Patents

Literature

60results about How to "Increase the winding space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

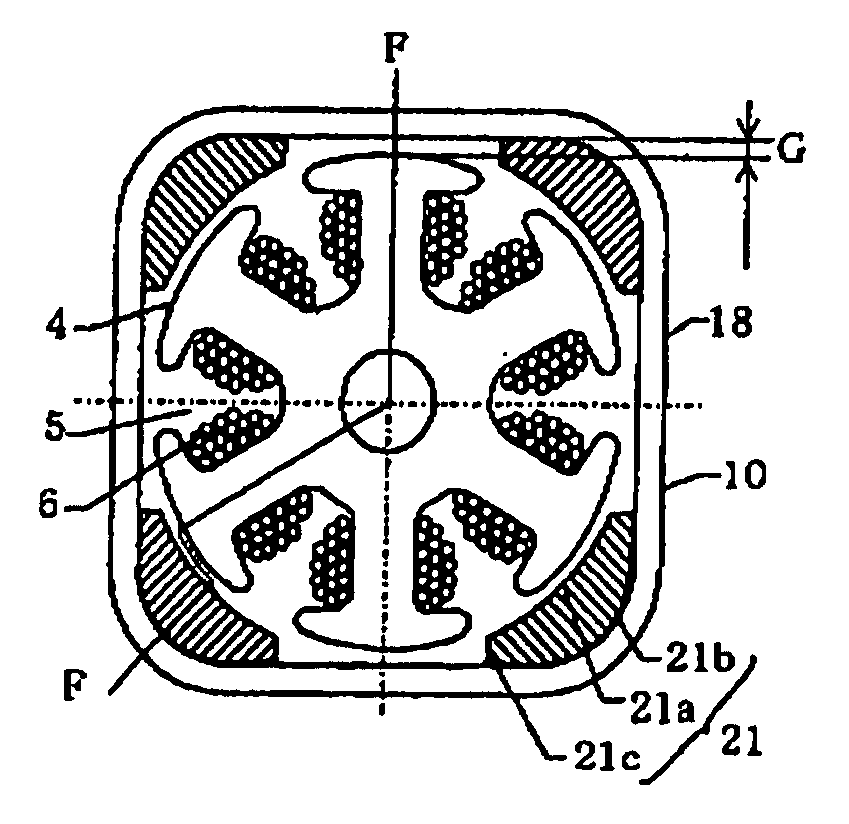

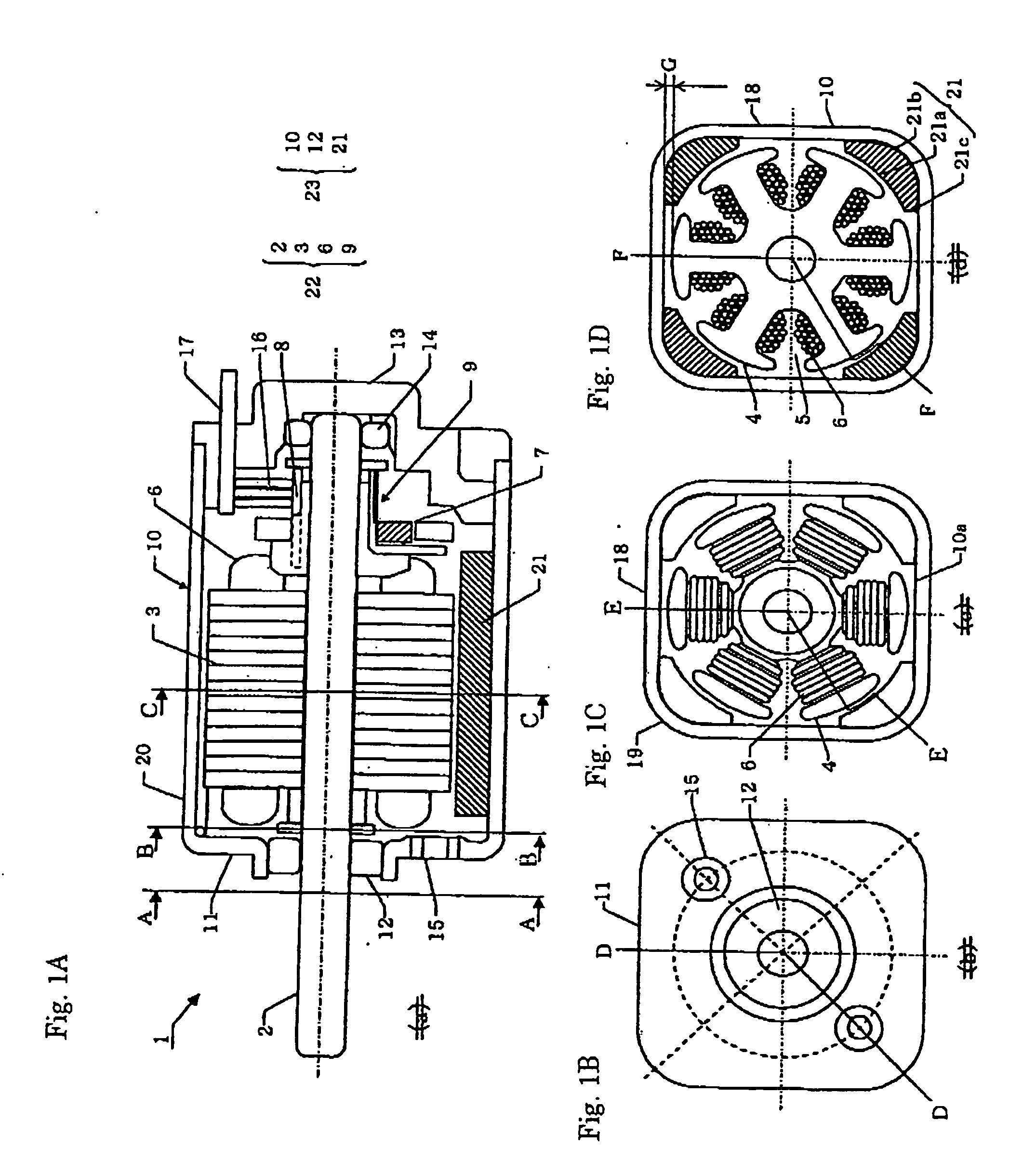

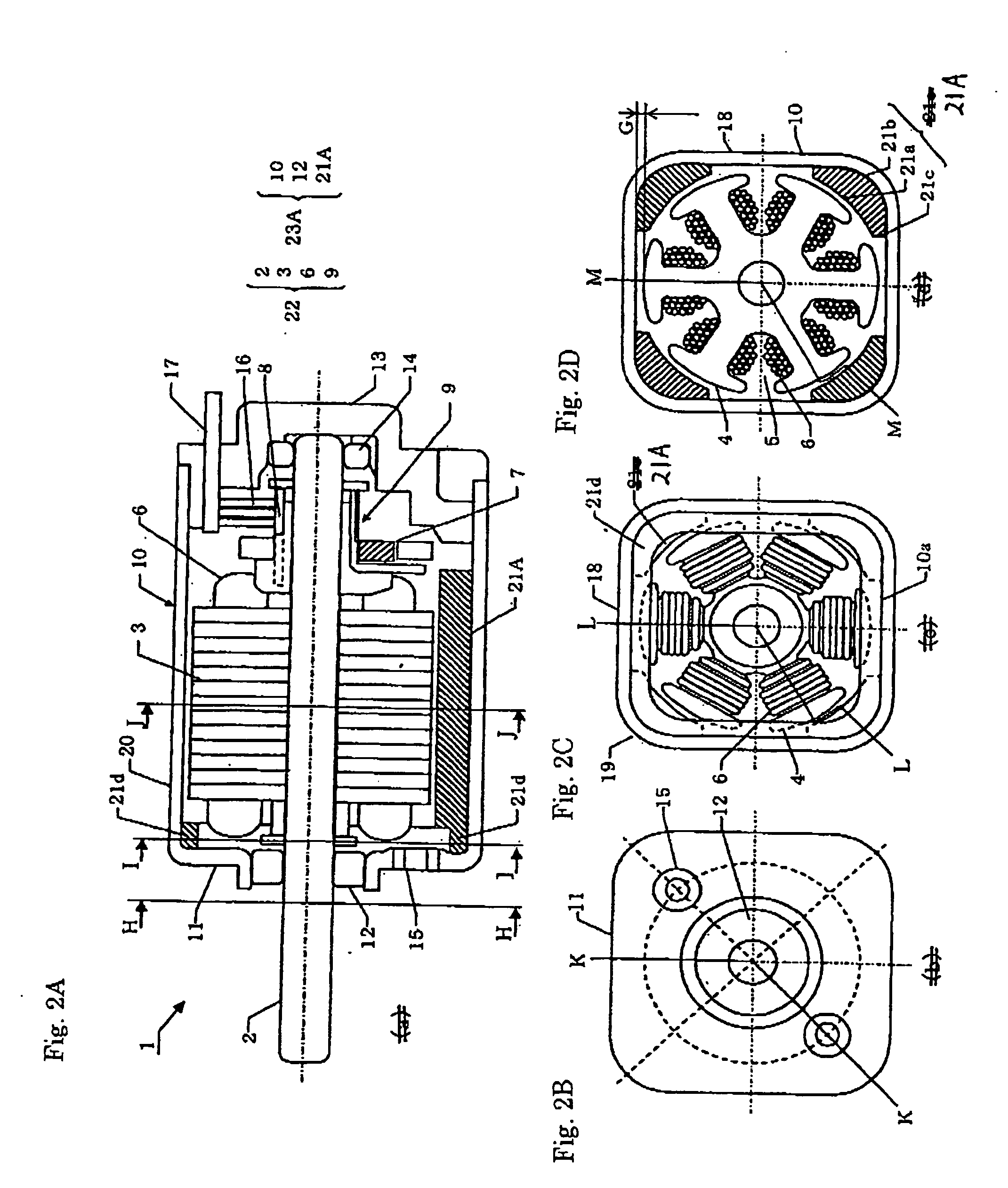

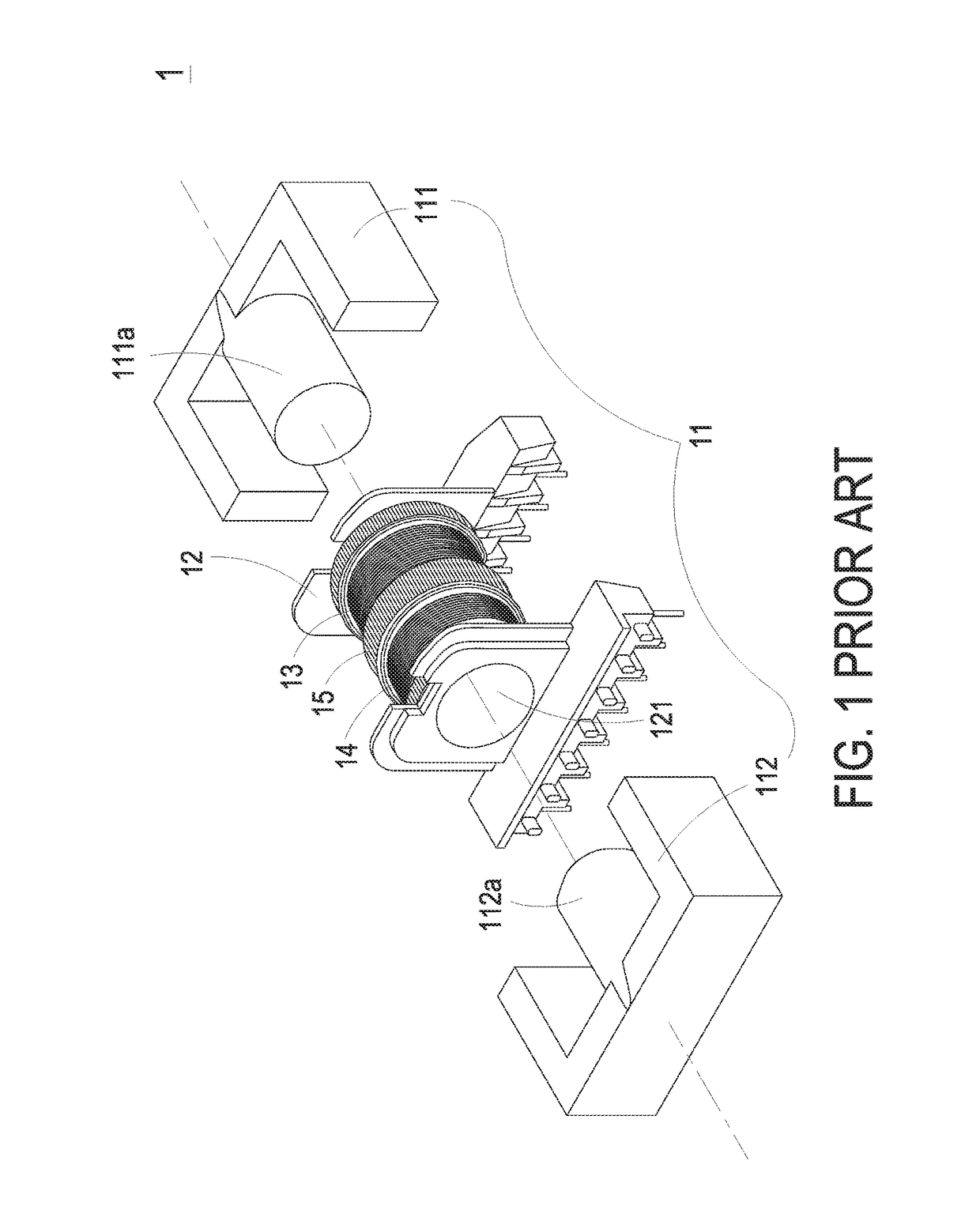

Small DC motor

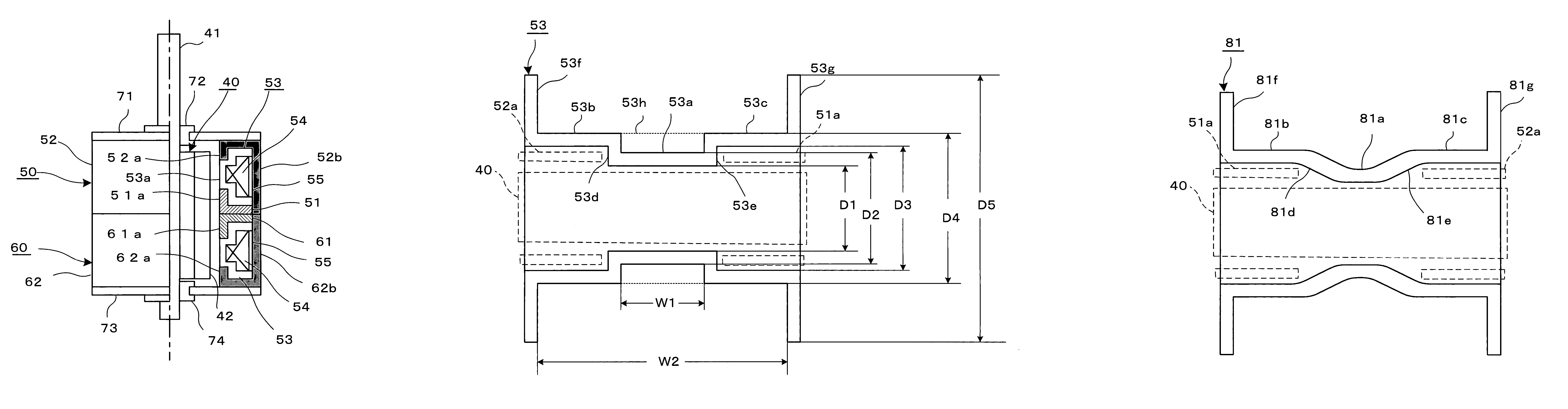

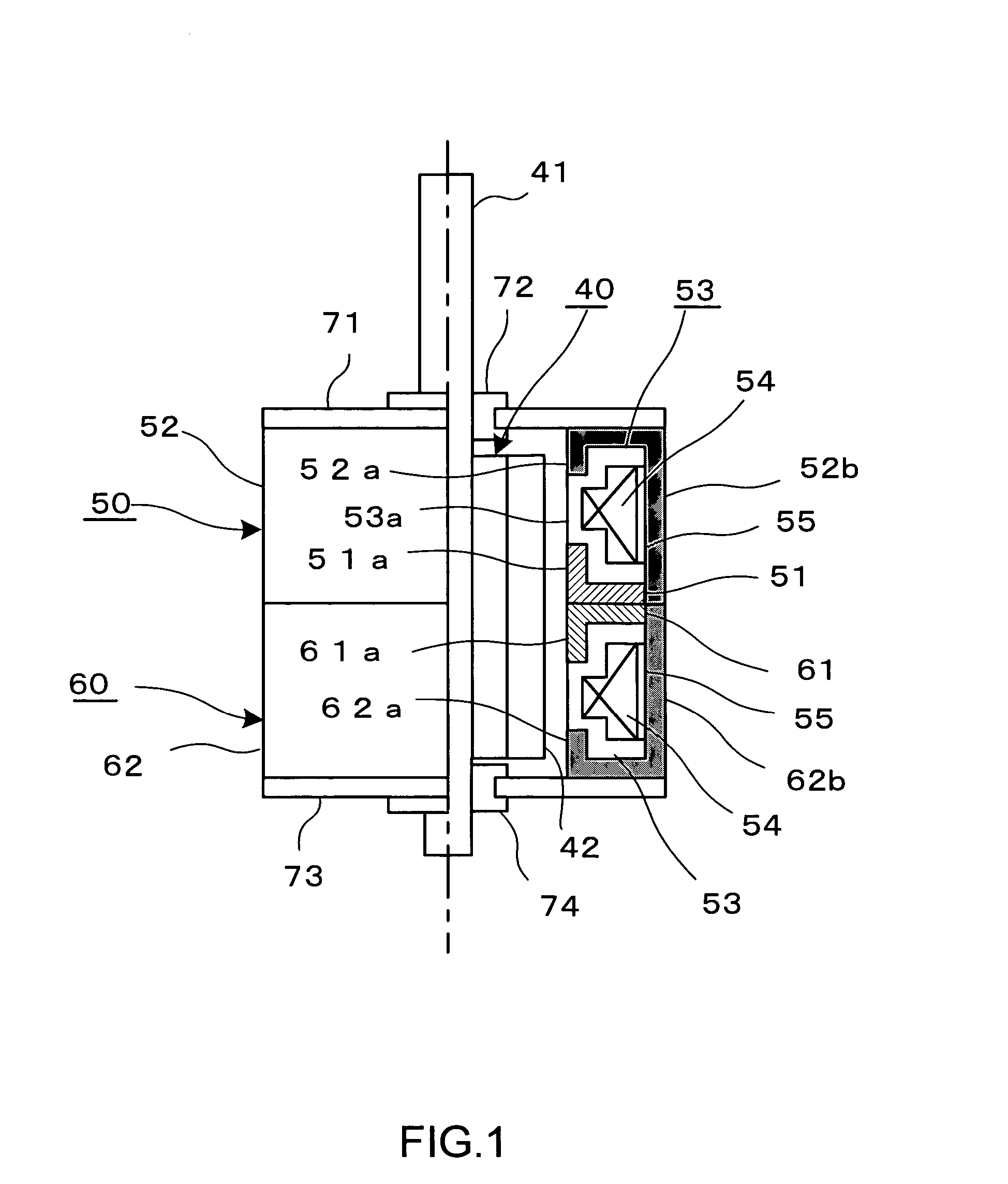

ActiveUS20070007838A1Quantity minimizationReduce motor sizeElectrostatic generators/motorsDC commutatorEngineeringDC motor

A small DC motor includes: a motor frame including a cylindrical portion, the cylindrical portion having a constant thickness and having a cross section in a shape that includes four sides and connecting portions, each of the connecting portions connecting adjacent two of the four sides and being located inward from a corresponding corner in a quadrangle including the four sides; field magnets; and an armature assembly, wherein the field magnets are provided so as to be spaced apart from each other, and the small DC motor includes an air gap between each of the four sides and a radially outermost surface of the armature assembly, the air gap being a minimum size needed to rotate the armature assembly.

Owner:MINEBEA MOTOR MFG

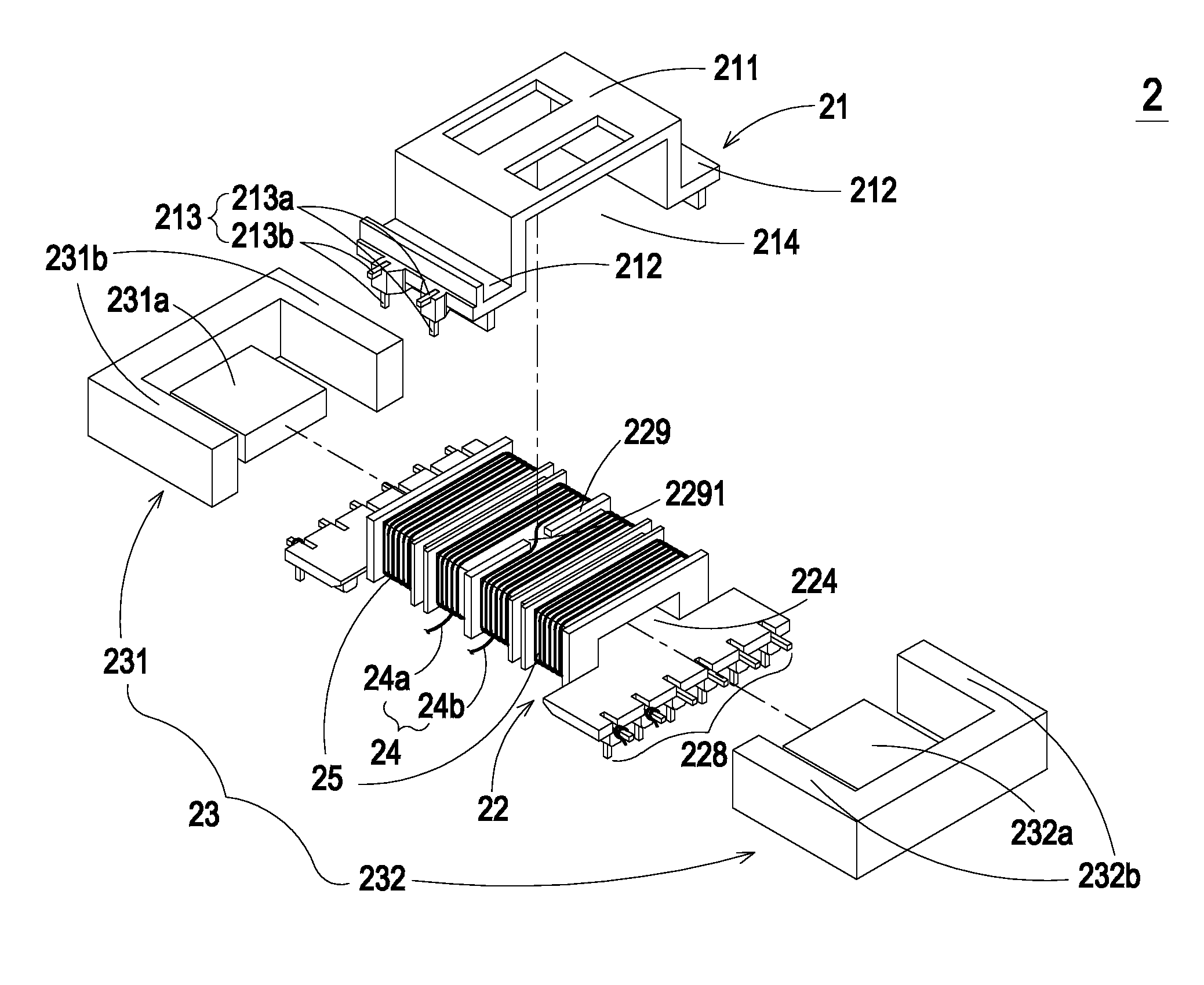

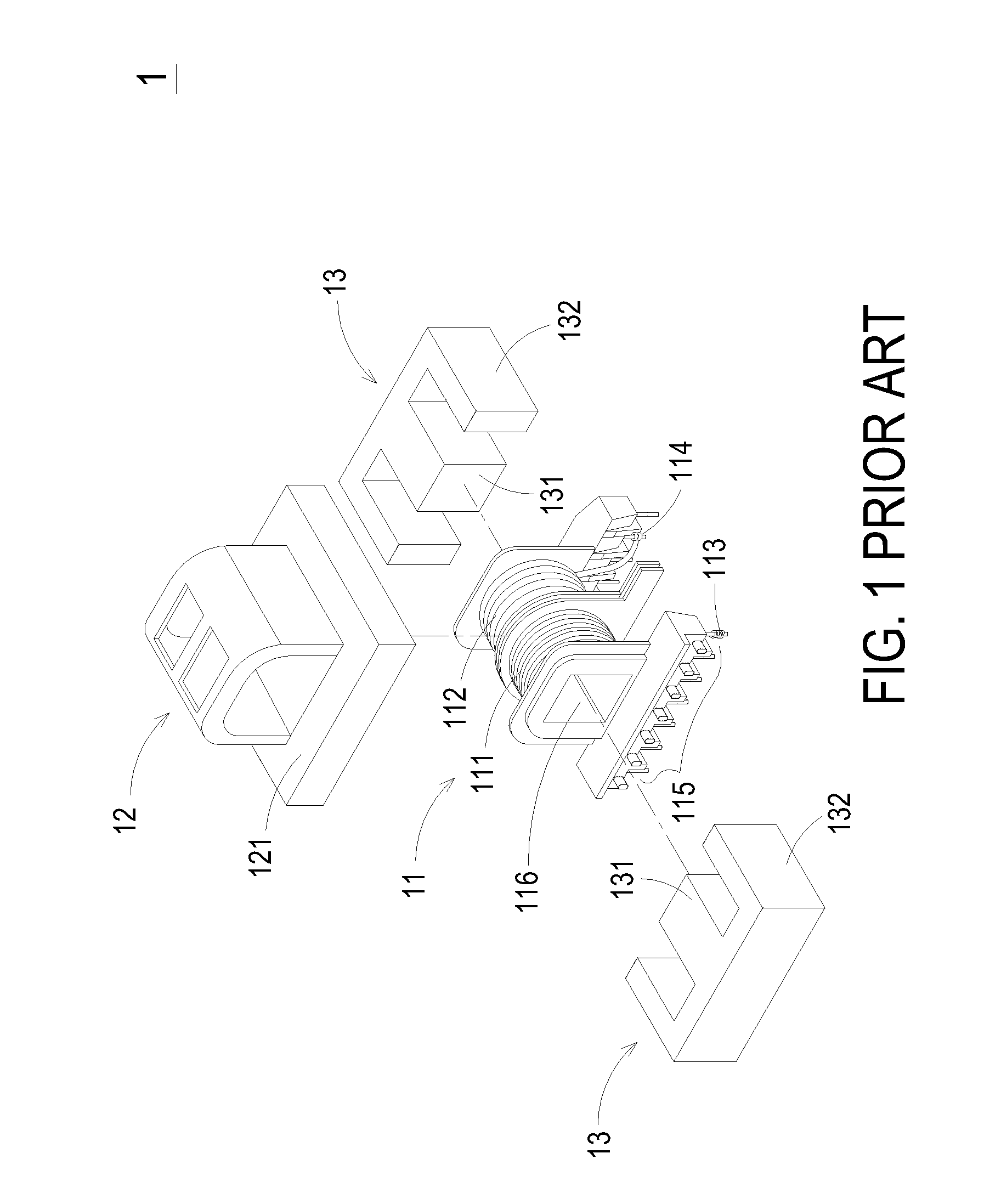

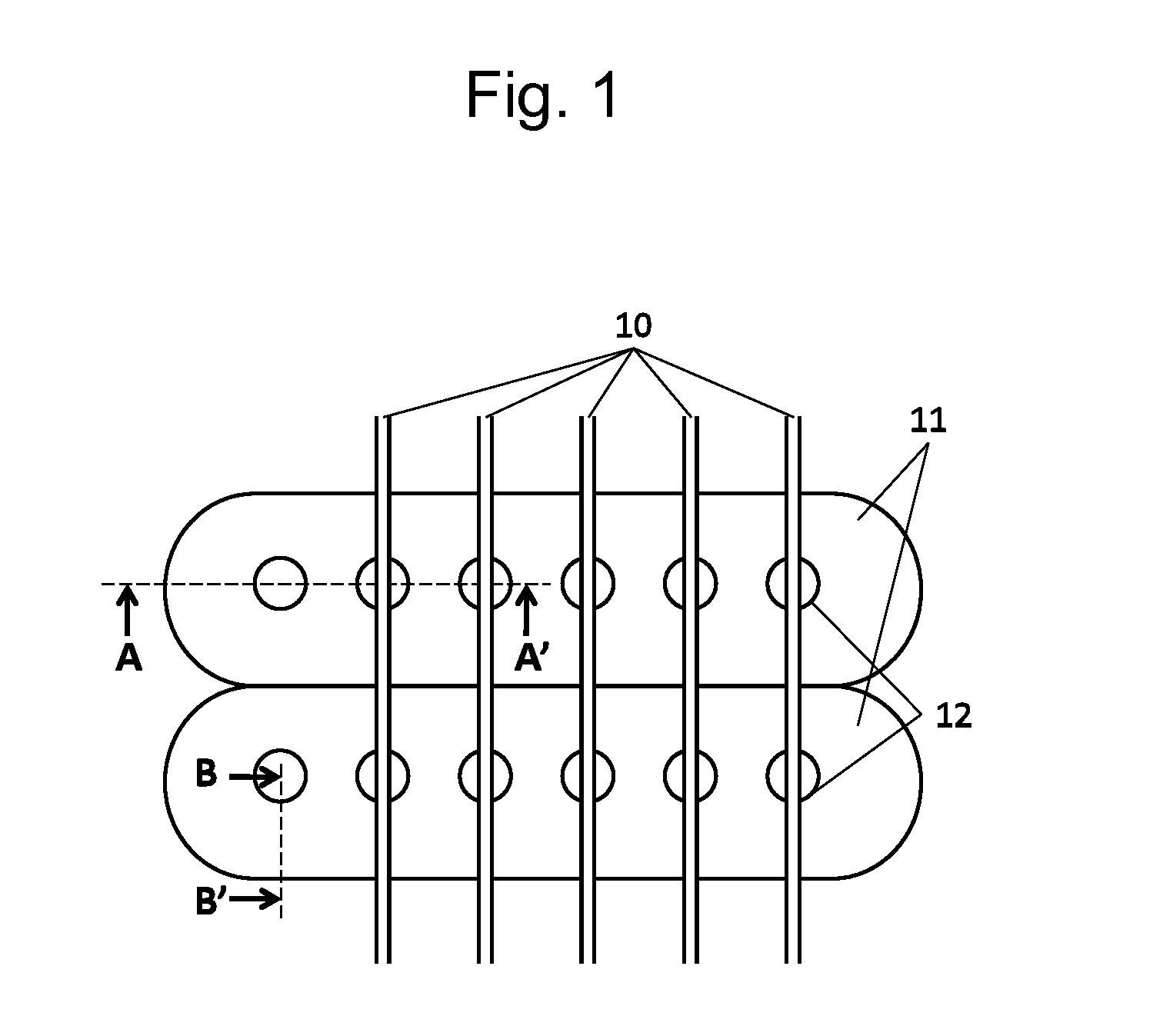

Transformer

ActiveUS8054152B2Control leakageIncrease the winding spaceTransformers/reacts mounting/support/suspensionTransformersBobbinTransformer

A transformer includes a covering member, a bobbin, a primary winding coil, plural secondary winding coils, and a magnetic core assembly. The covering member includes plural pins. The bobbin is combined with the covering member, and includes a bobbin body and a channel. A first winding section and plural single-trough second winding sections are defined on the bobbin body. The single-trough second winding sections are arranged at bilateral sides of the first winding section. The channel runs through the bobbin body. The primary winding coil is wound around the first winding section of the bobbin, and connected with the pins. The secondary winding coils are wound around respective single-trough second winding sections of the bobbin. The magnetic core assembly is partially embedded into the channel of the bobbin.

