End face spline type hub bearing unit

A hub bearing and spline technology, which is applied in the field of end face spline type hub bearing units, can solve problems such as low torque transmission efficiency, difficult assembly, abnormal driving noise, etc., and achieve elimination of abnormal driving noise, weight reduction of the assembly, and drive The effect of torque boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with accompanying drawing:

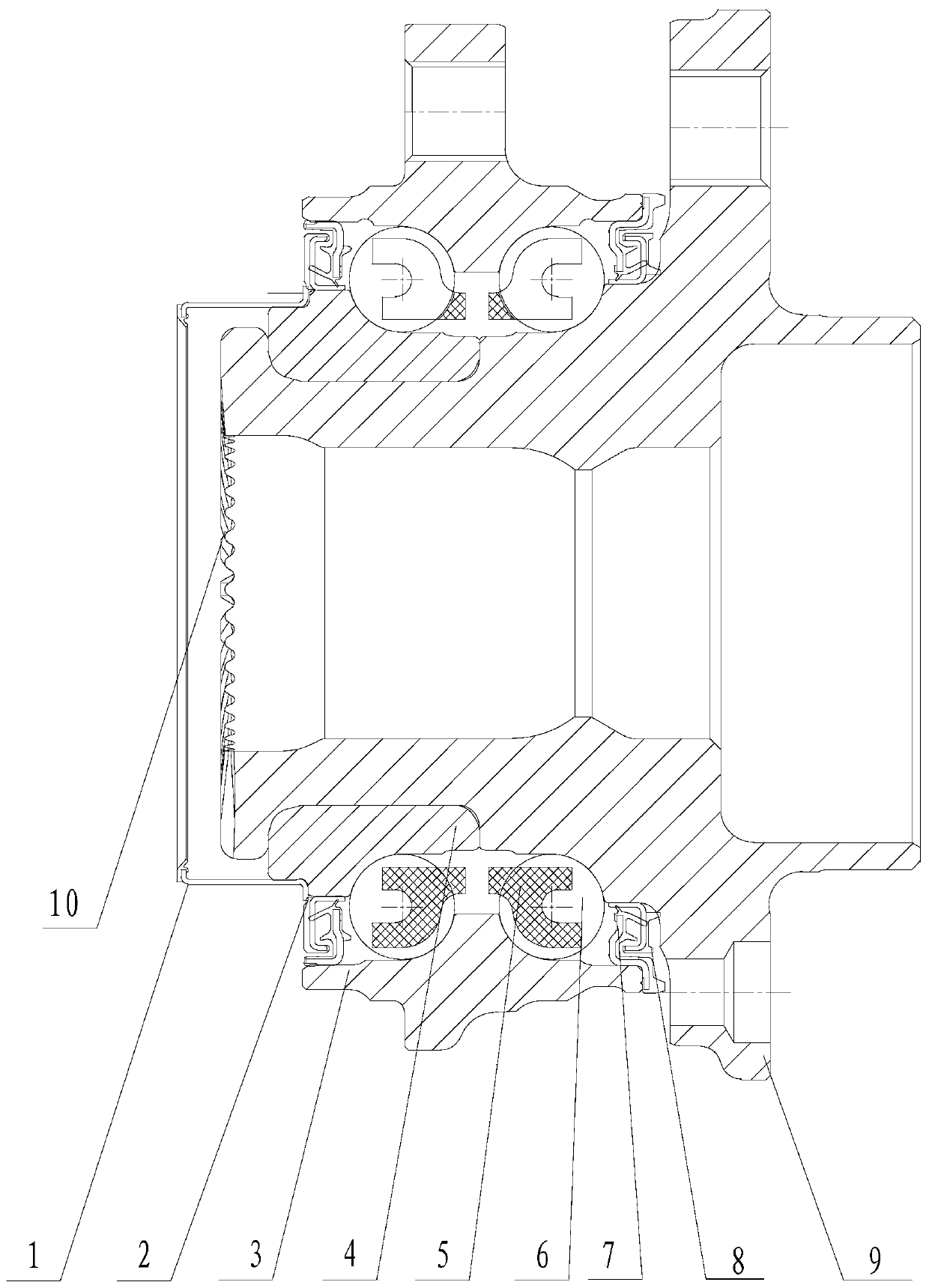

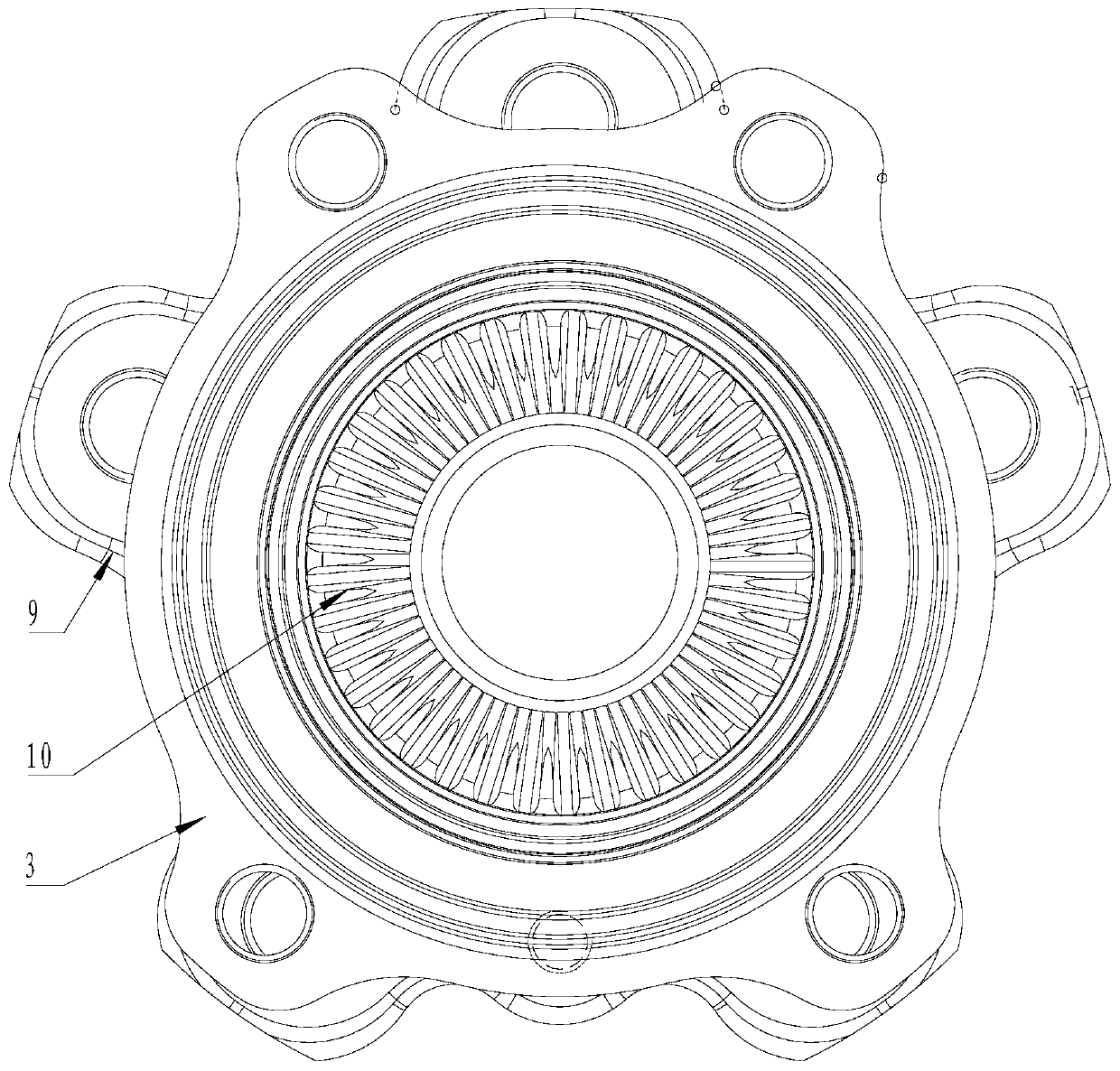

[0013] Embodiment: As shown in the accompanying drawings, this type of end face spline hub bearing unit mainly includes outer ring 3, inner ring 4 flange 9 and end face spline 10, the flange 9 is movable socketed There is an outer ring 3, and an inner ring 4 is provided between the outer ring 3 and the flange 9, which is nested with the flange 9 in a slotted position, and the root of the journal of the flange 9 is in contact with the flange 9. The outer raceway is set between the hub outer ring 2, and the outer raceway and the inner raceway arranged between the inner ring 4 and the outer ring 3 form a double-row raceway, which is used to install the rolling body 6, and the cage 5 is set on the The rolling body 6 is fixed outside; the outer circumference of the inner ring 4 is covered with an inner sealing ring 1, and the flange 9 and the inner ring 4 are connected and sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com