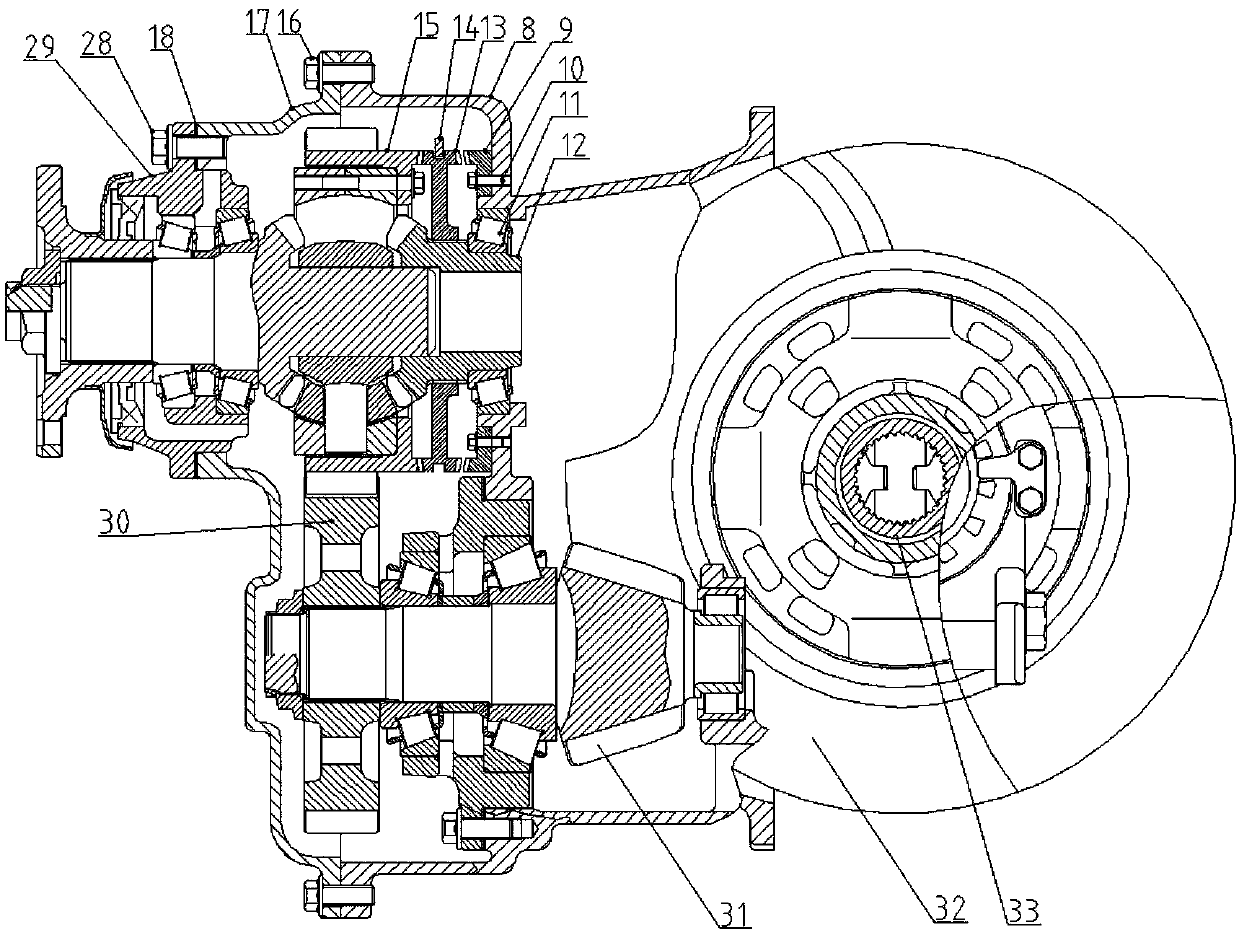

Drive axle double-speed reducer with planetary structure

PendingCN109611516AIncreased drive torqueIncrease driving speedGearboxesToothed gearingsReduction driveReduction ratio

The invention discloses a drive axle double-speed reducer with a planetary structure, and belongs to the technical field of automobile drive axles. The reducer comprises a reducer shell, a fixed meshing sleeve, a driven bevel gear, a sliding meshing sleeve, a planetary gear assembly, a bevel gear shell, a driving bevel gear assembly, a driven cylindrical gear and a driving bevel gear. The reduceradopts a double-speed reducer structure, when a commercial automobile is fully loaded, a large speed ratio is adopted to increase driving torque; when the commercial automobile is in zero-load, a small speed ratio is adopted to increase driving speed; and through the reasonable arrangement of the speed and the torque, the oil consumption is reduced, and the efficiency is improved. A planetary gearset structure is adopted, based on the double-speed reduction principle of a planetary bevel gear structure, the switching between one time reduction ratio and two times reduction ratio can be achieved; the shaft diameter of the driving bevel gear is used for radially positioning a cross shaft and the driven bevel gear; the sliding meshing sleeve adopts double-face end face teeth and is used forswitching between the two speed ratios; and through a driving cylindrical gear and an end face tooth structure, the two functions of transmission and speed change are realized.

Owner:FAW JIEFANG AUTOMOTIVE CO

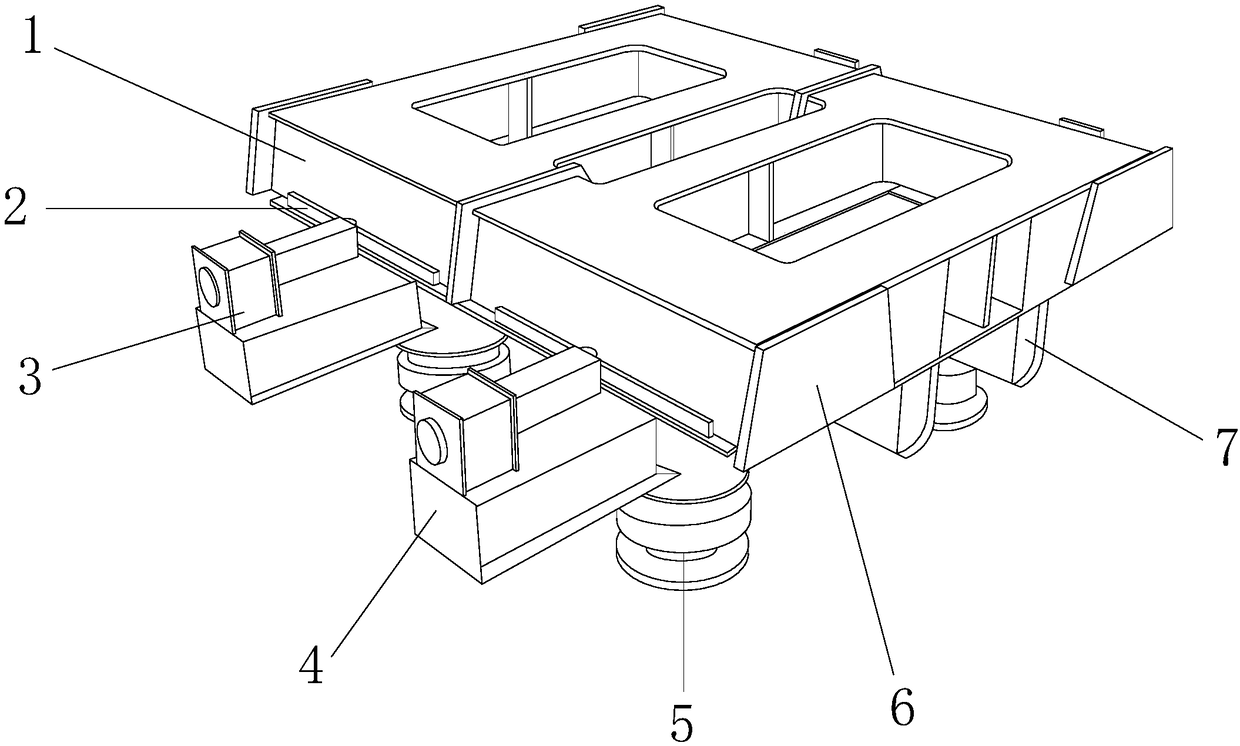

Novel walking-type jacking system

PendingCN108330843AAchieve precise positioningEasy to controlBridge erection/assemblyElectric machineryEngineering

The invention discloses a novel jacking system which structurally comprises a supporting seat, sliding rails, transverse guide devices, displacement synchronous supporting seats, jacking oil cylinders, reinforcing steel plates and a horizontal-pushing oil cylinder. By controlling rotating speed of a motor and rotating direction of a shaft, a transmission mechanism can be driven to change moving direction and speed provided by the motor so as to improve forward thrust of a sliding rod to a sliding seat, and moving direction provided by a horizontal-pushing transmission mechanism is changed through a guide mechanism to improve accuracy when an upper transverse moving mechanism and a lower transverse moving mechanism slide on the sliding rails so as to improve quality of engineering construction.