Owner:DELTA ELECTRONICS INC

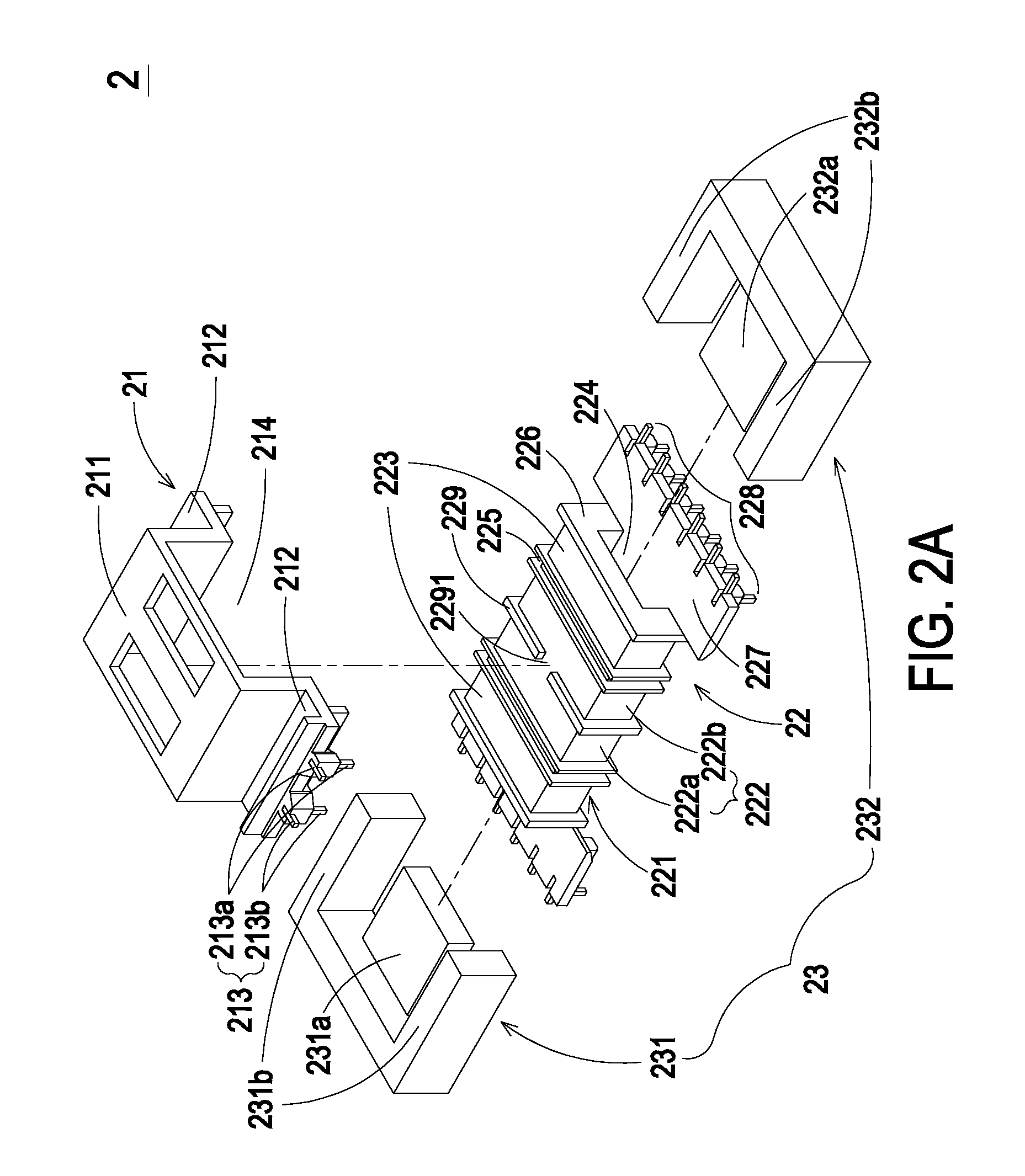

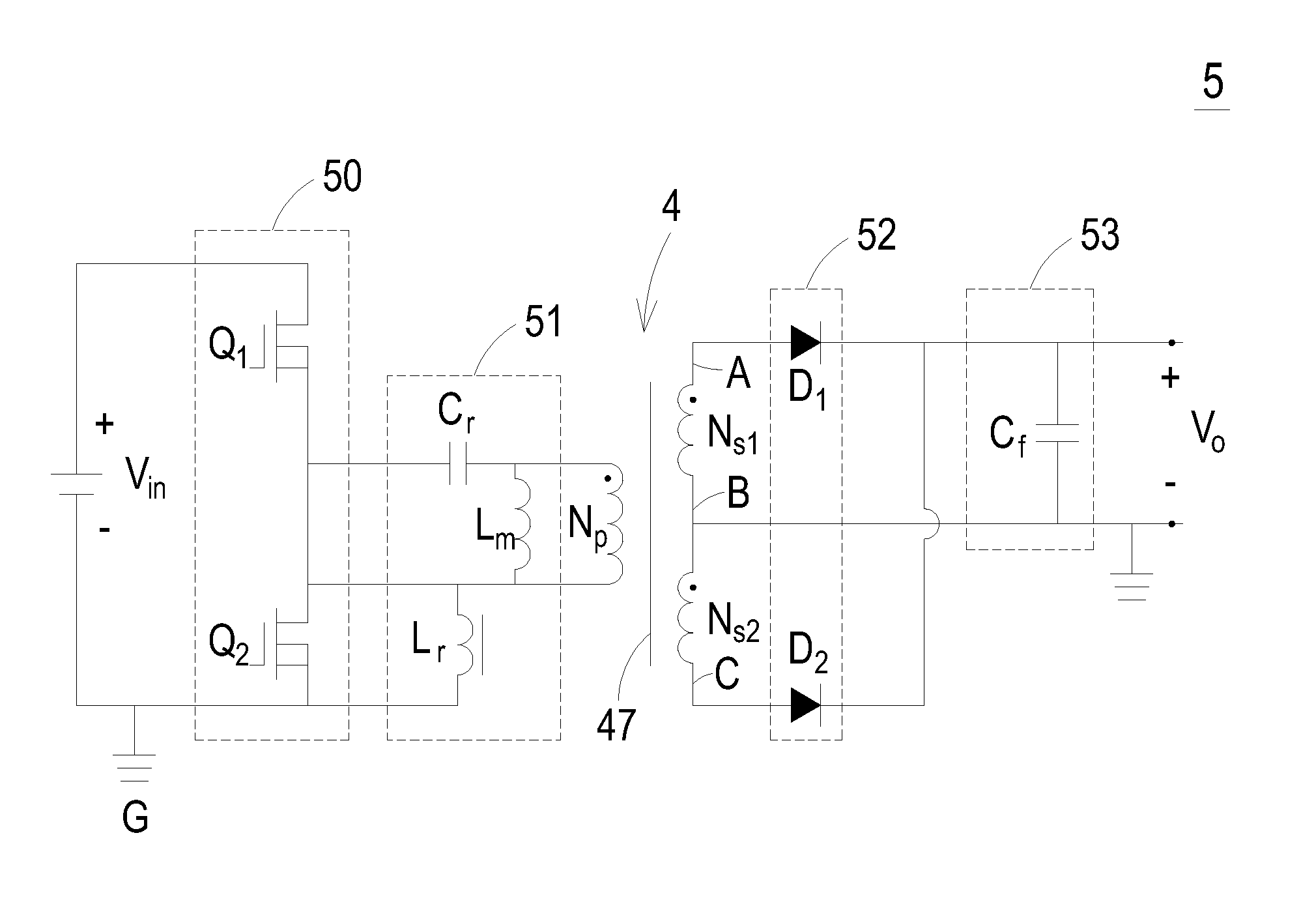

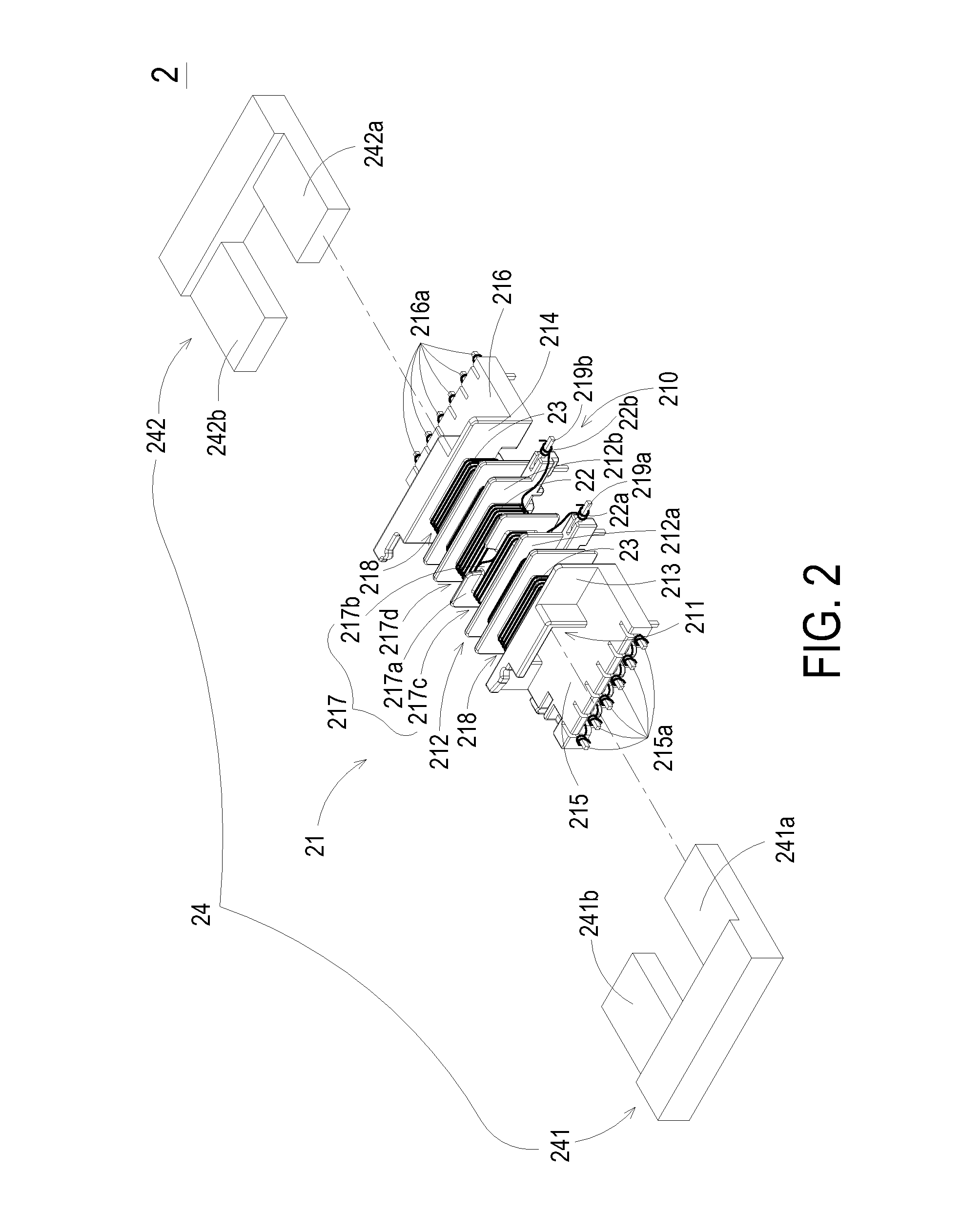

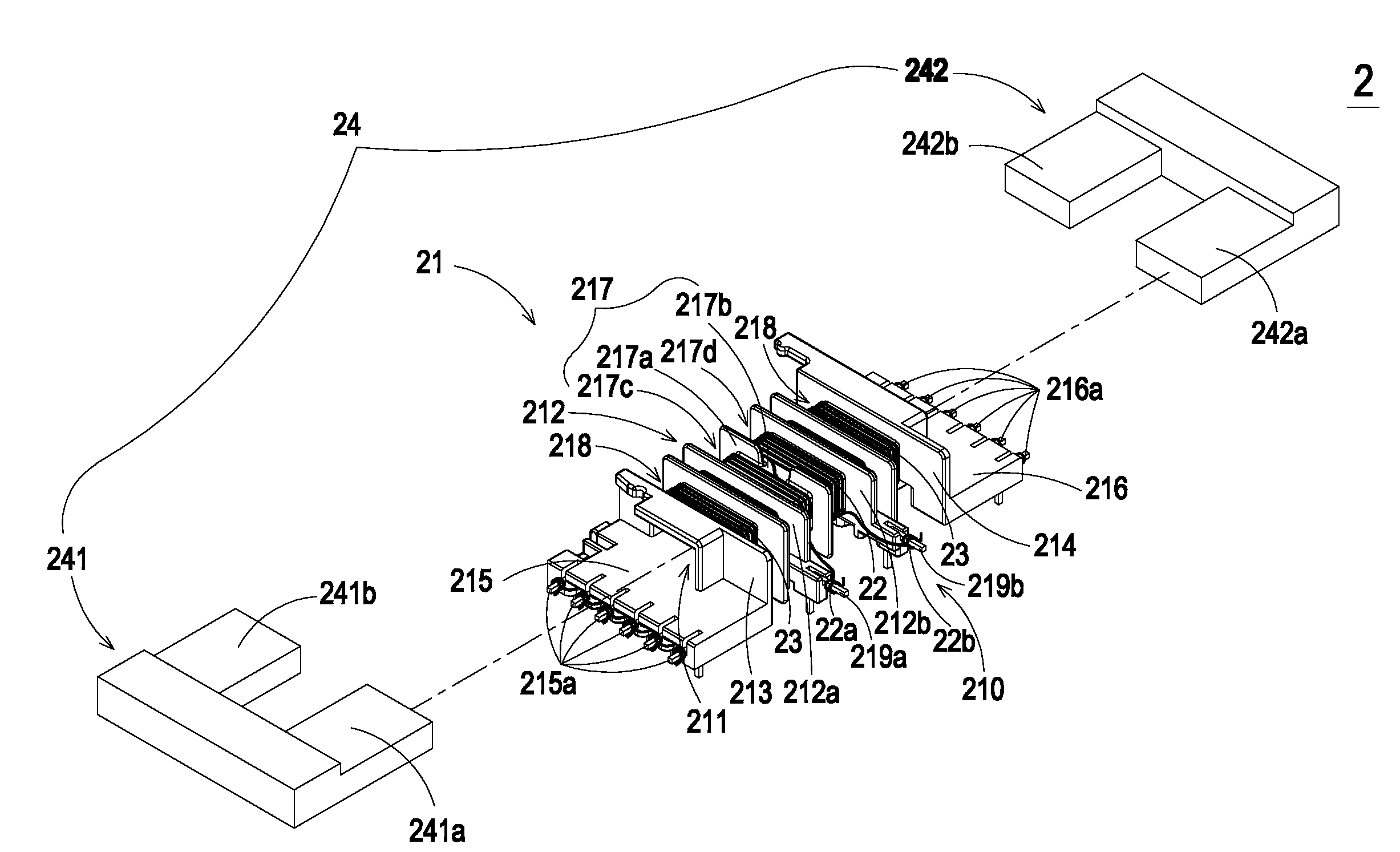

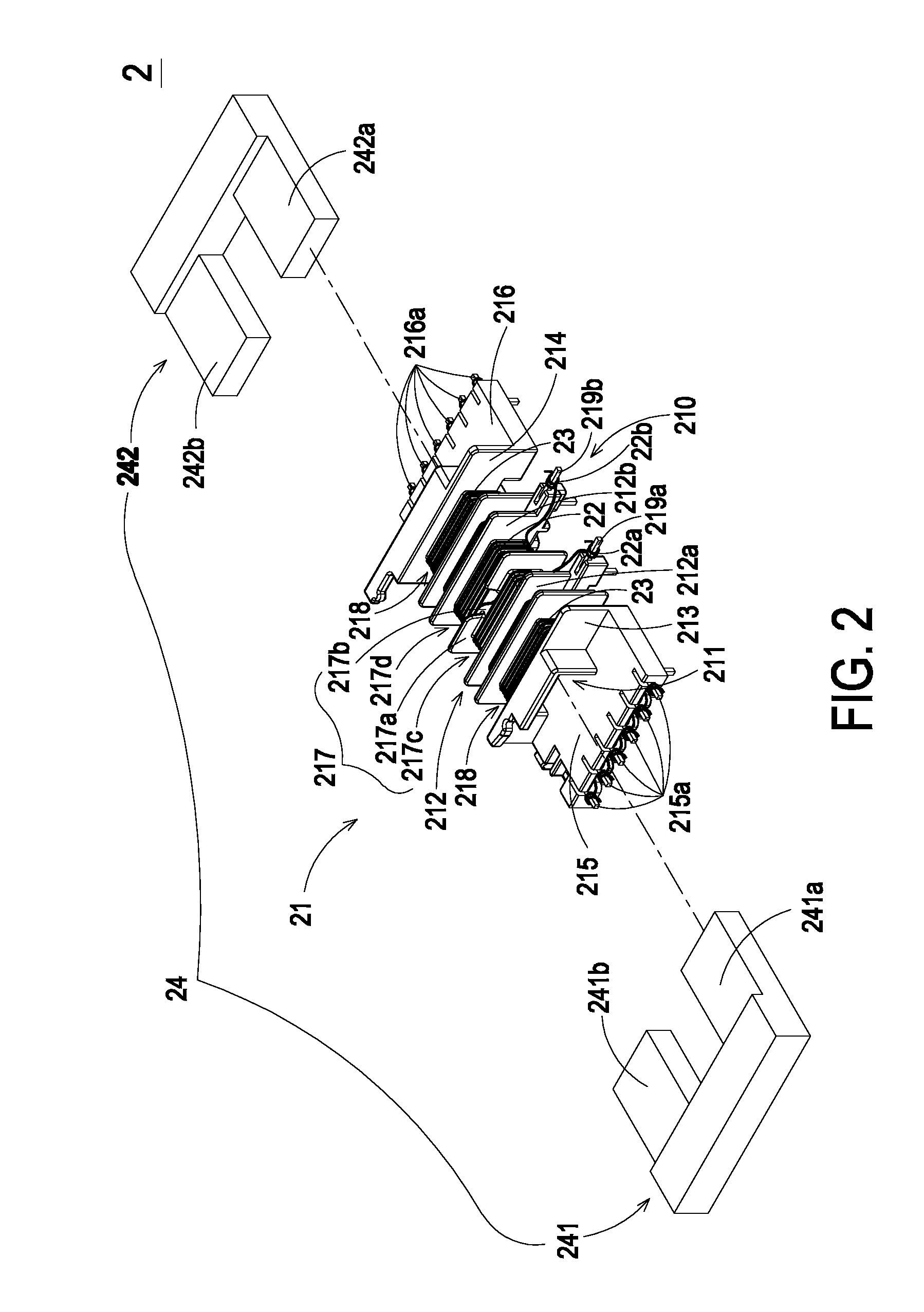

Resonant transformer and resonant converter employing same

ActiveUS20120106207A1Reduce electricity costsReduce manufacturing costTransformers/inductances coils/windings/connectionsDc-dc conversionBobbinEngineering

A resonant transformer and resonant converter are disclosed. The resonant transformer includes a first bobbin, a first primary winding coil, plural first secondary winding coils, a second bobbin, a second primary winding coil, plural second secondary winding coils and a magnetic core assembly. The first bobbin includes a first winding section and plural single-trough second winding sections. Plural pins are arranged at the first winding section. The first primary winding coil is wound around the first winding section and connected with the pins. The first secondary winding coils are wound around respective single-trough second winding sections. The second bobbin includes a third winding section and plural single-trough fourth winding sections. The second primary winding coil are wound around the third winding section and connected with the pins at the first winding section of the first bobbin. The second secondary winding coils are wound around respective single-trough fourth winding sections.

Owner:DELTA ELECTRONICS INC

Electromagnetic pickup with multiple wire coils wound around individual pole sets to attain multiple tones

InactiveUS20120118129A1Increase the winding spacePickup very versatile in terms of tonalityElectrophonic musical instrumentsElectric guitarEngineering

An electromagnetic pickup for electric guitars has a plural of wire coils around each pole set and two lead wires connected to each wire coil. Individual wire coils around a pole set have different oxygen contents and / or gages and / or turns and / or coating materials such that one wire coil produces a tone color distinctive from another wire coil.

Owner:JANG CHANGSOO

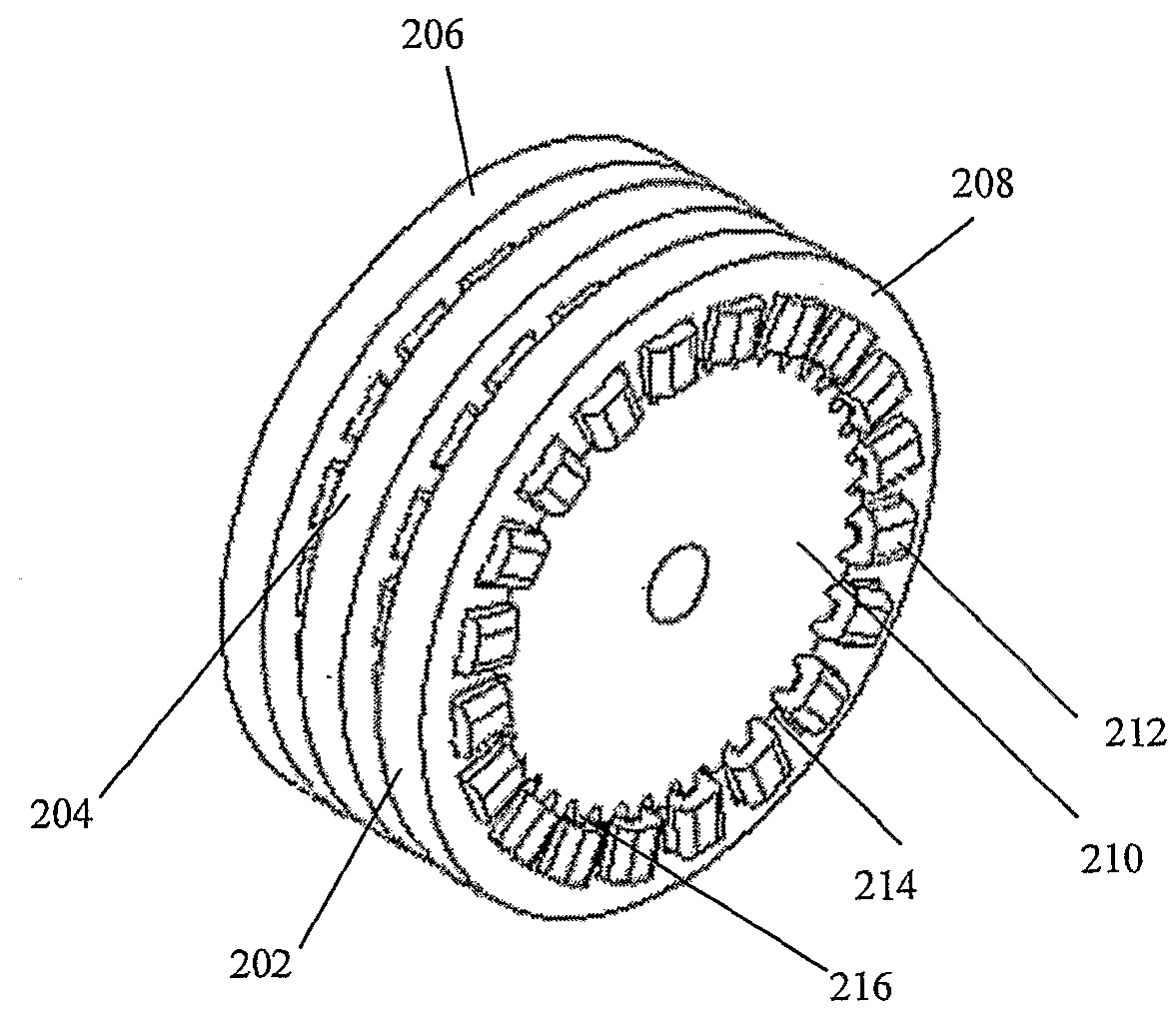

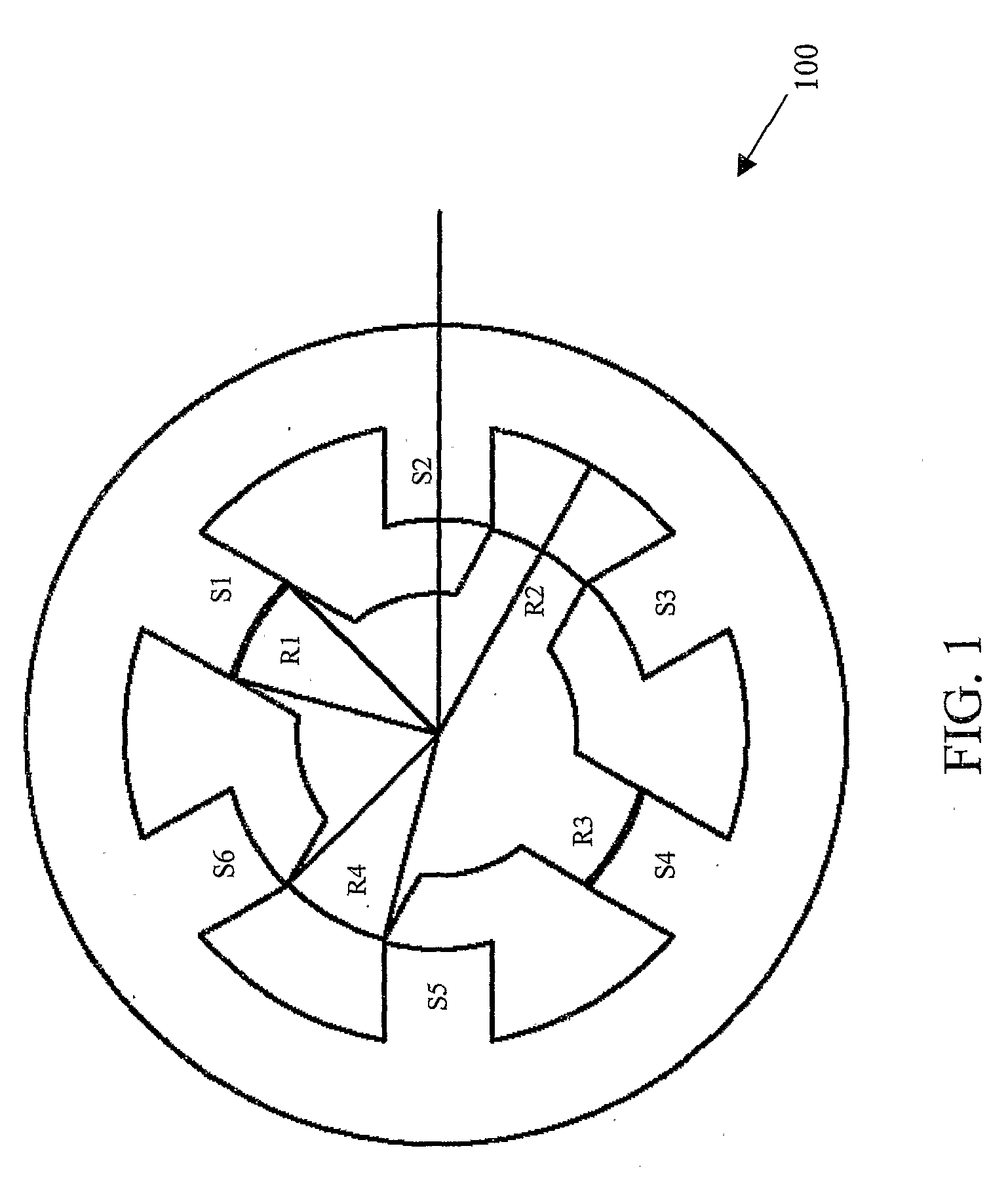

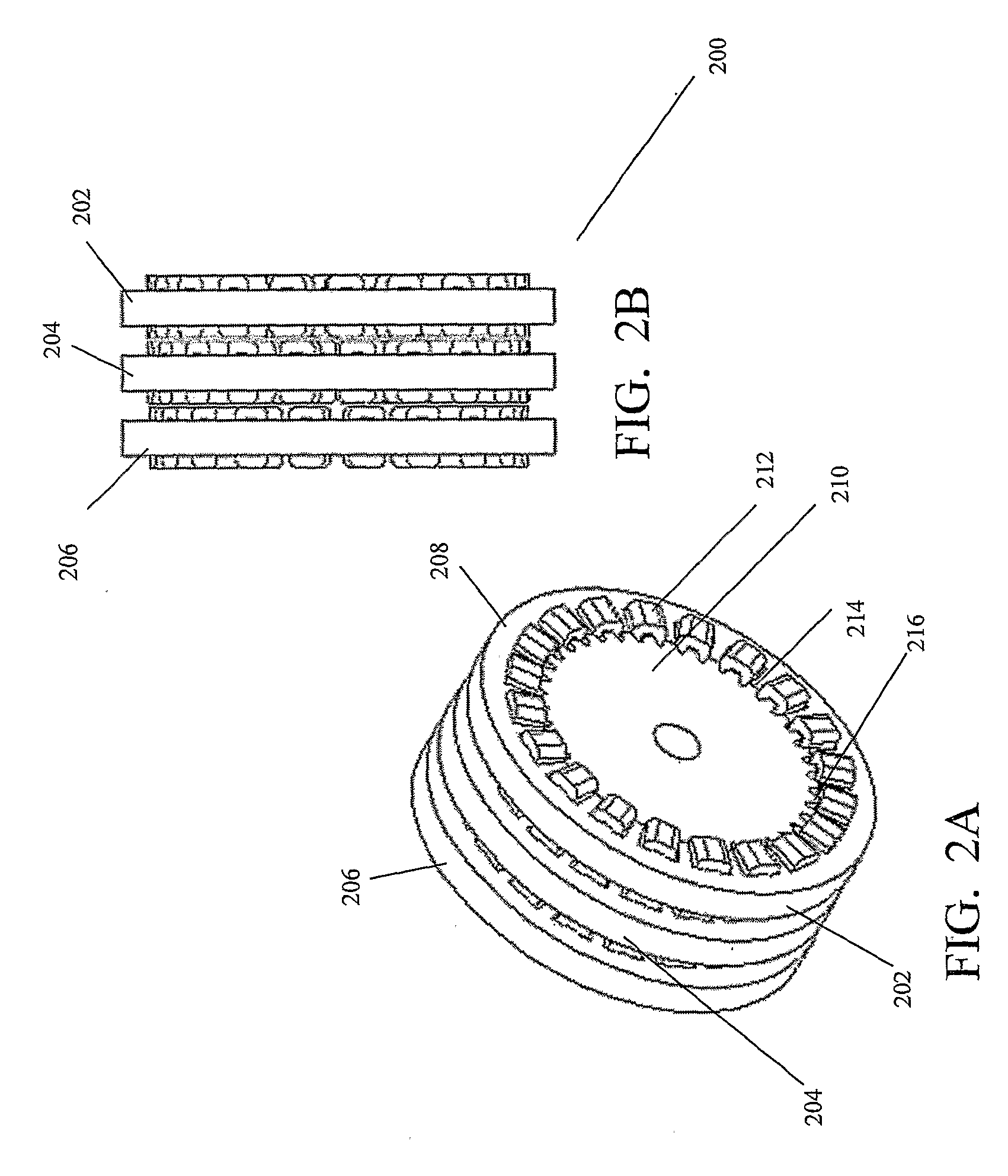

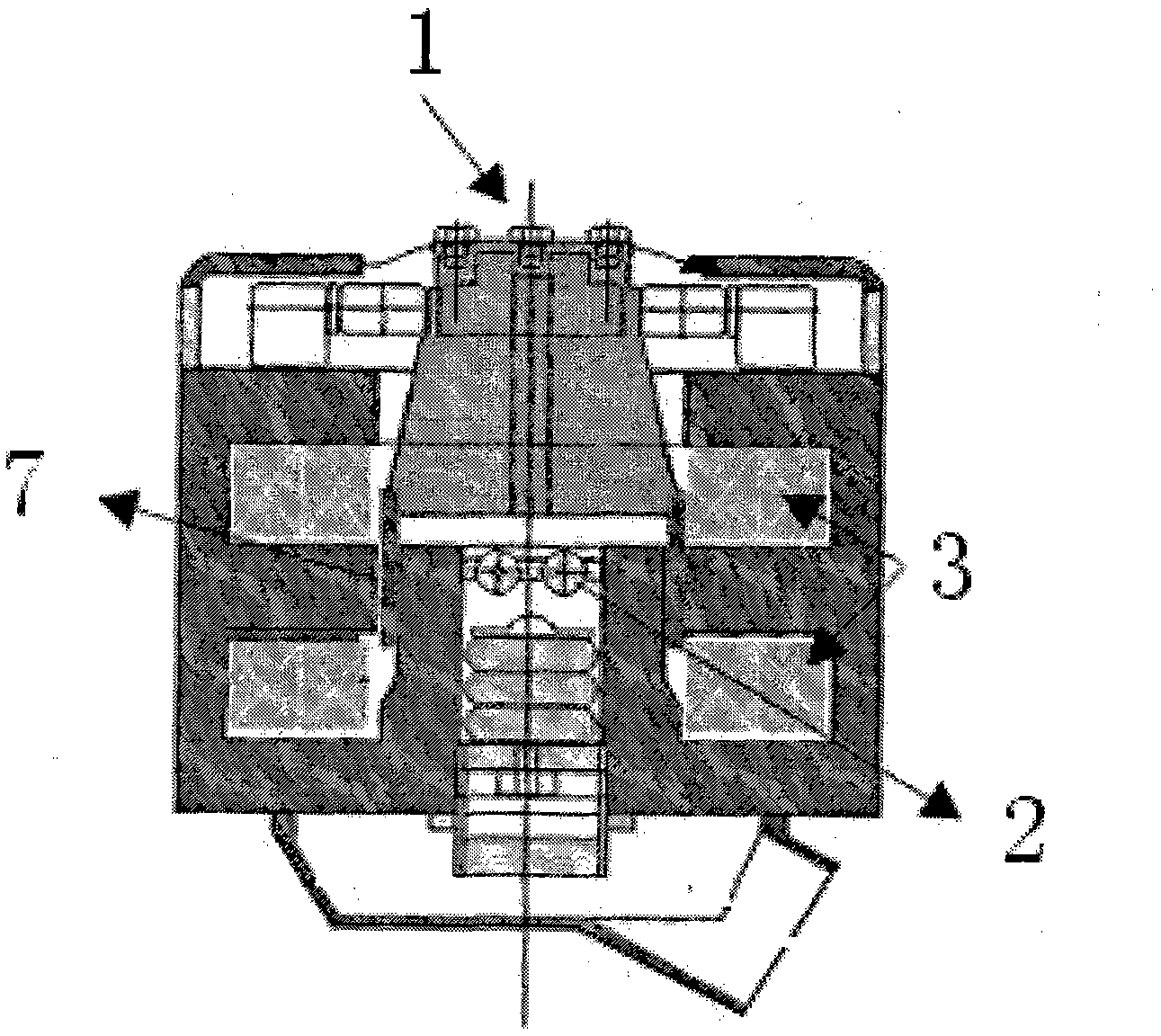

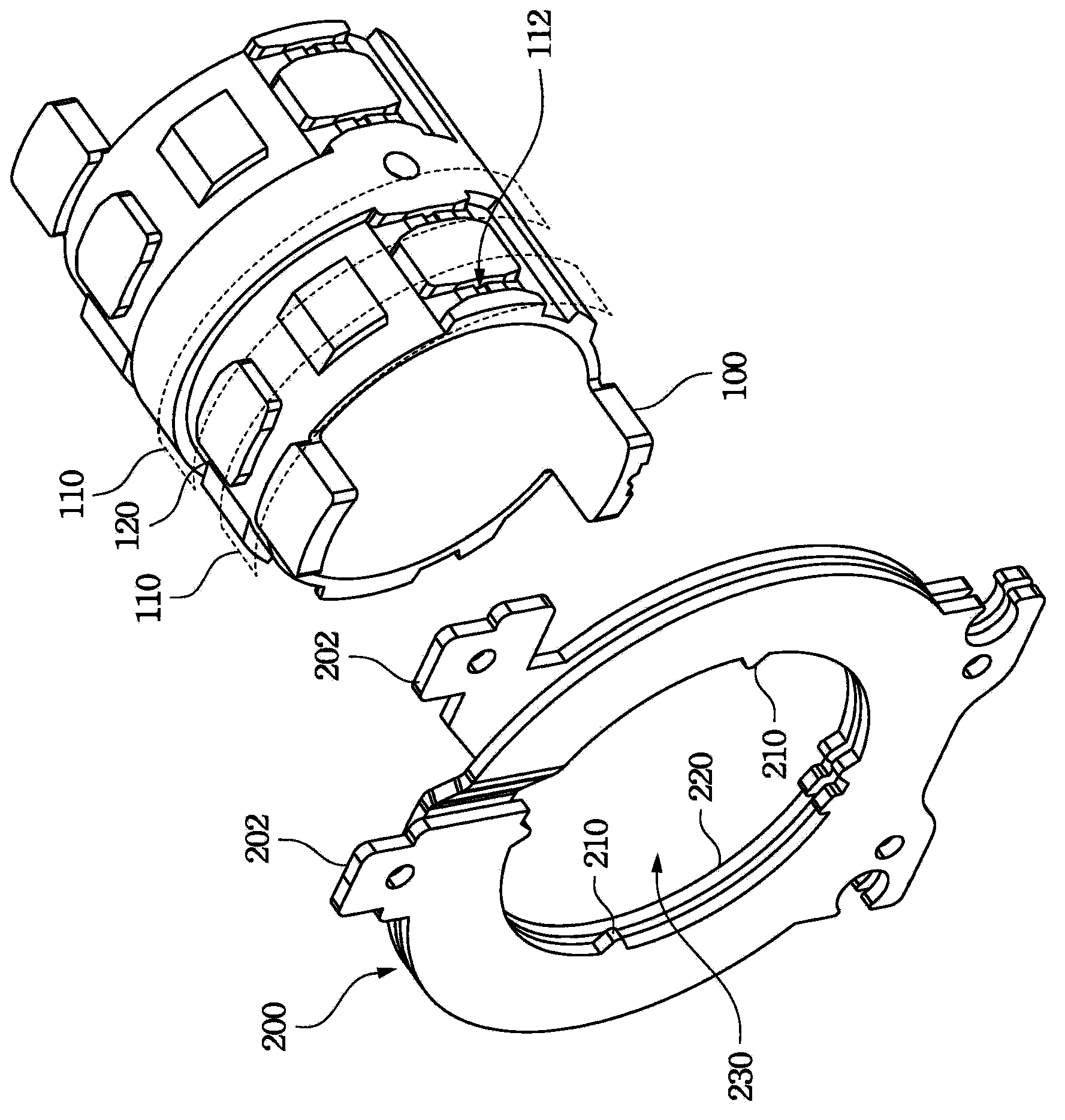

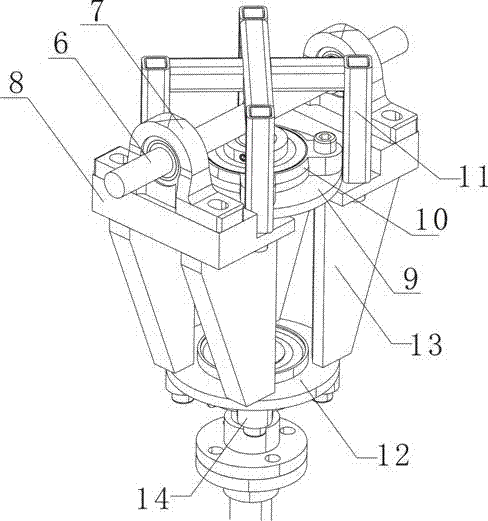

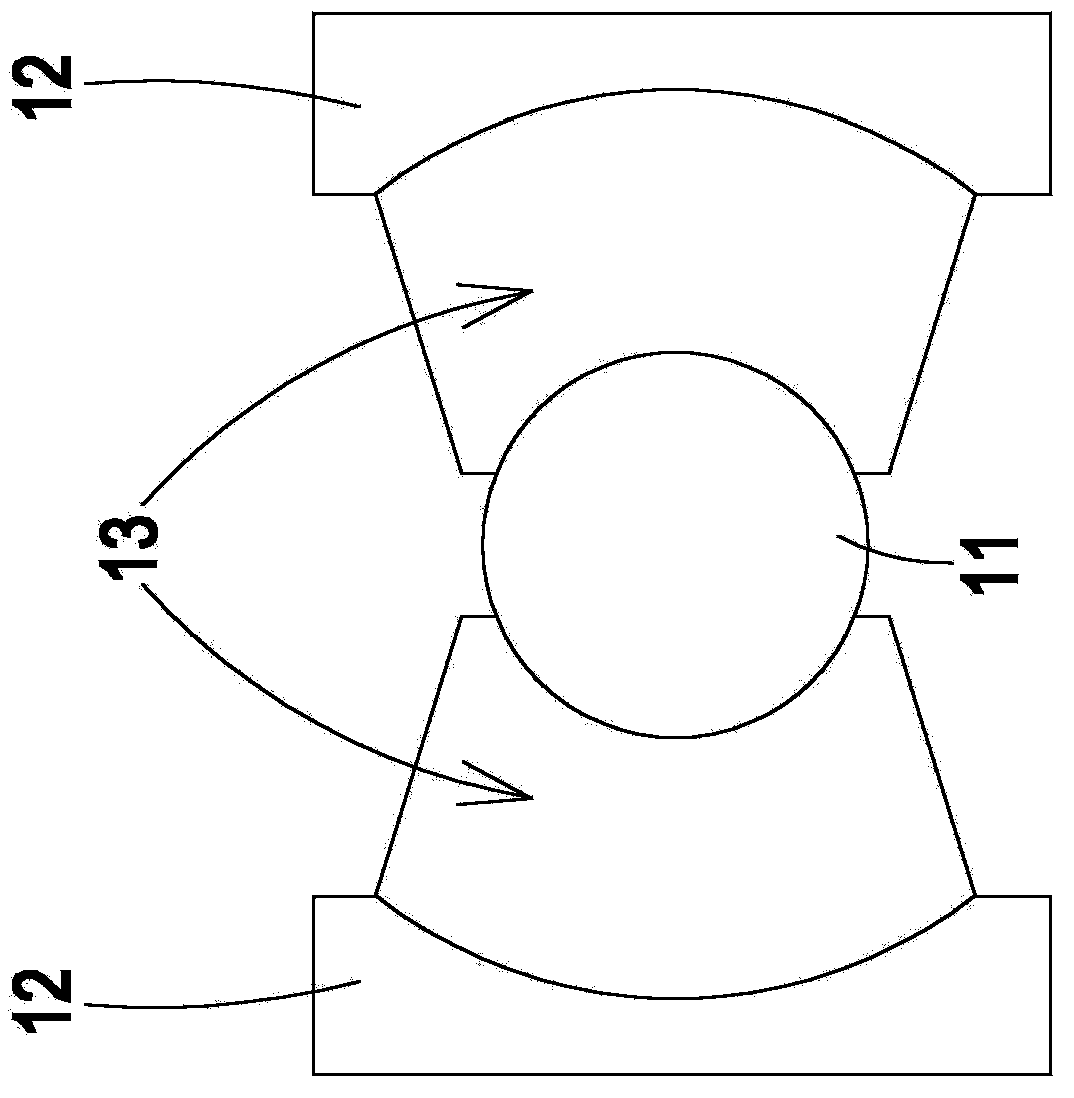

Switched Reluctance Machine And Method Of Operation Thereof

InactiveUS20090021192A1Eliminate the problemIncreased coil winding spaceAC motor controlMagnetic circuitControl mannerCentre of rotation

The present invention provides an S SRM (switched reluctance machine), which supports one or more phases and each phase comprises a stator, a rotor and coils. The stator is hollow, cylindrical and comprises stator poles extending inwards, such that a recess is formed between adjacent stator poles. The coils are wound on the stator poles and occupy the recess. The rotor is positioned inside the stator and has poles extending outwards. The rotor and stator poles subtend an angle having a maximum value of 0.5 electrical pole pitches at a center of rotation. The different phases are distributed along the axis of the S SRM. The rotor is rotated by a reluctance torque generated by energizing a phase in a current controlled manner until the rotor rotates through a minimum commutation angle required to maintain motion; de-energizing the phase by freewheeling it by using the energy stored in it and simultaneously energizing a second sequentially adjacent phase.

