Co-Ni-base alloy

A technology based on alloys and alloys, which is applied in the field of manufacturing springs, can solve the problems of limited space in mechanical watches, the inappropriate thickness or width of springs, and the lack of springs, etc., to increase the moment of inertia, reduce the change in travel time, and achieve high The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

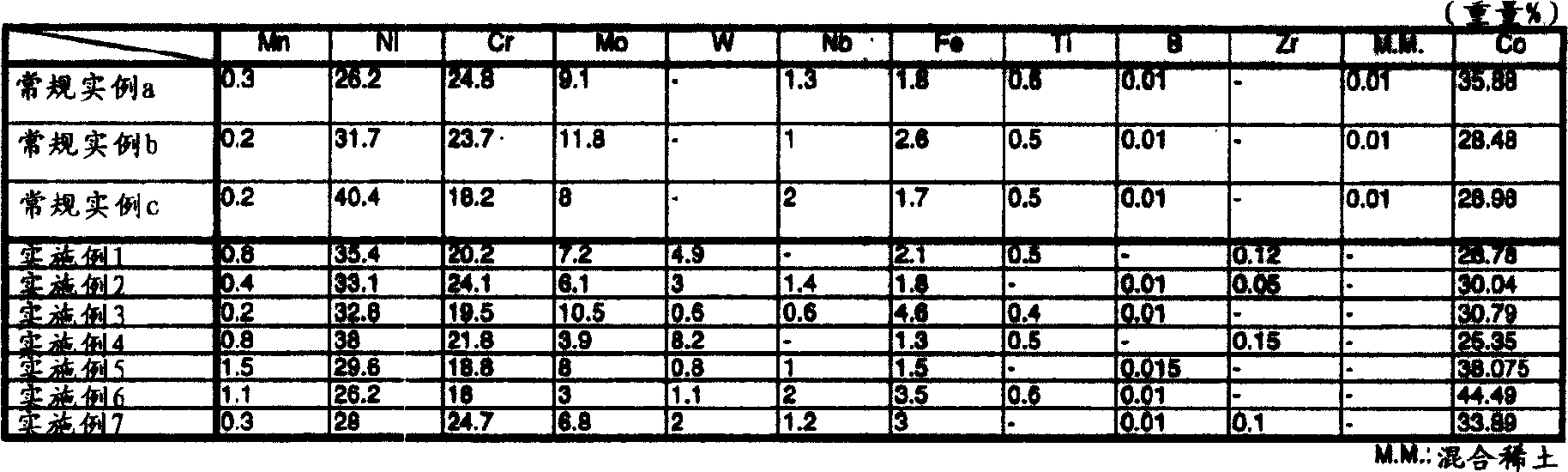

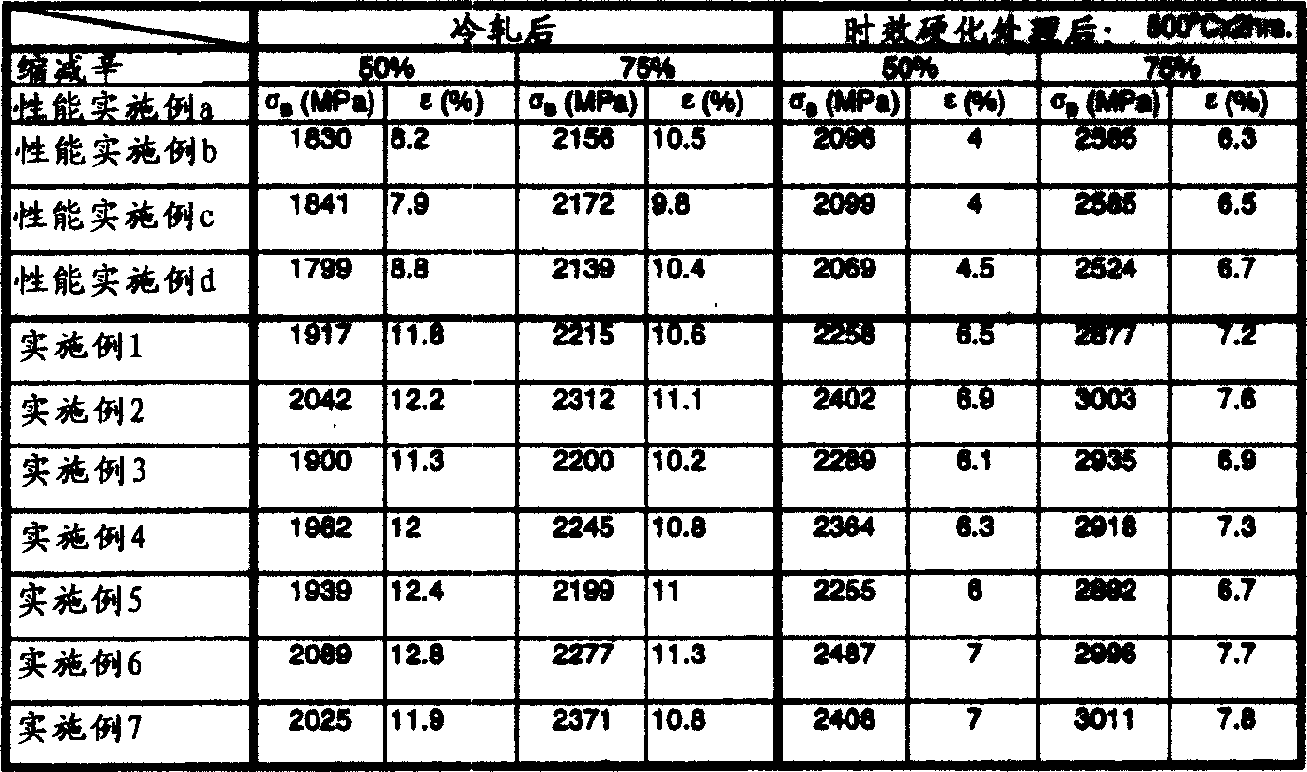

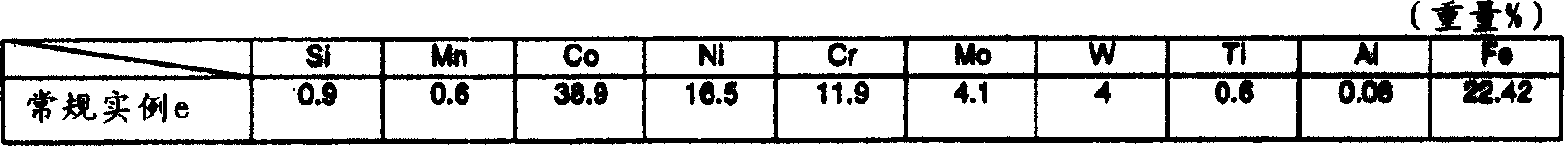

[0032] The composition of the Co-Ni base alloy of the present invention includes at least Co, Ni, Cr, Mo, W and Fe, and the weight percentage of each component is: 25% to 45% of Co, 25% to 40% of Ni, 18 % to 26% of Cr, 3% to 11% of Mo, 0.5% to 9% of W, wherein the total weight of Mo and W is 4% to 13%, and 1.1% to 5% of Fe, and the parent phase There are fine deformation twins. Preferably, the composition of the above alloy also includes one or more elements selected from Nb, Mn, B, Zr and Ti, and the weight percentage of the elements contained in the alloy is as follows: 0≤Nb≤2%, 0≤Mn≤2%, 0≤B≤0.02%, 0≤Zr≤0.2%, and 0≤Ti≤1%.

[0033] A spring made of a Co-Ni based alloy having the above composition.

[0034] The alloy used for making the spring in the present invention has good plastic workability and low stacking fault energy, so it has high work hardening performance. When it is subjected to cold plastic working, fine deformation twins are densely formed in the FCC phase, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com