Owner:刘佳佳

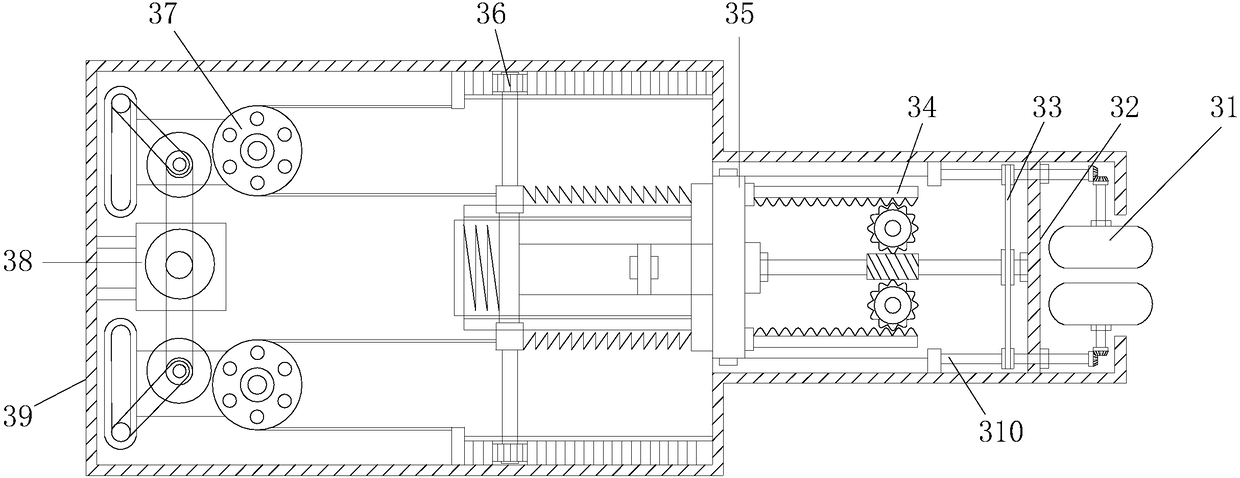

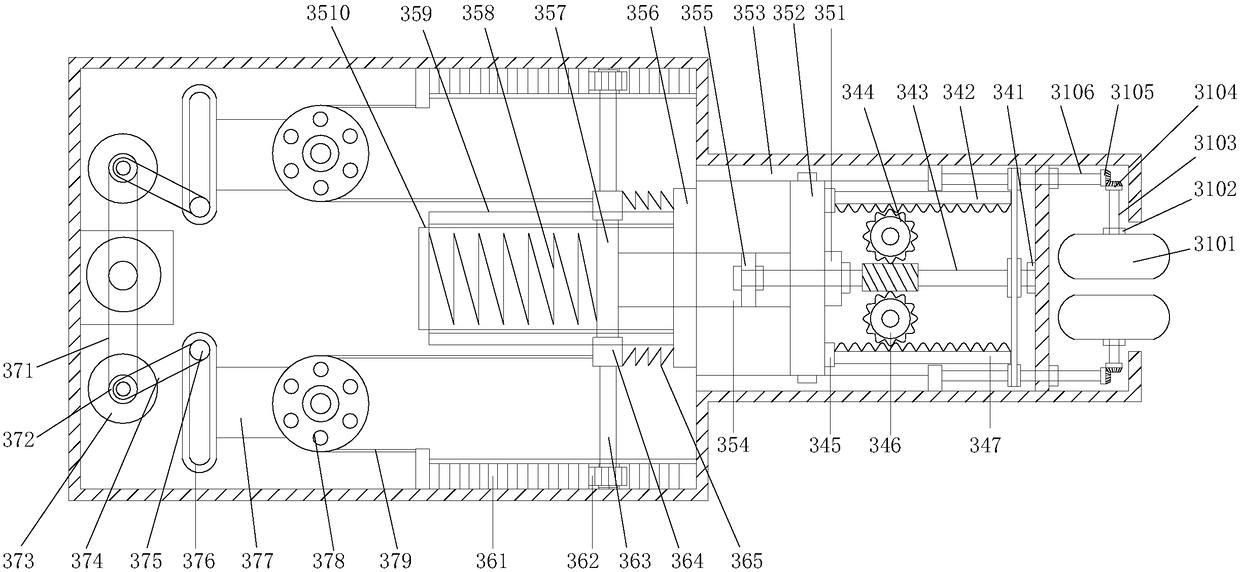

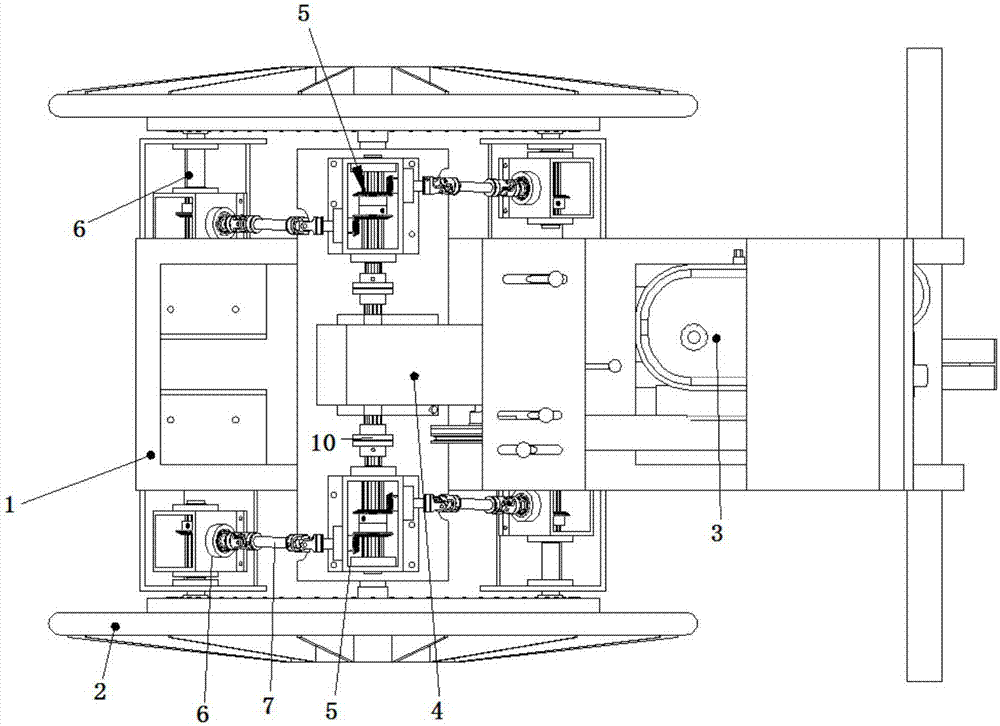

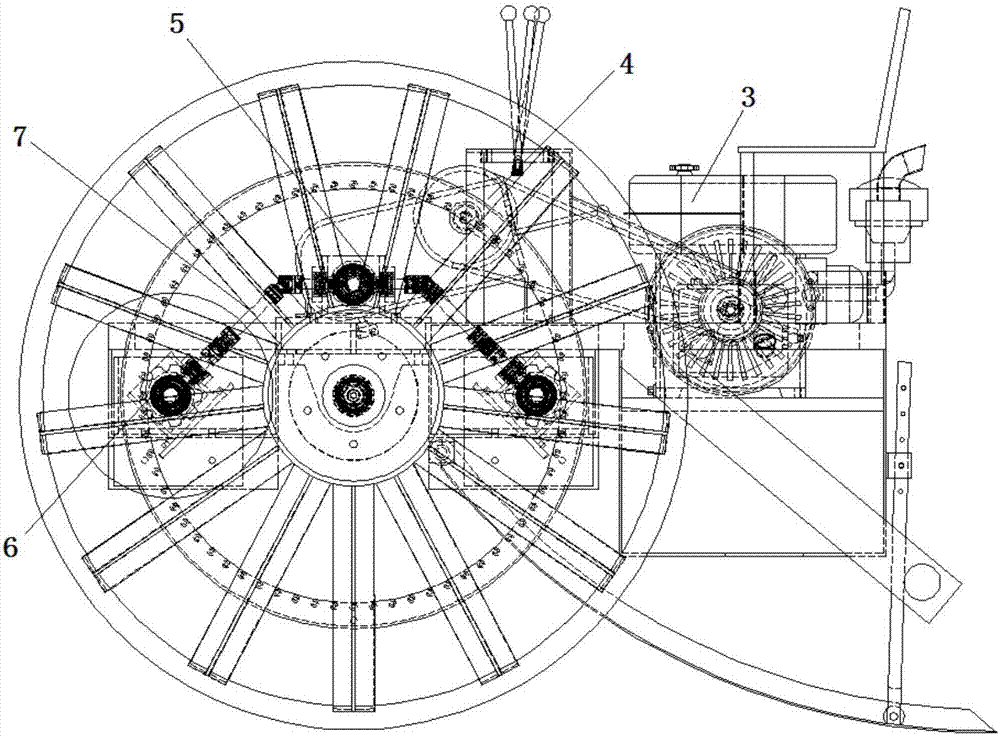

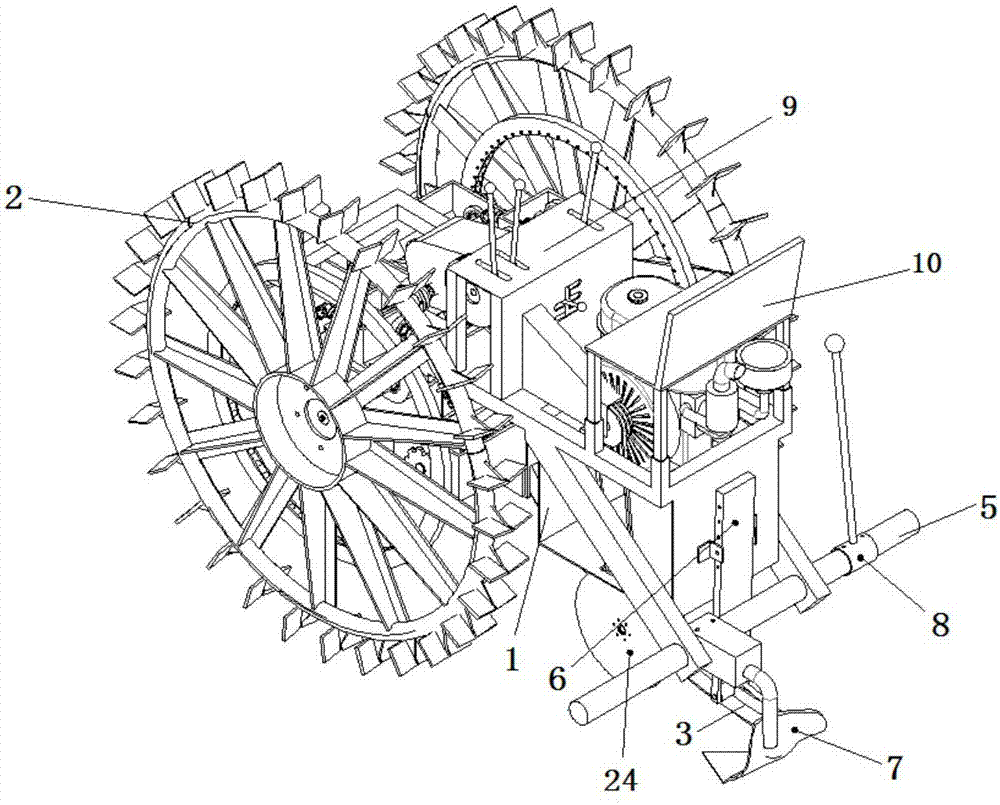

Rolling walking rack achieving high drive torque

The invention discloses a rolling walking rack achieving high drive torque. The rack comprises a rack body, main wheels are connected to the two sides of the rack body, a power device used for driving the main wheels to turn around and a gearbox are arranged on the rack, and the output end of the power device is connected with the input end of the gearbox; transmission shaft distribution boxes used for distributing power are symmetrically arranged on the left side and the right side of the gearbox, and small thumbwheel boxes used for driving the main wheels are symmetrically arranged at the front end and the rear end of each transmission shaft distribution box; the input end of each transmission shaft distribution box is connected with the output end of the gearbox, and the output end of each transmission shaft distribution box is connected with the input end of the corresponding small thumbwheel box through a universal coupling; a driving thumbwheel is connected to the output end of each small thumbwheel box; a transmission gear ring capable of being matched with each driving thumbwheel is fixedly connected to the inner side of the corresponding main wheel in a coaxial mode. Accordingly, the structure is simple, manufacturing and using are convenient, and the drive torque of the rolling walking rack is effectively increased.