Owner:KUDLIGI SRINIVAS

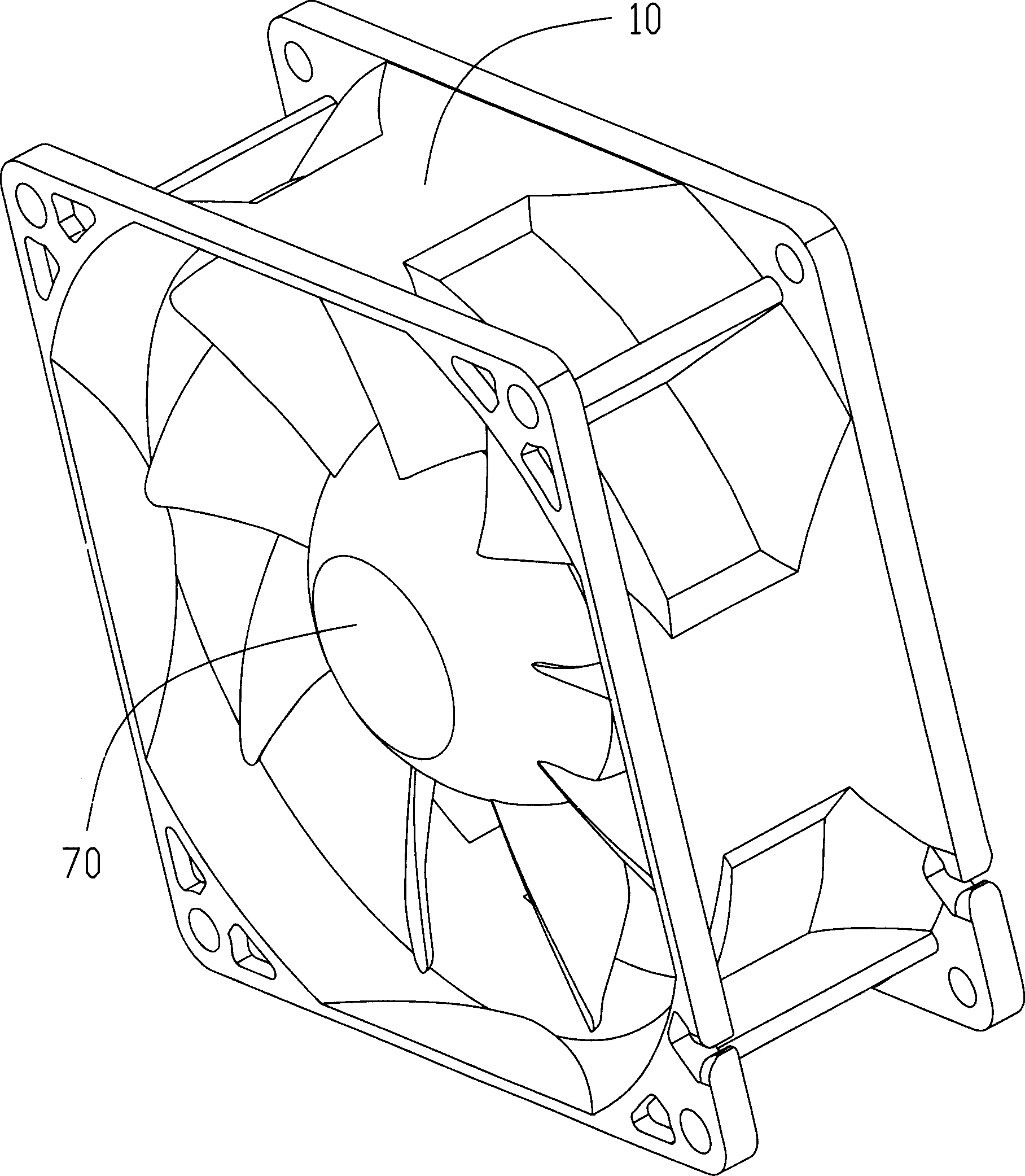

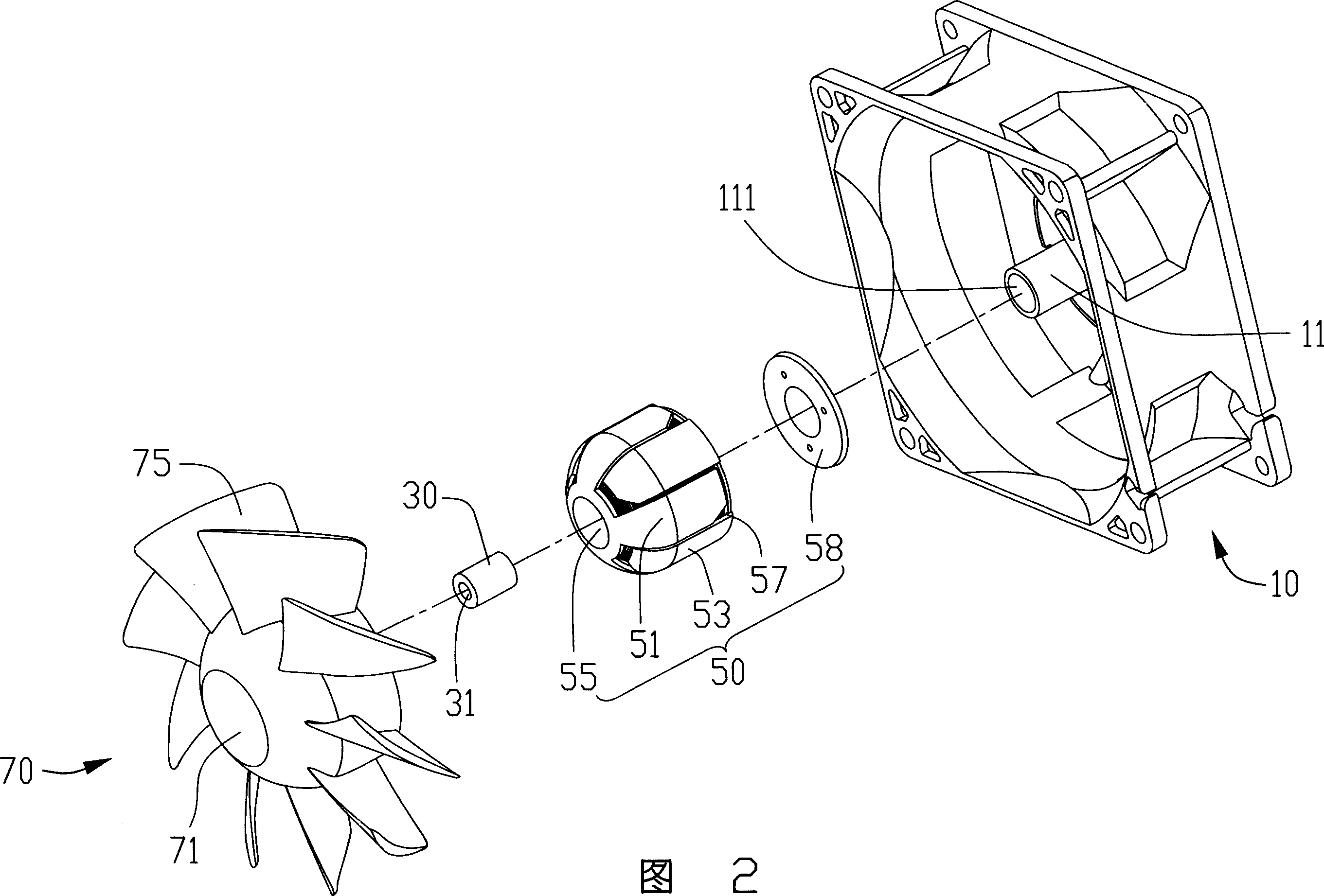

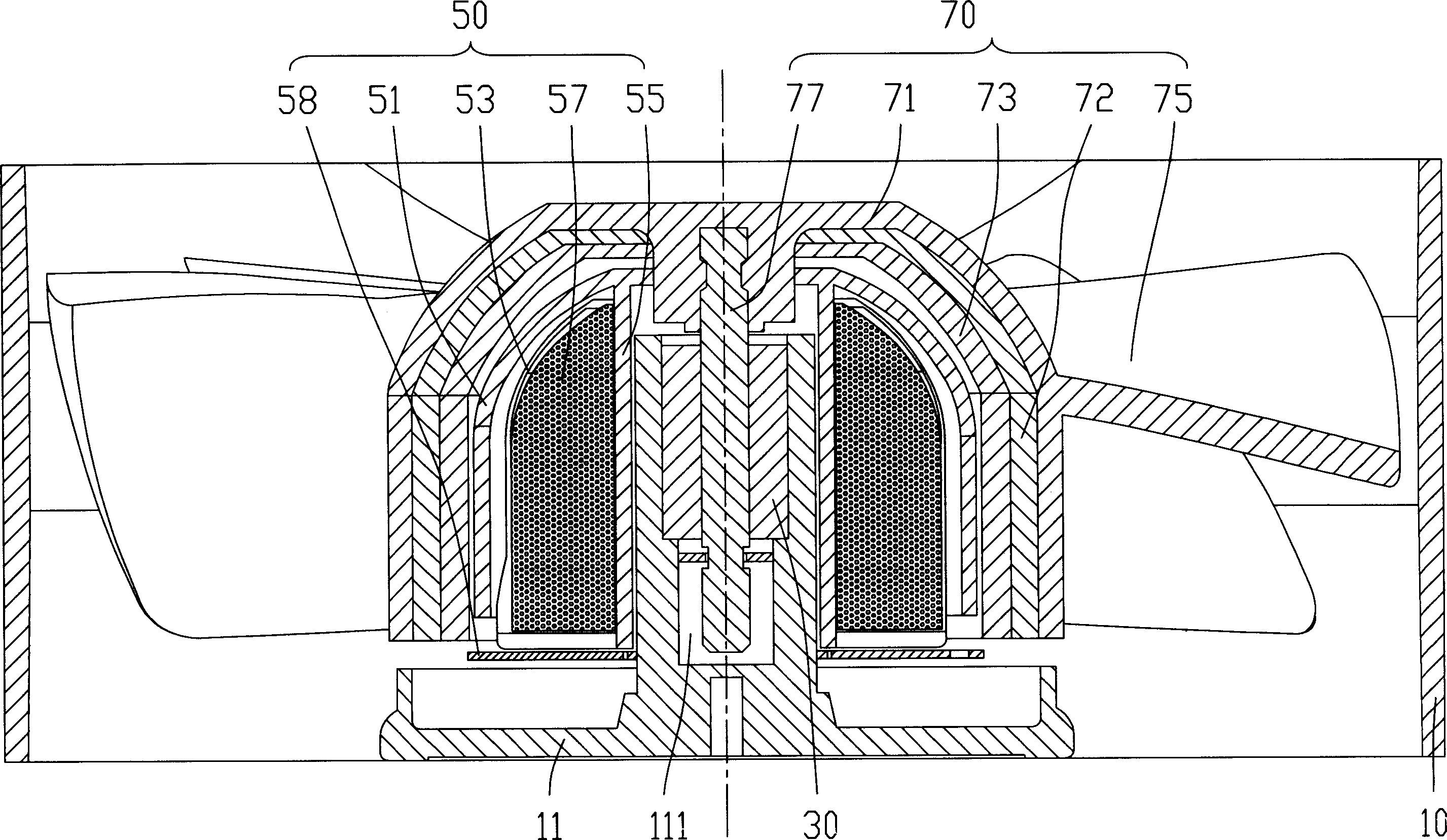

Radiation fan

InactiveCN1908447AIncrease air volumeReduce volumeWindingsMagnetic circuit rotating partsMagnetic polesEngineering

The invention relates to a heat radiation fan, which comprises: a frame with middle cylinder, a bearing inside the middle cylinder, a stator sheathing the middle cylinder and a rotator rotationally supported by the bearing, wherein said fan has one wind inlet and one wind outlet; the stator comprises two magnetic pole plates and a hollow tube between two plates; said two plates both comprise one main body and several sheets extending from the edge of main body; the sheets form the expanding curvature structure near the wind inlet along the inlet wind direction, to increase the magnetic conductive area and the winding space, and reduce the hub volume, to improve the wind amount of fan.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

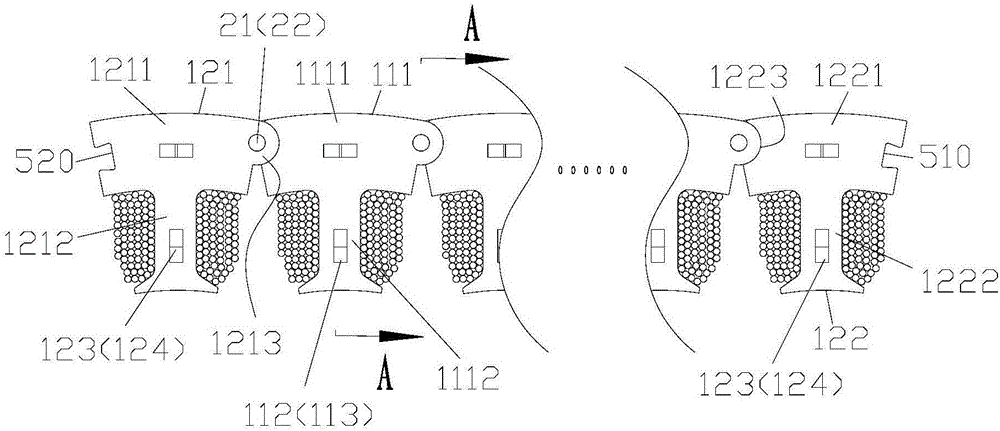

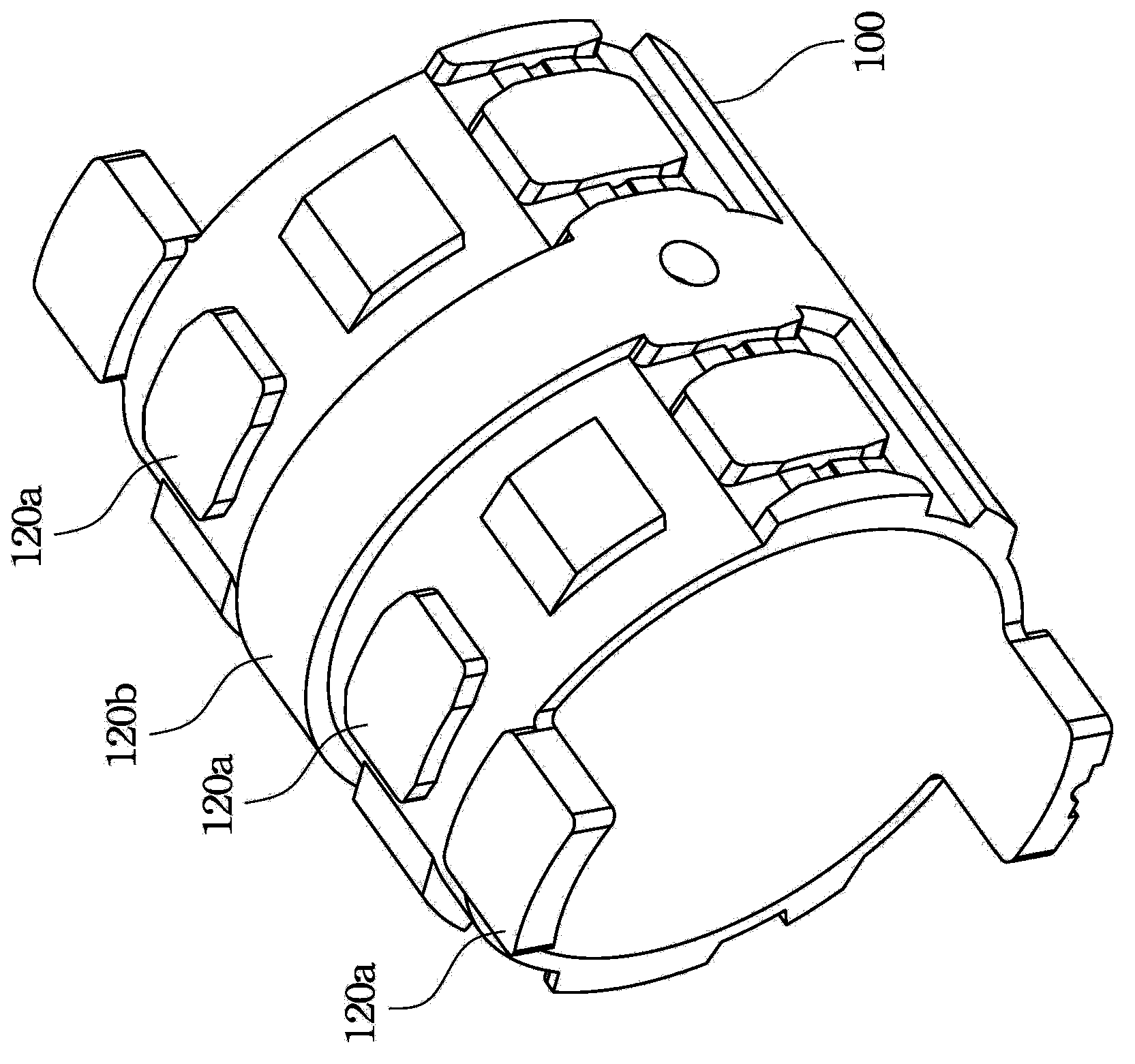

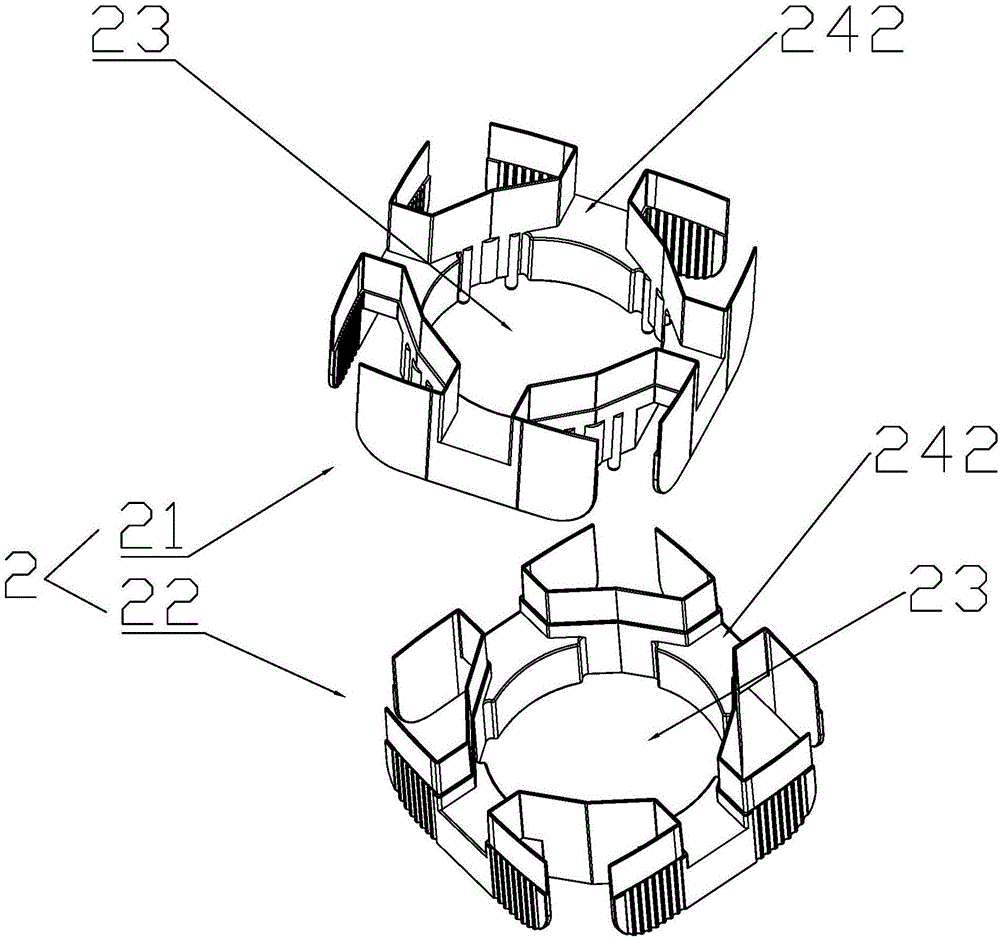

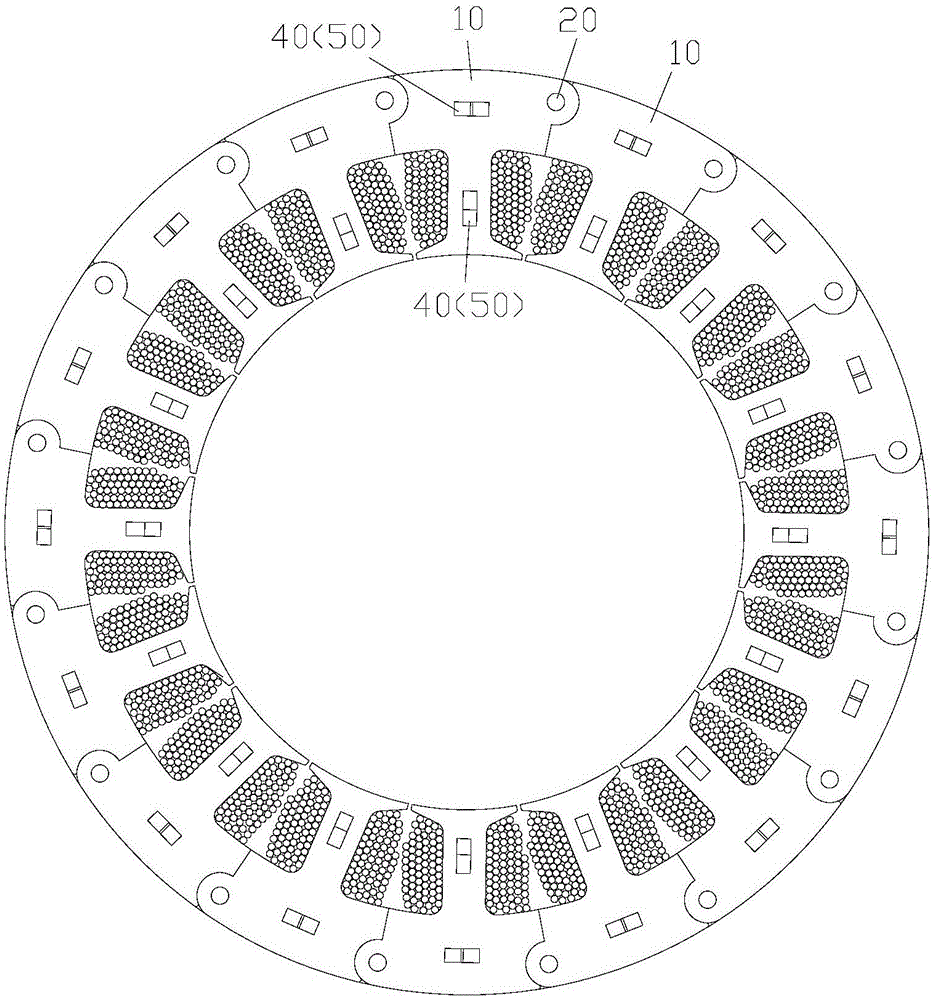

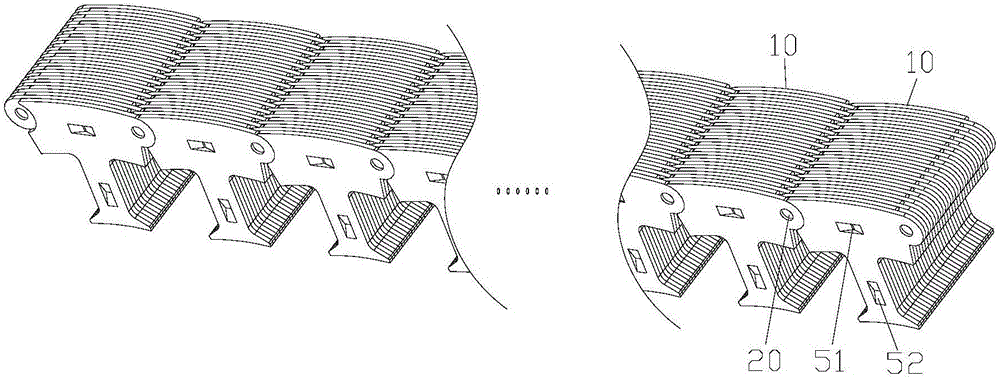

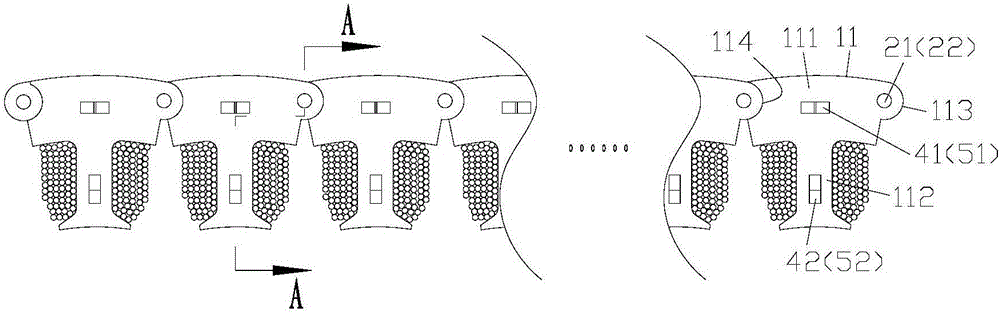

Stator core, stator, motor and air conditioner

InactiveCN106100169AIncrease the winding spaceIncrease slot fill rateMagnetic circuit stationary partsMechanical engineeringUtilization rate

The invention provides a stator core, a stator, a motor and an air conditioner. The stator core comprises a plurality of coiling iron cores sequentially connected, and first connecting structures which arranged between adjacent coiling iron cores, and through which the adjacent coiling iron cores are pivotally connected together. The coiling iron cores on two ends are directly connected together or connected through a second connecting structure. The problem that in the prior art, the stator core is low in coiling efficiency, poor in production size precision and quality, low in iron core raw material utilization rate and incapable of being used to produce motors with high coil space factor can be solved.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

