Method for compensation of vibration of horizontal stage electric machine

A compensation method and PTZ technology, applied in the field of vibration compensation, can solve problems such as monitoring performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

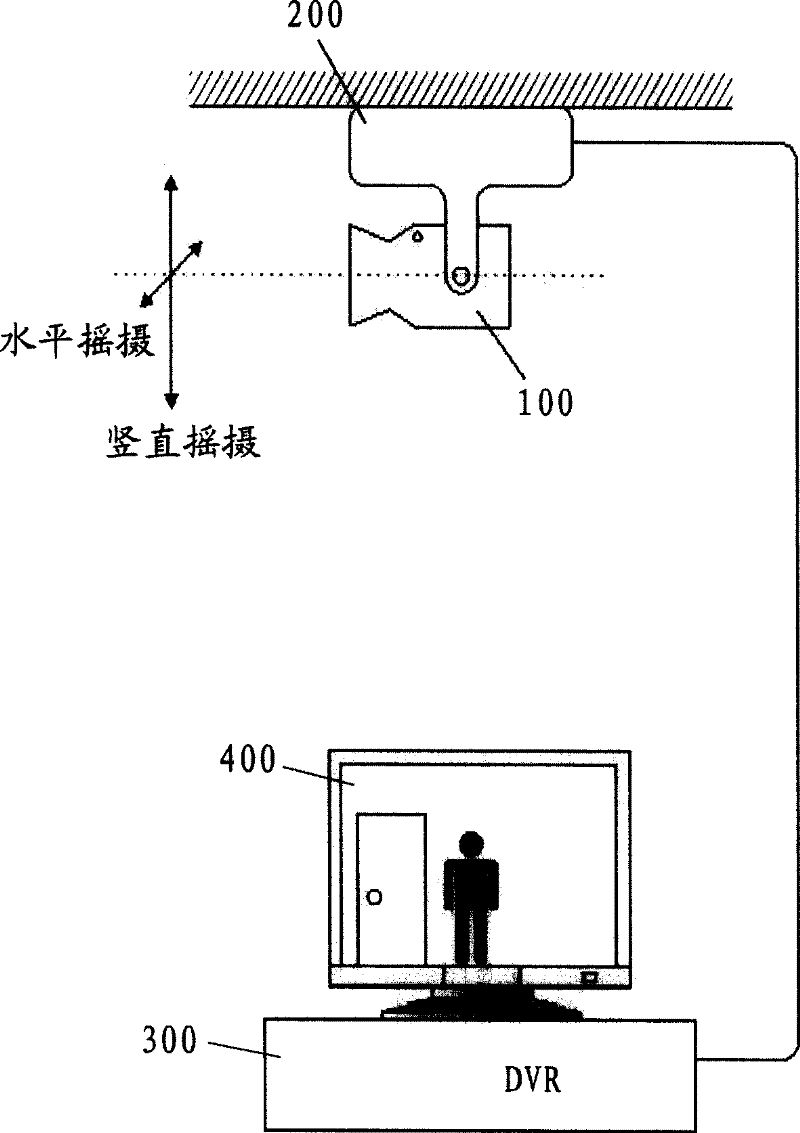

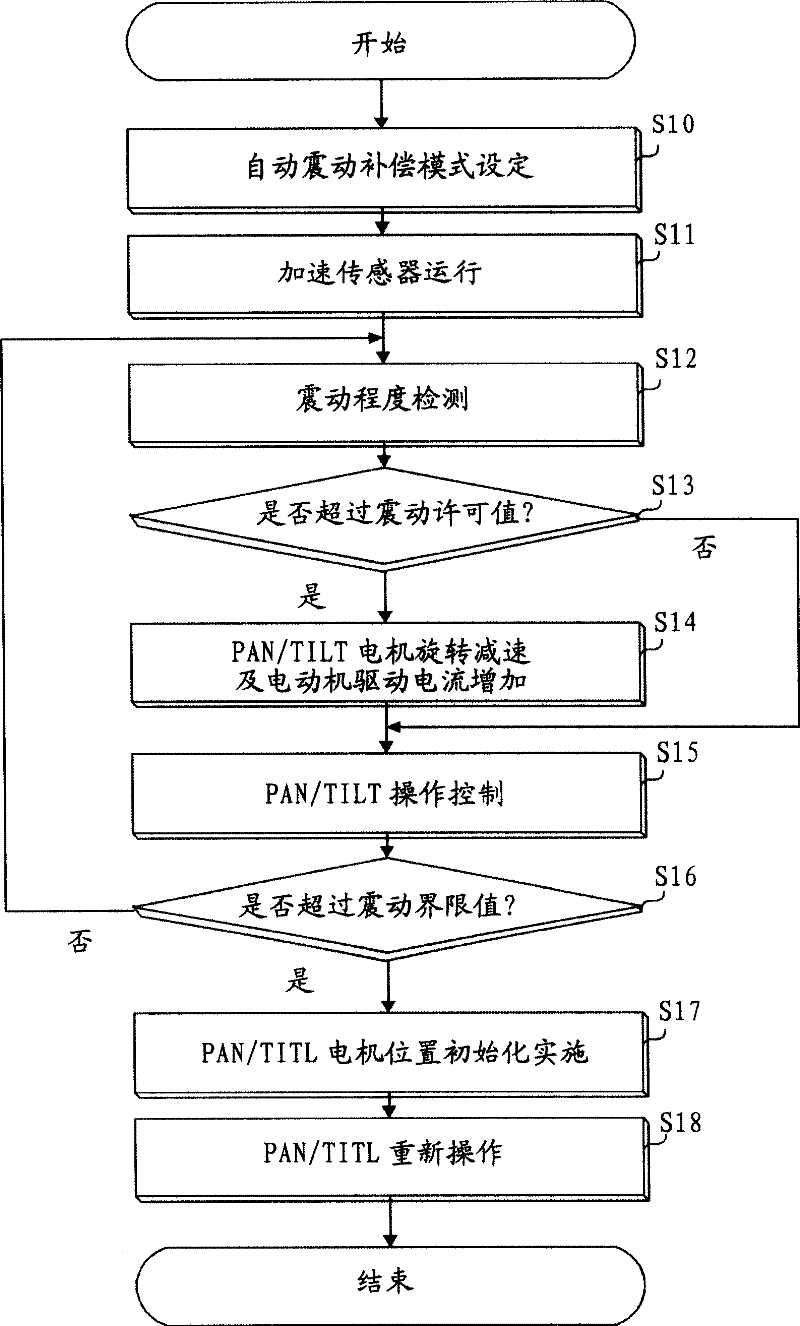

[0023] Hereinafter, an embodiment of the method for compensating the vibration of the pan-tilt motor according to the present invention will be described in detail with reference to the accompanying drawings.

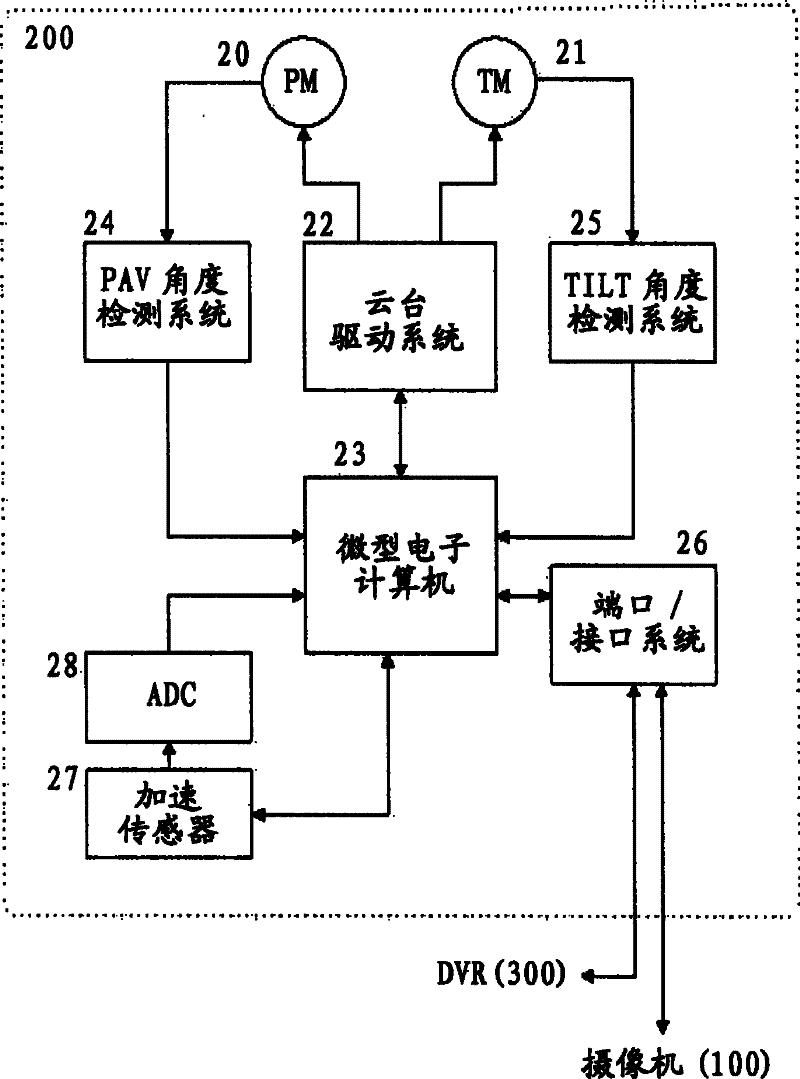

[0024] figure 2 According to the present invention, it is a schematic diagram showing the composition of the pan-tilt applicable to the vibration compensation method of the pan-tilt motor. It is composed of the following contents: panning in the horizontal direction (PAN) motor (PM) 2 0, panning in the vertical direction (TILT) motor (TM) 21, pan-tilt drive system 22, microcomputer 2 3, horizontal Directional pan (PAN) angle detection system 24, vertical direction pan (TILT) angle detection system 2 5 and port / interface system 2 6, meanwhile, acceleration sensor 2 7 and A / D conversion system (ADC) are added 28, etc., including the above content.

[0025] On the one hand, the above-mentioned acceleration sensor 27 is on the above-mentioned cloud platform 200, when it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com