Owner:彭广平

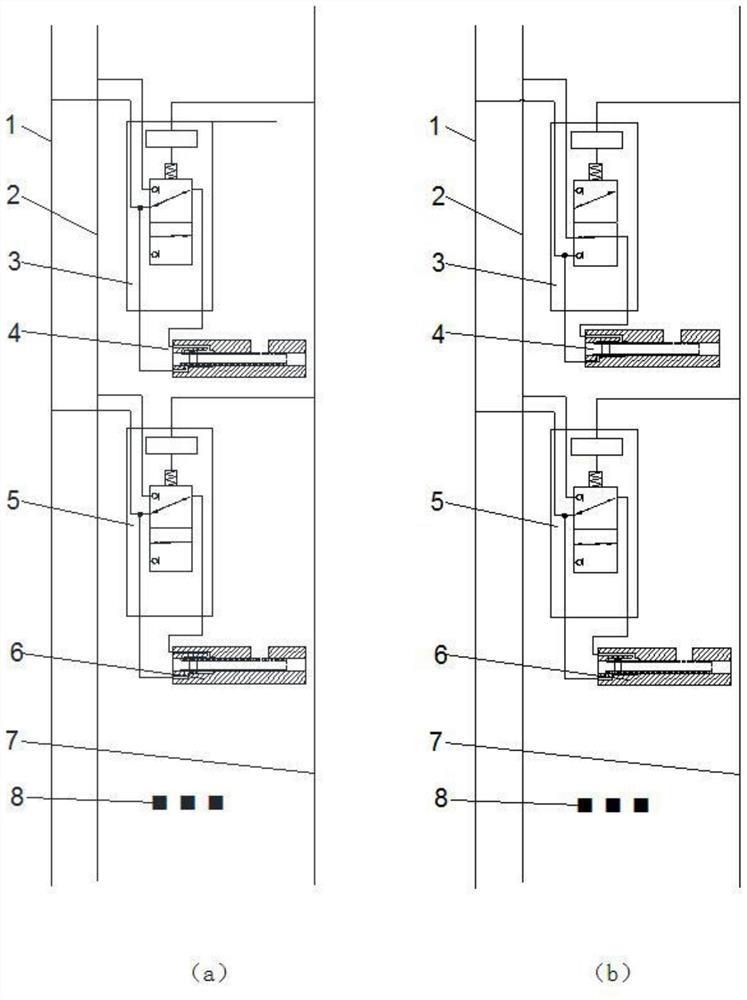

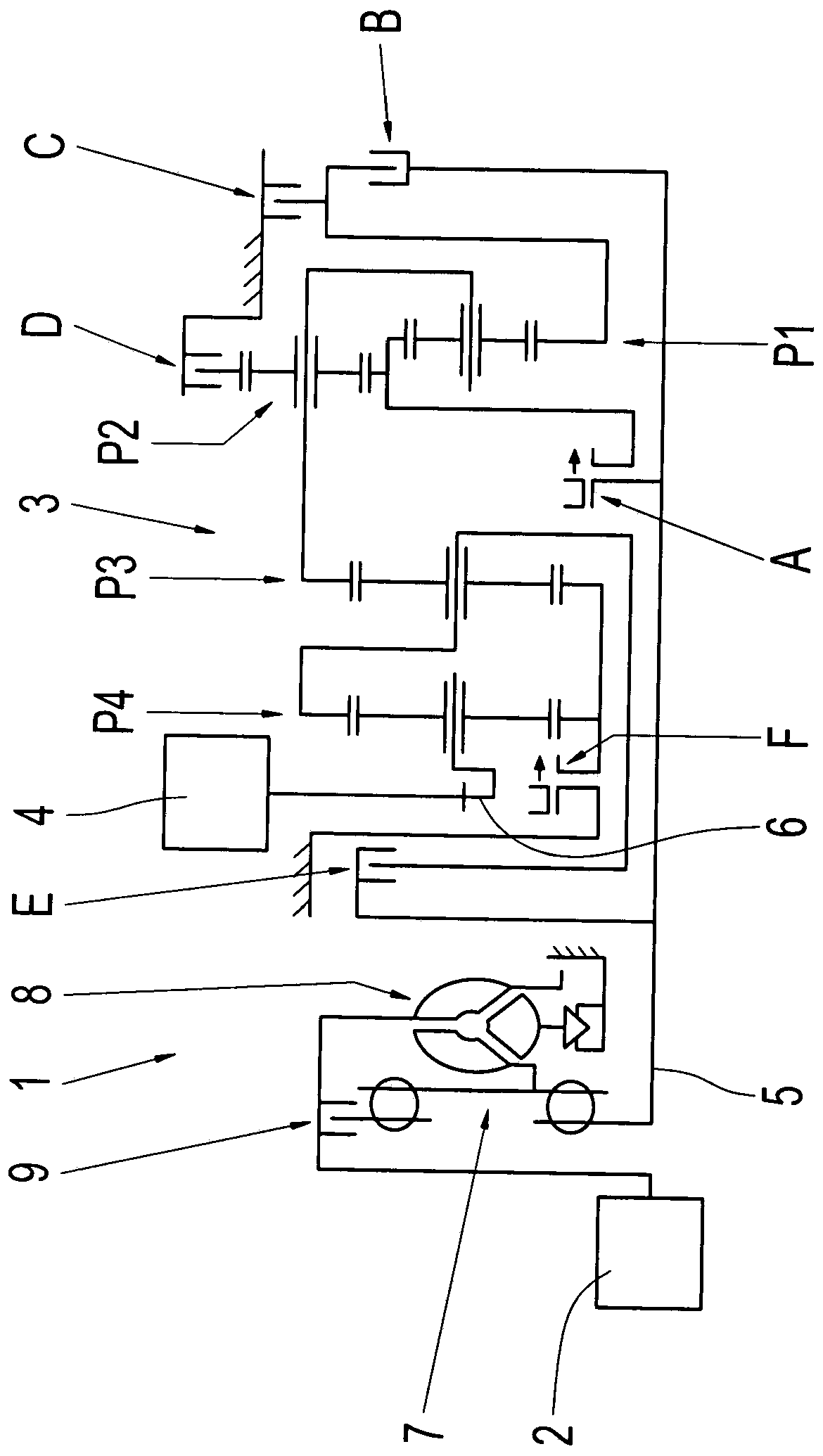

A kind of electric vehicle transmission and transmission method

The invention discloses an electric vehicle transmission and a speed changing method thereof, comprising a hydraulic torque converter with a locking function, a planetary gear mechanism, an oil pump, an oil pump motor, a controller, a speed reduction mechanism and a differential. The hydraulic torque converter with lock-up function includes a pump wheel, a turbine, an input shaft, an output shaft, etc., the drive motor is connected to the pump wheel through the input shaft, and the turbine is connected to the output shaft. The torque on the output shaft is transmitted to the planetary gear mechanism. The planetary gear mechanism includes sun gear, planet carrier, large ring gear, clutch, brake and other parts. The torque is output from the planet carrier through the planetary gear mechanism, and drives the vehicle to travel after passing through the reduction mechanism and the differential. The transmission can realize two mechanical transmission gears and one hydraulic torque conversion gear. The oil pump is used to provide pressure to the transmission hydraulic system. The electric vehicle transmission of the invention can improve the climbing performance and acceleration performance of the electric vehicle, and at the same time enhance the reliability of the vehicle.

Owner:HUNAN UNIV

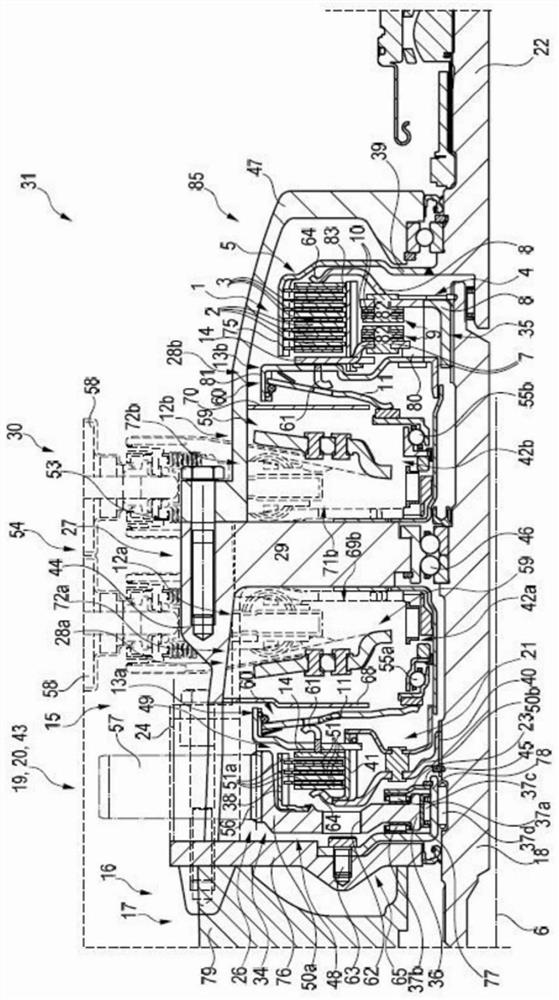

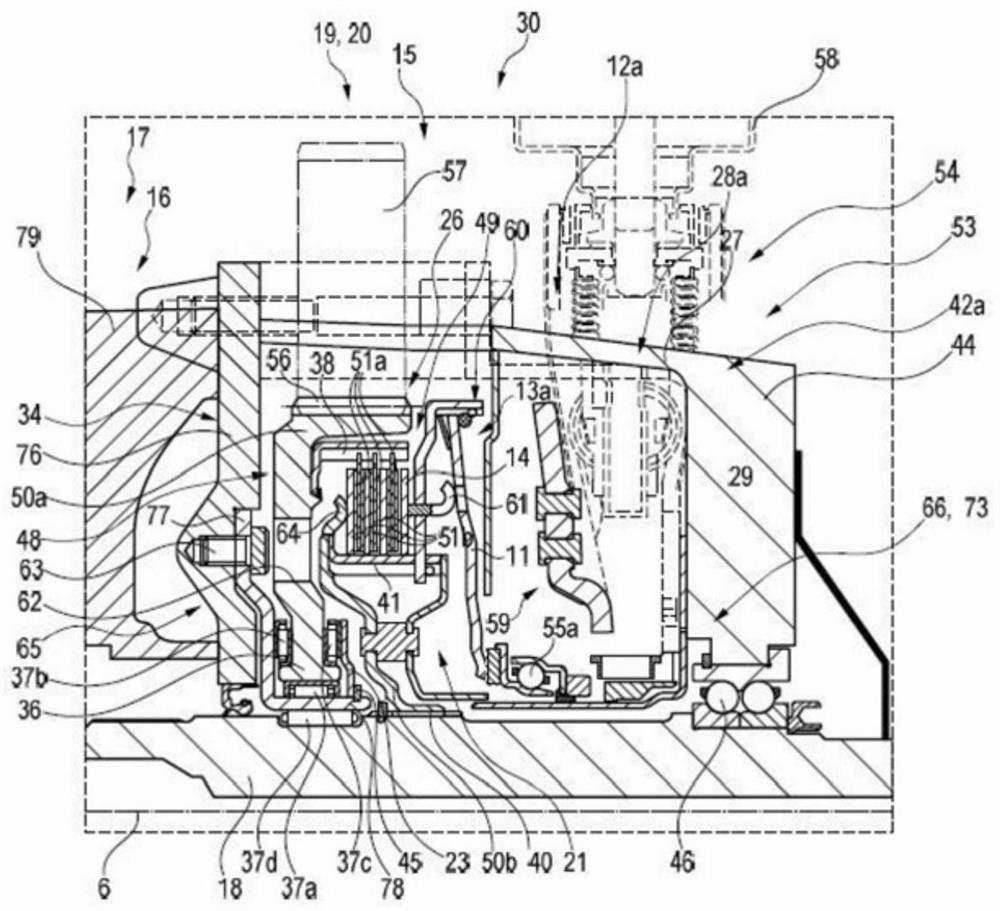

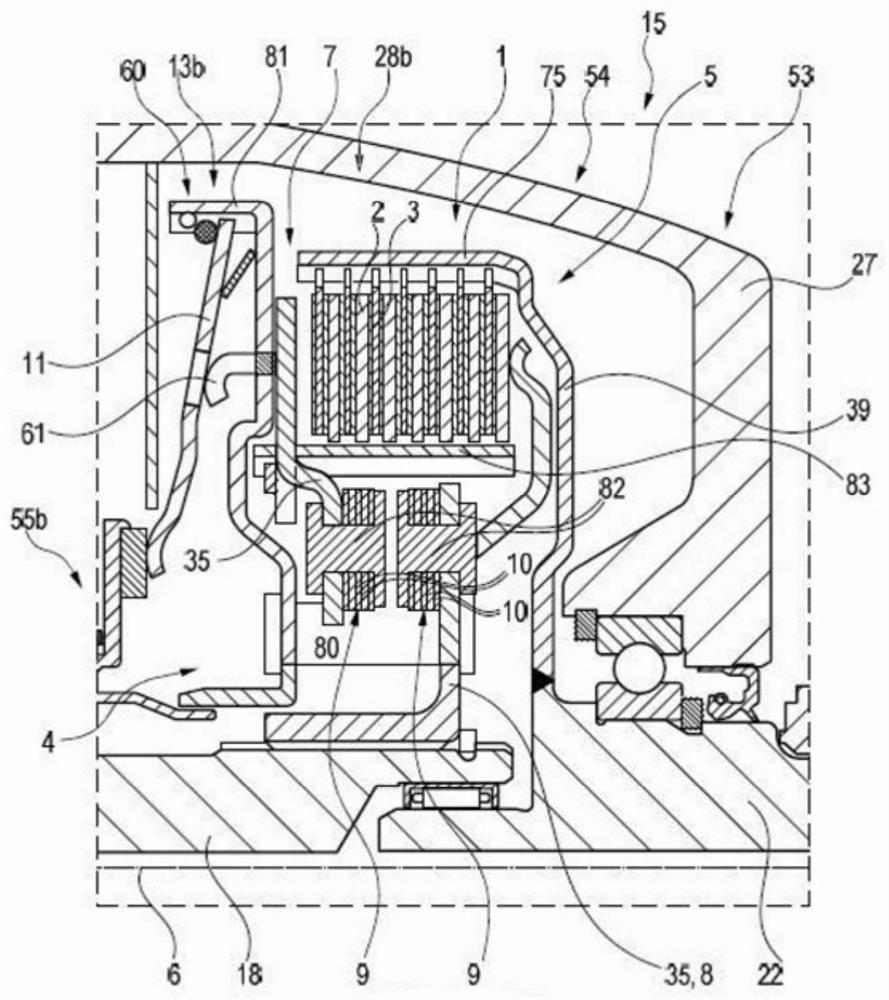

Friction clutch for motor vehicle powertrain, powertrain unit, transmission unit, and powertrain