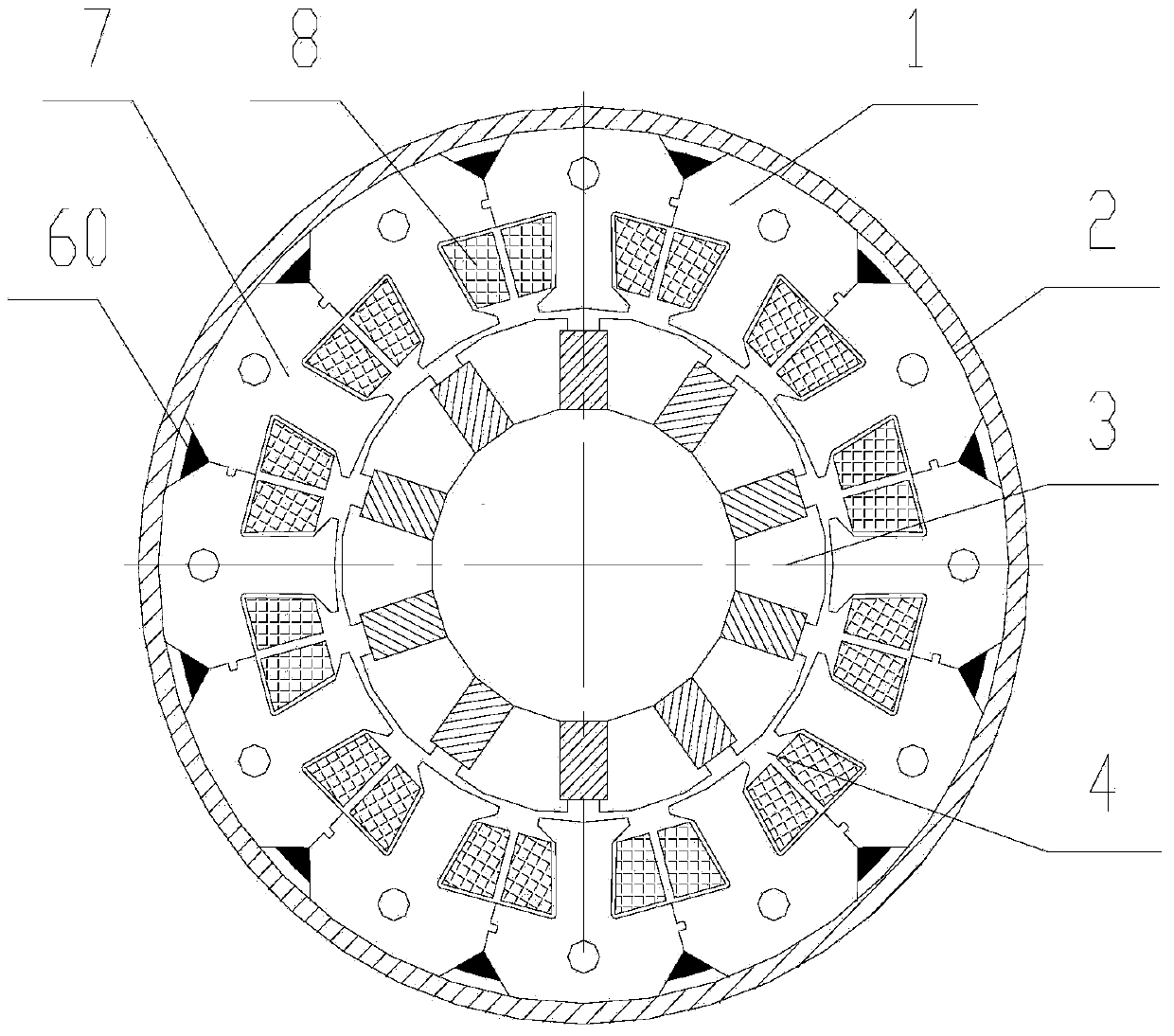

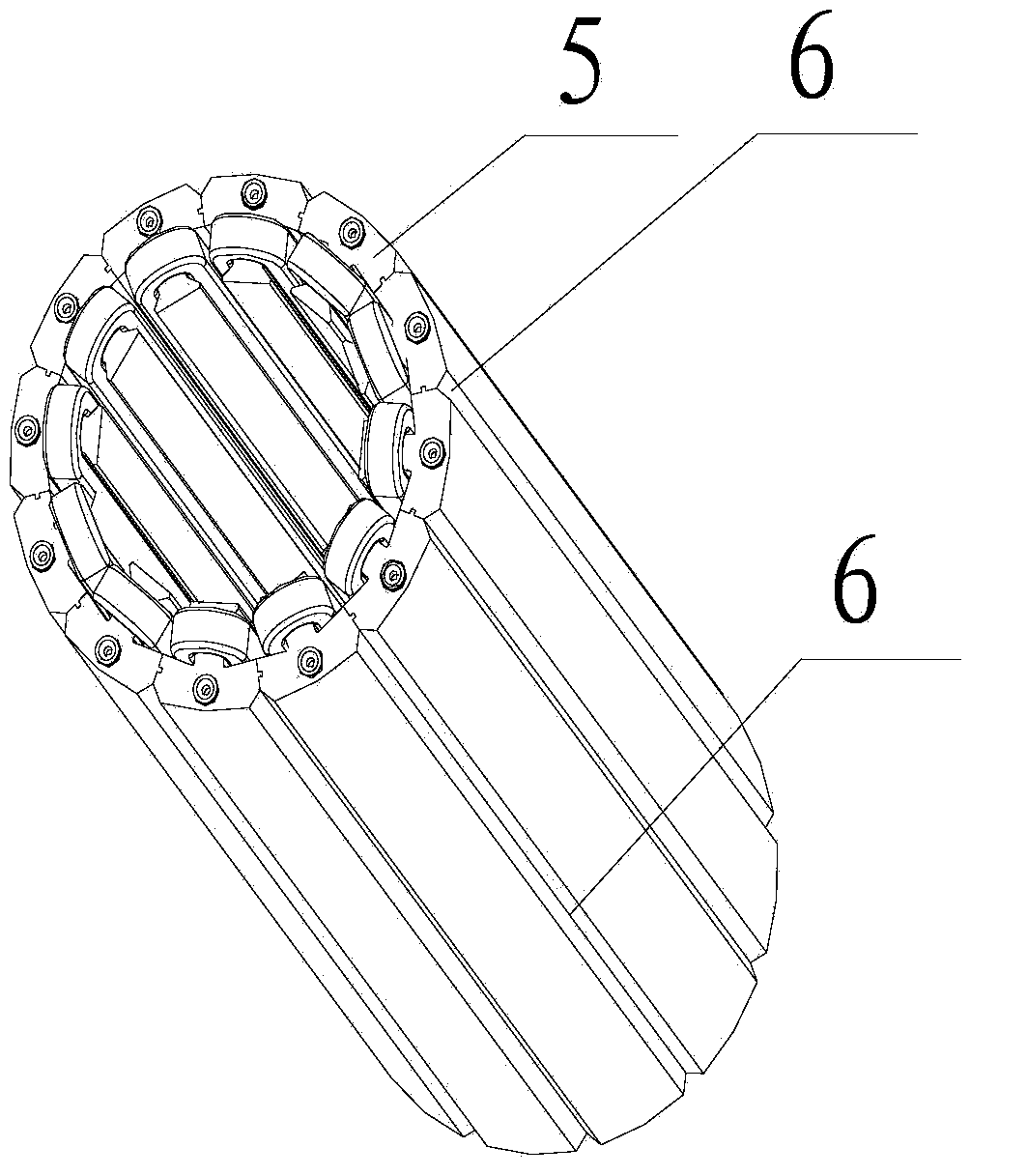

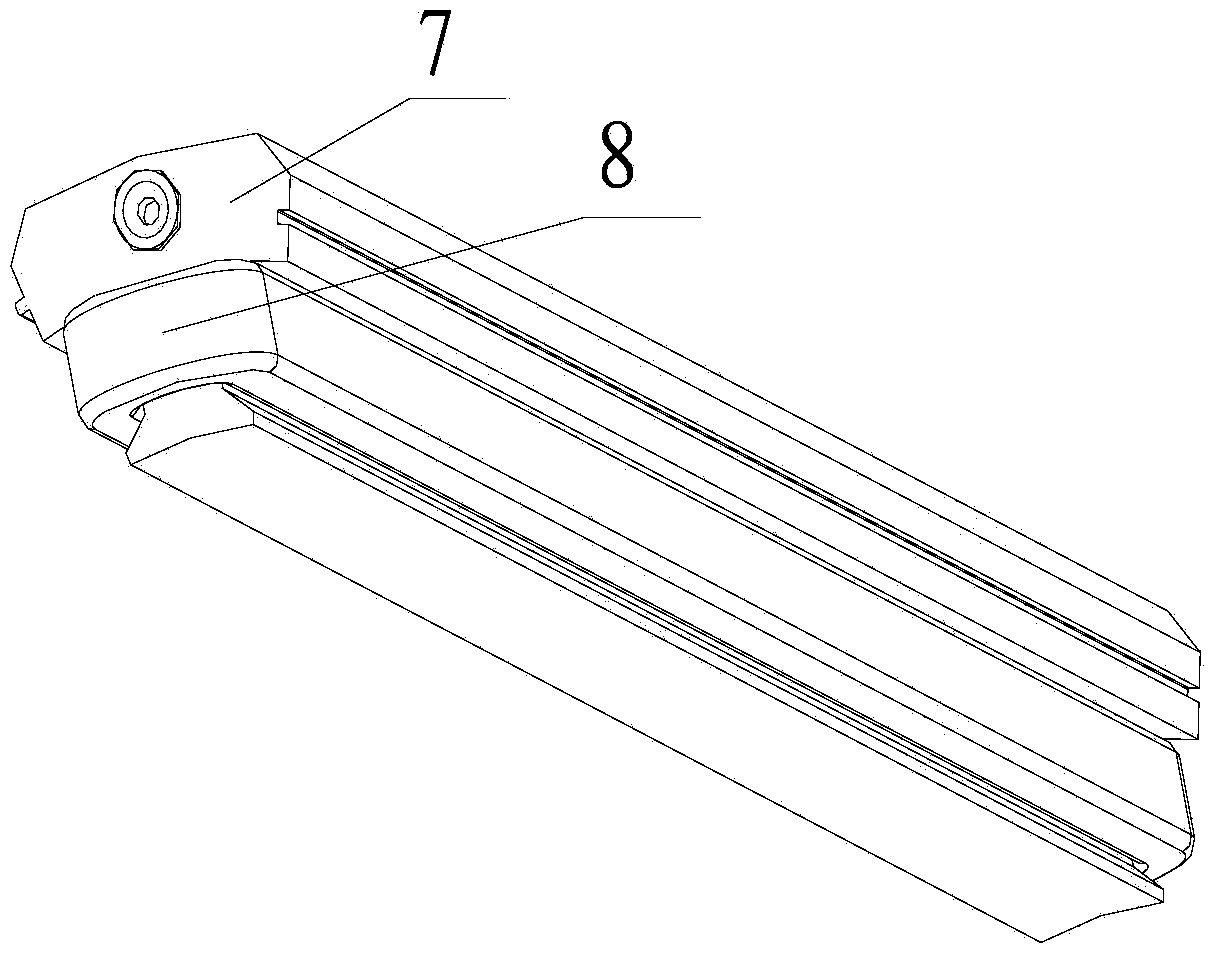

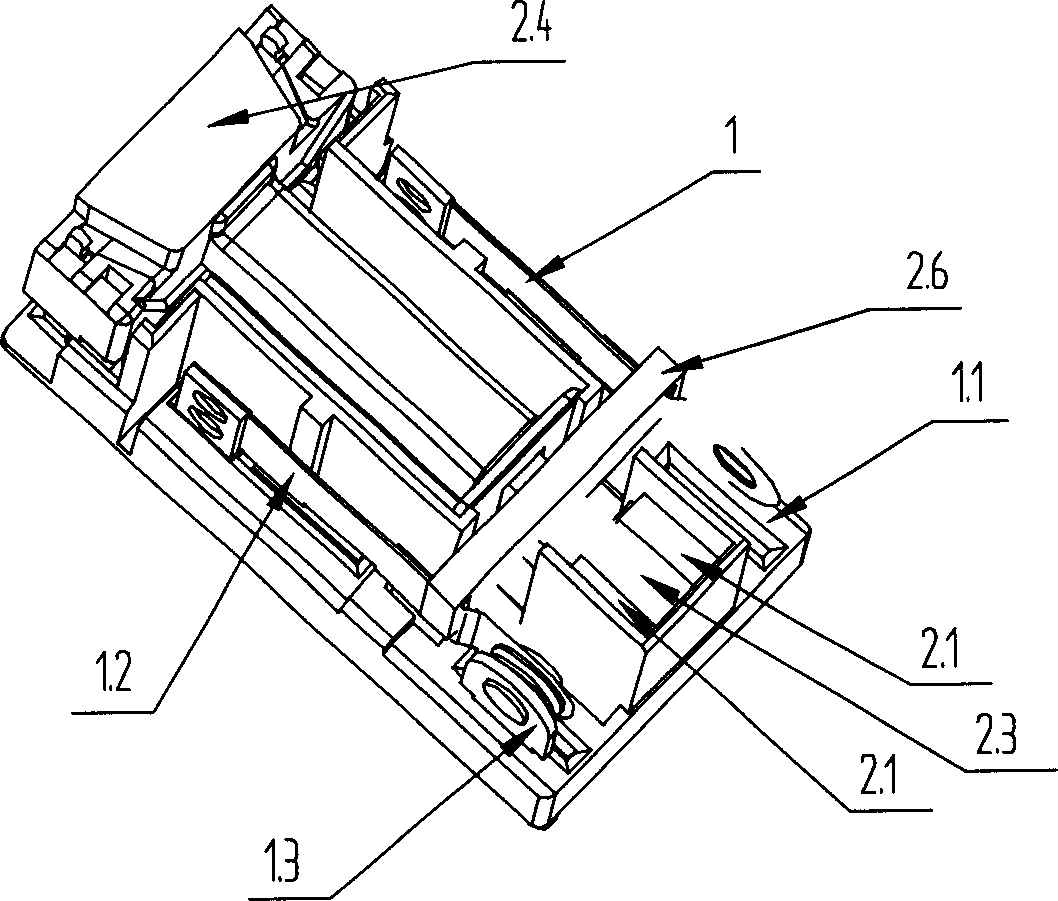

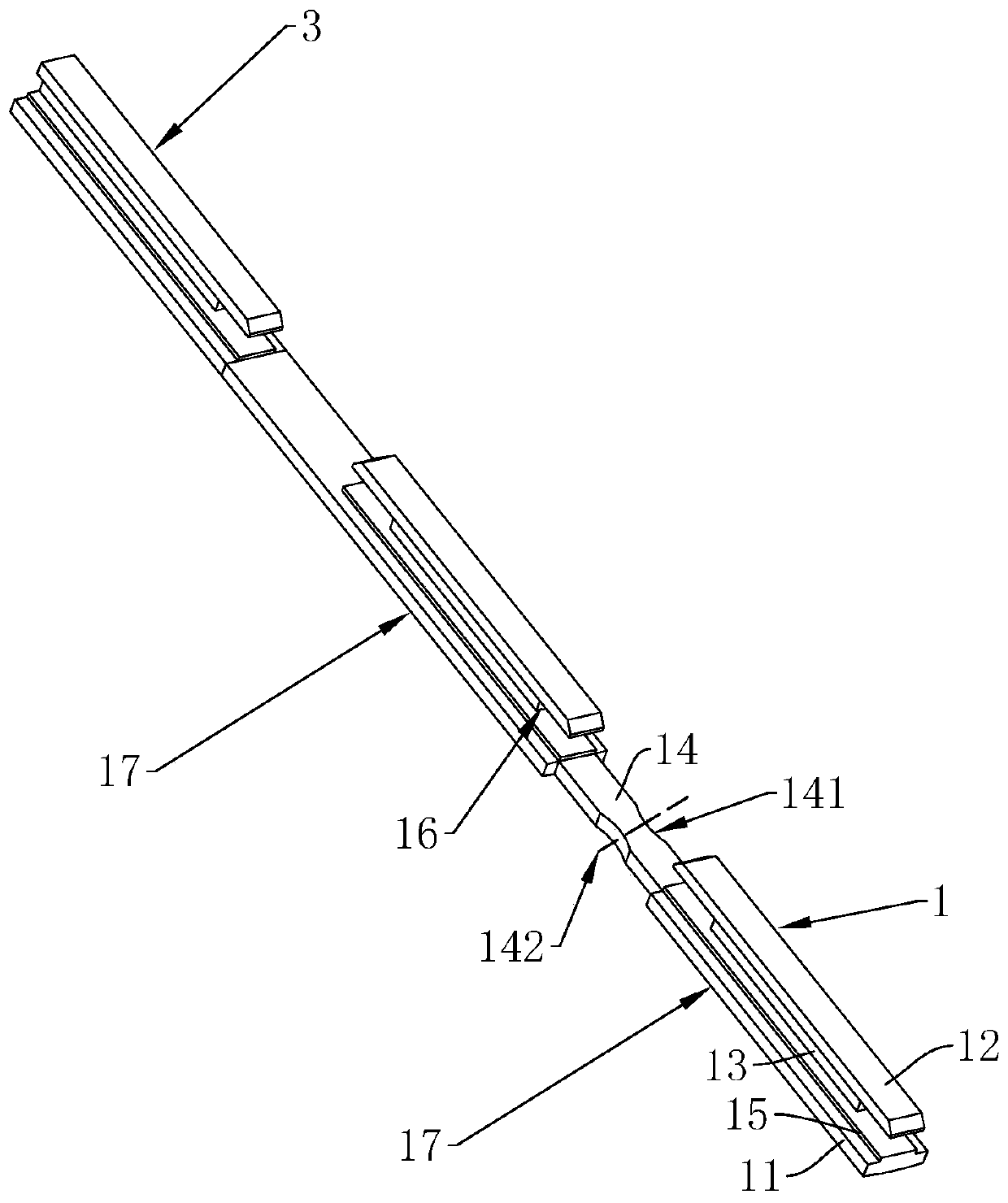

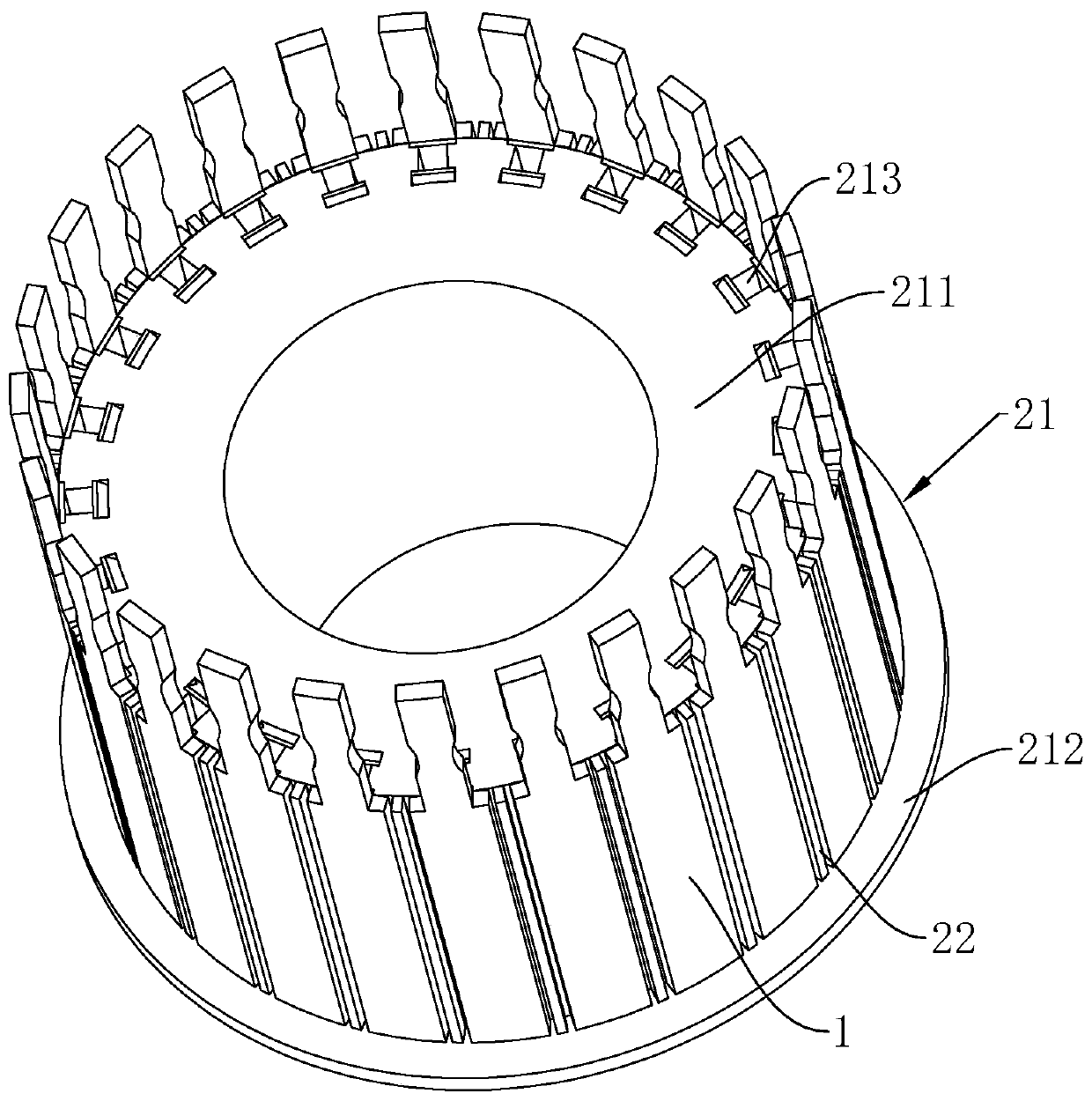

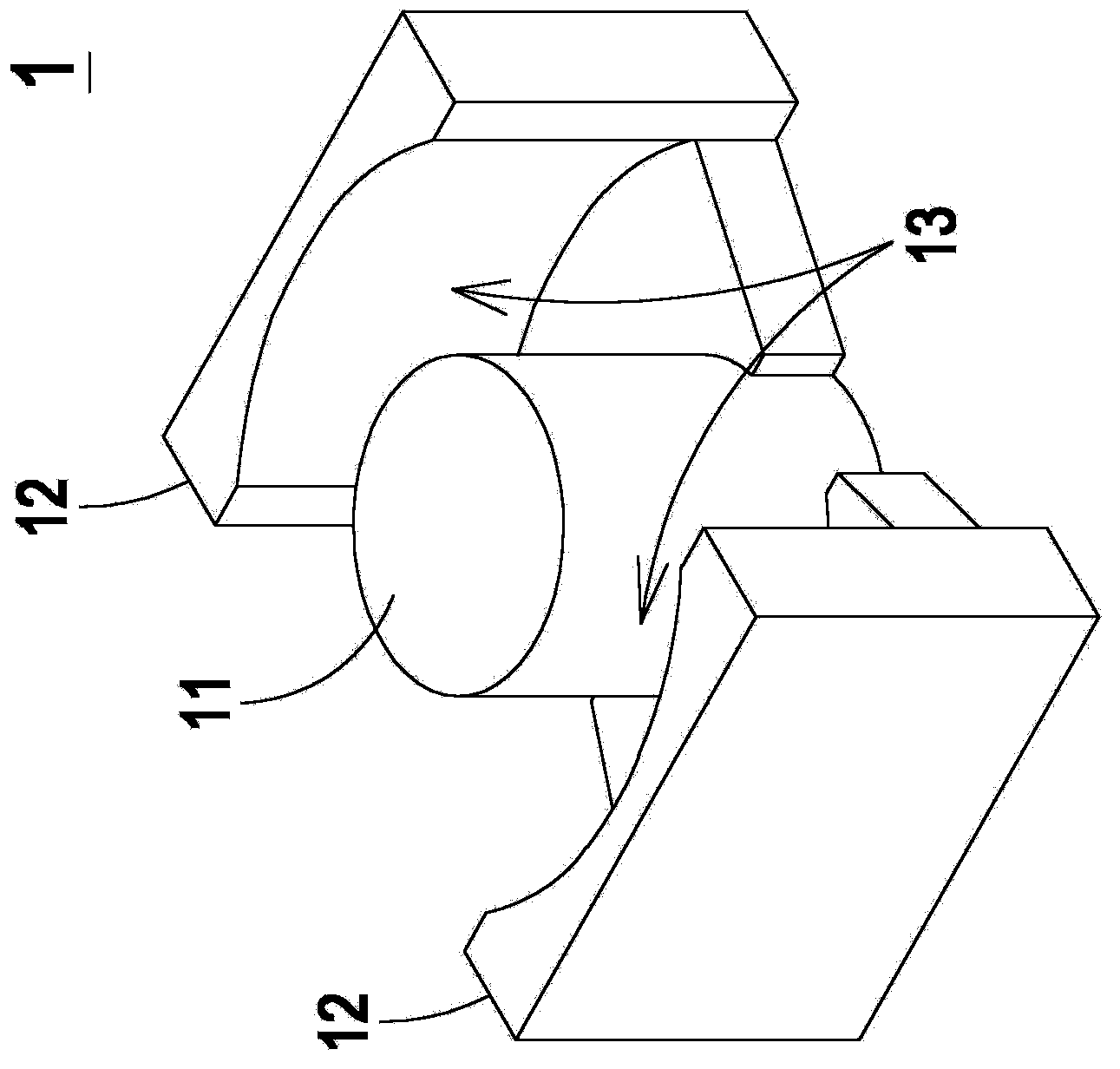

Oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and manufacture method

InactiveCN103633755AImprove the winding methodIncrease the winding spaceMagnetic circuit stationary partsManufacturing stator/rotor bodiesCopper wirePermanent magnet motor

The invention provides an oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and a manufacture method. The oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor comprises a motor unit, wherein the motor unit comprises a stator core of a split type structure, the stator core is assembled into an annular shape by multiple core blocks with windings, each core block with one winding comprises a slender core block and a winding copper wire, each slender core block is formed by overlaying T-shaped punched pieces and is provided with a stator tooth, and the winding copper wires are wound on the stator teeth. The manufacture method of the permanent magnet motor comprises the steps of overlaying the T-shaped punched pieces to form the slender core blocks, and winding the winding copper wires on the stator teeth to form the core blocks with the windings; connecting the multiple core blocks with the windings in sequence along the peripheral direction and assembling to form the annular stator core; arranging the annular stator core into an enclosure by press-fitting. The winding process of the core blocks with the windings is easy to realize, and the manufacturing is simple.

Owner:PETROCHINA CO LTD

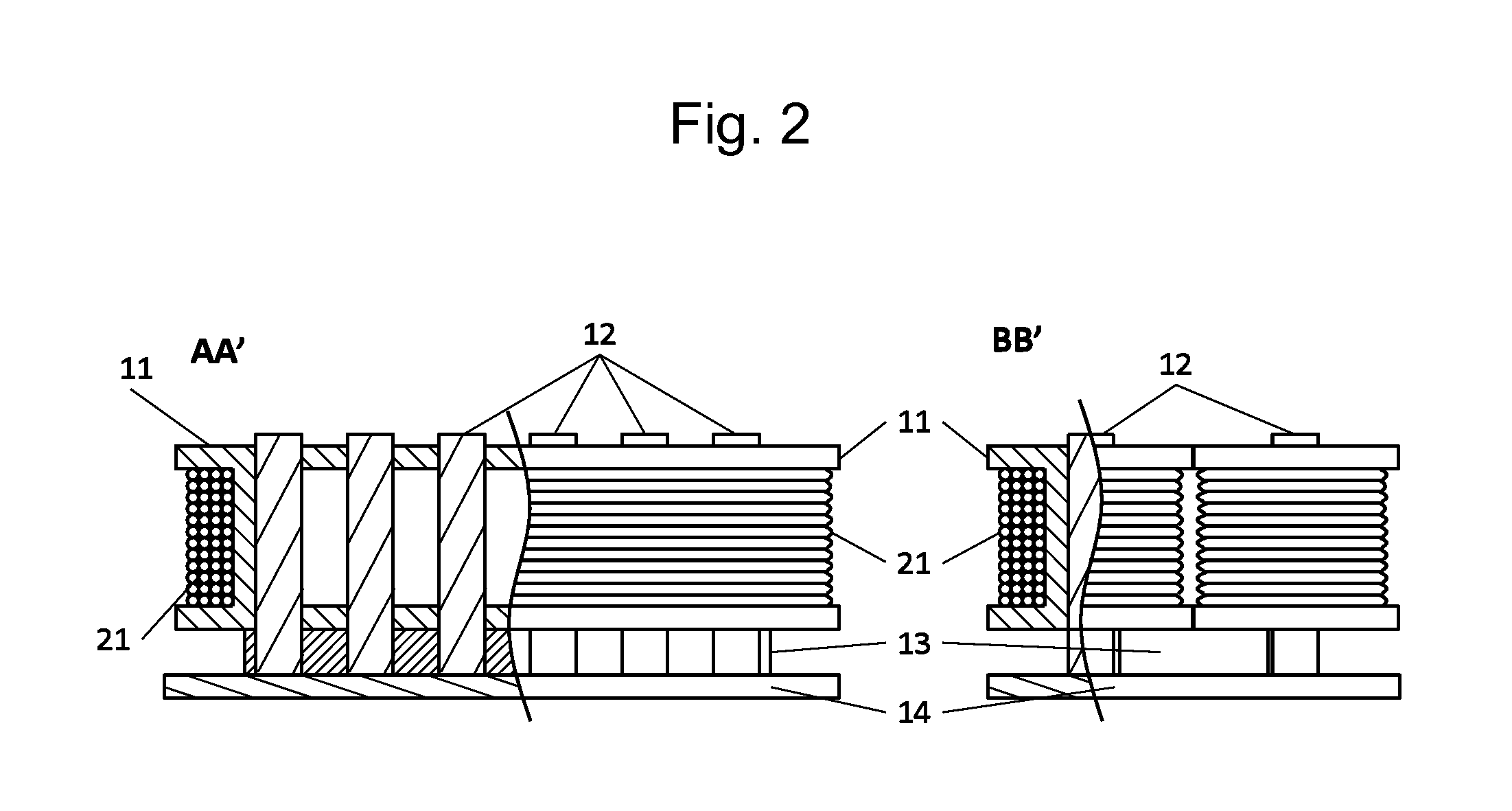

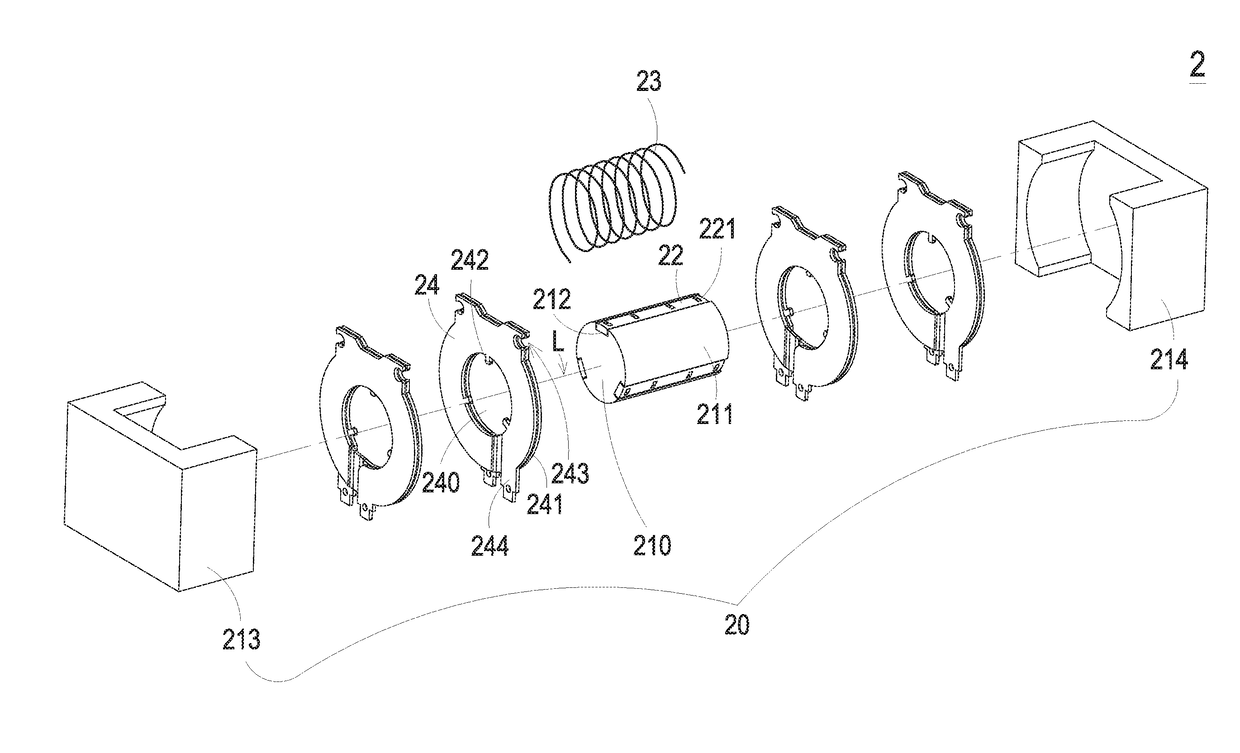

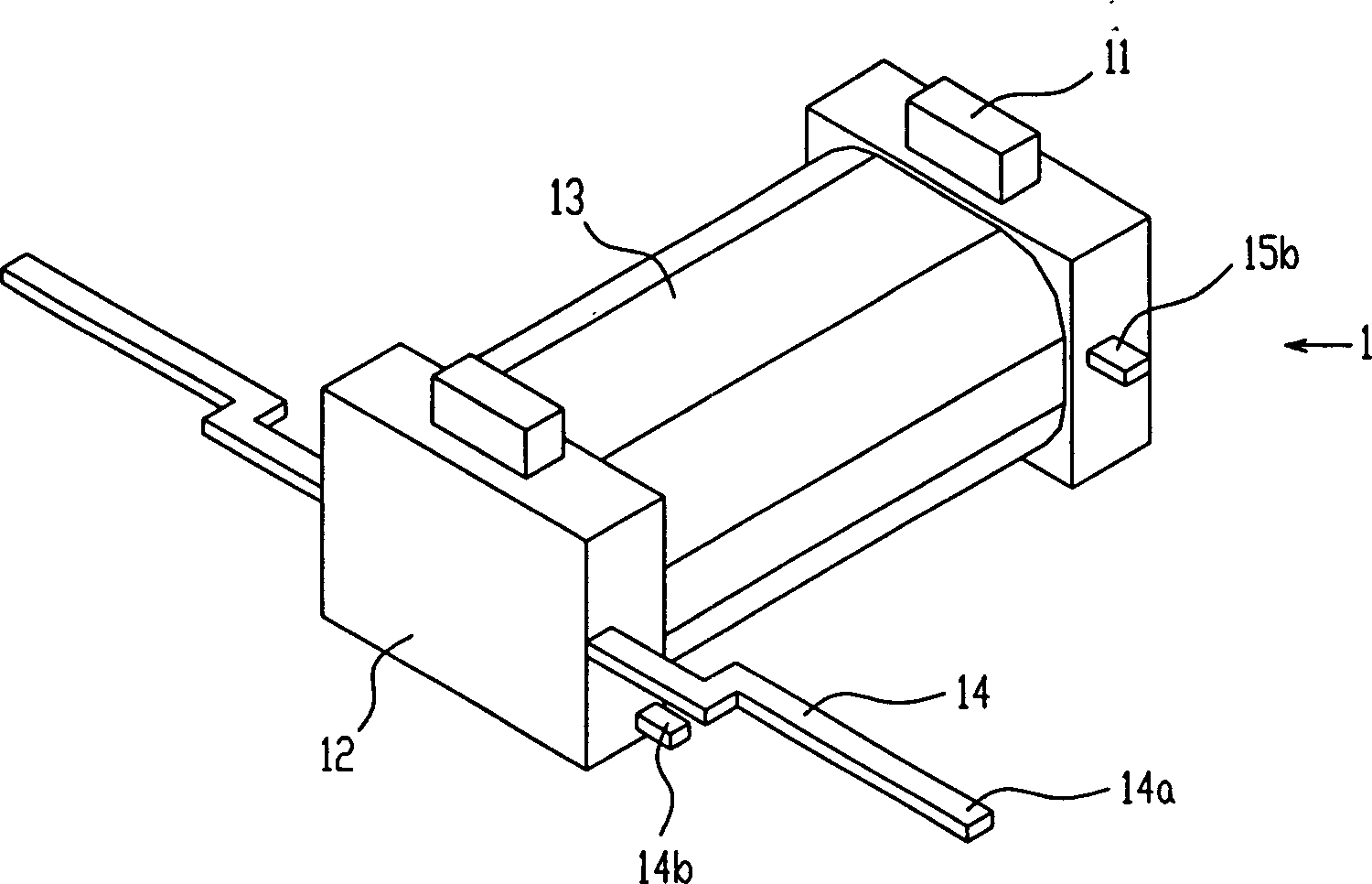

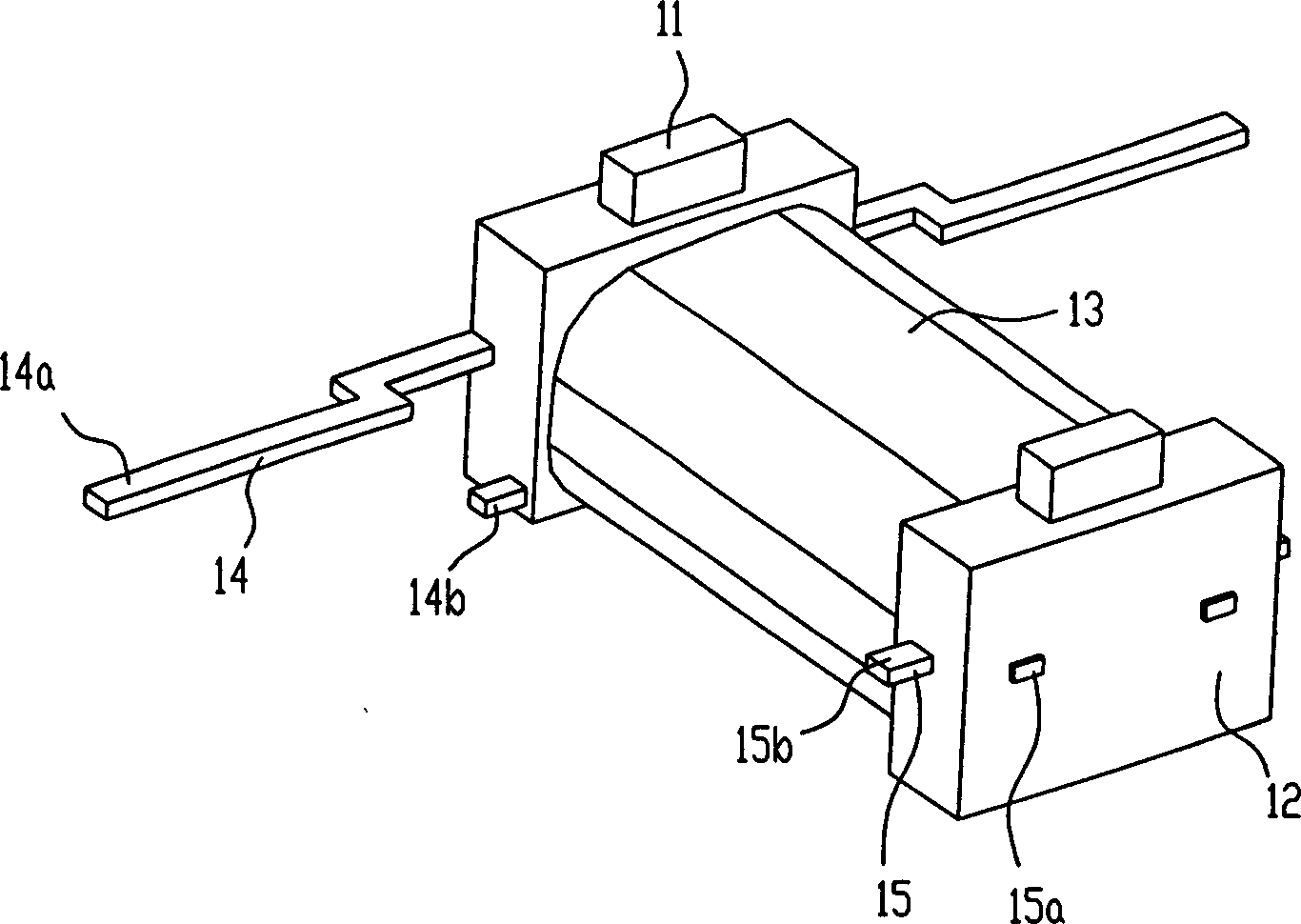

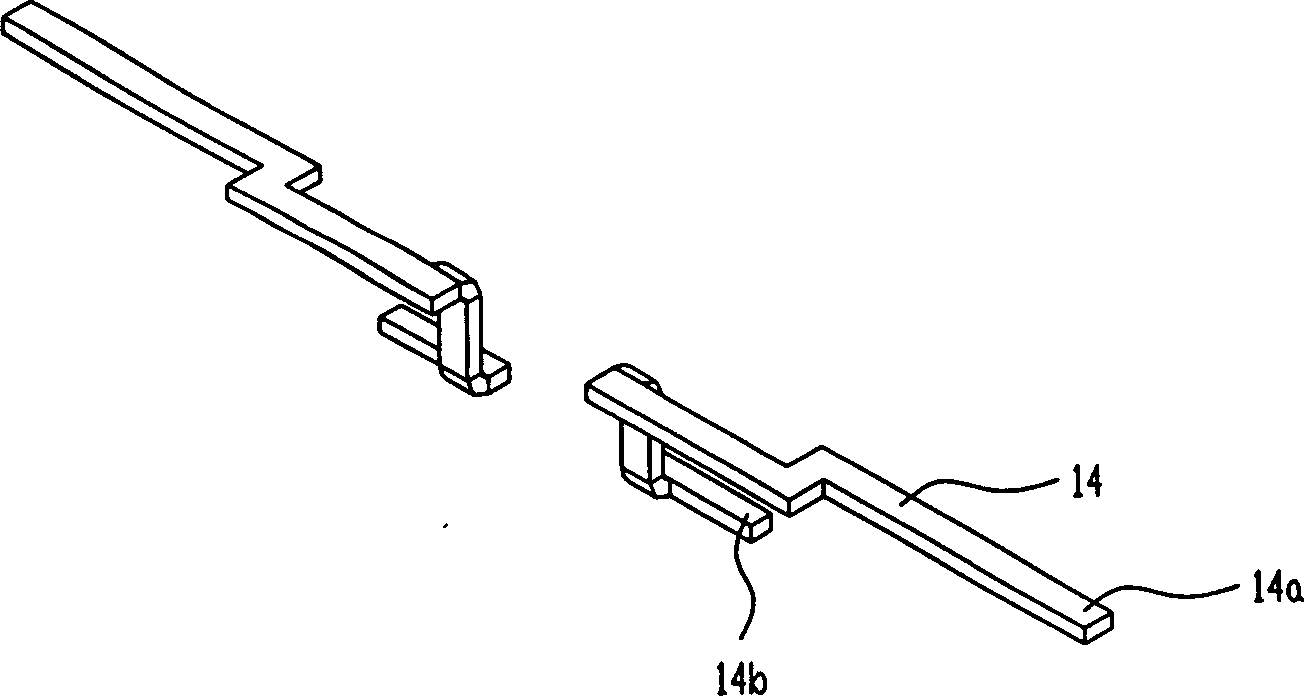

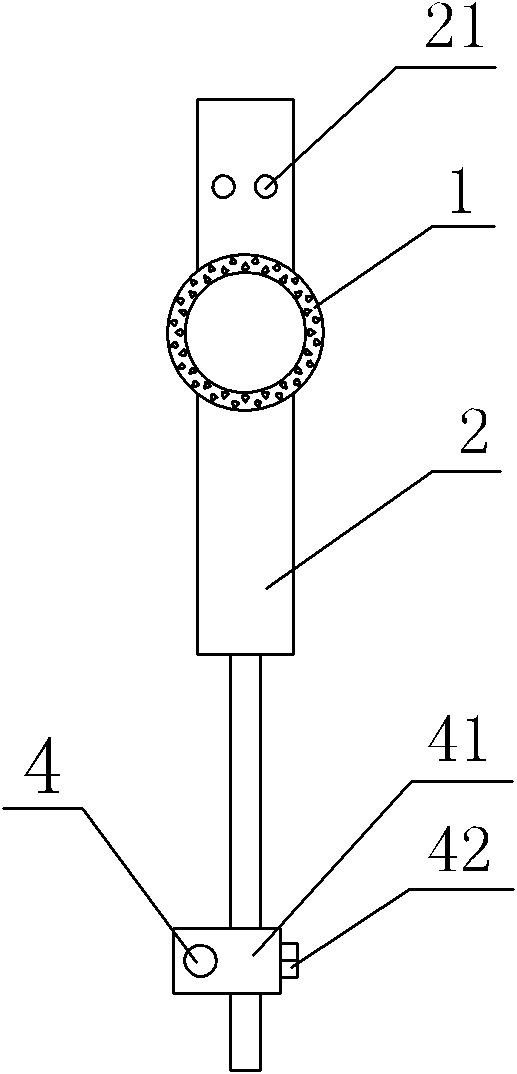

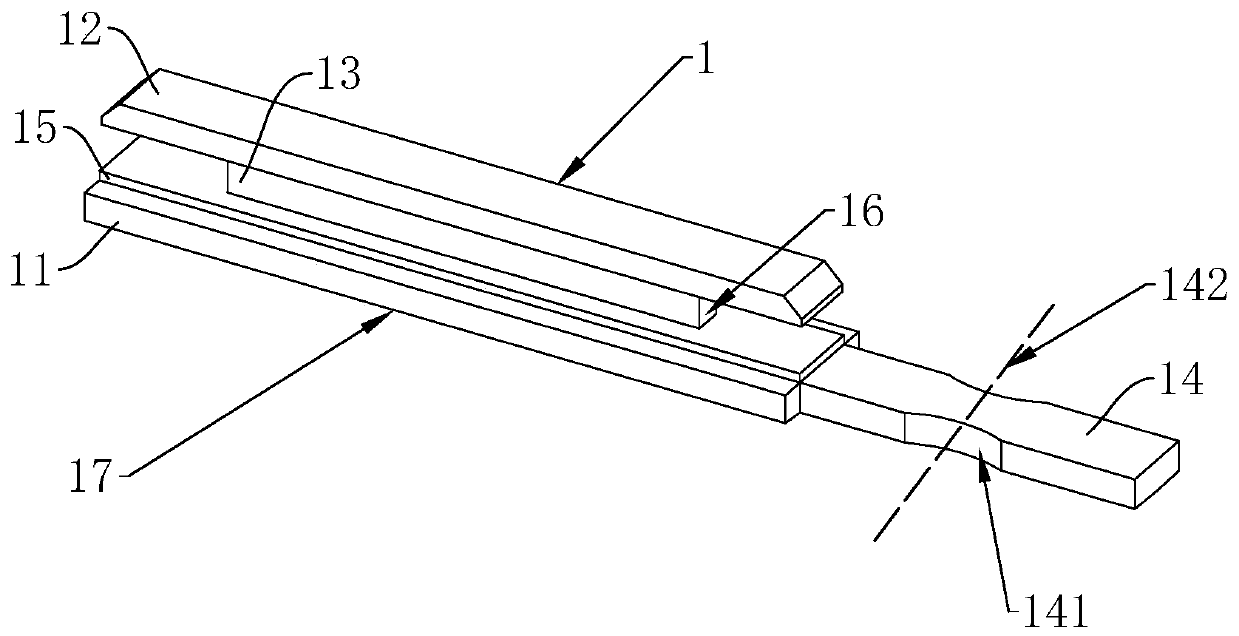

Bobbin, motor, and method of winding magnet wire

InactiveUS7132774B2Reduce the overall diameterIncrease the winding spaceSynchronous generatorsWindings insulation shape/form/constructionBobbinEngineering

A bobbin comprises three hollow-cylindrical sections, specifically a middle body section, and two lateral body sections. The middle body section has its diameter diminished compared to the two lateral body sections thus forming an annular recess which allows a magnet wire to be wound with an additional number of turns around the bobbin without increasing a motor size. With this bobbin structure, when the number of turns of a magnet wire is set to remain unchanged, the diameter of flanges of the bobbin can be reduced resulting in a downsized motor.