PendingCN112218774ACompact designReduce in quantityGas pressure propulsion mountingVehicle sub-unit featuresRotational axisAxial force

The invention relates to a friction clutch (1) for a motor vehicle powertrain. The friction clutch comprises two clutch components (4, 5), each of which has at least one friction element (2, 3). The friction elements (2, 3) of the different clutch components (4, 5) lie against each other in a frictionally locking manner in a closed position and are axially spaced from each other in an open position. A first clutch component (4) additionally has a first support part (7), which receives at least one first friction element (2), and a second support part (8), which is rotationally fixed to the first support part (7) by means of at least one leaf spring unit (9). A leaf spring (10) of the at least one leaf spring unit (9) is designed and positioned relative to a reference plane aligned perpendicularly to the rotational axis (6) in a set angle in the closed position such that an additional axial force is applied to the friction elements (2, 3) of the different clutch components (4, 5) in a drive rotational direction of the first clutch component (4). The invention additionally relates to a powertrain unit (15) for the hybrid vehicle, comprising the friction clutch (1), to a transmissionunit (30), and to a powertrain (31).

Owner:SCHAEFFLER TECH AG & CO KG

Bicycle pedal device

The invention relates to a bicycle pedal device which comprises a left crank and a right crank, connecting rods and pedals, wherein one end of each of the connecting rods is in hinged connection to each of the cranks; and the other end of the connecting rod is directly fixedly connected to each of the pedals. Relevant components used for hinged connection between the connecting rods and the pedalsare cancelled, so the structure is simplified; a large forward swing angle of the connecting rod is obtained; a driving torque obtained on the cranks by the same pedal force is greatly increased; anddriving efficiency is significantly increased.

Owner:王相军

Method for compensation of vibration of horizontal stage electric machine

InactiveCN101230887BEasy to controlIncreased drive torqueNon-rotating vibration suppressionStands/trestlesValue setElectric machine

The invention relates to a vibration compensation method of a tripod head electric motor, which comprises the first step of utilizing a sensor in the tripod head to detect the present vibration values and the second step of causing the driving interference of the tripod head electric motor to be increased if the vibration values detected exceed the vibration permit values set by a machine. Under the circumstances that a camera for monitoring vibrates on a boarded pan / tilter, the invention utilizes an acceleration sensor, etc. to detect the corresponding vibration values, simultaneously, causes the torque of the tripod head electric motor to increase or the position of the cloud platform electric motor to initialize. For errors of the control and the operation of the tripod head, because prevention can be carried out before the errors happen, even if the vibration happens, the right tripod head control can be carried out.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

An electro-hydraulic composite control downhole decoding device and its decoding method

ActiveCN112696172BResolve delayReduce decreaseWell/borehole valve arrangementsSealing/packingSolenoid valveControl system

The invention provides an electro-hydraulic composite control downhole decoding device and a decoding method thereof. The first hydraulic control pipeline and the second hydraulic control pipeline are respectively connected with the electro-hydraulic composite control device, and the signal control cable of the electro-hydraulic composite control decoder is connected with the electro-hydraulic composite control device. The ground control equipment is connected, and the lower electro-hydraulic composite control system is arranged below the electro-hydraulic composite control device located at the bottom of the well. The circuit system is used to realize horizon recognition, so as to realize the action of the two-position three-way solenoid valve, guide the pressure fluid, improve the horizon recognition efficiency, solve the delay problem of the hydraulic decoding system, and improve the recognition accuracy; Compared with the full electronic control mode, the driving of the sliding sleeve reduces the existence of motors and electronic components, improves the driving torque, and thus improves the overall process reliability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

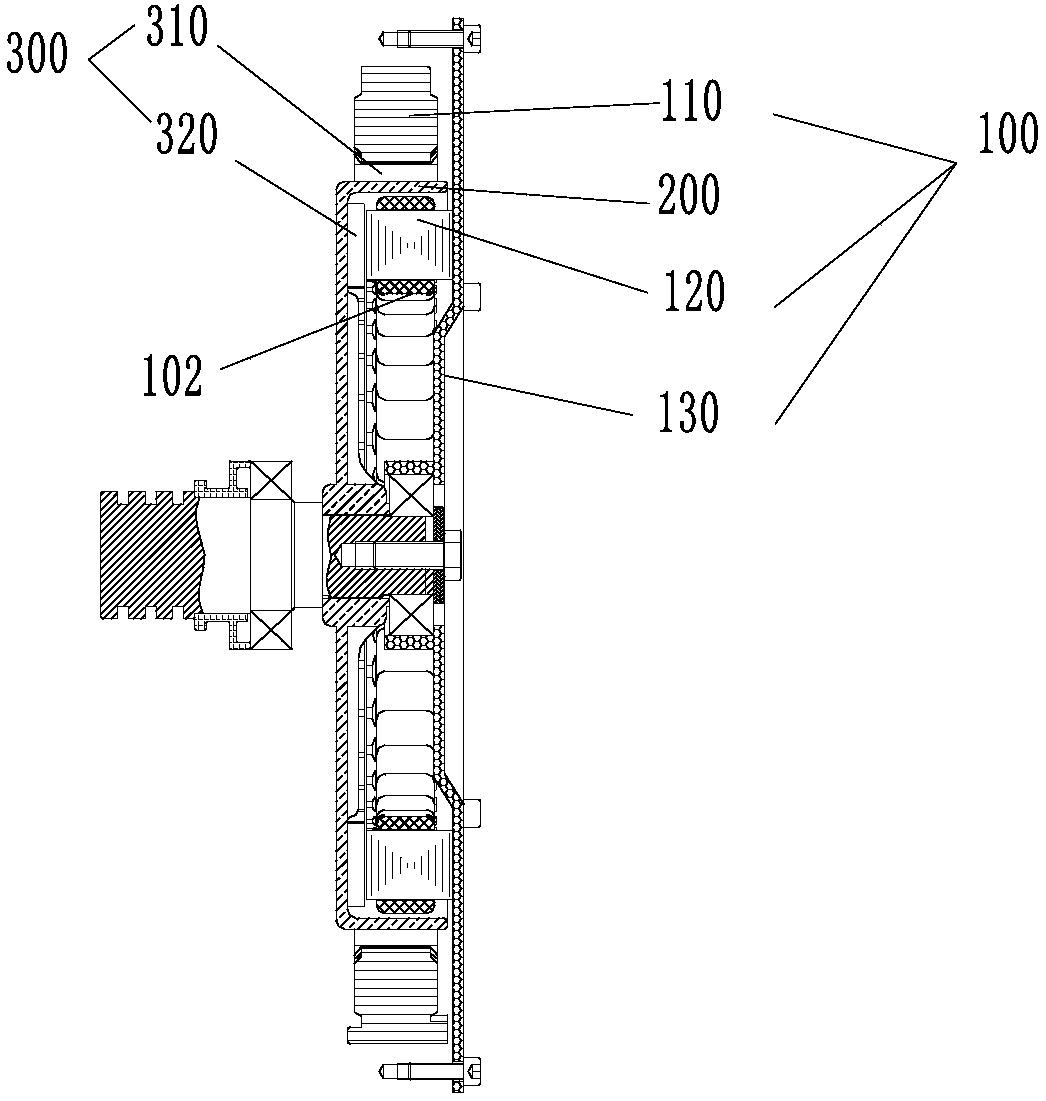

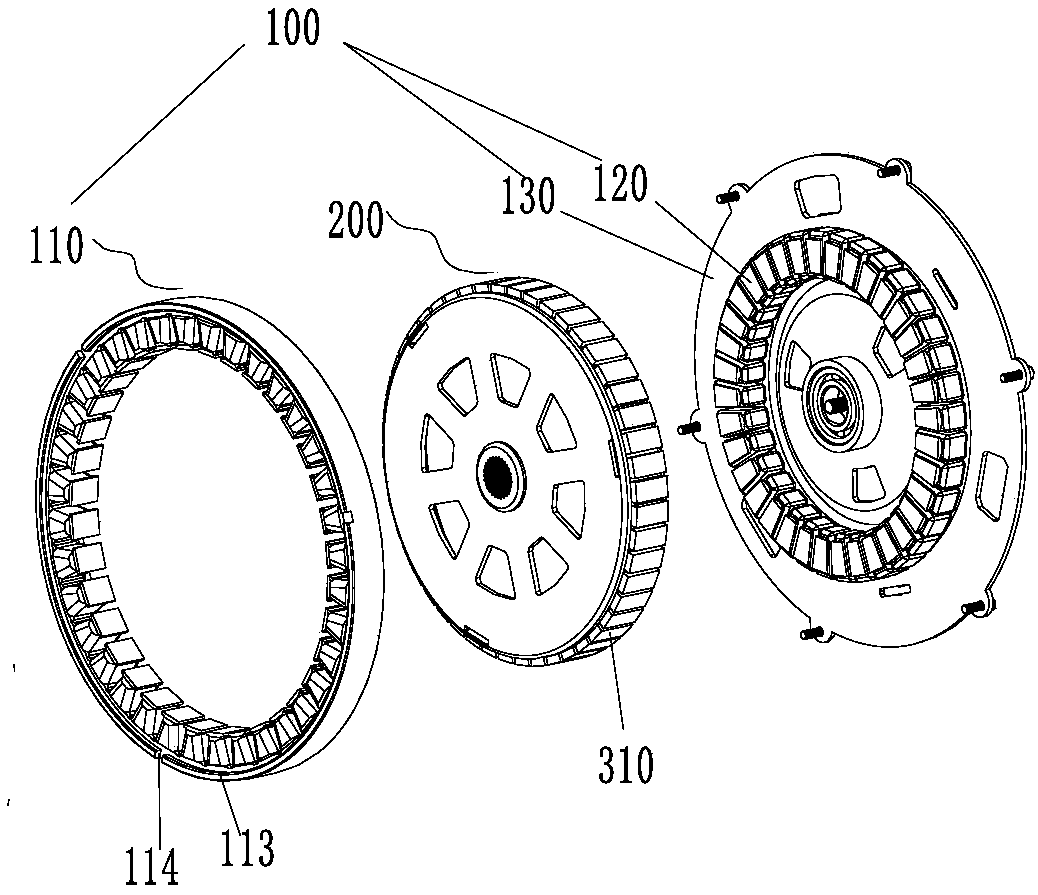

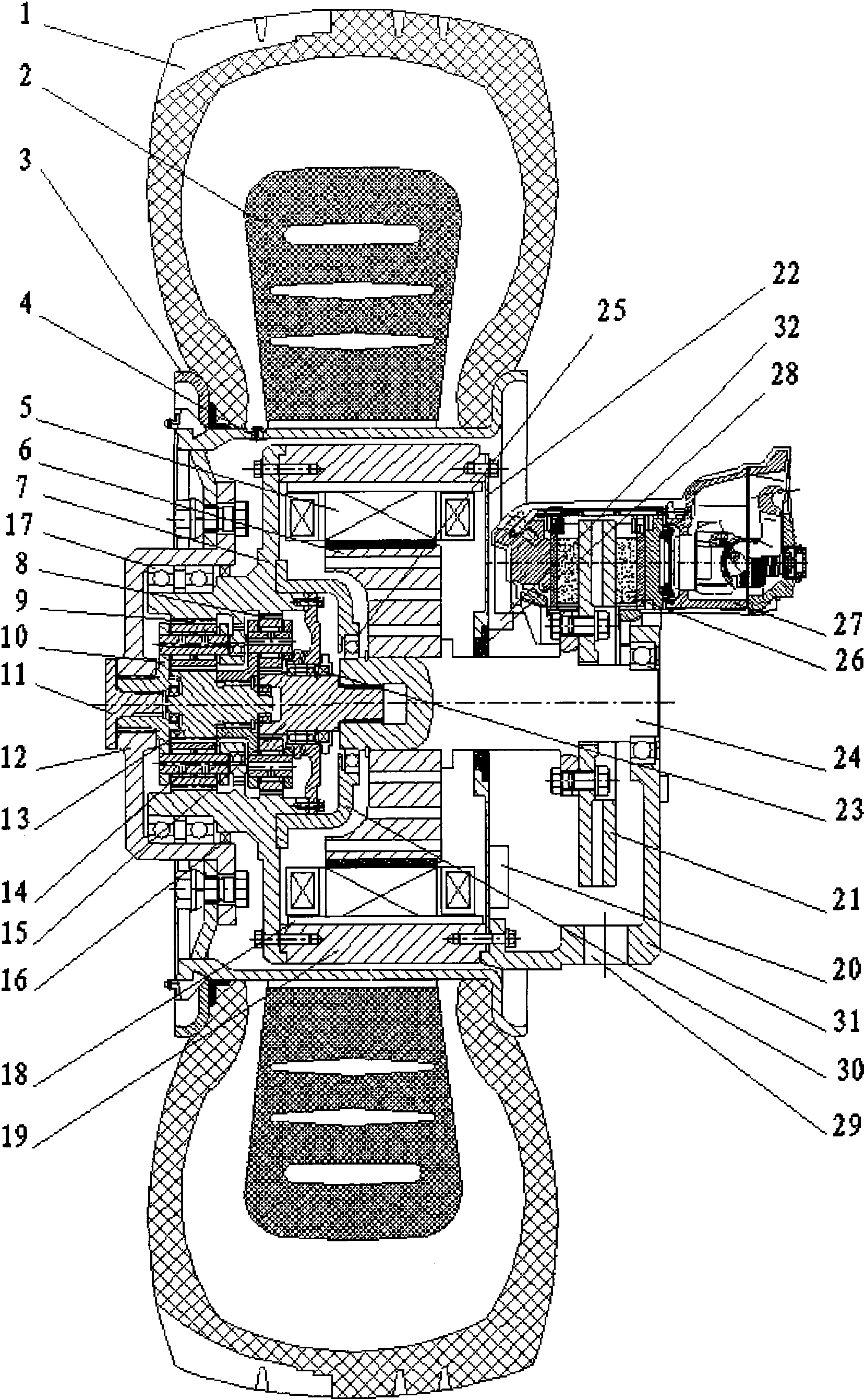

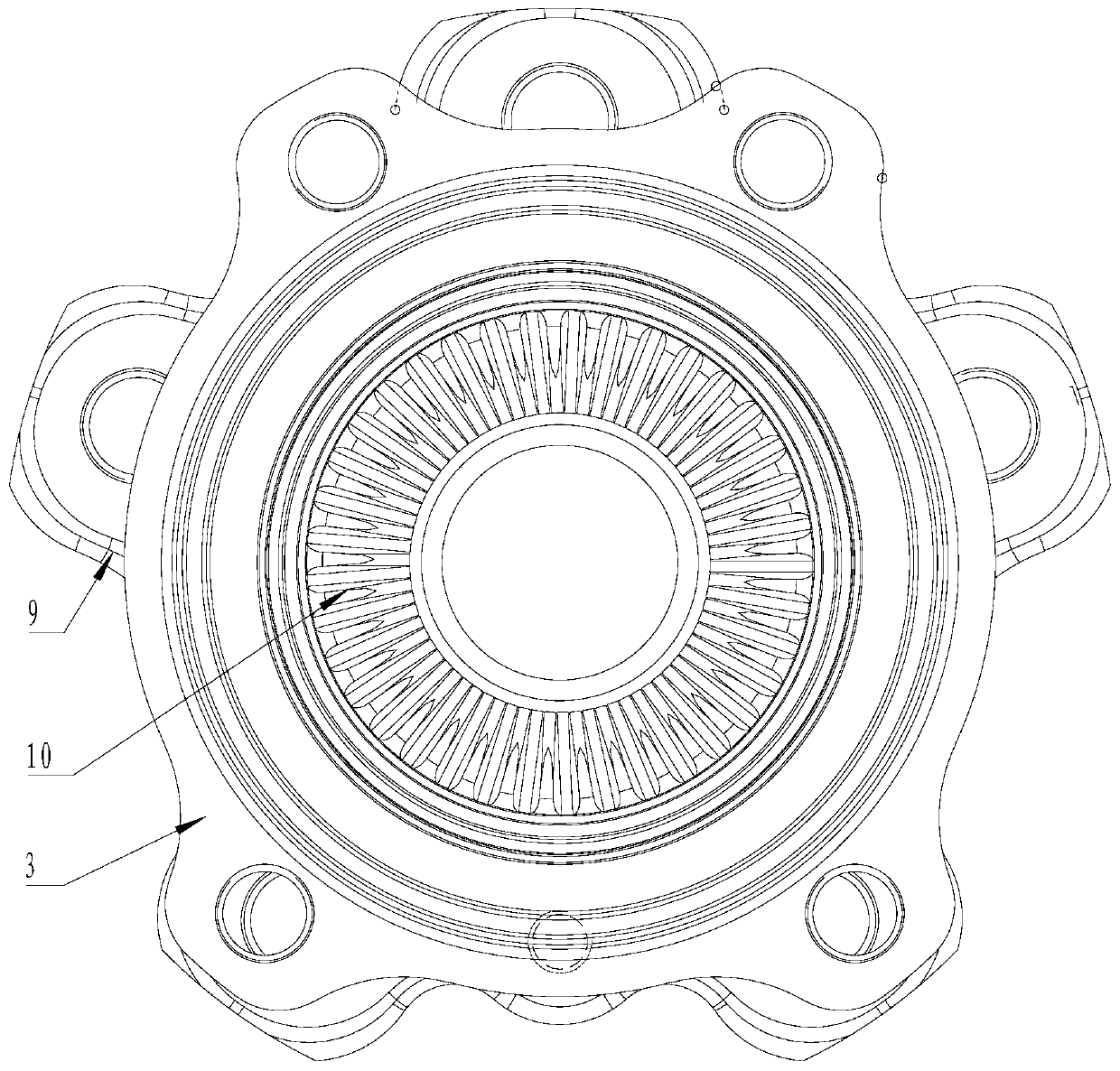

Mechanical and electrical integrated driving wheel system

InactiveCN102050005BIncreased drive torqueGood driving torqueBraking element arrangementsMotor depositionSystem integrationDrive wheel

The invention provides a mechanical and electrical integrated driving wheel system, which comprises a tyre rim, tyre rubber, a transmission main shaft and a brake system, wherein the transmission main shaft of the driving wheel is connected with a driving motor system, a speed-reducing torque-increasing system and the brake system; and the driving motor system and the speed-reducing torque-increasing system are integrated in the tyre rim. The wheel changes the condition that only the brake system is arranged in the prior art; the driving motor system and the speed-reducing torque-increasing system are subjected to structural design in an uneven space, and the system integration level is improved; and the wheel has high power density and high universality, and meets the using requirements of most medium and heavy duty wheeled vehicles in China at present.

Owner:CHINA NORTH VEHICLE RES INST

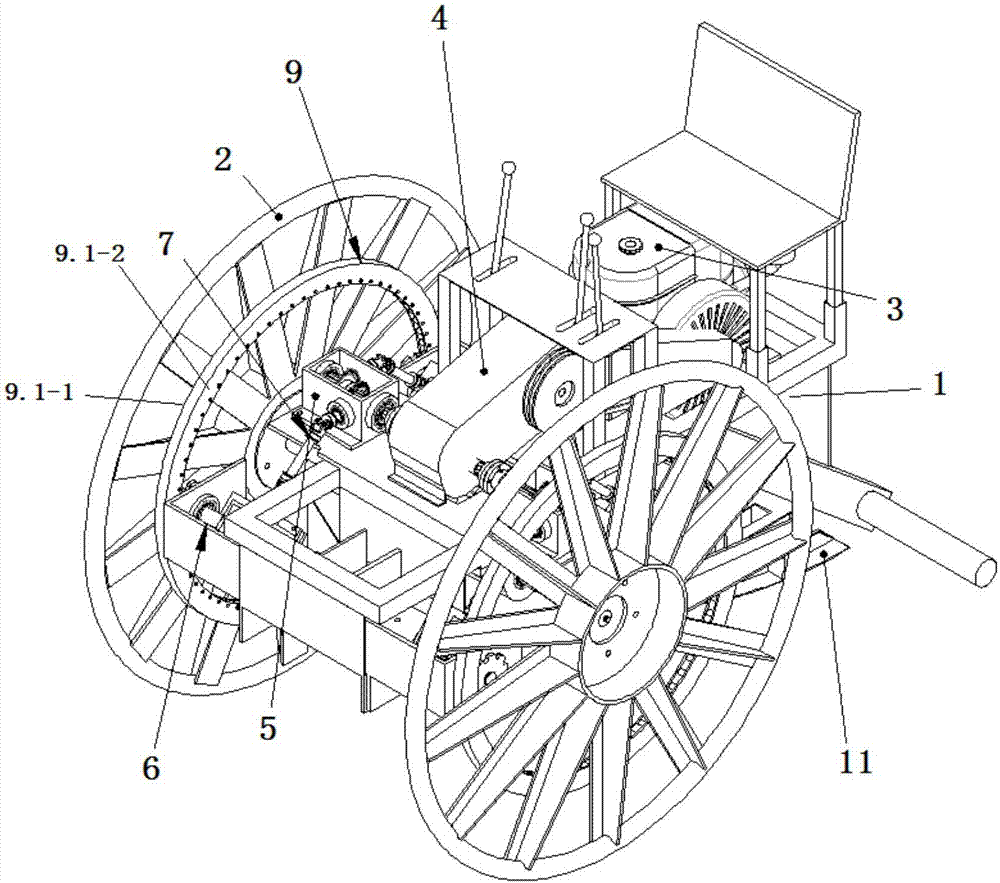

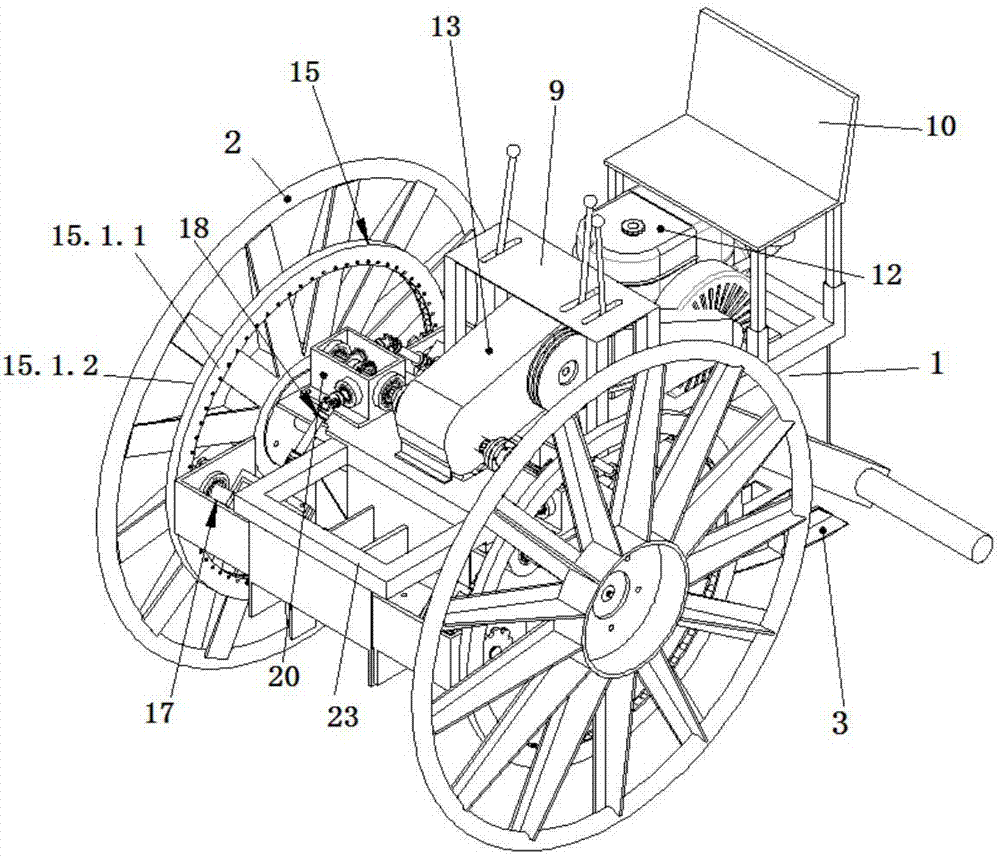

Agriculture multifunctional platform

PendingCN107371427AEasy to assembleEasy to replaceAgricultural undercarriagesAgricultural engineeringDistributed power