Owner:MINEBEA CO LTD

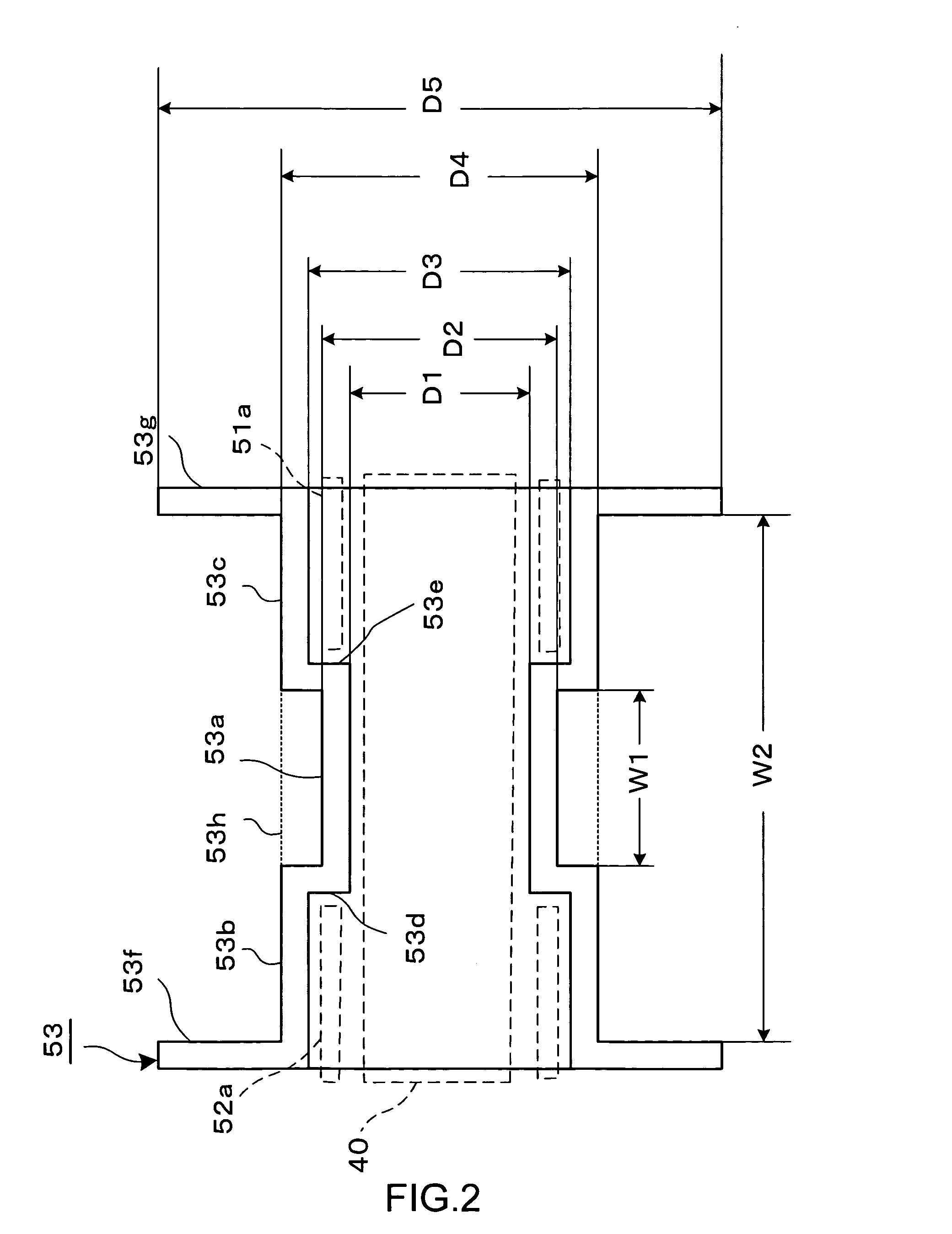

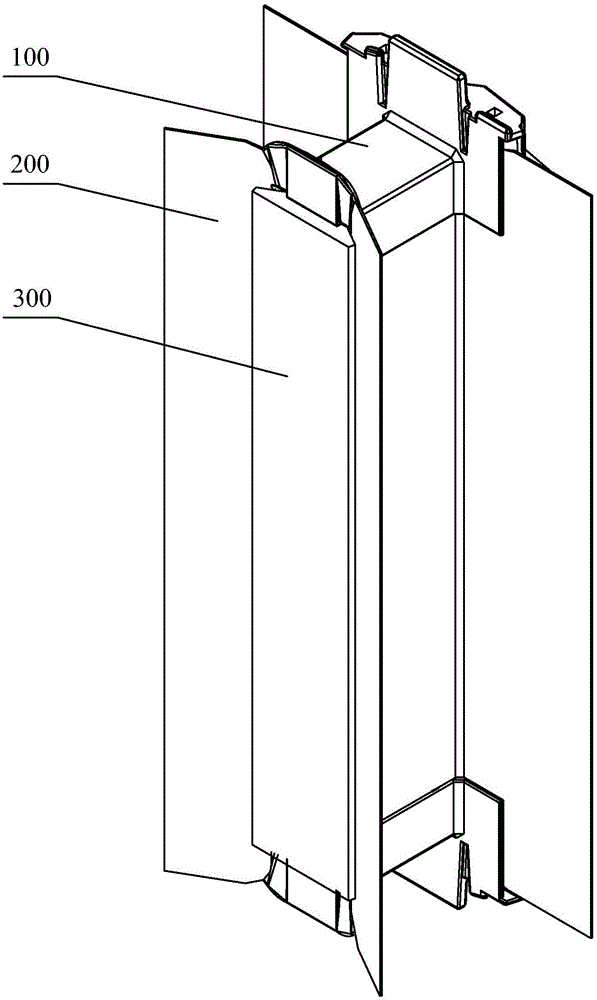

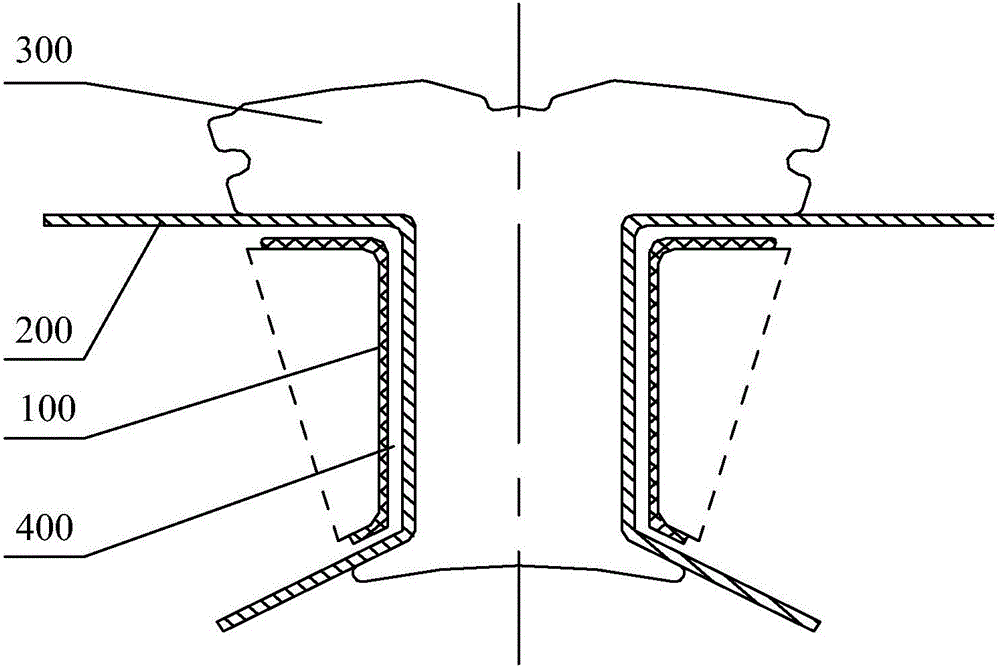

Insulated frame and motor

ActiveCN105006901ABig spaceGuaranteed slot fullnessWindings insulation shape/form/constructionCopper wireEngineering

The embodiment of the present invention discloses an insulated frame which comprises a first frame body which is bonded to insulating groove paper of one side of an iron core and a second frame body which is bonded to insulating groove paper of the other side of the iron core. The first frame body and the second frame body are in a fit. The insulated frame is different from the prior art, a splice structure is employed, the insulated frame is designed to be two parts, two frame bodies are installed from two sides of the iron core in assembly, the inner walls of the installed first frame body and second frame body can be bonded to insulating groove paper closely, thus the space of copper wire winding is increased, the groove full rate is ensured, the installation from the two sides is easy, and the installation difficulty is reduced. The invention also discloses a motor.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

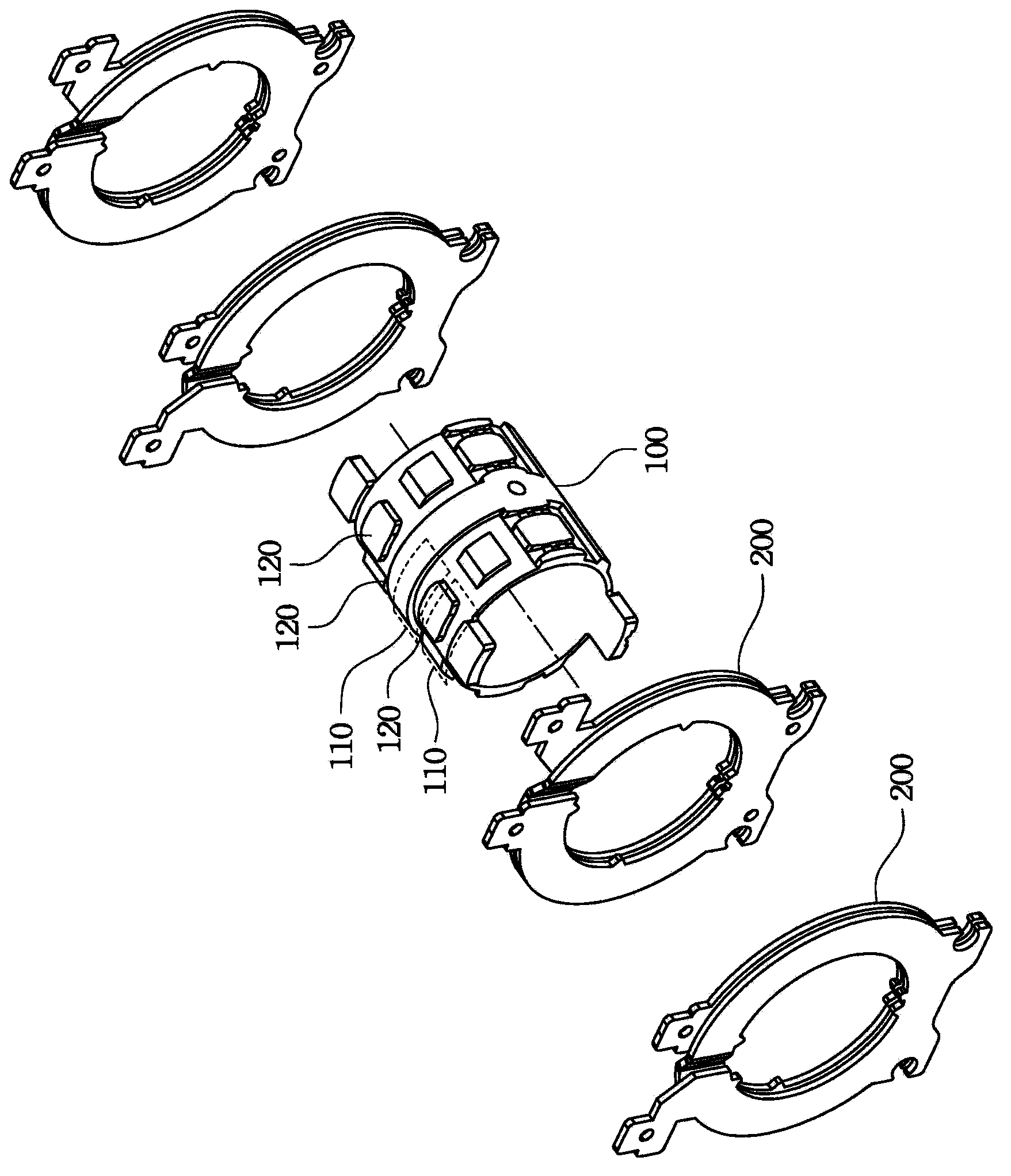

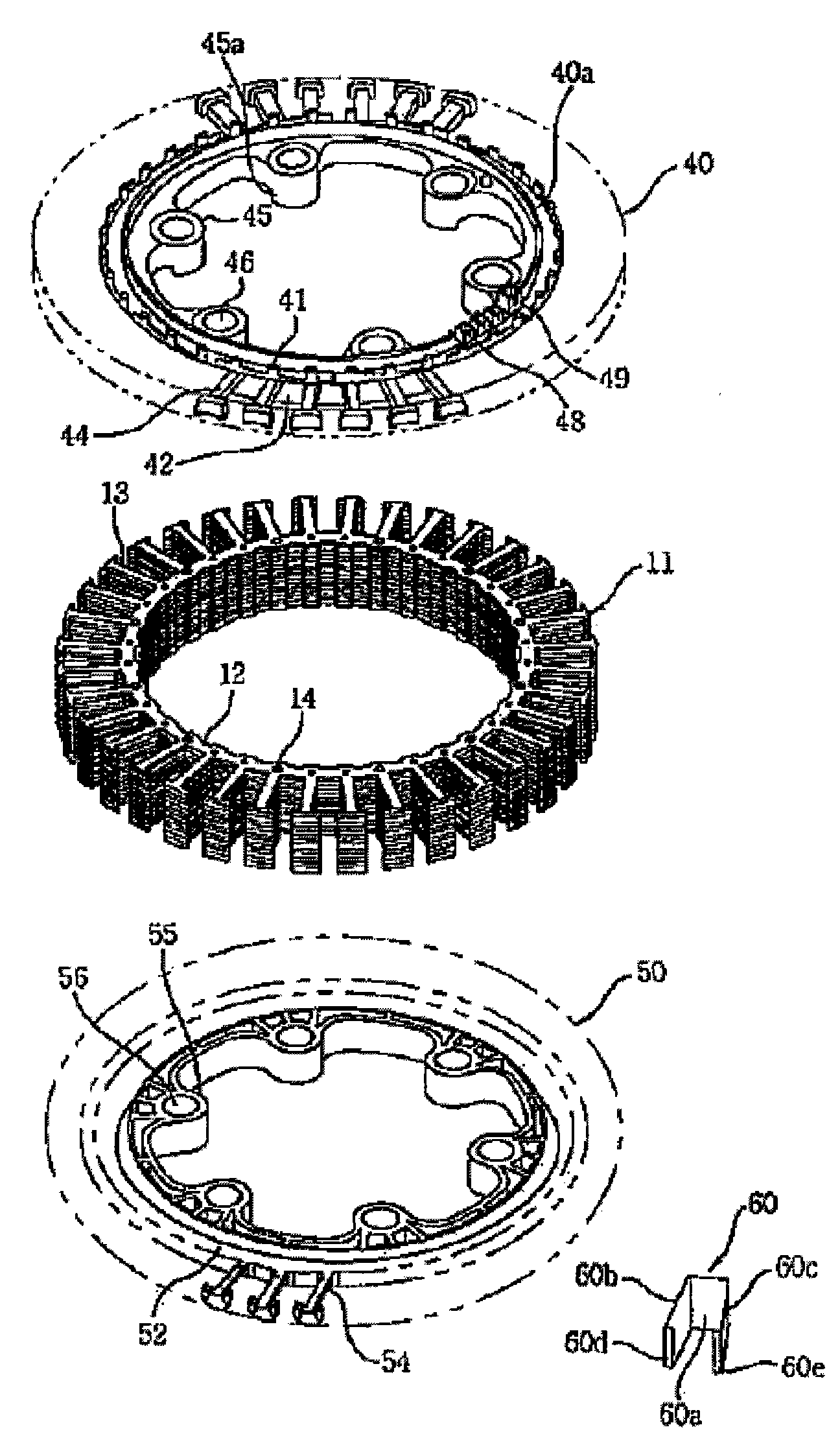

Magnetic component

ActiveUS20170278622A1Increase the winding spaceImprove efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

A magnetic component is disclosed. The magnetic component includes a magnetic core assembly, a fastening element, a first winding set and a second winding set. The magnetic core assembly includes at least a pillar. The fastening element is provided on an outer peripheral surface of the pillar. The first winding set is disposed around the outer peripheral surface of the pillar. The second winding set is disposed around the outer peripheral surface of the pillar and engaged with the fastening set. The first winding set and the second winding set are located adjacent to each other and disposed around the outer peripheral surface of the pillar.

Owner:DELTA ELECTRONICS INC

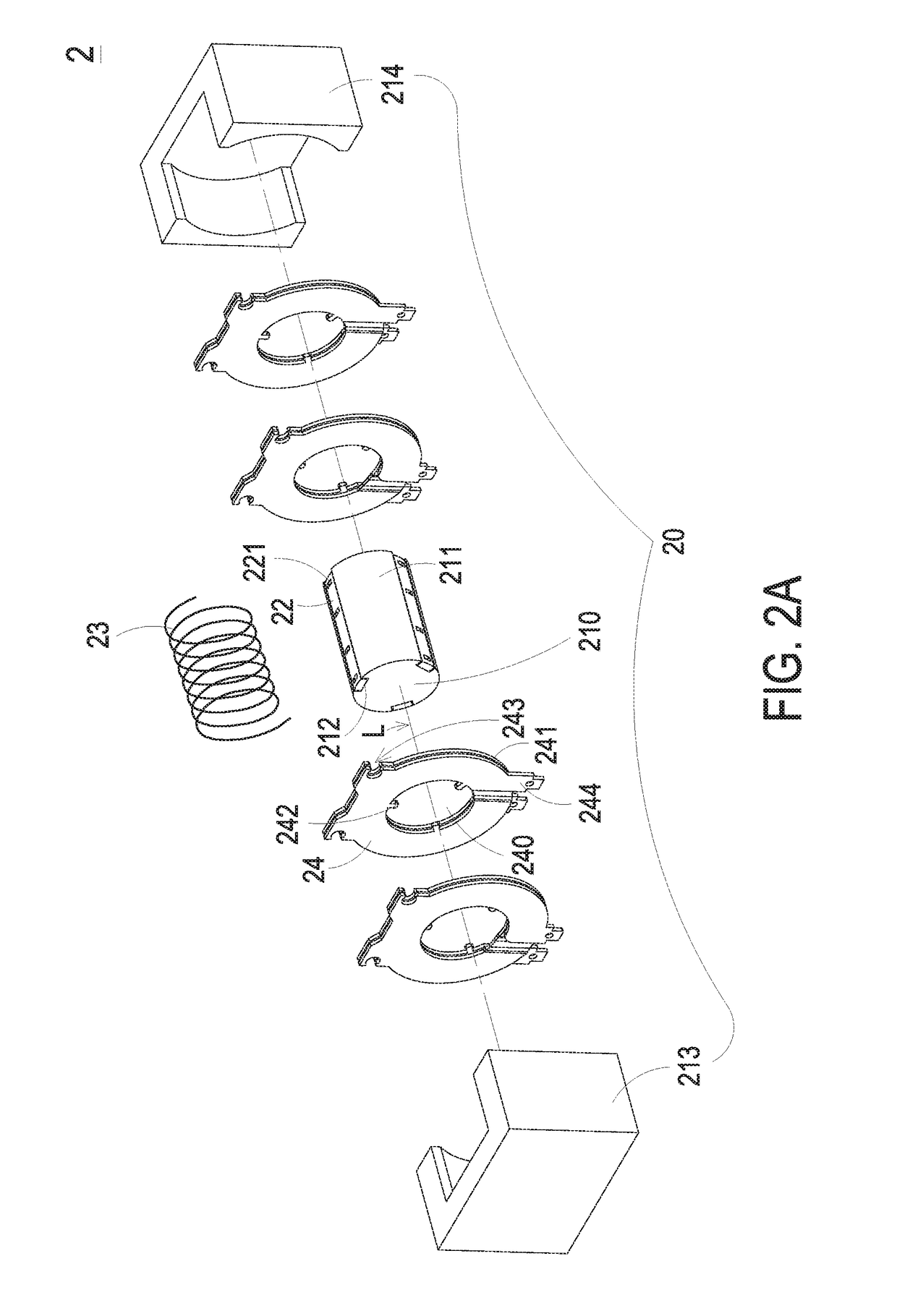

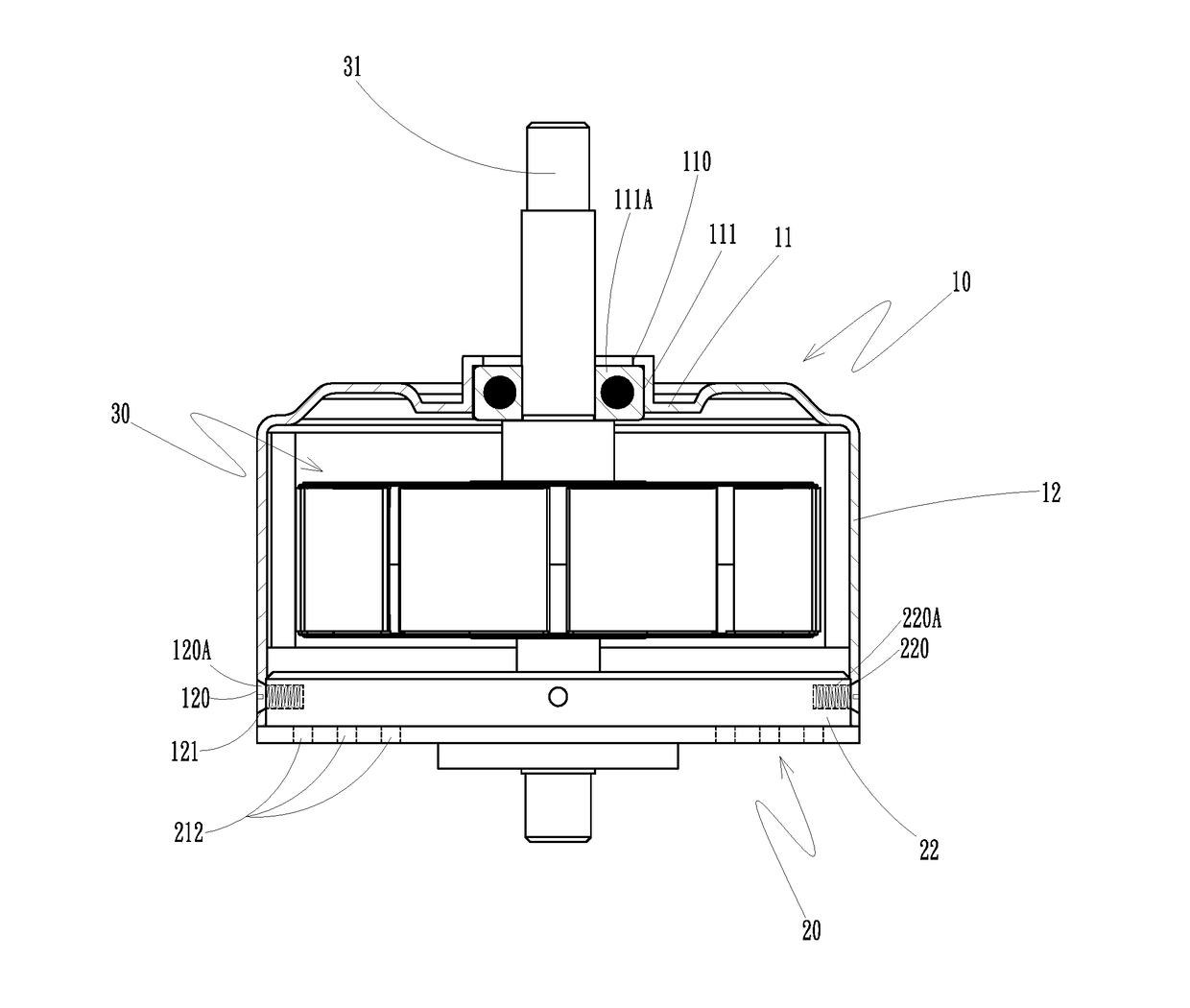

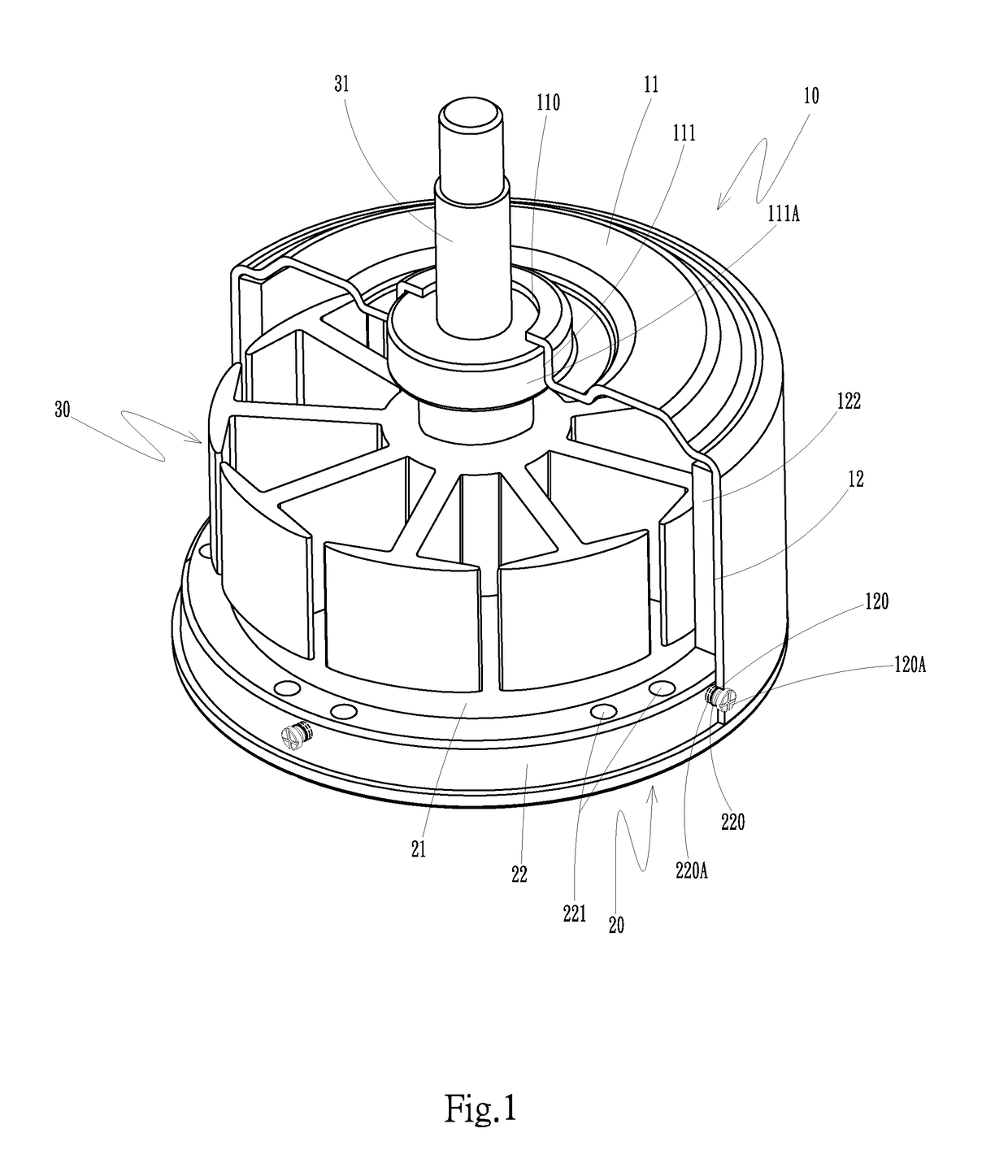

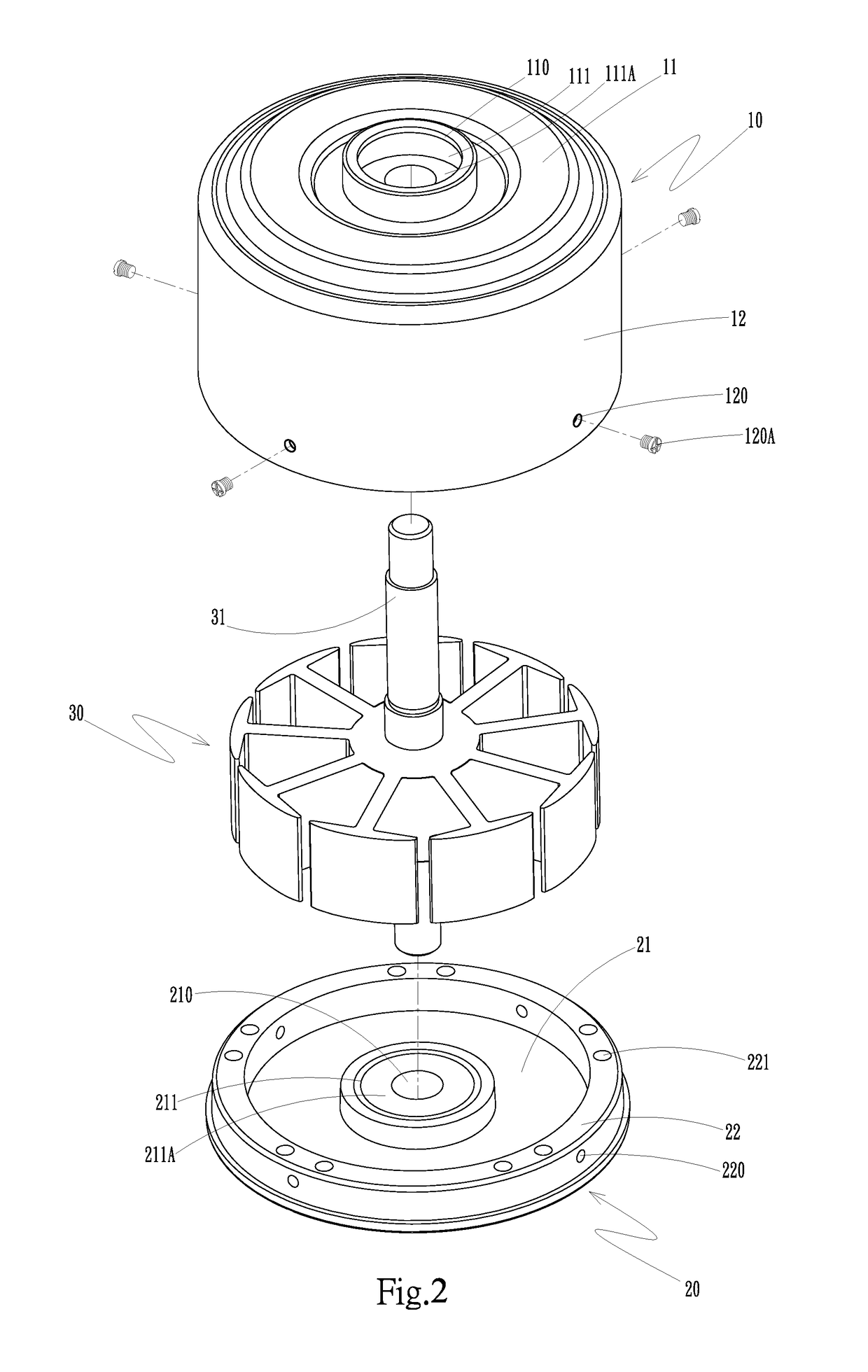

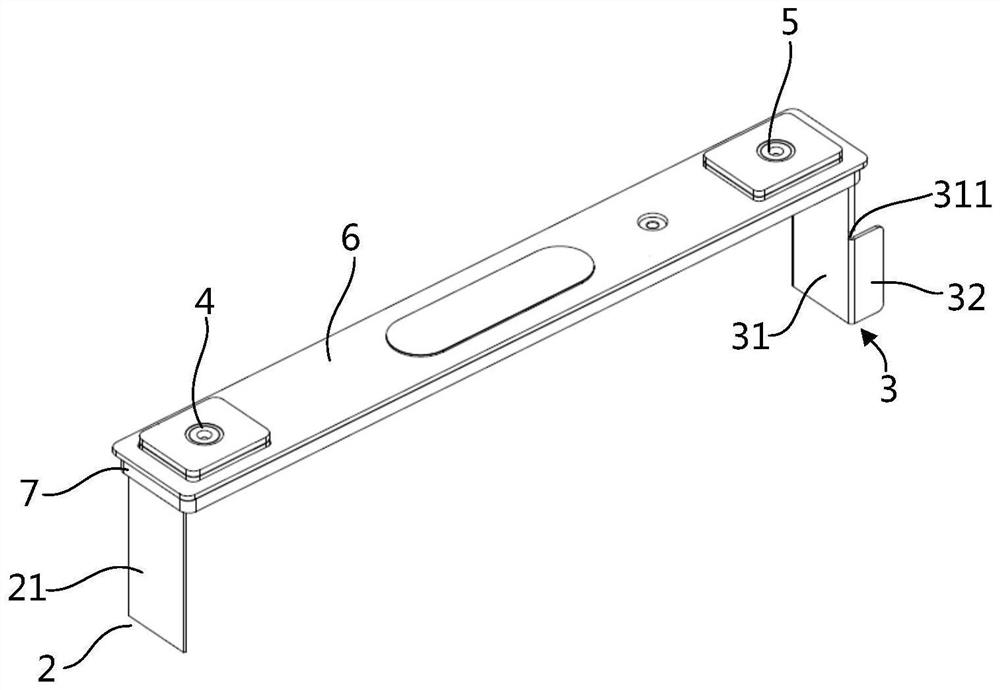

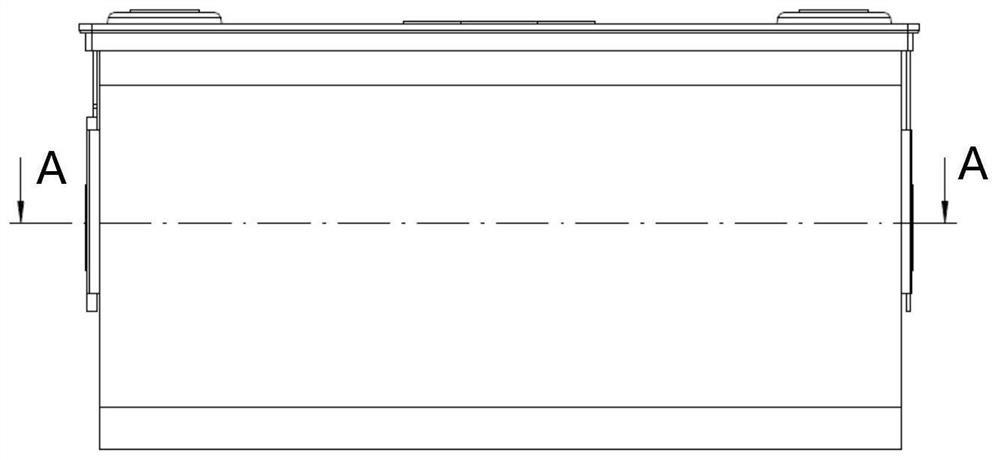

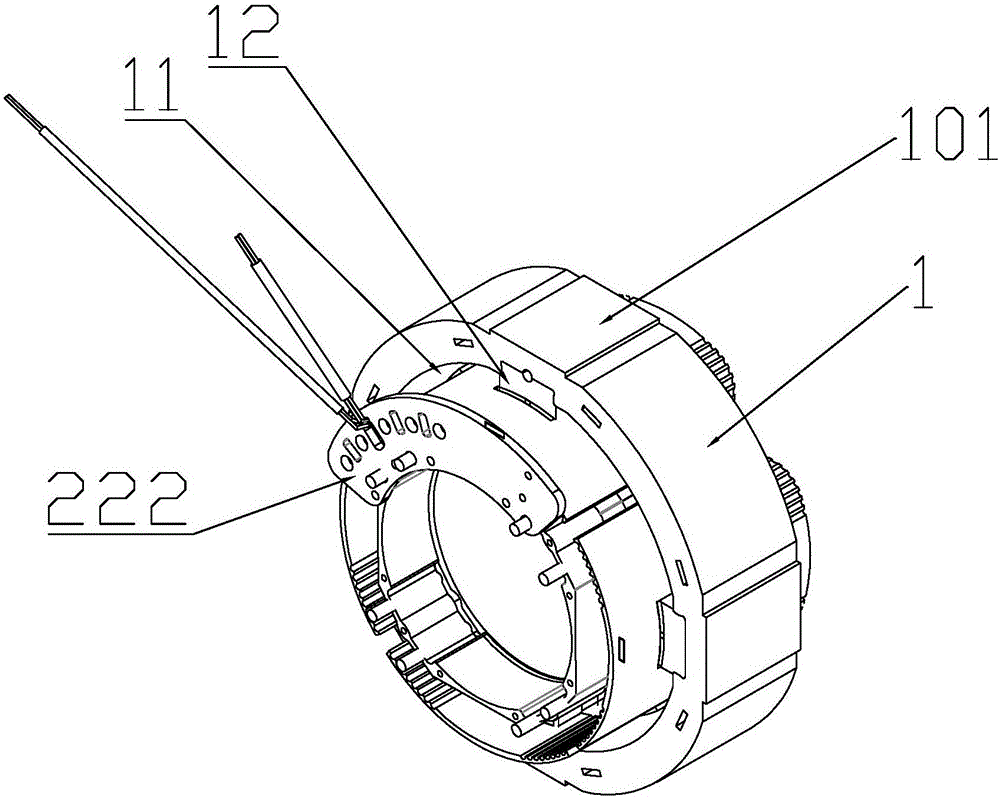

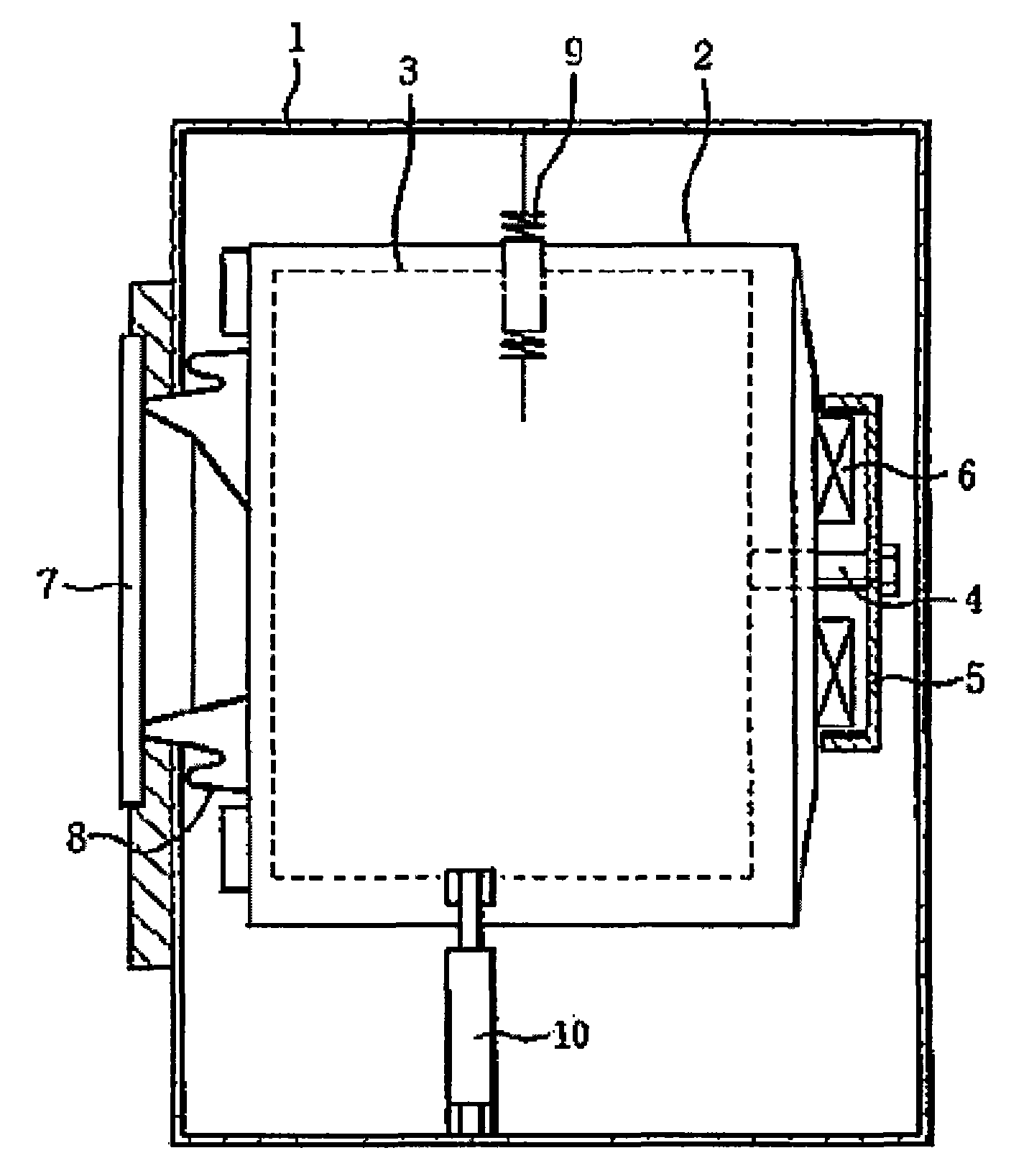

Ceiling fan motor housing and cover side fixing structure

ActiveUS20170175774A1Increase widthImproving wire winding space differencePump componentsMagnetic circuitCeiling fanEngineering

A ceiling fan motor housing and cover side fixing structure includes a motor housing, a cover and a stator. The motor housing includes a rotor and plural side guide holes formed on a sidewall. The cover includes plural fixing holes formed at an edge of a top circular flange, and the side guide holes opposite to the fixing holes are fixed by plural passing-through fixing members, so that the motor housing and the cover are combined for accommodating the stator to simplify the overall assembly of the ceiling fan motor effectively, and provide a convenient way of combining the motor housing and the cover without increasing the width. Further, the wire winding space of the stator in the motor housing and the cover of the ceiling fan motor is increased for convenient assembling.