The invention discloses an agriculture multifunctional platform which comprises a framework. Main wheels are connected with two sides of the framework, a diesel engine, a gearbox, an operation panel and a seat are fixedly connected onto the framework, the gearbox is positioned in the middle of the framework, the operation panel is positioned at the upper end of the gearbox, the seat is positioned at the rear of the operation panel, and transmission gear rings are coaxially fixedly connected with the inner sides of the main wheels; two transmission gears for distributing power are arranged on the left side and the right side of the gearbox, and driving shifting wheels are connected with output ends of the transmission gears; an arc-shaped pulling plate is arranged at the bottom of the framework, a hang rod is hinged to the tail of the framework, and a transposition operating rod is connected onto the hang rod. The agriculture multifunctional platform has the advantages that the agriculture multifunctional platform is simple in structure and convenient to use and has multiple functions, and the universality of the agriculture multifunctional platform can be effectively improved; the agriculture multifunctional platform is creatively provided with eccentric driving shafts, tractive driving force of the agriculture multifunctional platform can be effectively increased, and accordingly diversified farming tools can be simultaneously assembled on the agriculture multifunctional platform.

Owner:彭广平

Pitching transferring integrated waist structure of human-like robot

The invention relates to a waist structure of robot whose pitching and turning motions are integrated, belonging to the robot technique. Wherein, the angle contact ball bearing is inside the end cover, to be fixed via binding ring and end cover axle; the left part of thorax plate and the left part of connecting plate are connected by the end cover axle; the stable wheel of second harmonic reducer is connected to the right part of connecting plate; the movable wheel of second harmonic reducer is connected to the right upright plate of thorax plate; the input axle sleeve of second harmonic reducer is sheathed on the output axle of pitching driving motor; the stable wheel of first harmonic reducer is fixed to the cover plate of abdominal cavity; the movable wheel of first harmonic reducer is connected to the connecting plate; the input axle of first harmonic reducer is sheathed on the output axle of transfer driving motor. The invention uses integrated structure, while the pitching driving motor and the transfer driving motor are serially connected to themselves harmonic reducers coaxially, with large motion range. Said waist structure can meet the pitching and transfer demands in wide range.

Owner:SHANGHAI JIAOTONG UNIV

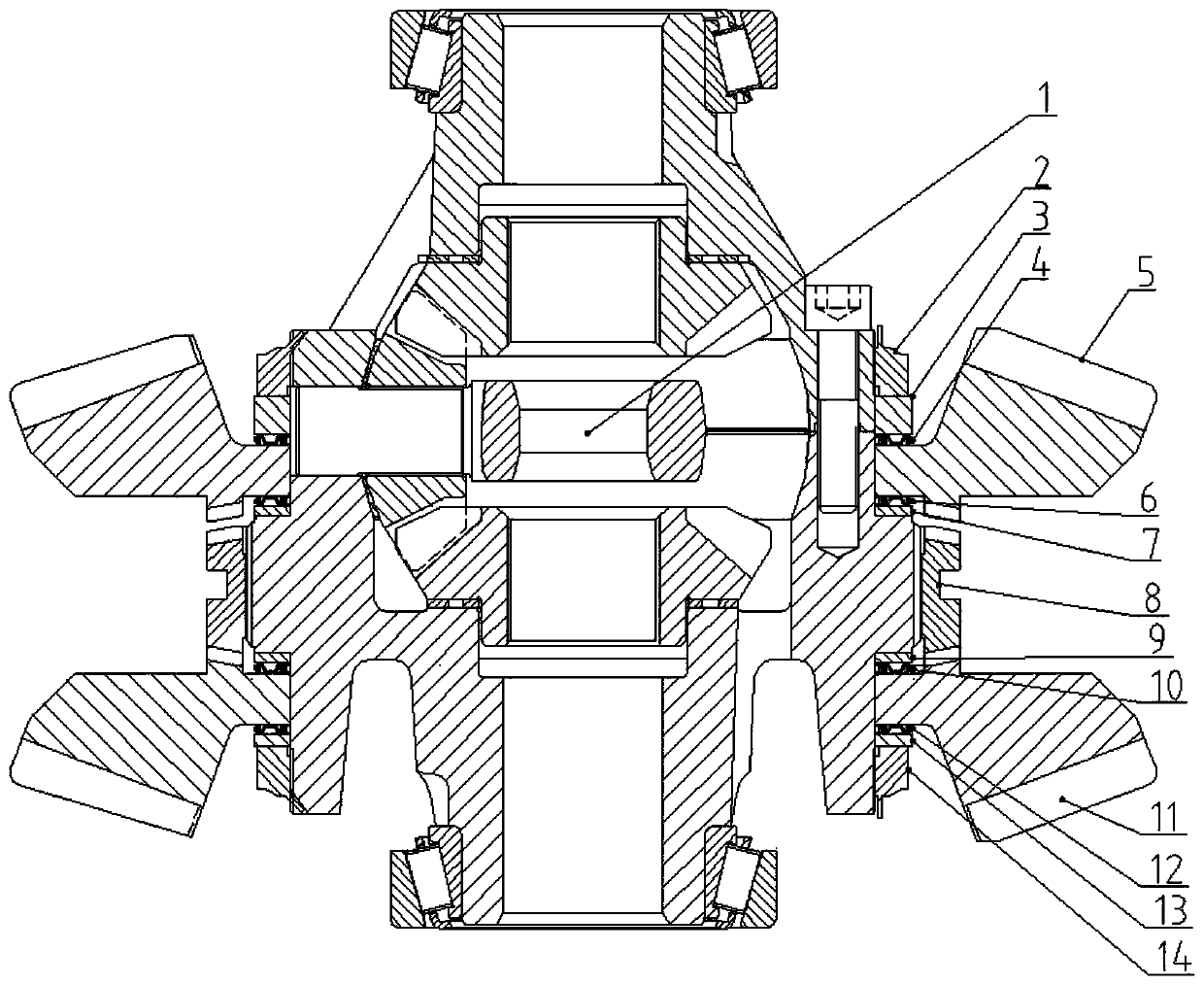

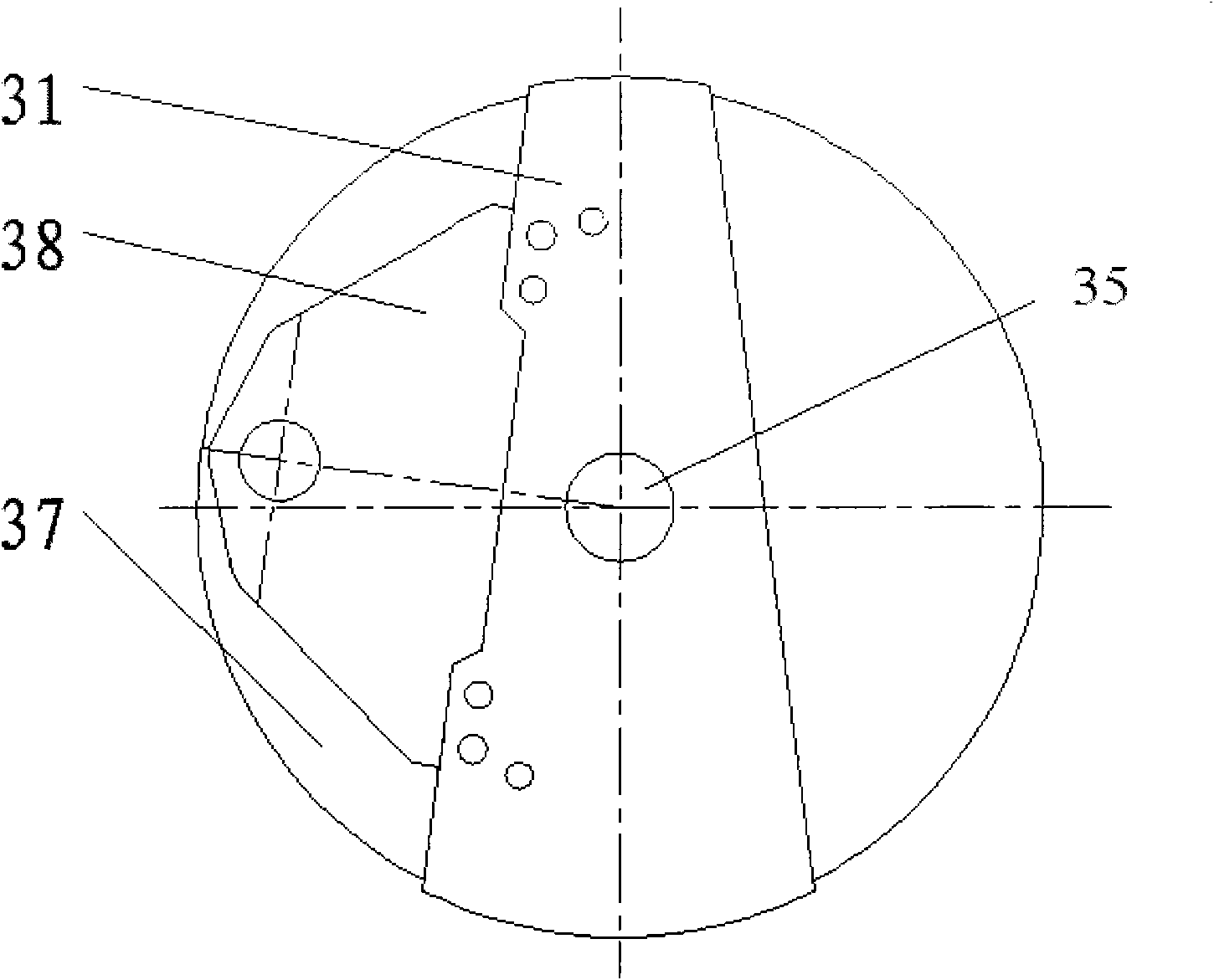

Driving and steering integrated wheel of moon craft

InactiveCN100364856CRealize drivingRealize steering movementExtraterrestrial carsBall bearingGear wheel

A driving and steering integrated wheel for the moon exploration car is mainly composed of 31 parts including rim, external and internal sealing plate, hub, drive set, connecting frame, ball bearing, two DC speed-reducing motors for drive and steering, harmonic speed reducing gear, harmonic speed reducing wave generator, etc.