Owner:CHAMP RAY INDAL

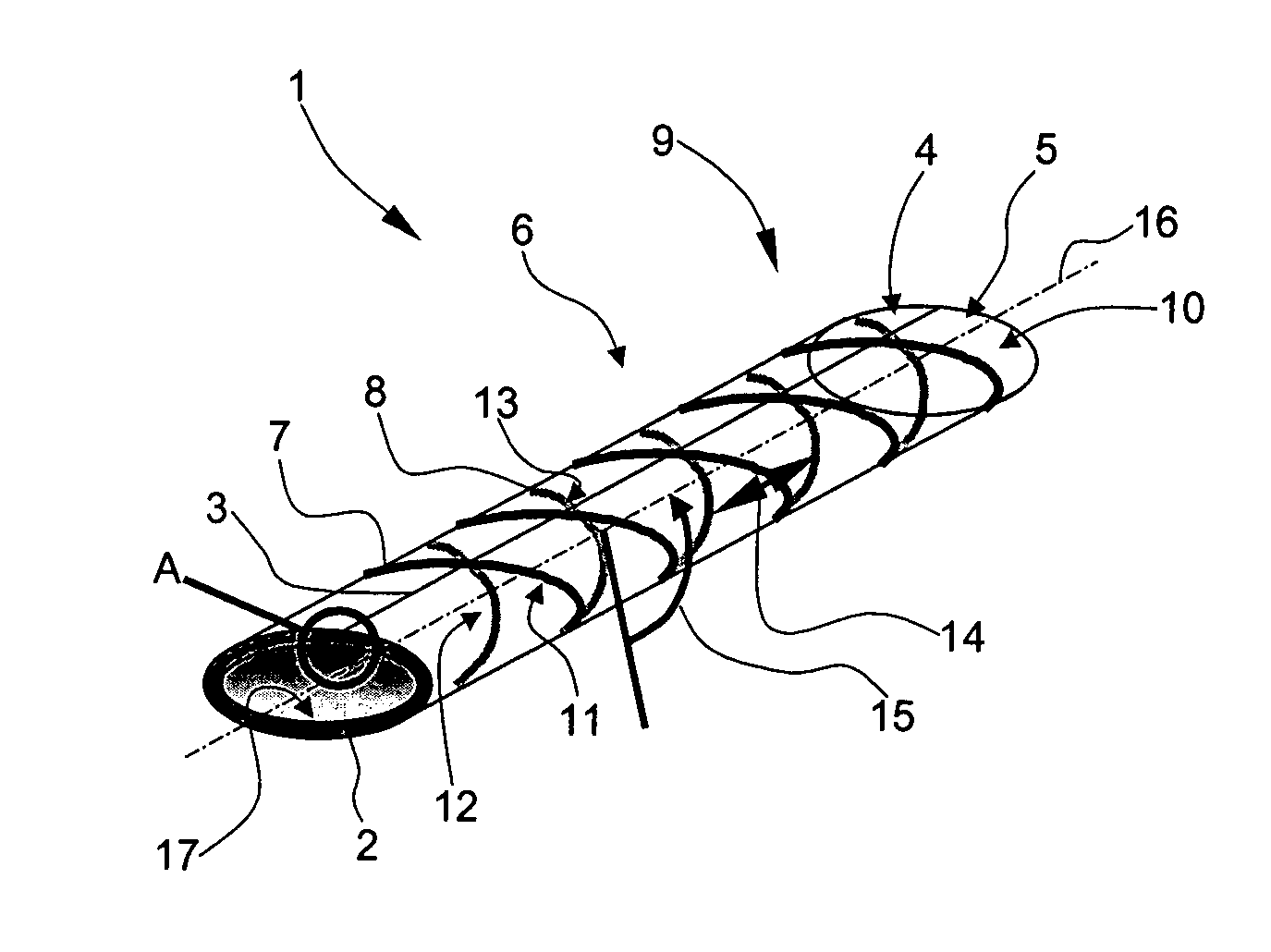

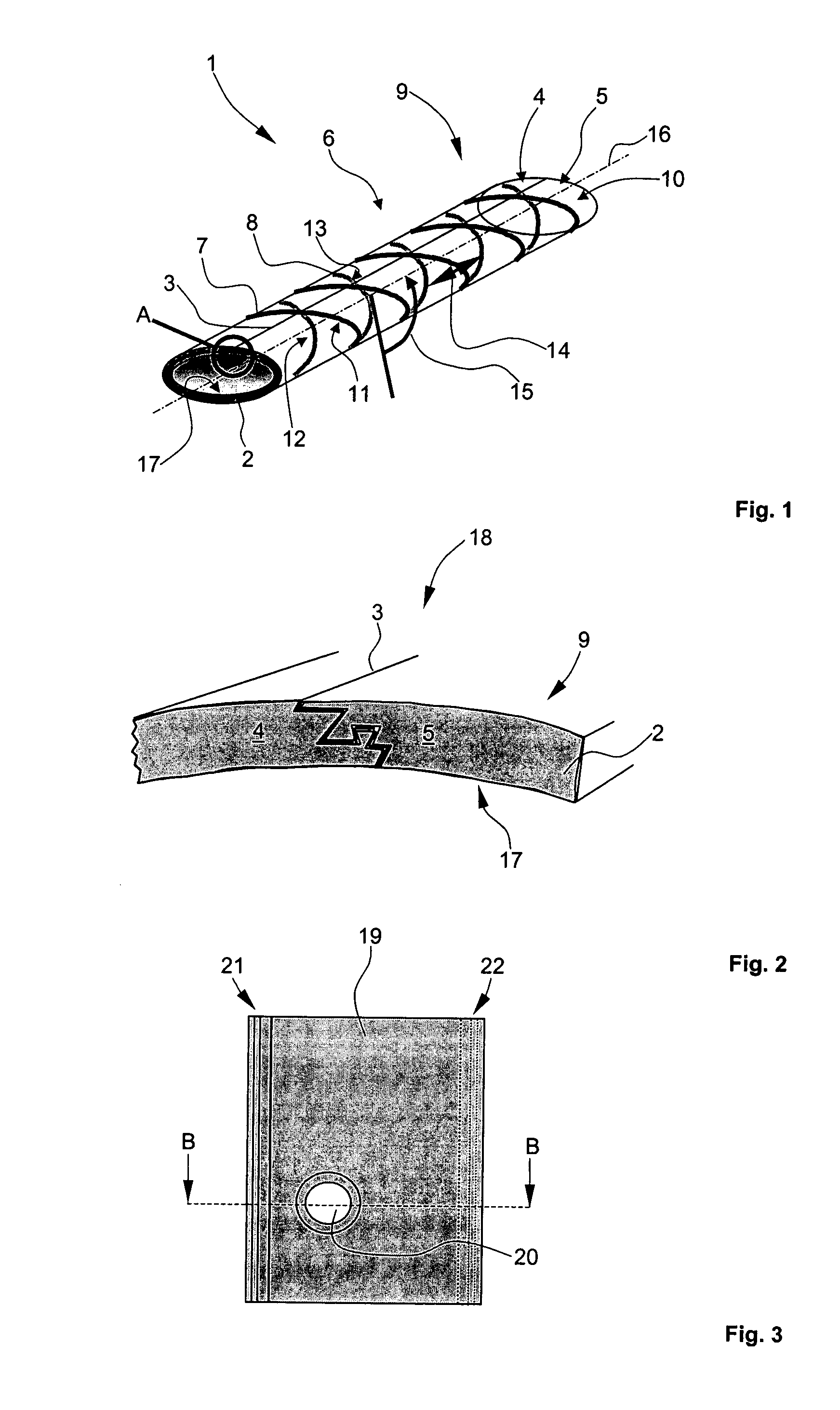

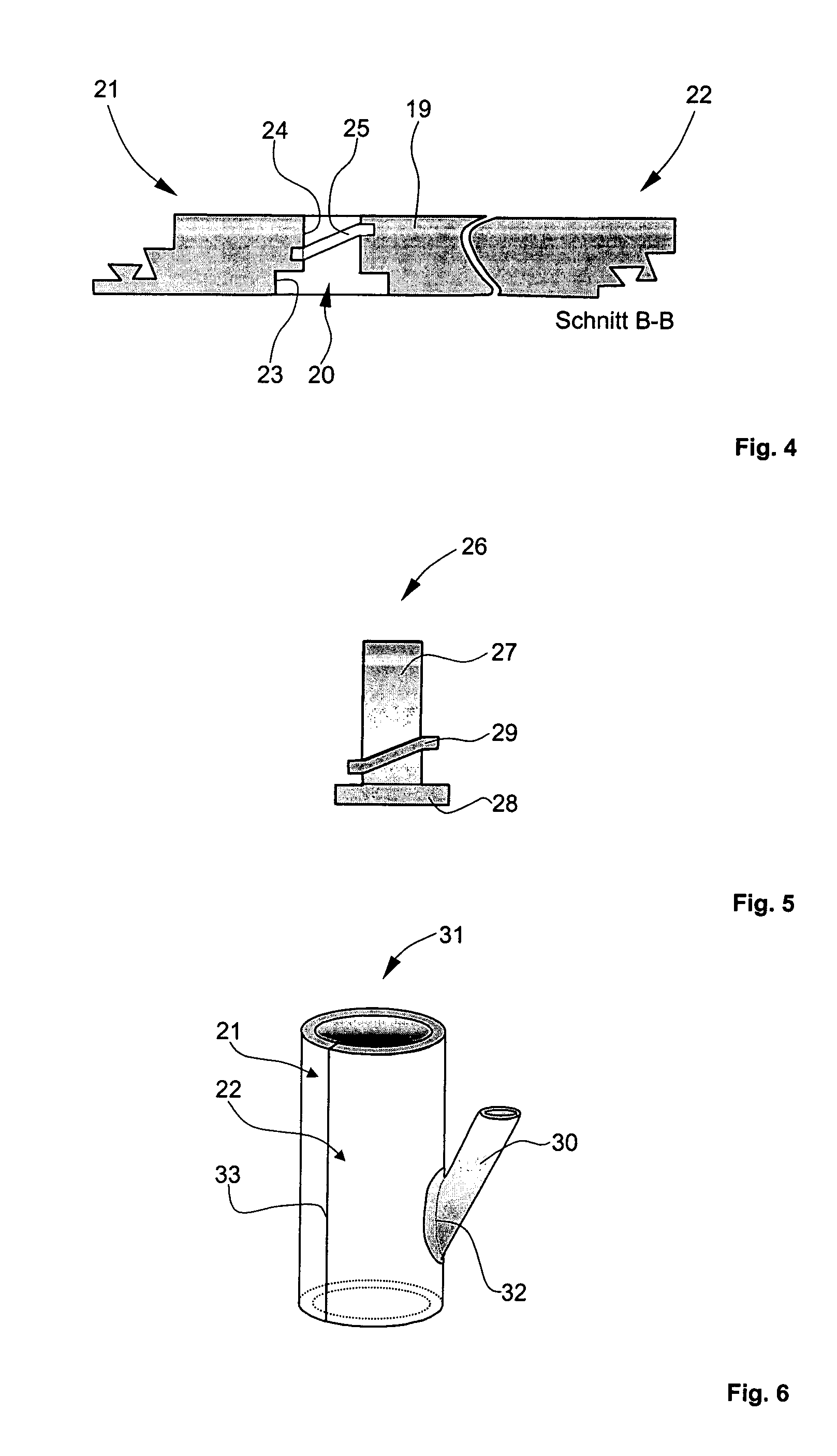

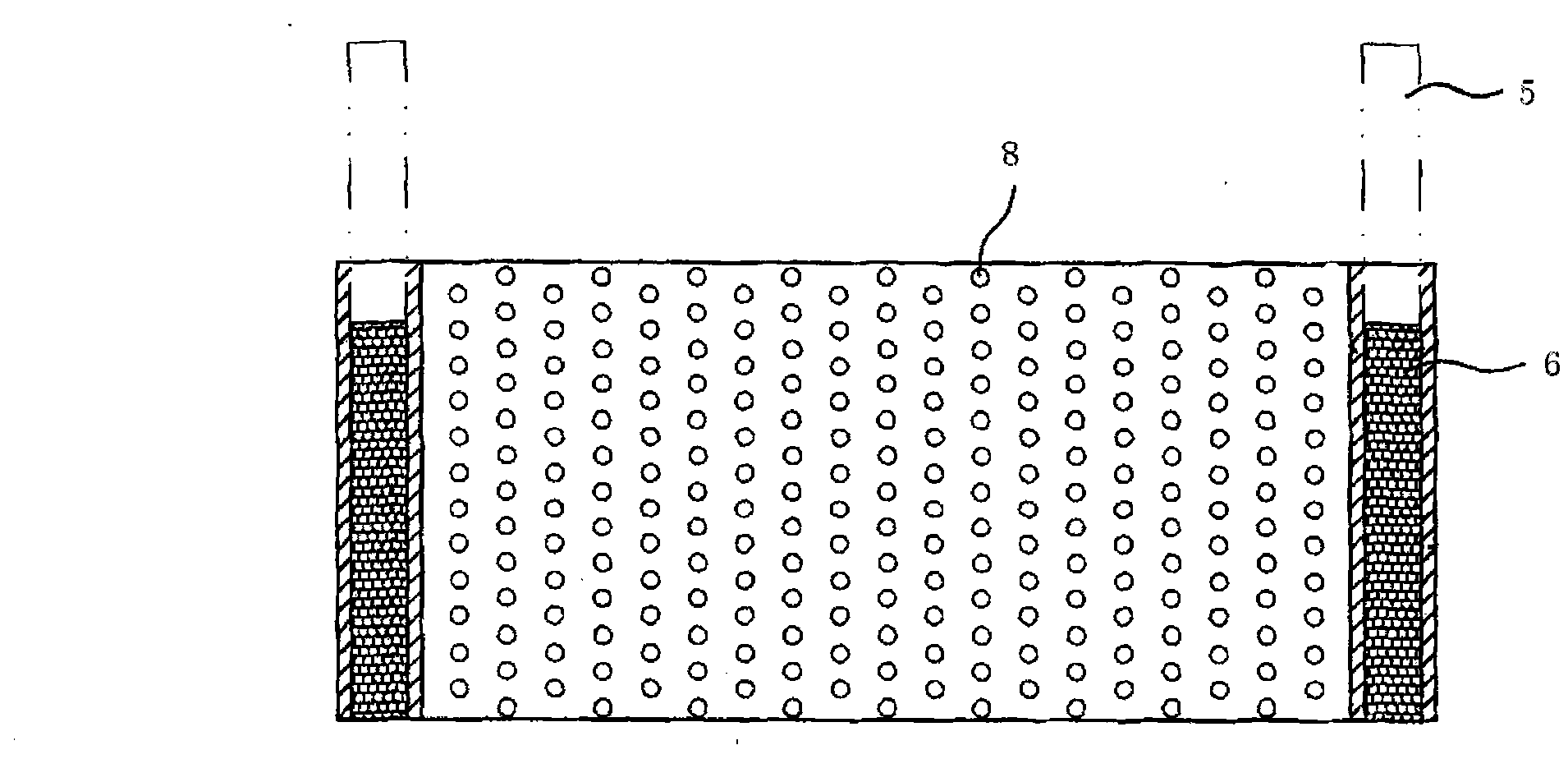

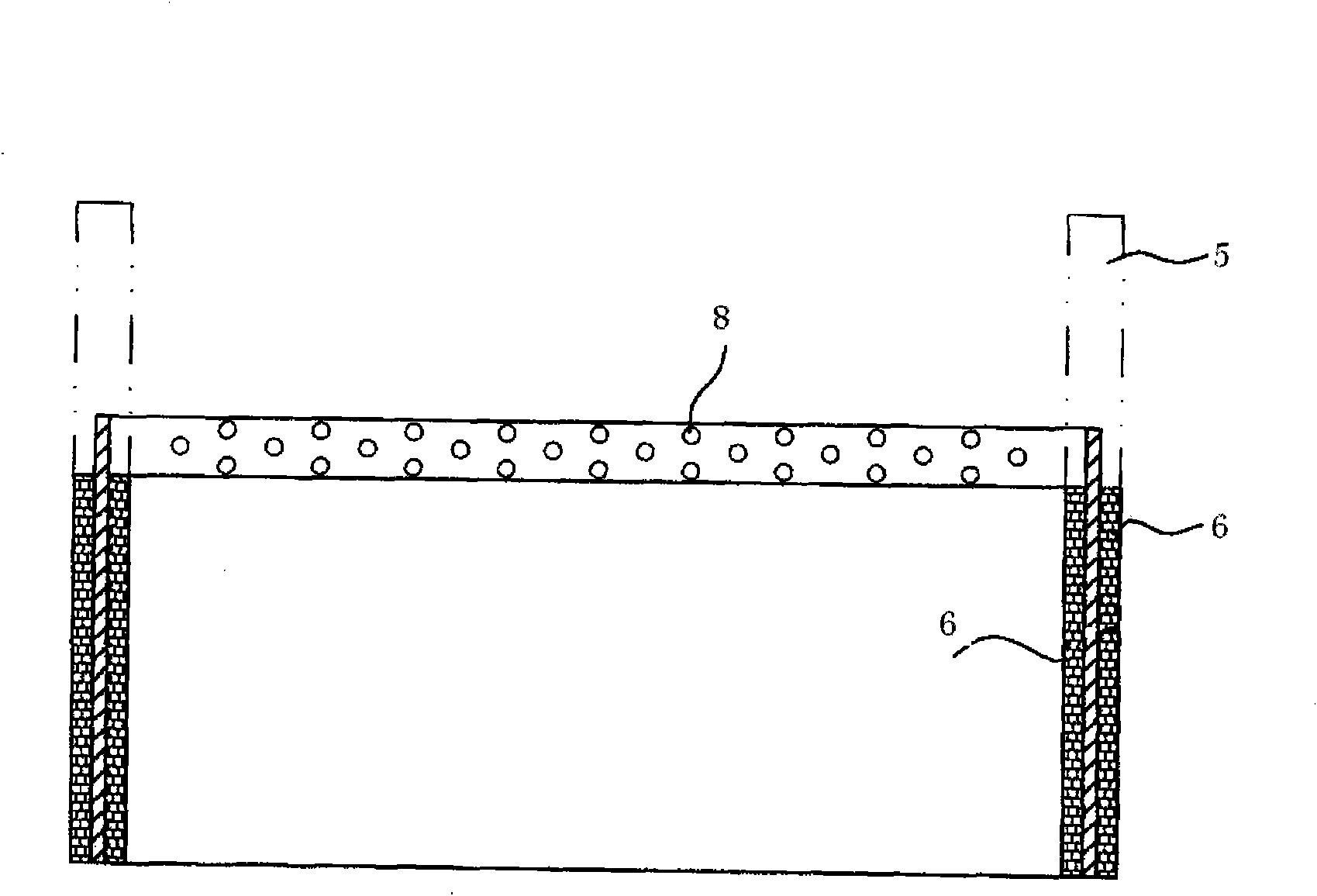

Pipeline for conducting air for air conditioning in aircrafts

InactiveUS8006722B2Improve air tightnessPressure dropLighting and heating apparatusAir-treatment apparatus arrangementsPlastic materialsContact layer

A pipeline for conducting air for air conditioning in aircrafts includes a body portion formed with foamed plastics material or with a dense plastics material. The body portion defines a longitudinal axis and includes an outer surface carrying a wrapping for reinforcing the pipeline. The wrapping includes a plurality of adjacent contacting layers formed by at least one linear reinforcing element wound into a plurality of windings, with adjacent layers having windings angled in opposite directions to form a net-like structure of the wrapping. At least one of the spacing between the windings along the longitudinal axis or the angle of slope between the windings and the longitudinal axis varies in certain sections to change the winding density as a function of local mechanical load requirements on the pipeline.

Owner:AIRBUS OPERATIONS GMBH

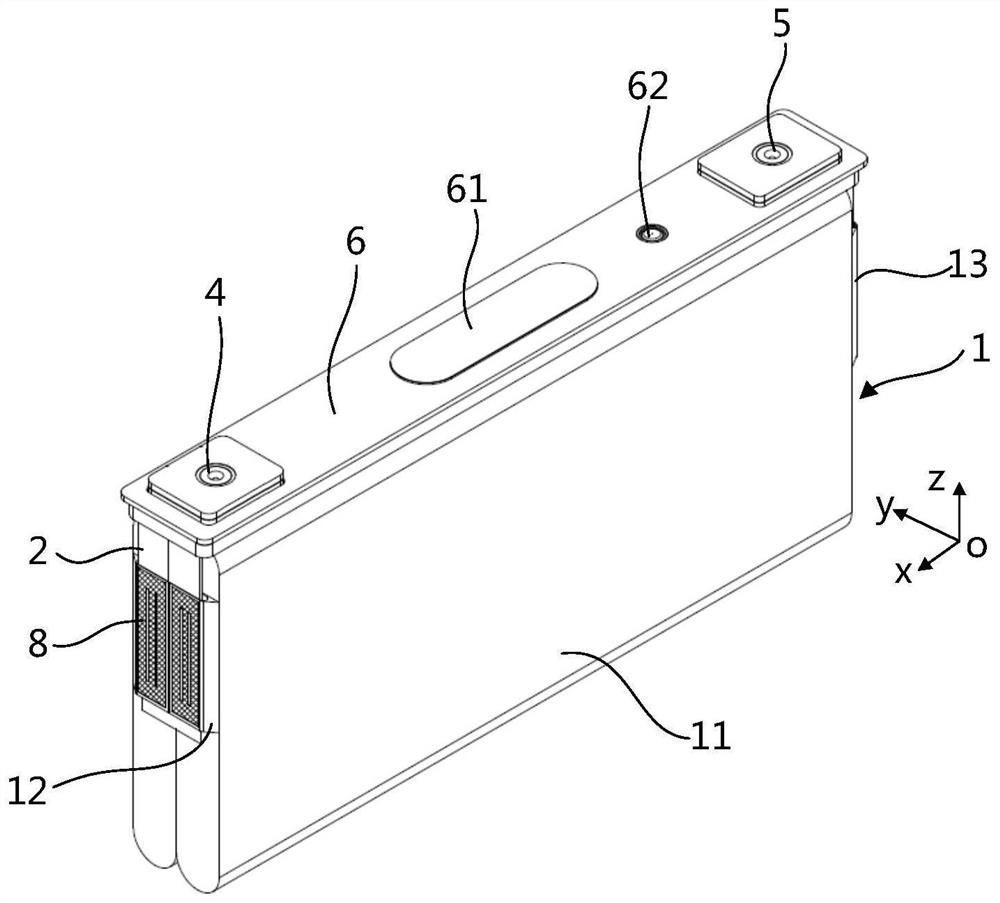

Battery unit and manufacturing method thereof and battery module

PendingCN111987340AIncrease winding spaceIncrease energy densityFinal product manufactureElectrode carriers/collectorsPhysicsEngineering

Owner:CONTEMPORARY AMPEREX TECH CO

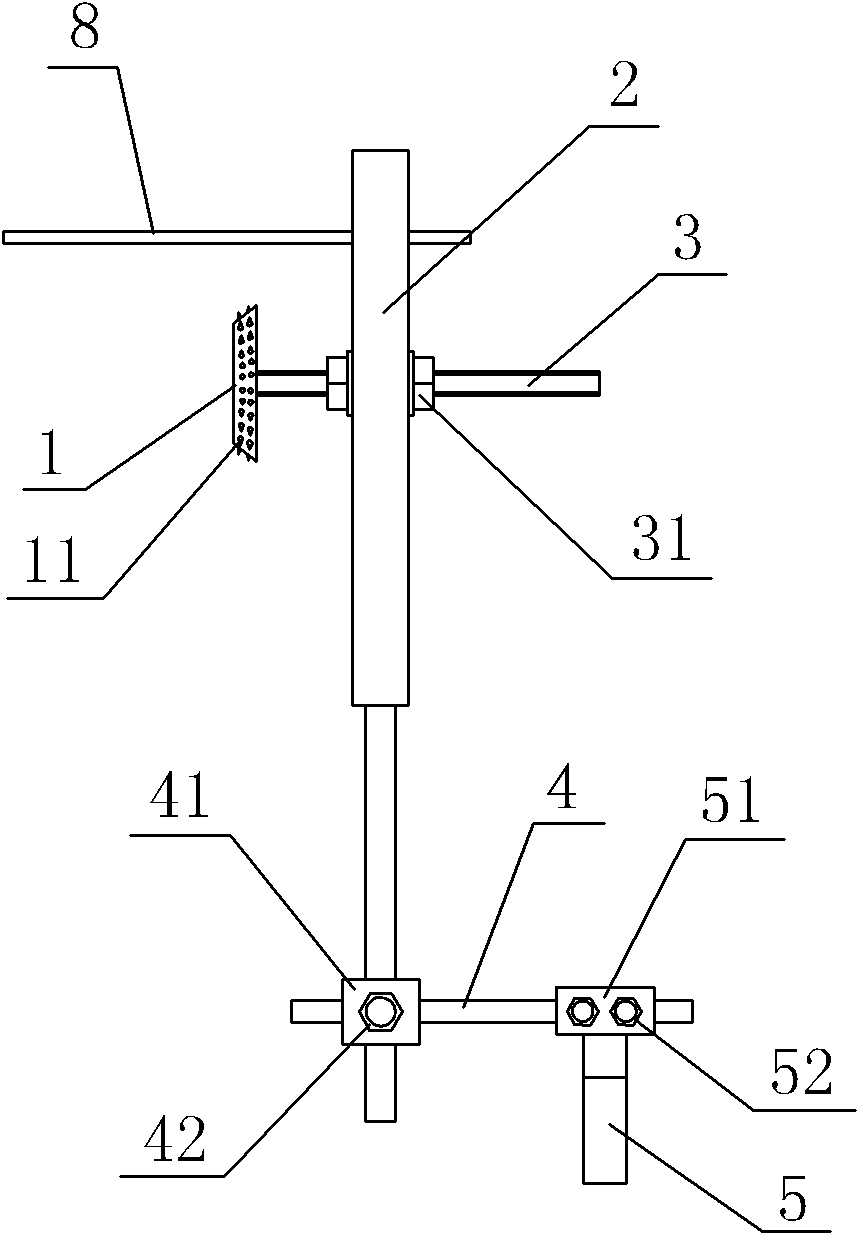

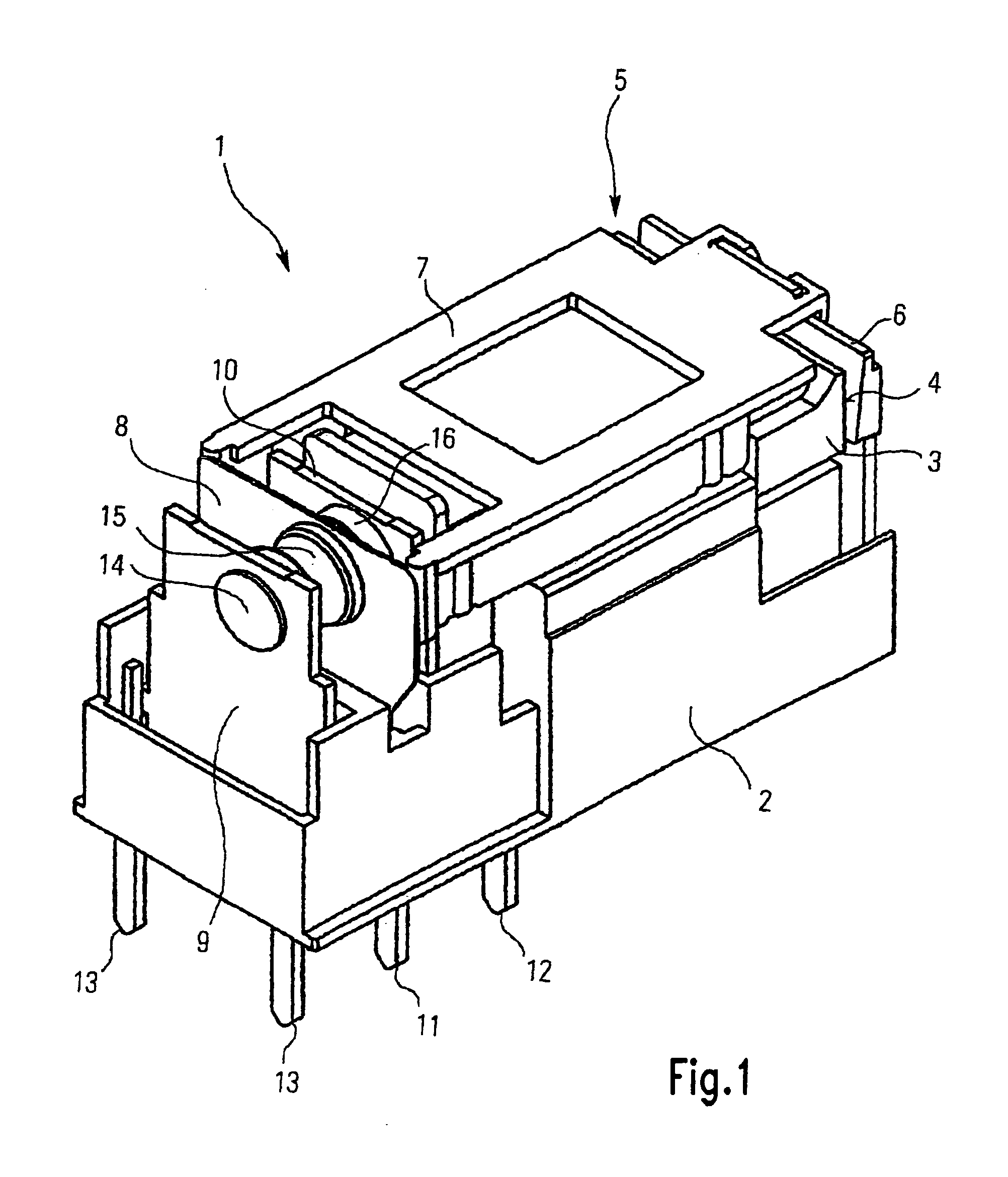

Coil component of electromagnetic relay

ActiveCN1697112AIncrease the winding spaceImprove magnetic efficiencyElectromagnetic relay detailsMiniaturizationEngineering

The invention discloses coil assembly with C-shaped magnetic guiding part of electromagnetic relay. The coil assembly includes C-shaped magnetic guiding part, insulating coil former, coil, and at least one pair of pin of lead out wire. Coil is wound on the insulating coil former. Each pin of lead out wire includes two free ends; one free end is pin of lead out wire of relay, and the other free end is a wrapping end for coil. In the invention, the said wrapping end and the pin of lead out wire of relay are combined as an integrated pin of lead out wire, which is injection-molded with part of coil former. Thus, the invention possesses advantages of omitting procedure for welding contact piece and lead out piece etc, eliminating cold joint, simplifying production technique, miniaturized relay, and raising stability, acceptability of products as well as production efficiency etc.

Owner:XIAMEN HONGFA SIGNAL ELECTRONICS CO LTD

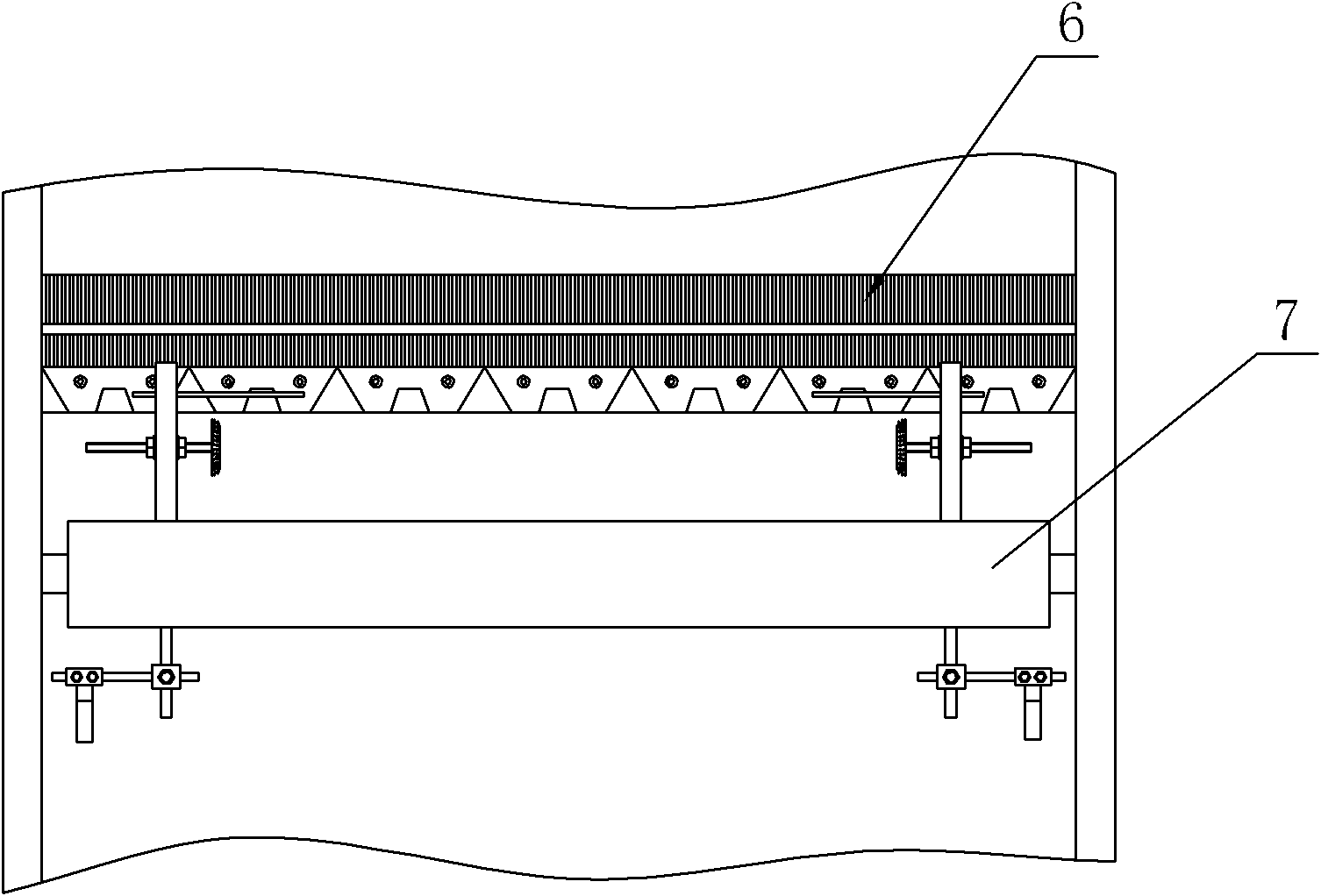

Electrodynamic vibration shaker

InactiveCN102338686ARaise the first order resonance frequencyImprove reliabilityVibration testingCooling effectConductor Coil

The invention discloses an electrodynamic vibration shaker which comprises: a shaker body, a magnetic cylinder, an exciting winding, a moving coil skeleton, a drive coil, a suspension supporting guiding device and a cooling device. A wall-cylinder-type metal winding reel is arranged on a bottom of the moving coil skeleton. The metal winding reel is formed by rolling a stainless steel plate. Through holes are arranged on a surface of the stainless steel winding reel. By using the electrodynamic vibration shaker, moving-coil first-order resonant frequency and moving-coil reliability can be raised; a cooling effect of an air-cooled bench can be increased. The stainless steel winding reel and the moving coil skeleton are fission structures so that components and parts processing difficulty and moving-coil winding technology difficulty can be substantially reduced.