Owner:SHANGHAI JIAOTONG UNIV

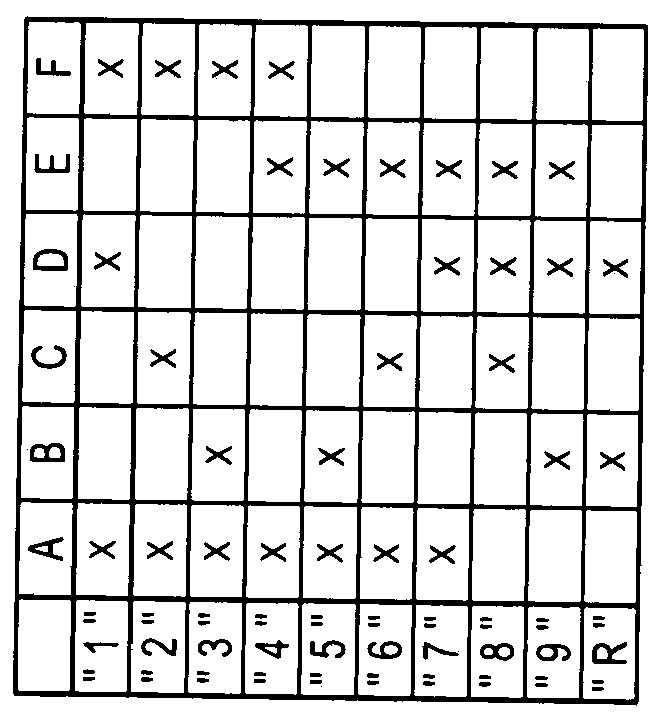

Method and control unit for operating transmission

ActiveCN111255887AIncreased drive torqueLow costGearing controlTransmission elementsHydraulic pumpPhysics

A method for operating a transmission is provided, which includes a hydraulic pump drivable on a transmission-input end and at least one form-locking shift element. The shift element comprise two shift element halves that can be connected with each other in a locking mode. One of the shift-element halves is displaceable between a first end position and a second end position with a hydraulic pressure of the hydraulic pump. The end positions are corresponding to the closing operation state and the opening operation state of the shift element. The current position of the shift-element half is detected with a sensor and is stored as a specified end-position value if the shift-element half is located in one of the end positions, the hydraulic pump is driven, and the shift-element half is actuated, with the hydraulic pressure, towards the current end position. When the hydraulic pressure is less than a threshold value, a deviation is determined between the current position of the shift-element half and the specified end-position value. The hydraulic pressure is increased when the deviation is greater than a threshold value.