Owner:周爱香

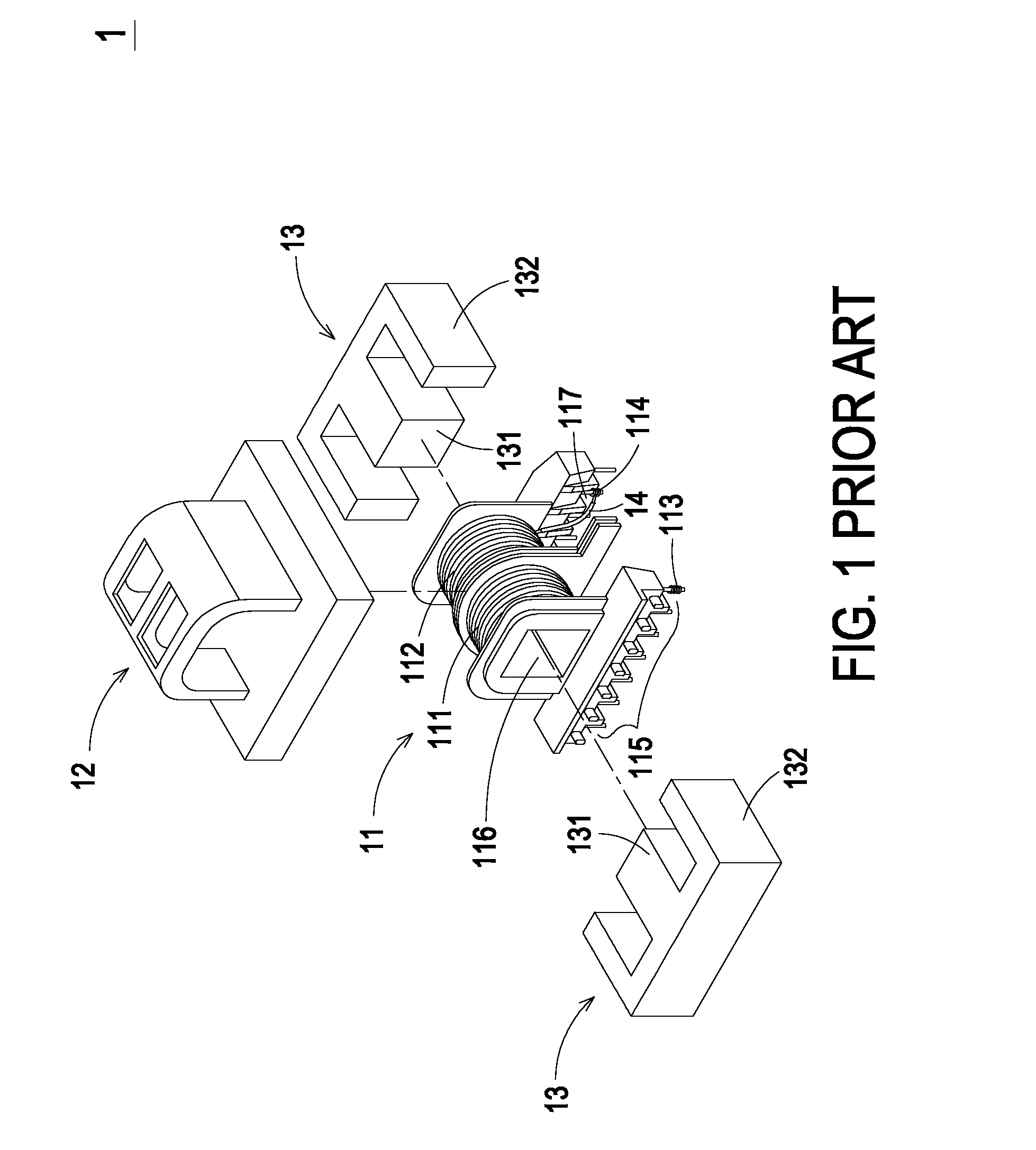

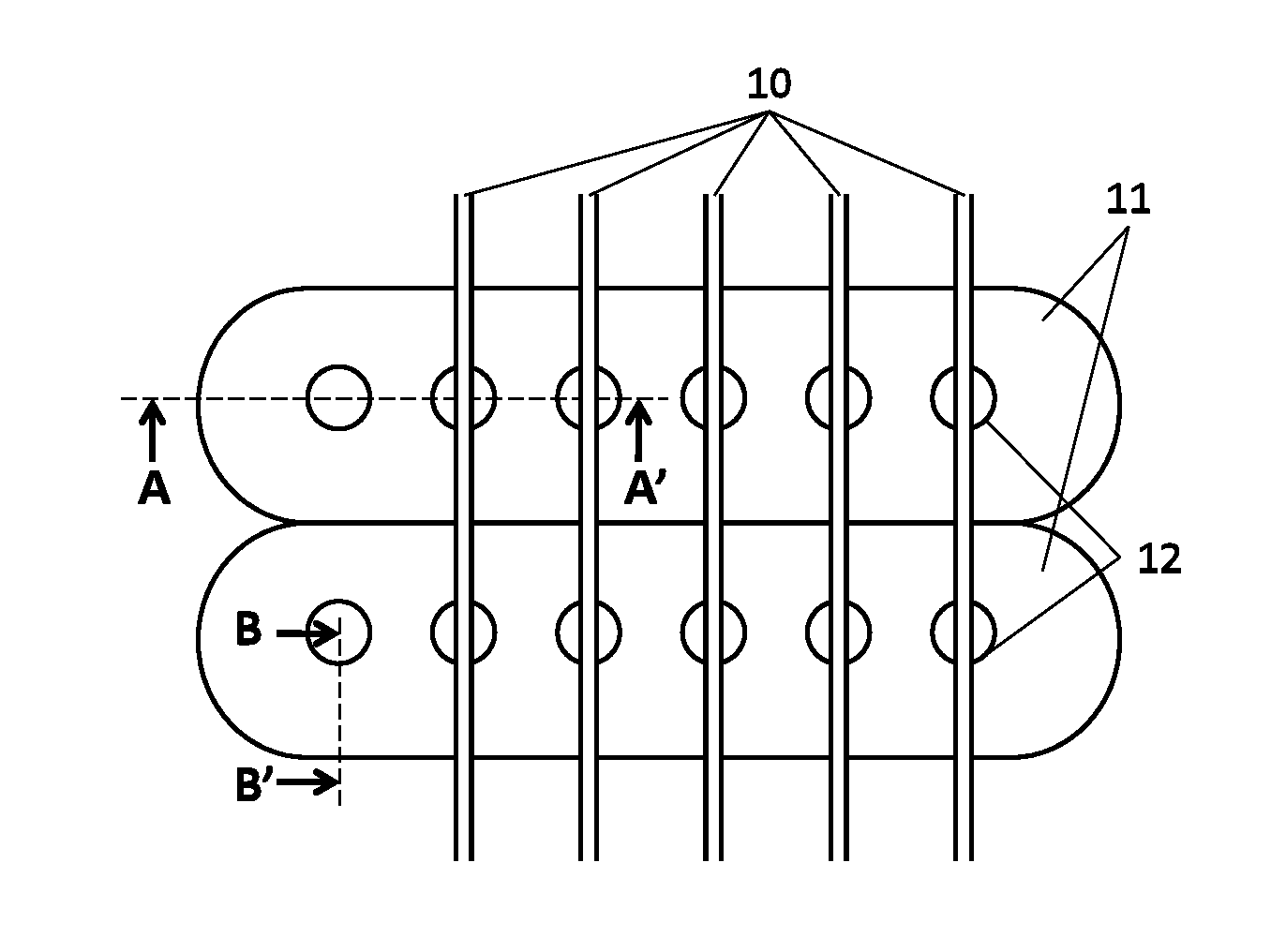

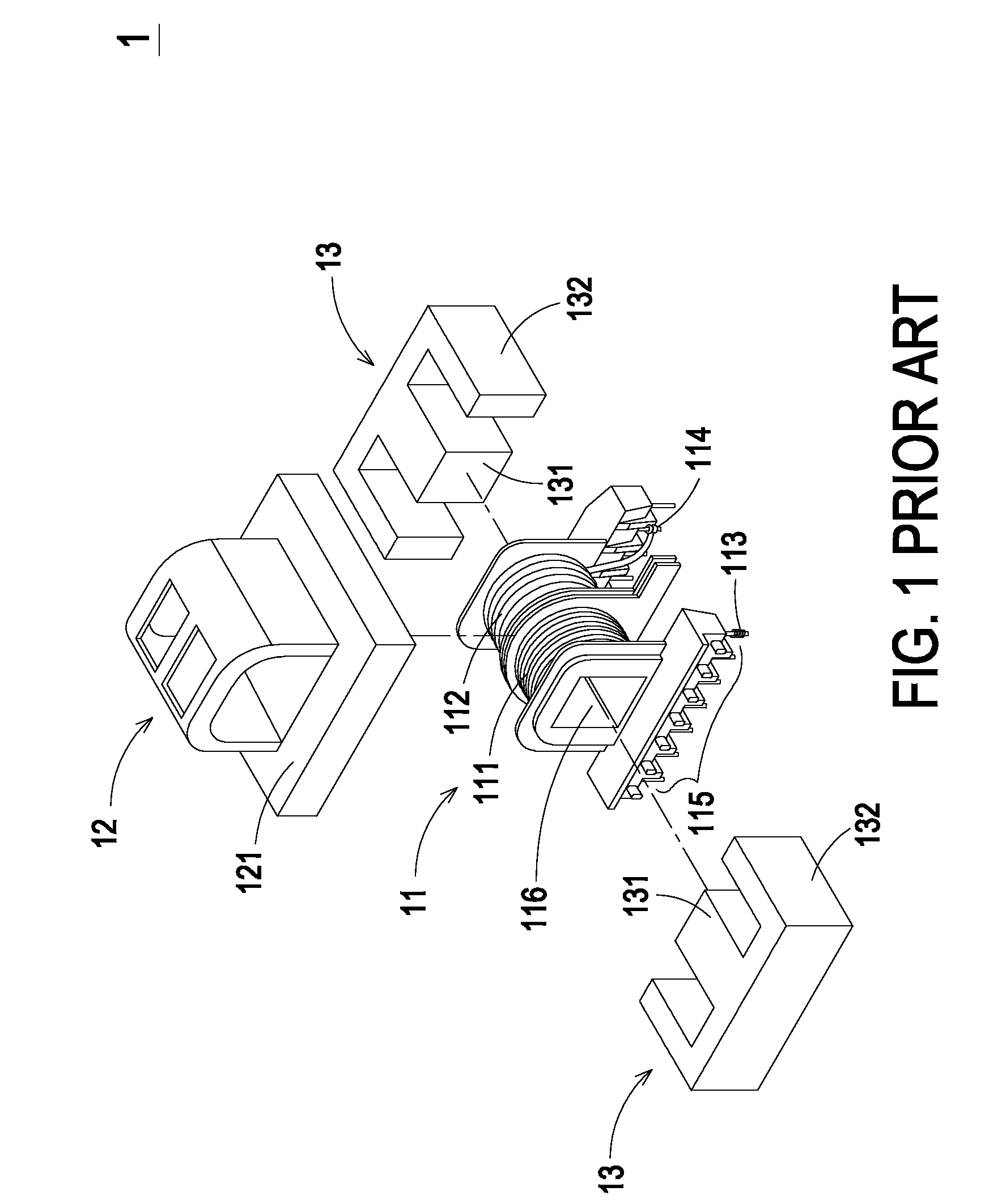

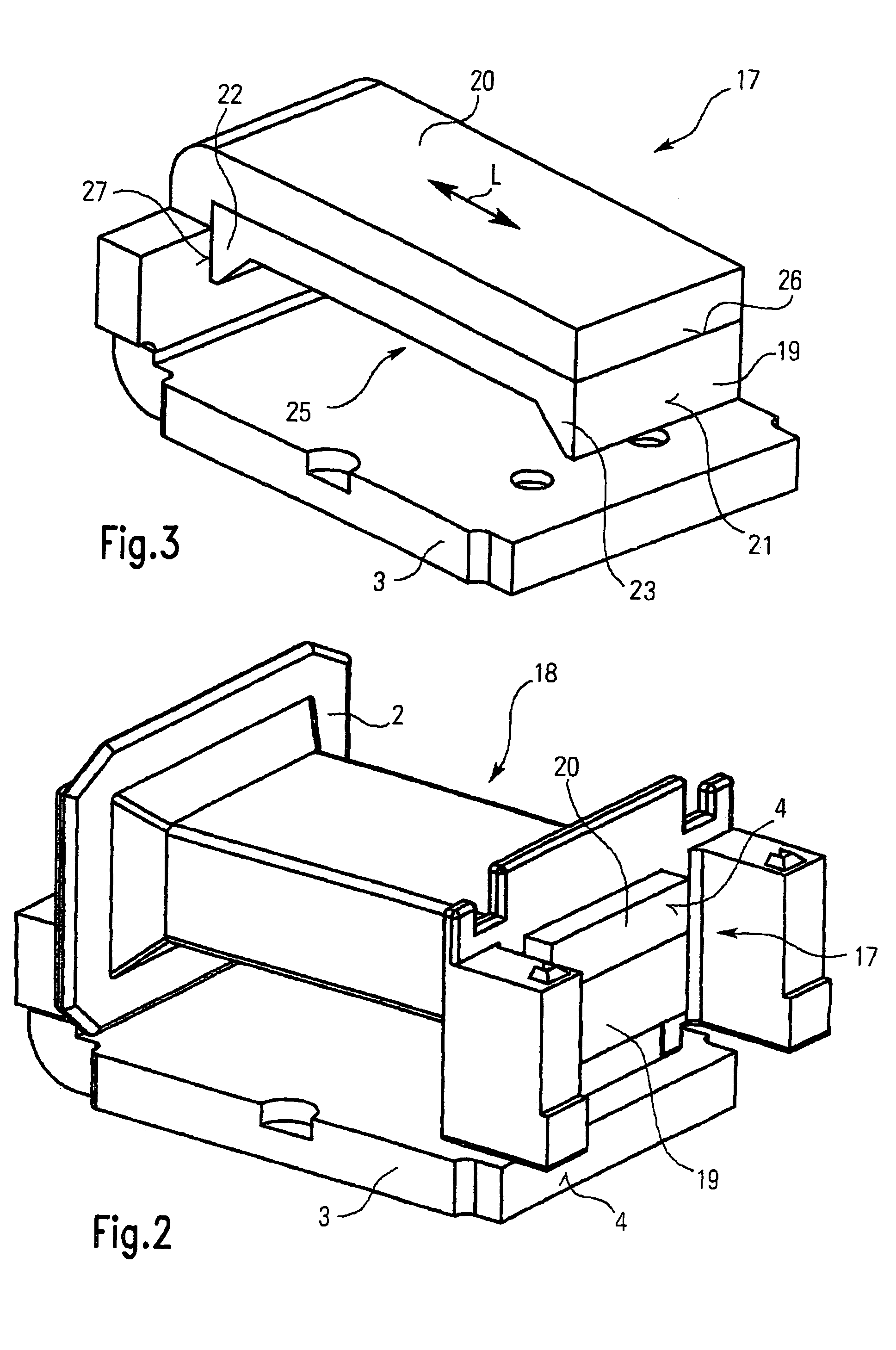

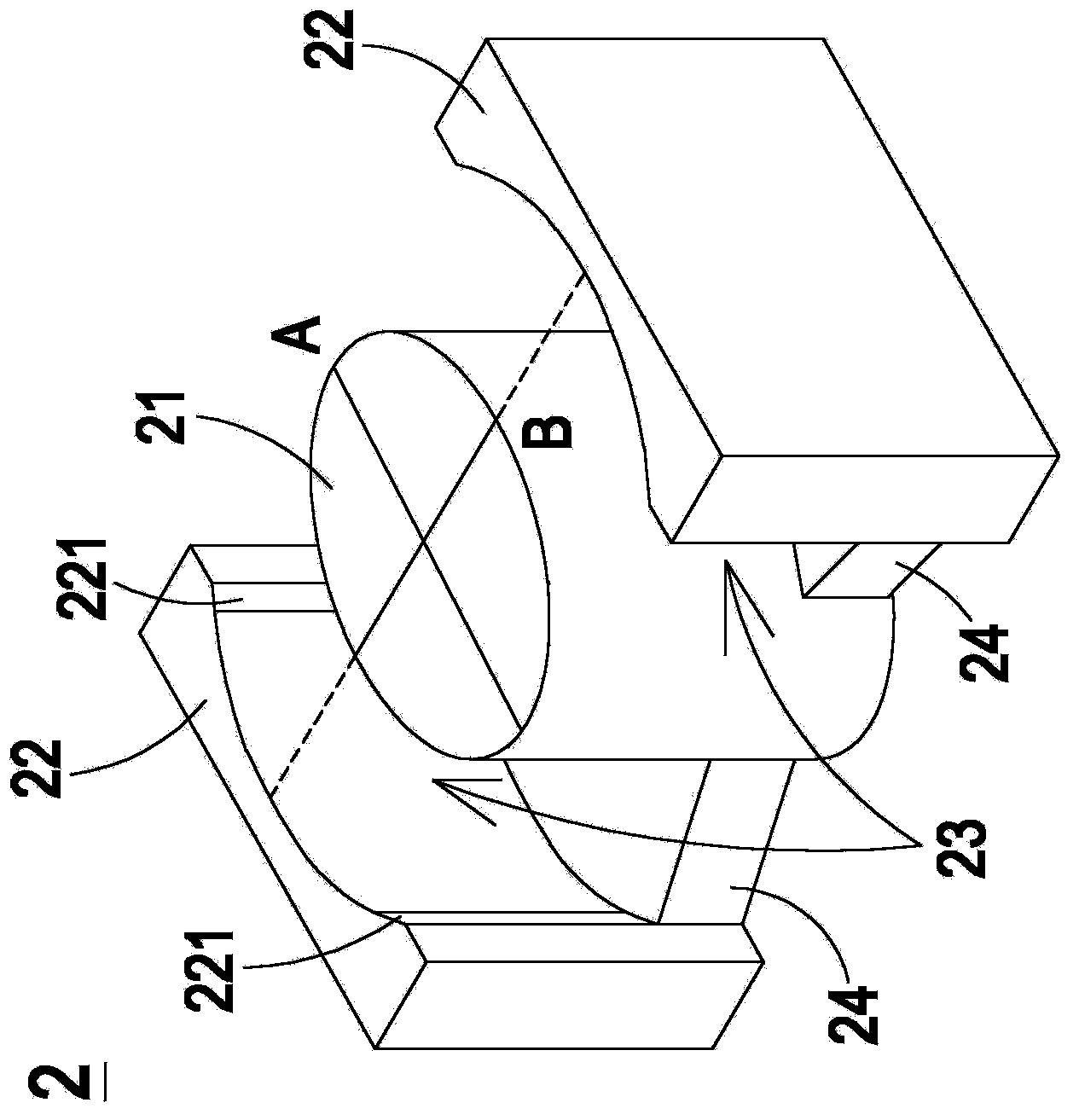

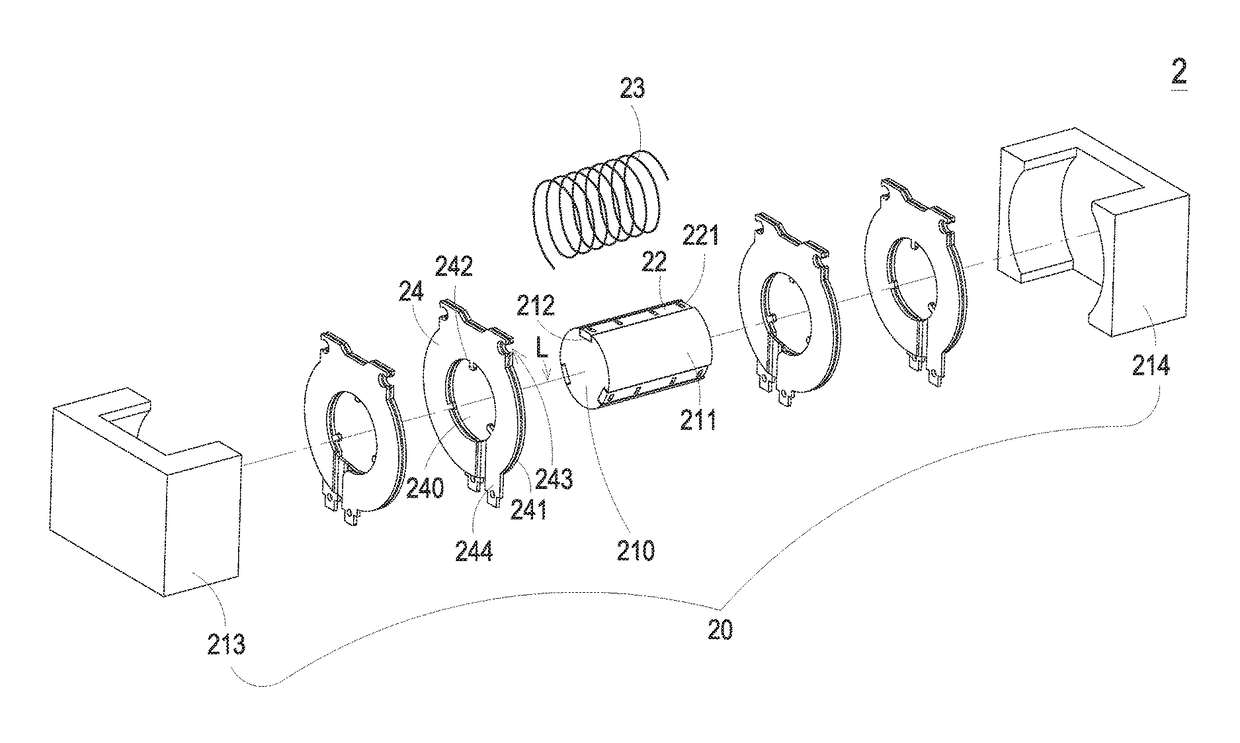

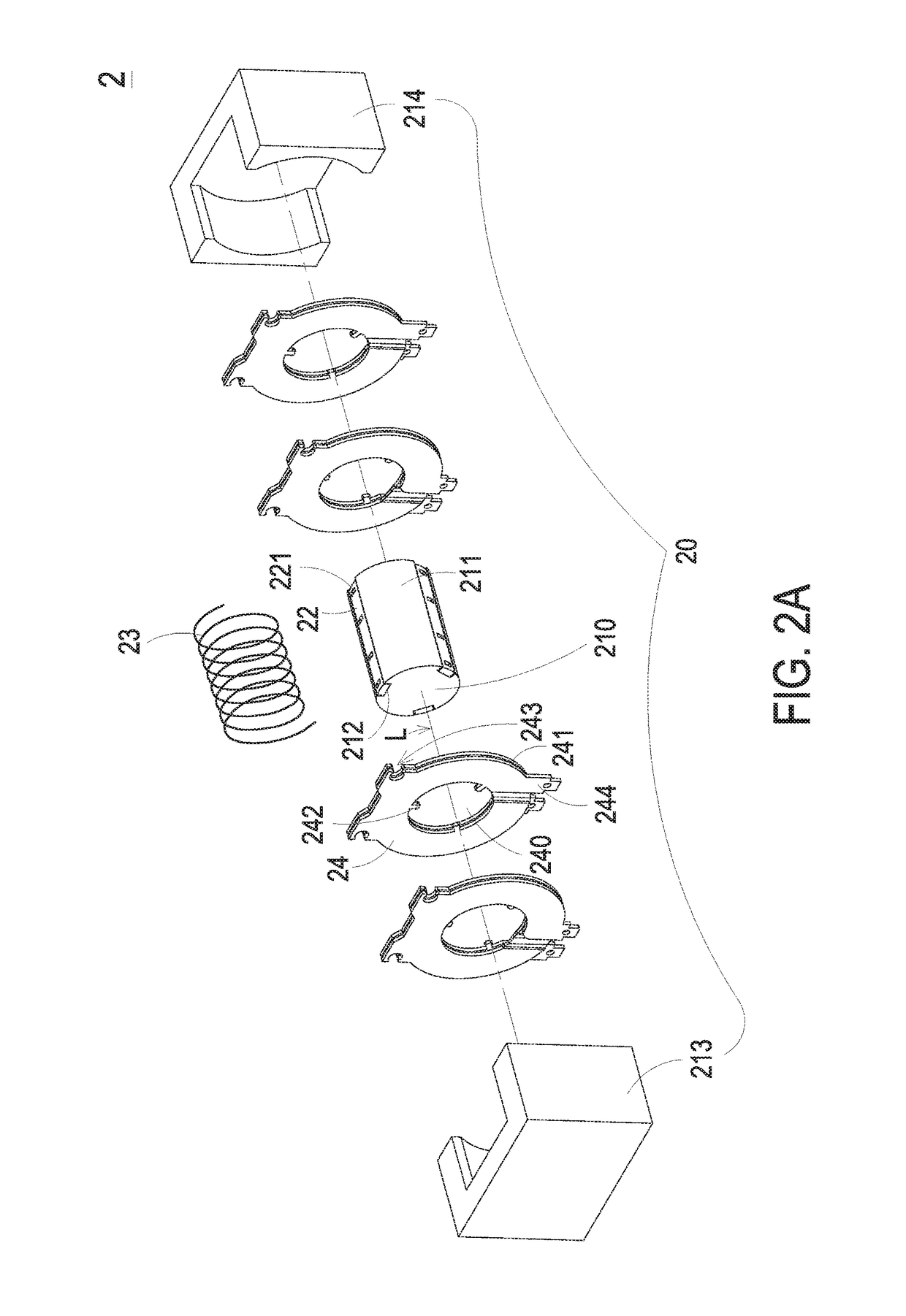

Resonant transformer

InactiveUS20110102119A1Control leakageIncrease the winding spaceTransformers/inductances coils/windings/connectionsBobbinTransformer

A resonant transformer includes a bobbin, a primary winding coil, plural secondary winding coils, and a magnetic core assembly. The bobbin includes a main body and a channel running through the main body. The main body includes a first winding section and plural single-trough second winding sections. Plural pins are arranged at the first winding section. The single-trough second winding sections are arranged at bilateral sides of the first winding section. The primary winding coil is wound around the first winding section of the bobbin and connected with the pins. The secondary winding coils are wound around respective single-trough second winding sections of the bobbin. The magnetic core assembly is partially embedded into the channel of the bobbin.

Owner:DELTA ELECTRONICS INC

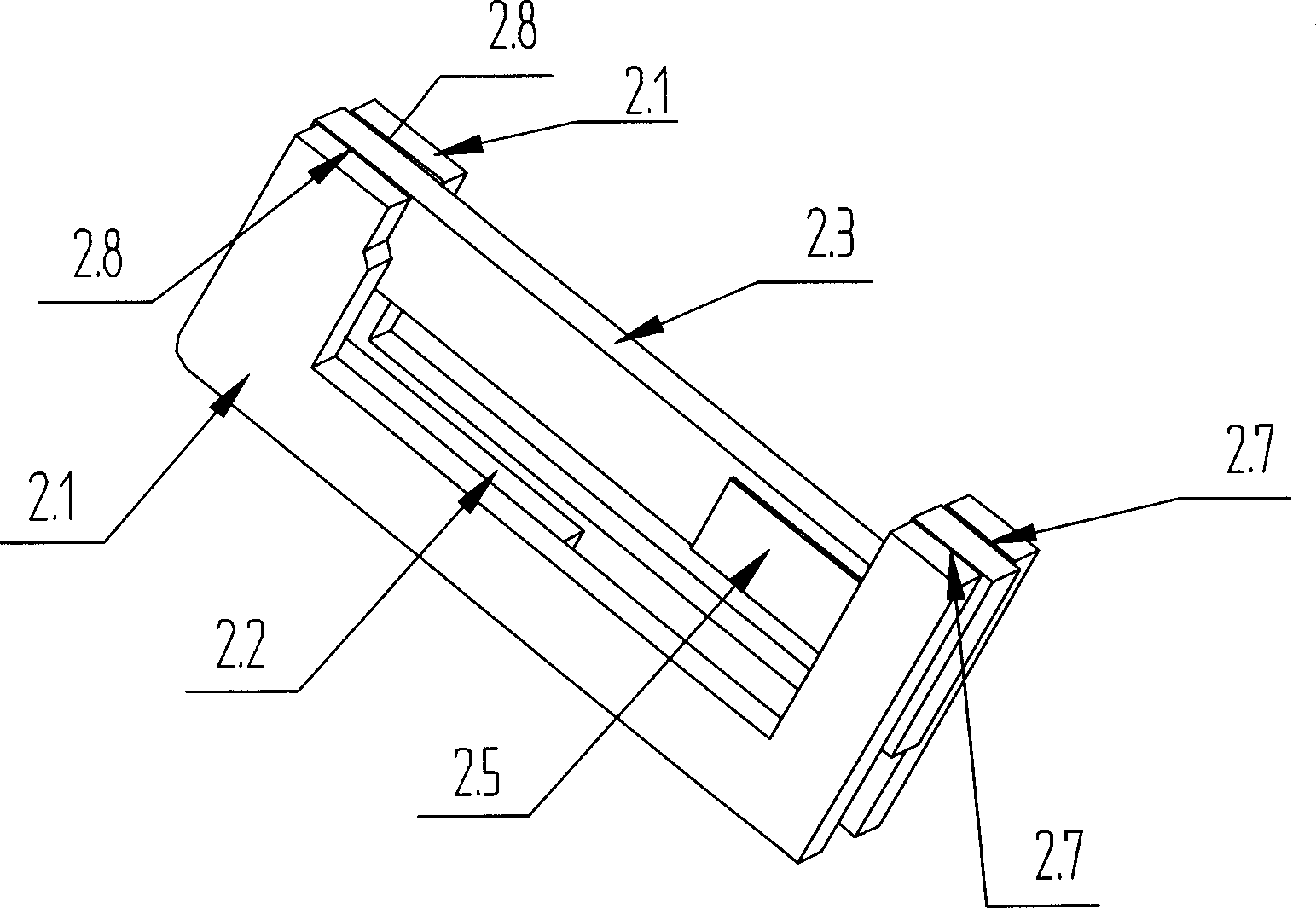

Magnetic assembly and winding frame thereof

ActiveCN103680866ASmall sizeIncrease the winding spaceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

The invention provides a magnetic assembly and a winding frame of the magnetic assembly. The winding frame applied to the magnetic assembly comprises a winding sleeve and a plurality of conducting piece sets. The winding sleeve is provided with a plurality of limiting grooves and a plurality of winding bases. The winding bases are roughly arrayed on the outer surface of the winding sleeve in the axial direction of the winding sleeve, and the limiting grooves are isolated from the winding bases. The conducting piece sets are sleeved with the limiting grooves and abut against the winding bases.

Owner:DELTA ELECTRONICS INC

Polarized relay with high sensitivity

InactiveCN1877768AIncrease the winding spaceHigh ampere-turnsElectromagnetic relay detailsBridge typeRelay

The invention discloses a polarization relay with high-sensibility, which is composed of chassis part, magnetic circuit part and case, wherein the chassis part contains chassis, active spring part and static spring part; the magnetic circuit part contains at least armature part, coil part and separating magnetic sheet; the coil part consists of iron core and coil; the armature part concludes magnetic steel, two armatures, pushing part with magnetic steel between two armatures; the armature, magnetic steel and iron core constitute bridge-typed magnetic circuit, whose two non-double-working air gaps load separating magnetic piece to form double-working air gap magnetic circuit; the armature part is divided into movement part of magnetic circuit, whose rotary shaft lies on the side of non-working gap.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Knitting machine

The invention discloses a knitting machine, which comprises a warp knitting assembly, a first traction shaft and a cloth coiling device. The knitting machine is characterized in that the knitting machine comprises a cloth tension adjusting device, wherein the cloth tension adjusting device comprises a pinch roller, a fixed rod and a first connecting rod; the pinch roller is positioned between the warp knitting assembly and the first traction shaft; the pinch roller is coupled on the first connecting rod; the first connecting rod is connected on the fixed rod; the fixed rod is connected on the knitting machine; and a plurality of uniformly distributed spurs are integrally arranged on the peripheral surface of the pinch roller. The knitting machine has the advantages that: when the knitting machine processes elastic cloth, two sides of the cloth are pressed by using the pinch roller in a process of coiling the elastic cloth into a cloth coil, so that the two sides of the cloth are prevented from being contracted to the middle, the two sides of the cloth are tensioned, and loss of the cloth is prevented due to edge breakage of the cloth; and a vertical displacement adjusting mechanism is arranged on the fixed rod, and a horizontal displacement adjusting mechanism is arranged on a second connecting rod, so that the requirements for processing the cloth of different widths and different fabrics are met by adjusting the positions of the pinch roller in the horizontal and vertical directions.

Owner:NINGBO SANDO KNITTING

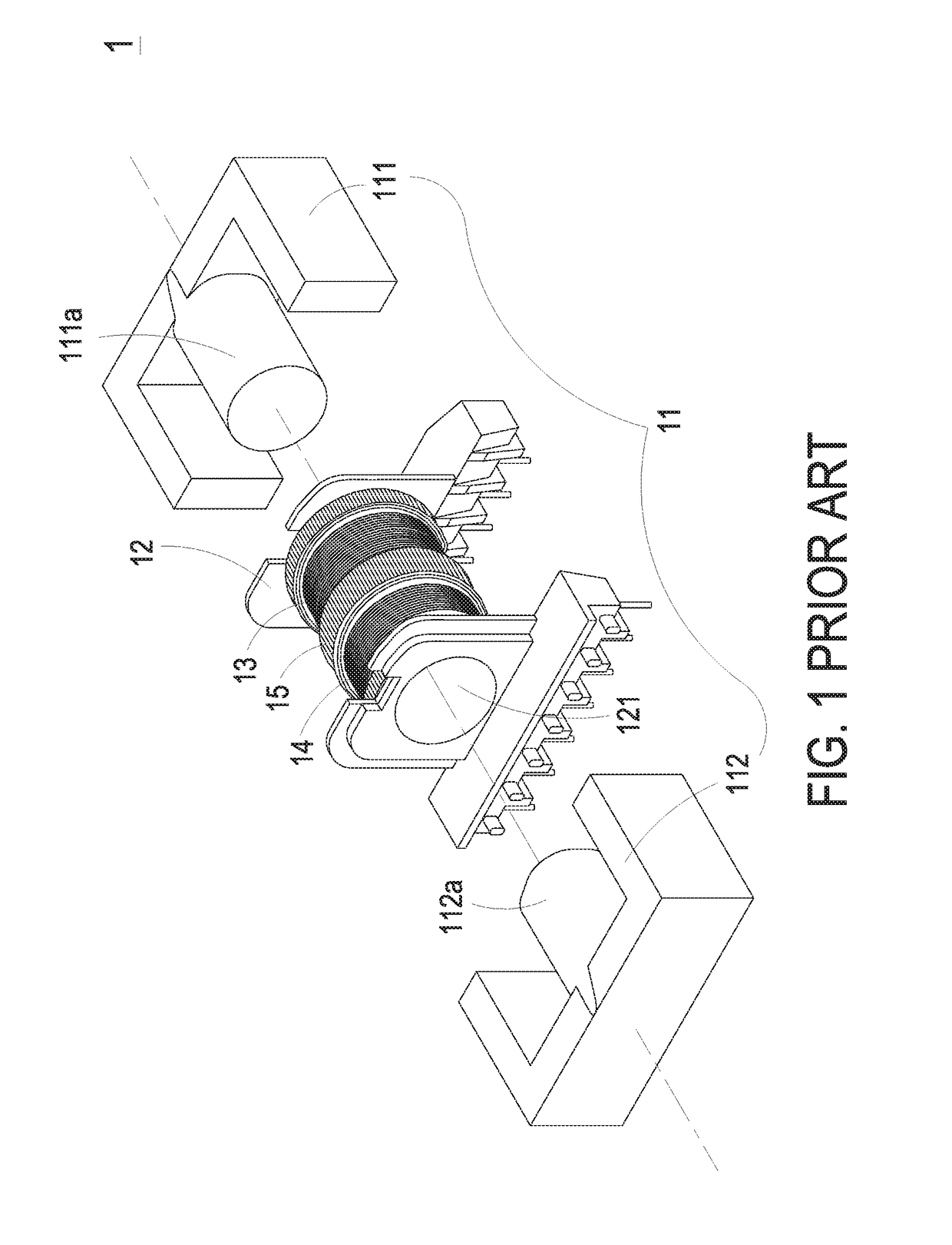

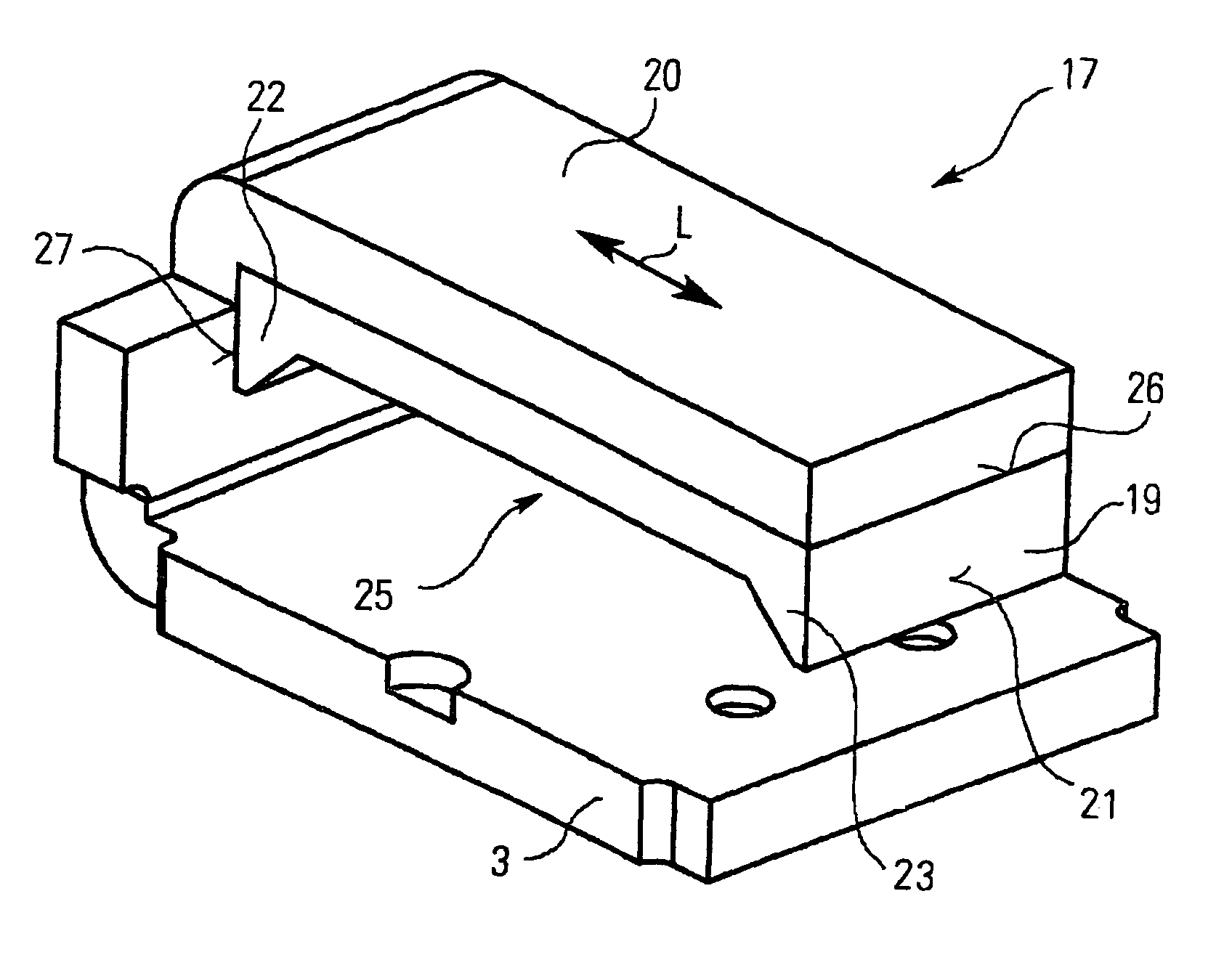

Relay with a core having an enlarged cross-section

ActiveUS7026896B2High switching forceSimple constructionElectromagnetic relay detailsSelector switchesMagnetic coreMagnetic flux

The invention relates to a relay comprising a coil bobbin, a core penetrating the coil bobbin and a yoke. To achieve a high switching force with a low overall height, the cross-sectional area of the core is greater in the region toward the transition to the yoke than in the central region of the coil bobbin. Increased magnetic flux can be conveyed from the core owing to the cross-sectional enlargement and at the same time more coil windings can be arranged in the central region owing to the reduced cross-section there. Both measures act together and allow high switching forces with low overall height.