Owner:ZF FRIEDRICHSHAFEN AG

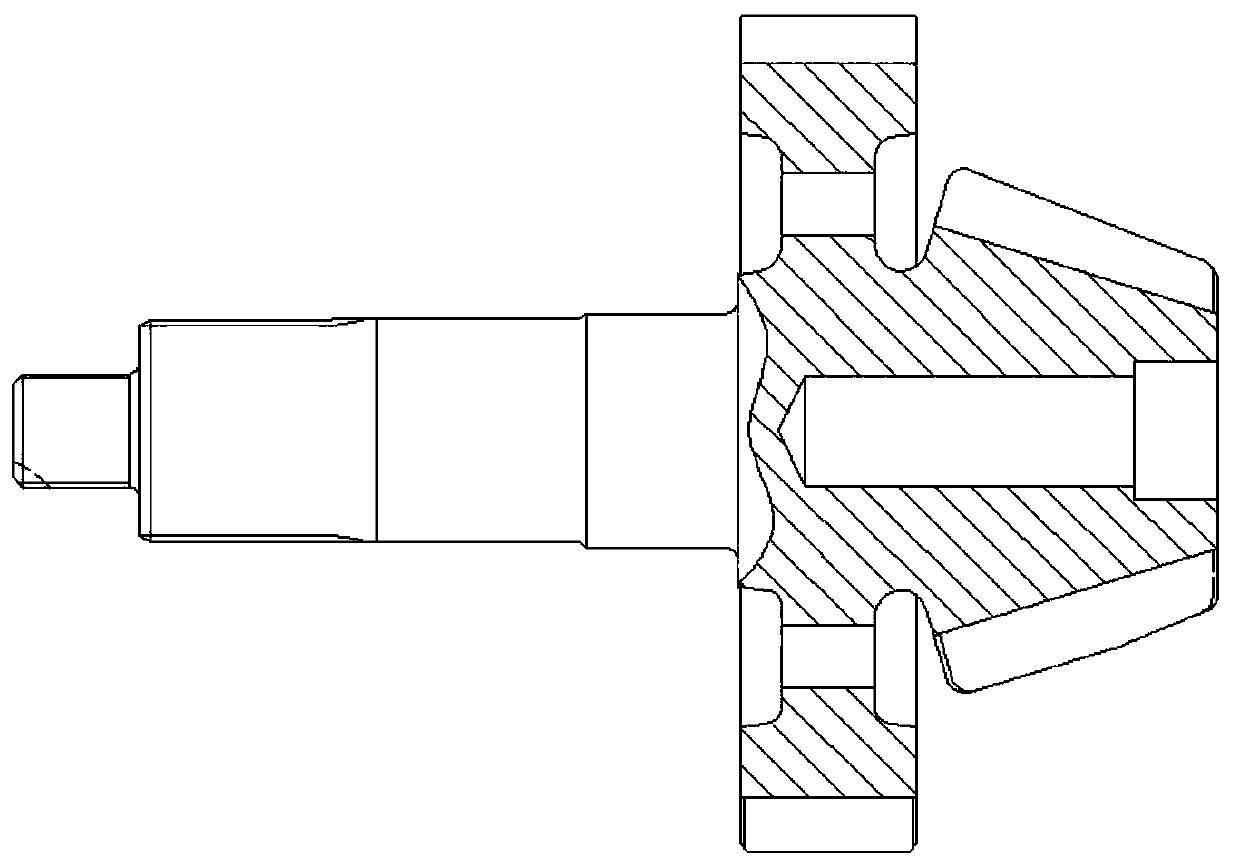

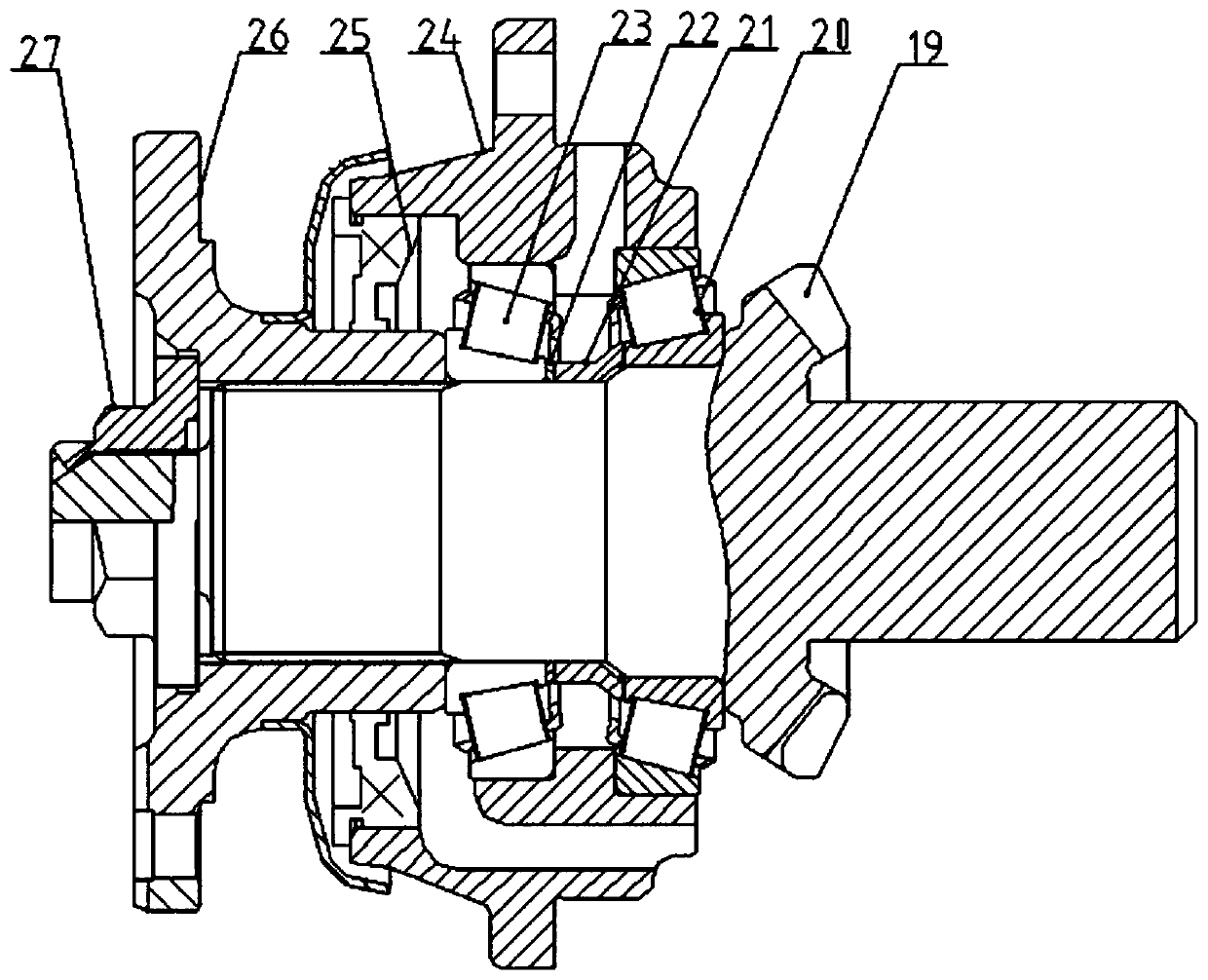

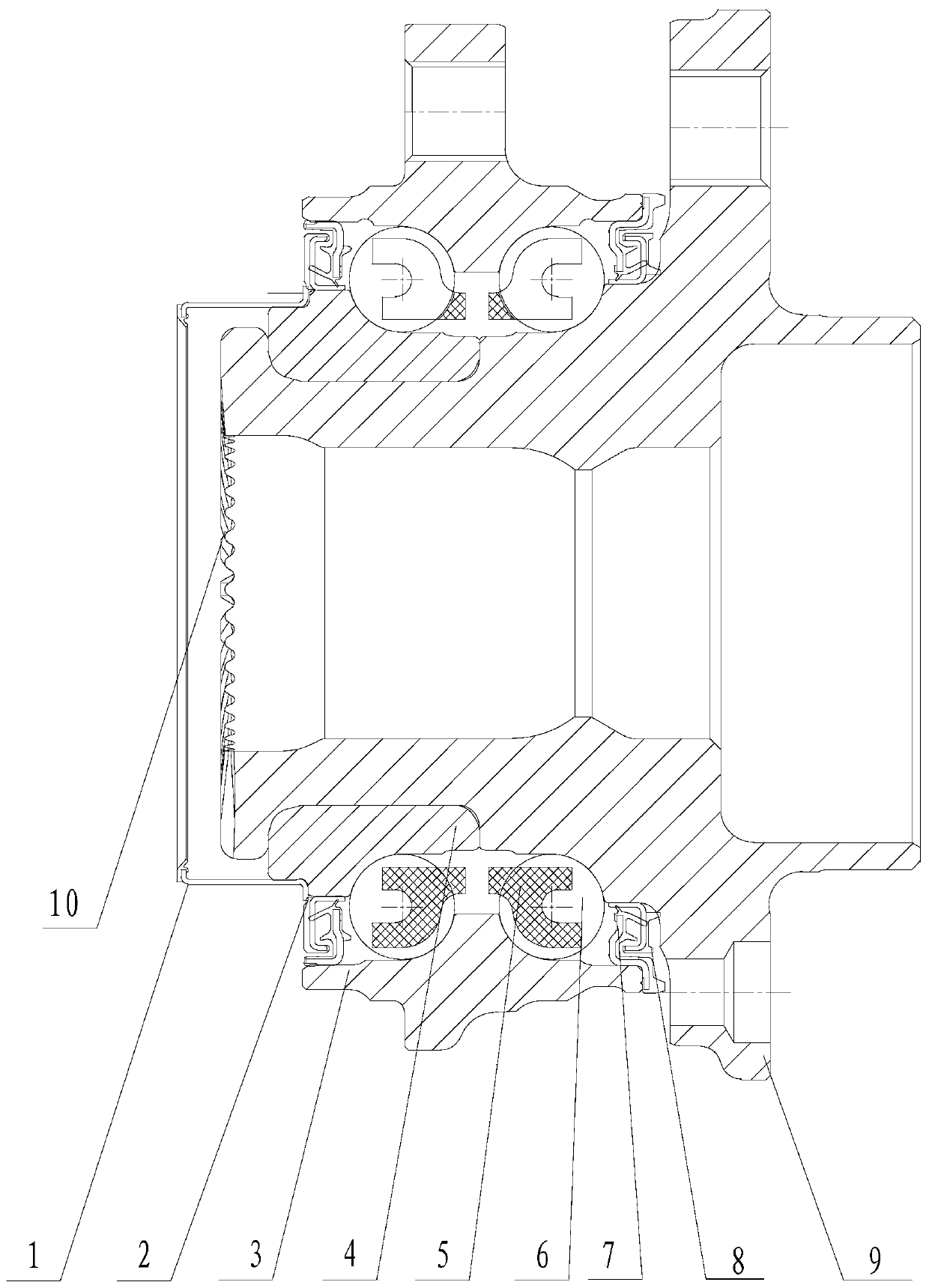

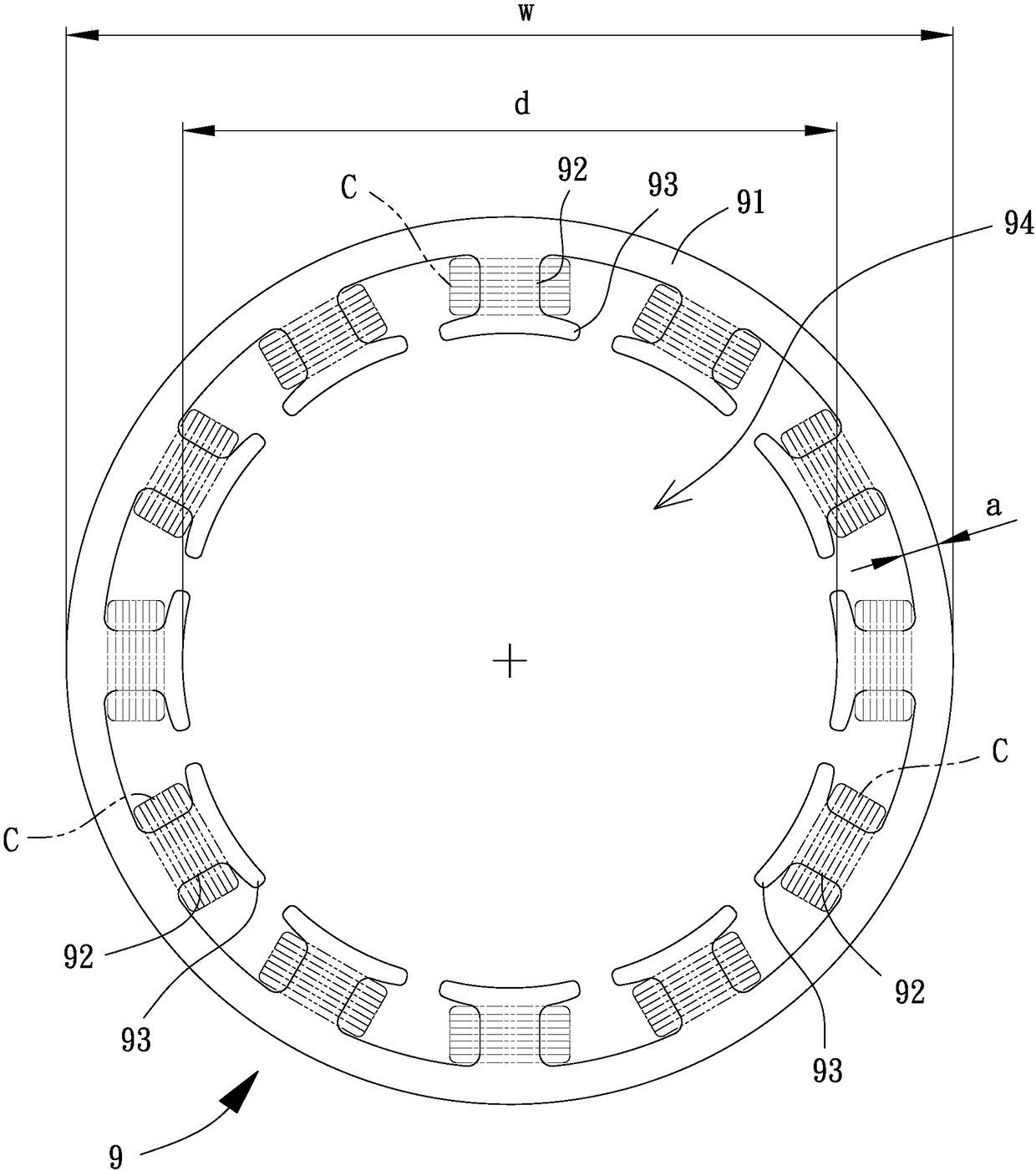

End face spline type hub bearing unit

PendingCN111255800AIncreased drive torqueImprove NVH performanceHubsBall bearingsStructural engineeringTorque transmission

The invention discloses an end face spline type hub bearing unit, and relates to the field of hub bearings. The end face spline type hub bearing unit comprises an outer ring, an inner ring, a flange plate and an end face spline, an outside roller path is arranged between the shaft neck root of the flange plate and the outer ring of a hub bearing, the outside roller path and an inside roller path arranged between the inner ring and the outer ring form a double roller path, a roll rim is arranged at the side, close to an inner side sealing ring, of the flange plate, and the end face spline is arranged on the side end face and used for being directly connected with a drive shaft. The end face spline type hub bearing unit has the beneficial effects that the end face spline of the hub bearing unit can be connected with the drive shaft, is used as a transmission device for torque transmission to lift a drive torque, and compared with existing inner spline transmission, torque driving is obviously improved; the full vehicle NVH performance is effectively improved, the disassembly and disassembly convenience in the full vehicle production and maintenance process is improved, the weight ofthe hub bearing is reduced, and light weight is realized; and the hub bearing with end face spline teeth can effectively eliminate drive clearances, and eliminate drive abnormal sound.

Owner:ZHEJIANG WANXIANG PRECISION IND +1

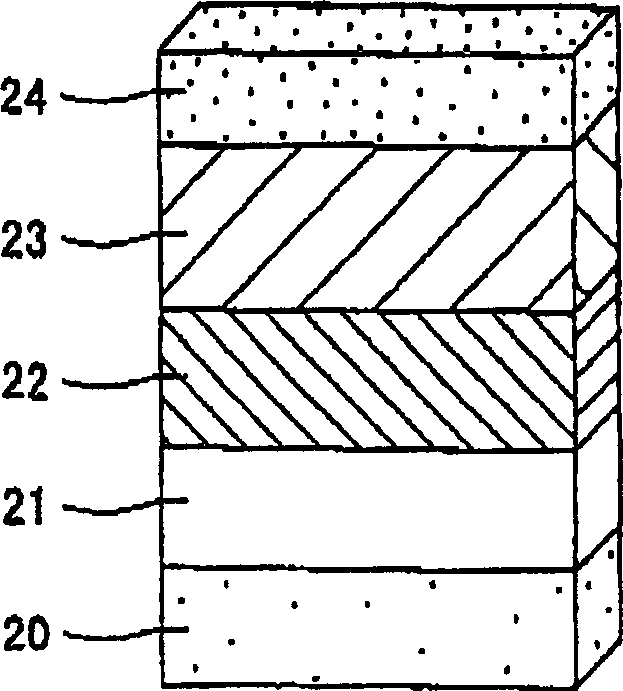

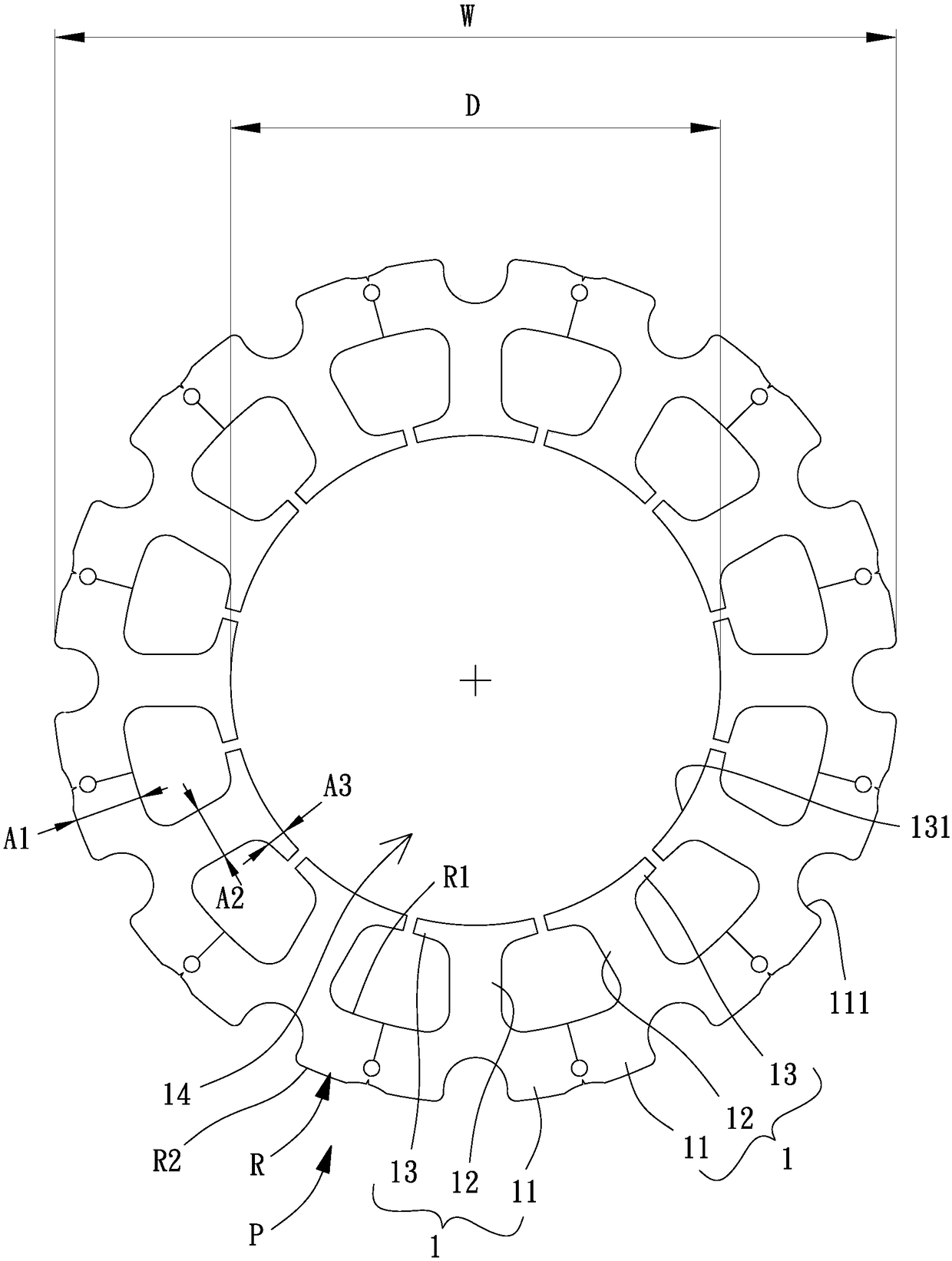

Silicon steel plate for motor stator

InactiveCN108155732AIncreased drive torqueIncrease the winding spaceMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsMagnetic polesPole piece

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com