Owner:TYCO ELECTRONICS AUSTRIA

Commutator segment for commutator and production equipment of commutator segment

InactiveCN110739592AIncrease the winding spaceReduce mutual interferenceRotary current collectorCommutators manufacturePhysicsEngineering

The invention discloses a commutator segment for a commutator and production equipment of the commutator segment and belongs to the technical field of commutators. The invention aims to solve the problem that bulges and burrs are generated due to the fact that two sides of the hook part of a commutator segment are extruded outwards under pressure in a hooking process. The commutator segment is characterized in that the commutator segment comprises a segment body and a hook par; the segment body comprises a contact block and a clamping block; the contact block is provided with a connecting block in the length direction of the contact block; the connecting block is provided with a connecting sheet in the vertical direction of the connecting block; one end, far away from the contact block, ofthe connecting sheet, is fixedly connected with the clamping block in the length direction of the connecting sheet; the contact block, the connecting block, the connecting sheet and the clamping block are fixedly connected with one another; two ends of the connecting block, two ends of the connecting sheet and two ends of the clamping block jointly clamping grooves; one end of the contact block in the length direction of the contact block is fixedly connected with the hook part; deformation grooves are formed in two ends of the hook part in the width direction of the hook part; and the two deformation grooves penetrate through the upper end surface and the lower end surface of the hook part. With the commutator segment for the commutator and the production equipment of the commutator segment of the invention adopted, the problem that bulges and burrs are generated due to the fact that two sides of the hook part of a commutator segment are extruded outwards under pressure in a hookingprocess can be solved.

Owner:苏州工业园区安固电器有限公司

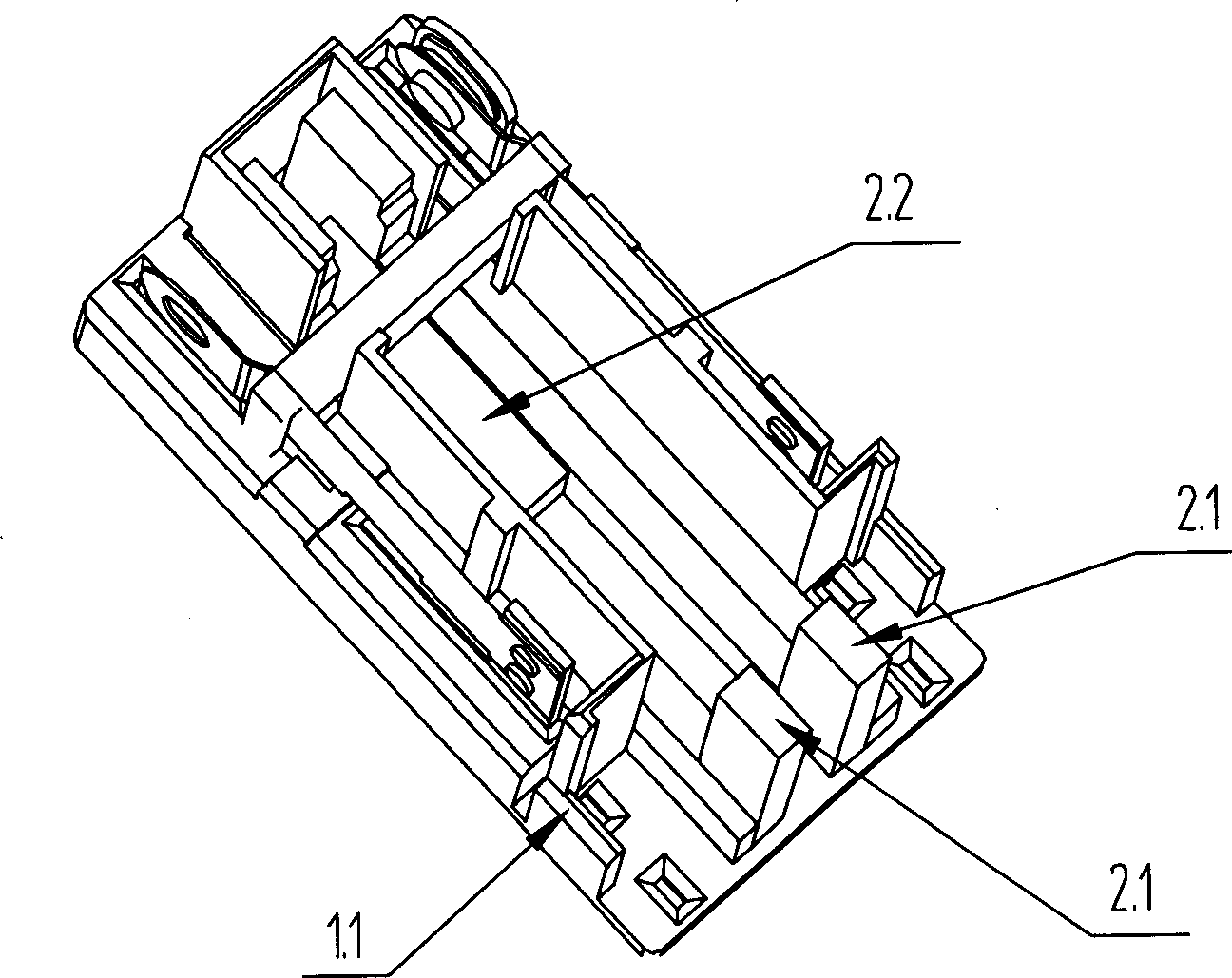

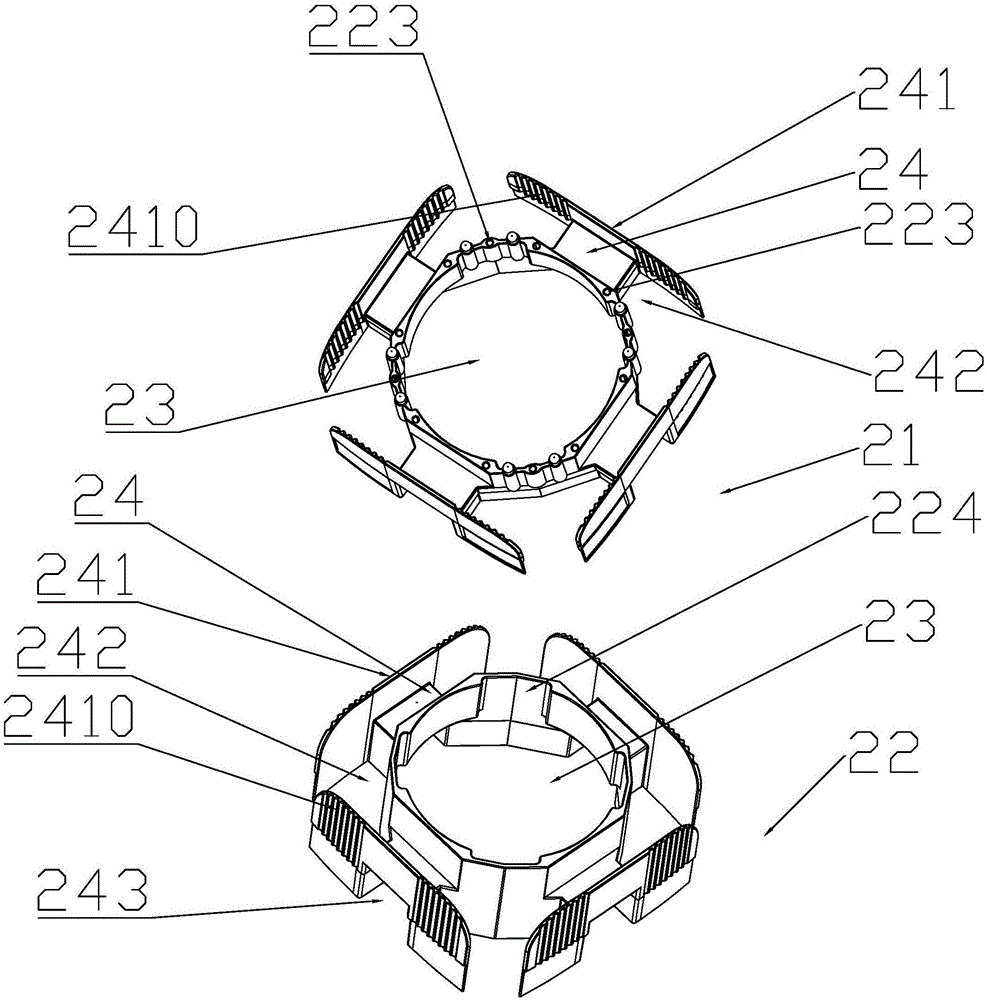

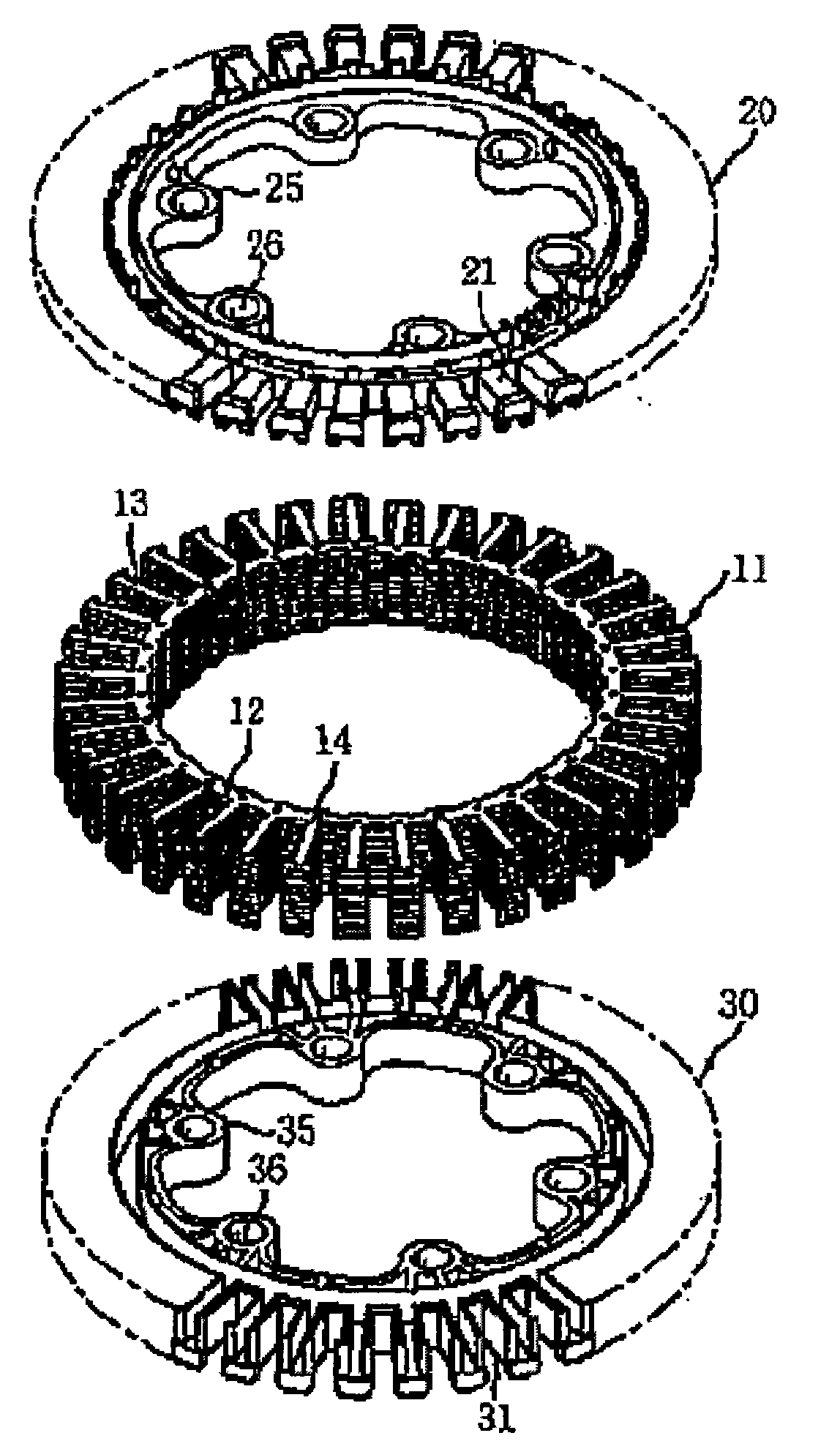

Motor stator apparatus

ActiveCN106230140AReduce stressClosely arrangedWindingsMagnetic circuit stationary partsCopper wireEngineering

The invention discloses a motor stator apparatus. A stator tooth sheet fixing hole is formed in the middle of a yoke ring part; a stator tooth sheet group is arranged on the stator tooth sheet fixing hole; four tooth sheet pins extend out of the stator tooth sheet group and are clamped on the yoke ring part; a rotor hole I is formed in the middle of the stator tooth sheet group; a centralized winding type stator insulating winding frame is fixed on the stator tooth sheet group; the centralized winding type stator insulating winding frame comprises a ring shell upper frame and a ring shell lower frame; and the ring shell upper shell and the ring shell lower frame are inserted into each other to be fixedly connected into one body. The motor stator apparatus is applicable to automatic feeding and unloading mechanically, so that the production efficiency can be improved, and the motor performance can be improved; compared with a conventional distributed winding, the centralized winding has the advantages of applicability to mechanical production, and capabilities of reducing dosage of copper wires and lowering human cost; and a novel insulating structure needs to be re-designed for developing a centralized type winding motor.

Owner:FOSHAN CITY SHUNDE DISTRICT XIECHUANG MOTOR MFG

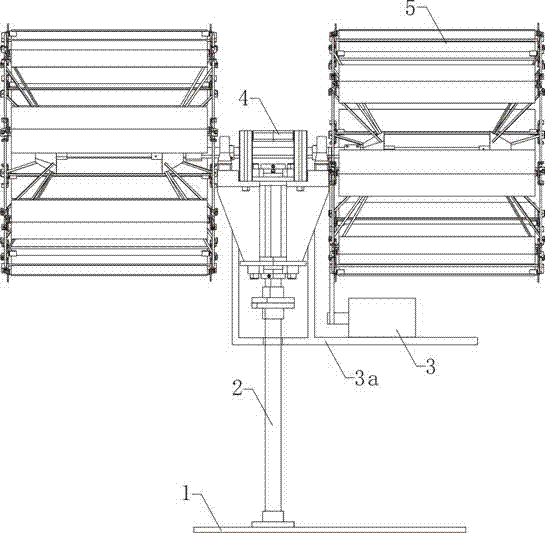

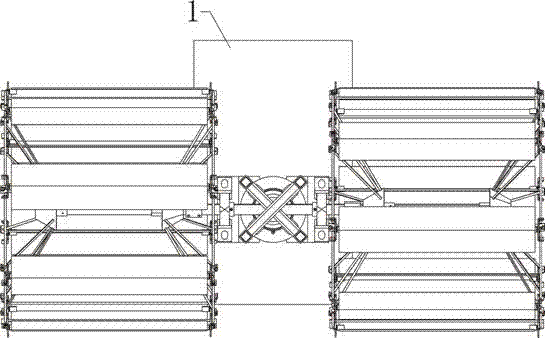

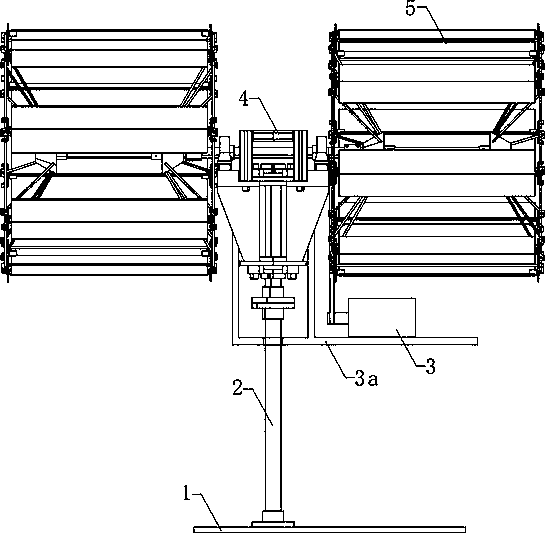

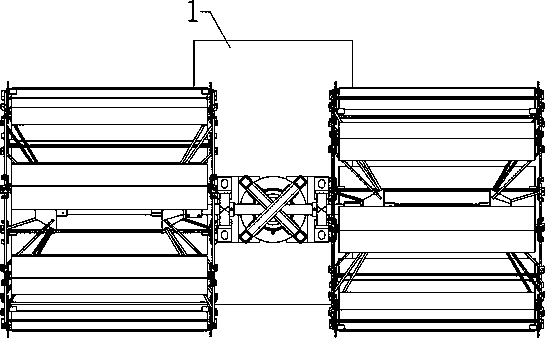

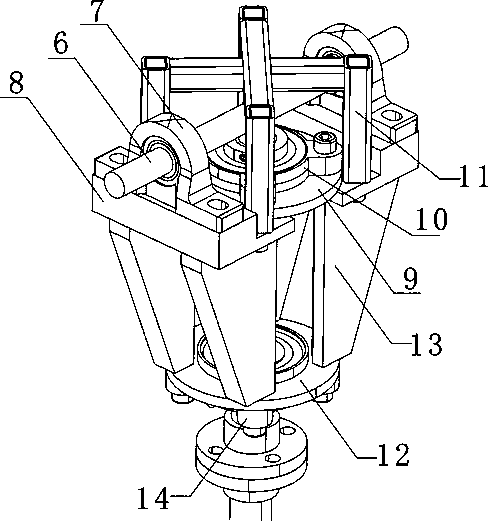

Rotary electric winding device for textiles

The invention discloses a rotary electric winding device for textiles. The winding device comprises a base, a supporting rod, a rotating motor, a roller supporting and rotating mechanism, winding roller mechanisms and a roller supporting and rotating spindle. By improving and providing the rotary electric winding device for textiles, the winding work can be automatically performed; and the winding speed is regulated by the rotating motor, so that the labor time of a worker is saved, and the economic benefits of textile enterprises are increased. When the rotary electric winding device is used, the rotating motor rotates to drive the roller supporting and rotating spindle to rotate by virtue of a chain, the roller supporting and rotating spindle drives the winding roller mechanisms at two sides to rotate, so that the normal winding work is realized; and the roller supporting and rotating mechanism can drive the winding roller mechanisms to realize horizontal rotation in the use process, so that the winding space and range are increased.

Owner:河北南冠科技有限公司

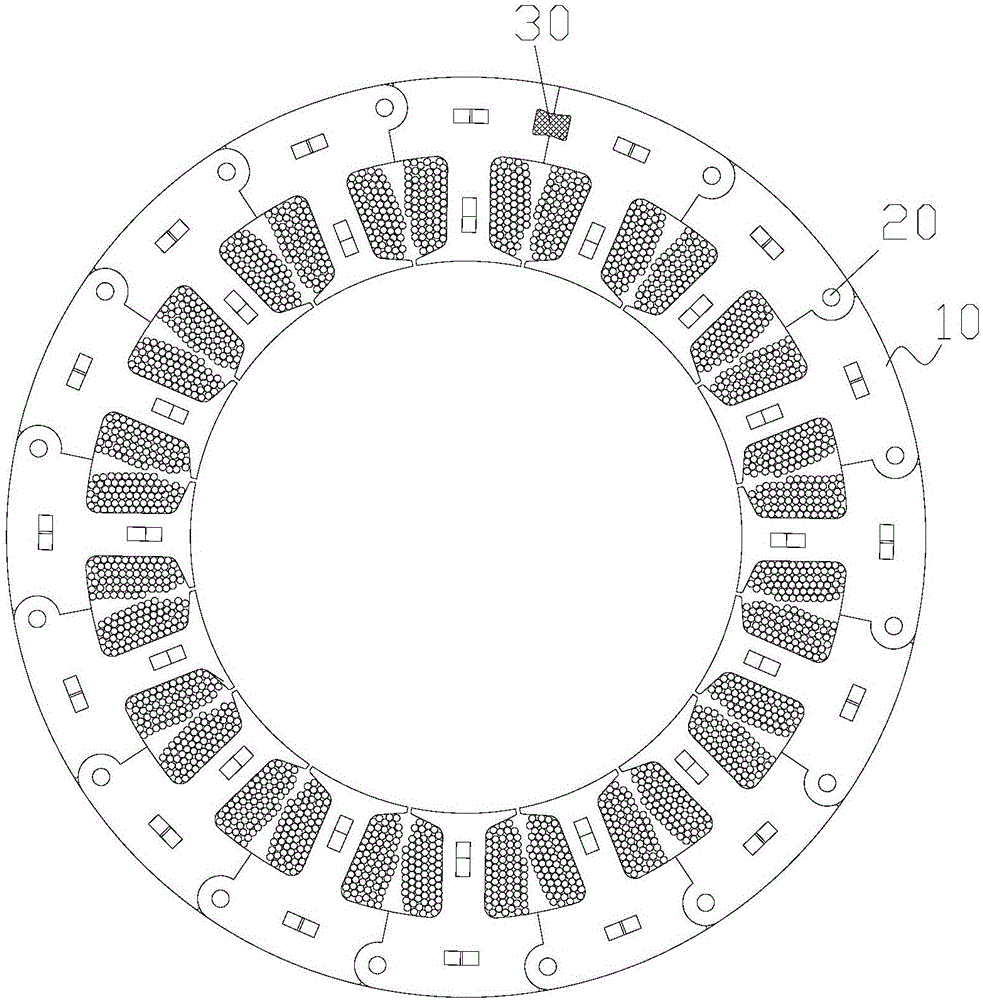

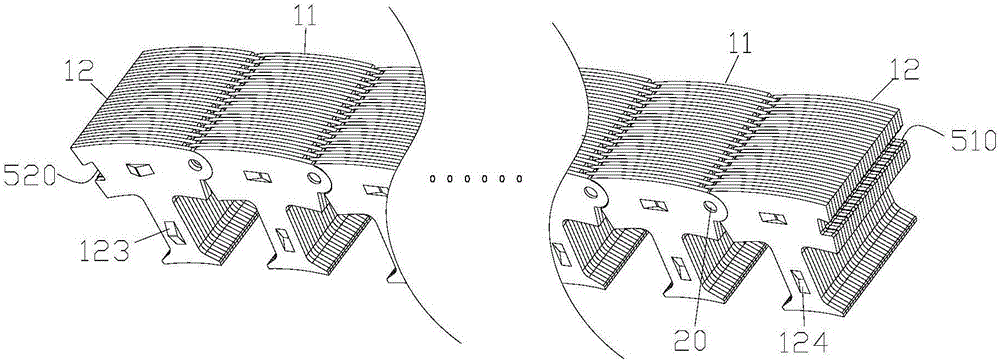

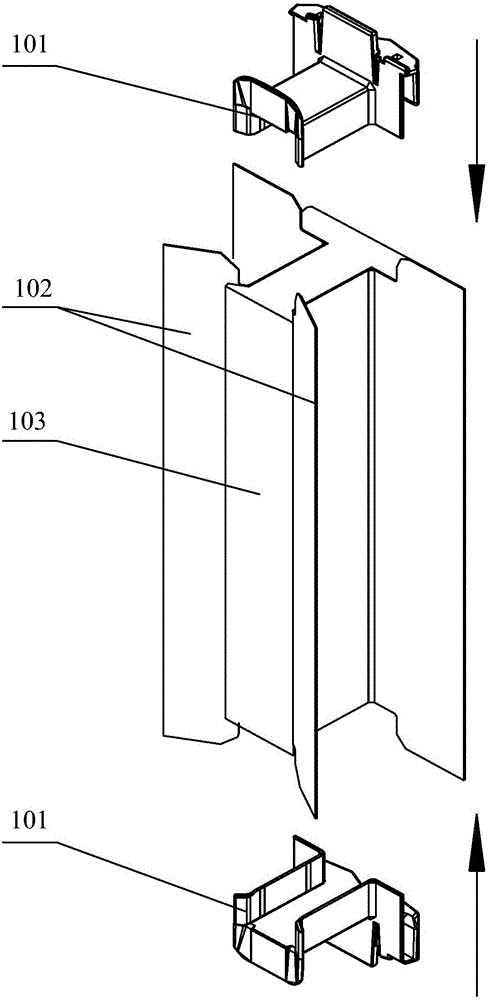

Stator core, stator, motor and air conditioner

InactiveCN106230141AIncrease the winding spaceIncrease production capacityMagnetic circuit stationary partsStatorEngineering

The invention provides a stator core, a stator, a motor and an air conditioner. The stator core comprises coiling iron cores and connecting structures, wherein the coiling iron cores are connected successively to form an annular structure, each connecting structure is arranged between two adjacent coiling iron cores, and the adjacent coiling iron cores are connected via the connecting structure. According to technical schemes of the invention, the problems that in the prior art the coiling efficiency of the stator core is low, the size precision and quality of production are low, the raw material utilization rate of the iron core and a motor of a higher slot filling factor cannot be produced are solved.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

Magnetic core and applicable magnetic element of magnetic core

InactiveCN104252951ASmall diameterSave space for windingTransformers/inductances magnetic coresInductance with magnetic coreLong axisSafety specification

The invention discloses a magnetic core and an applicable magnetic element of the magnetic core. The magnetic core at least comprises an oval center post and two side posts, wherein the oval center post is provided with a long shaft and a short shaft; the length of the long shaft is greater than that of the short shaft; the two side posts are oppositely arranged at two sides of the oval center post, are connected with the oval center post, and define at least one winding space together with the oval center post. Through the arrangement of the oval center post, the magnetic core has the advantages that the winding space is enlarged, the diameter of a wining coil is increased, the temperature of a winding solenoid is lowered, the winding solenoid is prevented from being oversize, and the safety distance between the winding solenoid and a reel is increased to accord with the safety specification.

Owner:DELTA ELECTRONICS INC

Magnetic component

ActiveUS9959960B2Increase the winding spaceImprove efficiencyTransformers/inductances coils/windings/connectionsCores/yokesEngineeringConductor Coil

A magnetic component is disclosed. The magnetic component includes a magnetic core assembly, a fastening element, a first winding set and a second winding set. The magnetic core assembly includes at least a pillar. The fastening element is provided on an outer peripheral surface of the pillar. The first winding set is disposed around the outer peripheral surface of the pillar. The second winding set is disposed around the outer peripheral surface of the pillar and engaged with the fastening set. The first winding set and the second winding set are located adjacent to each other and disposed around the outer peripheral surface of the pillar.

Owner:DELTA ELECTRONICS INC

Motor

ActiveCN101552495AIncrease the winding spaceWindings insulation shape/form/constructionMagnetic circuit stationary partsEngineeringMechanical engineering

The invention relates to a motor, in particular to a motor which does not reduce space between adjacent cogs of a stator mold core and can increase the winding number of a coil hereby. The motor can be the one applicable to washing machines, but is not limited therein. In the motor and the barrel washing machines installed with the motor, insulators at the upper part and the lower part and adjacent to the upper side and the lower side of the cog of the stator mold core can widen the utilizable space between adjacent cogs.

Owner:NANJING LG PANDA APPLIANCES

A rotary electric winding device for textile

The invention discloses a rotary electric winding device for textiles. The winding device comprises a base, a supporting rod, a rotating motor, a roller supporting and rotating mechanism, winding roller mechanisms and a roller supporting and rotating spindle. By improving and providing the rotary electric winding device for textiles, the winding work can be automatically performed; and the winding speed is regulated by the rotating motor, so that the labor time of a worker is saved, and the economic benefits of textile enterprises are increased. When the rotary electric winding device is used, the rotating motor rotates to drive the roller supporting and rotating spindle to rotate by virtue of a chain, the roller supporting and rotating spindle drives the winding roller mechanisms at two sides to rotate, so that the normal winding work is realized; and the roller supporting and rotating mechanism can drive the winding roller mechanisms to realize horizontal rotation in the use process, so that the winding space and range are increased.

Owner:河北南冠科技有限公司

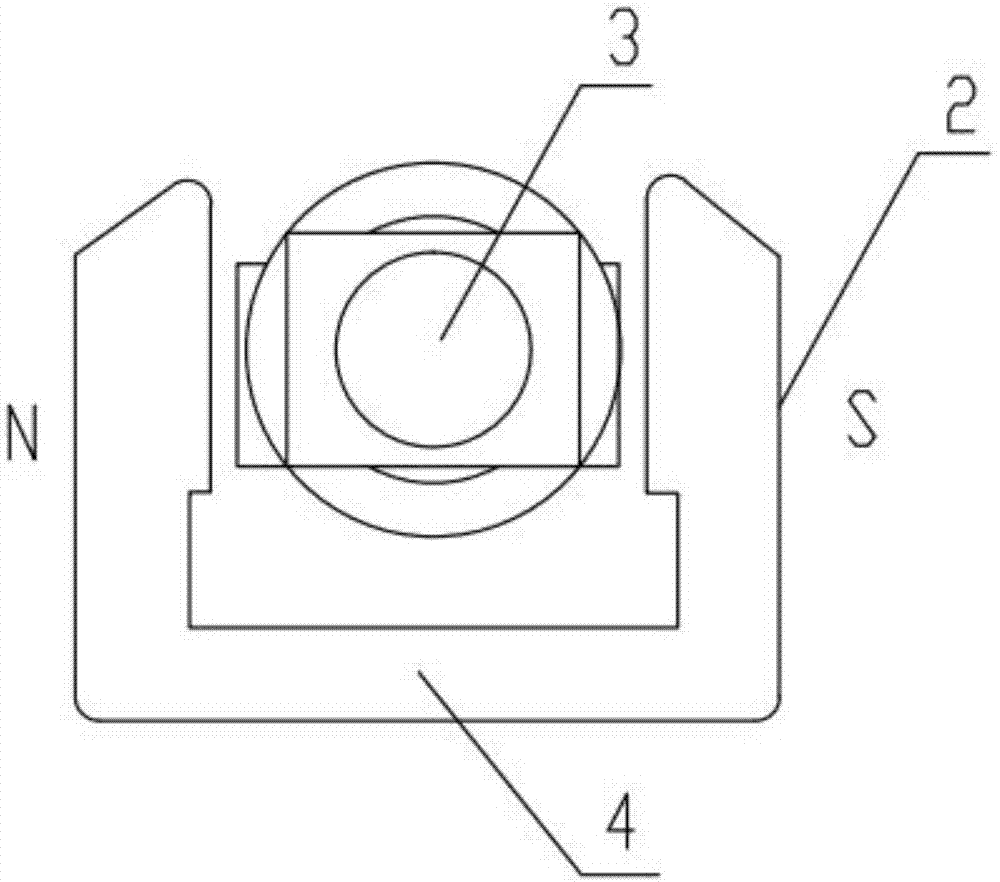

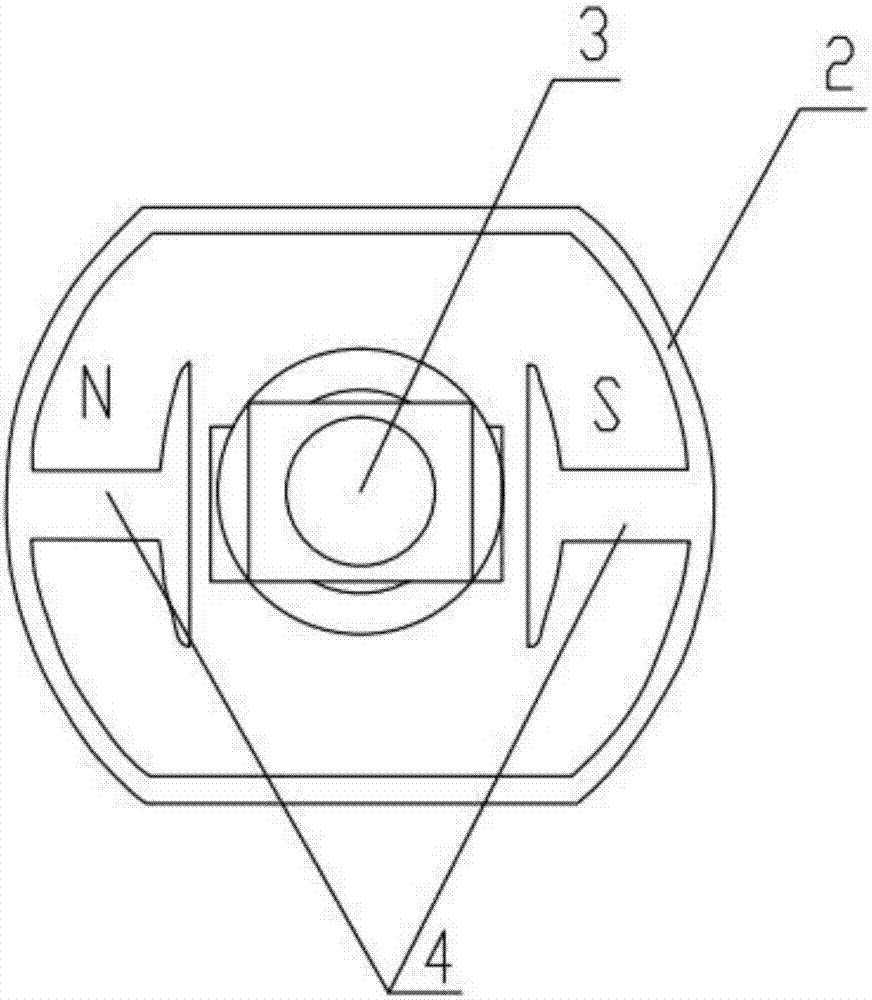

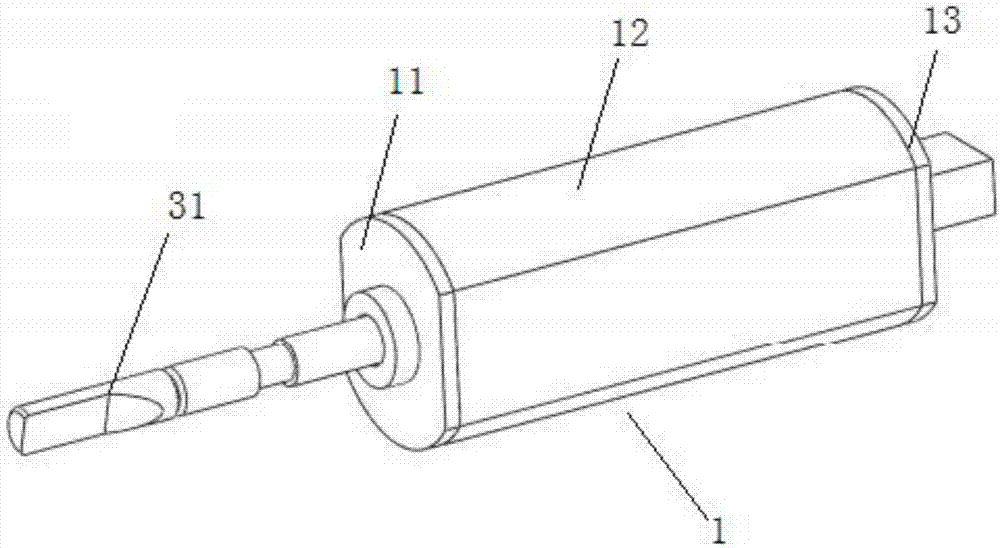

DC vibration motor

ActiveCN107070074ALarge output torqueHigh strengthMechanical energy handlingElectric machineMagnetic field magnitude

The invention discloses a DC vibration motor, relating to a technical field of the motor having one rotor and one stator. The motor comprises a housing, a stator and a rotor; the stator comprises an upper winding shaft, a lower winding shaft, a stator group and coils; a stator group comprises a C-shaped left stator group and a C-shaped right stator group; two free ends of the left stator group and the right stator group are arranged oppositely and then a rectangle-shaped coil winding frame is constituted; the coils are respectively wound on two horizontal parts of the winding frame; and after two coils are simultaneously powered on, the N poles and the S poles of the two coils are on same sides, and the S poles and the N poles of the two coils are on other same sides. The left stator group and the right stator group which have single polarity interact with each other to form an external magnetic field; a magnetic field torque is generated between the external magnetic field and the rotor to drive the rotor to rotate; and strength of a magnetic field under a common action of two winding coils are bigger, so that the output torque of the motor is bigger.

Owner:东莞市维斗科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com