Coil component of electromagnetic relay

A technology for electromagnetic relays and coil components, which is applied to electromagnetic relays, detailed information of electromagnetic relays, relays, etc., can solve the problems of complicated coil winding process, reduced coil winding space, and difficulty in miniaturizing relays, so as to eliminate virtual welding. The effect of avoiding hidden dangers, improving winding space, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

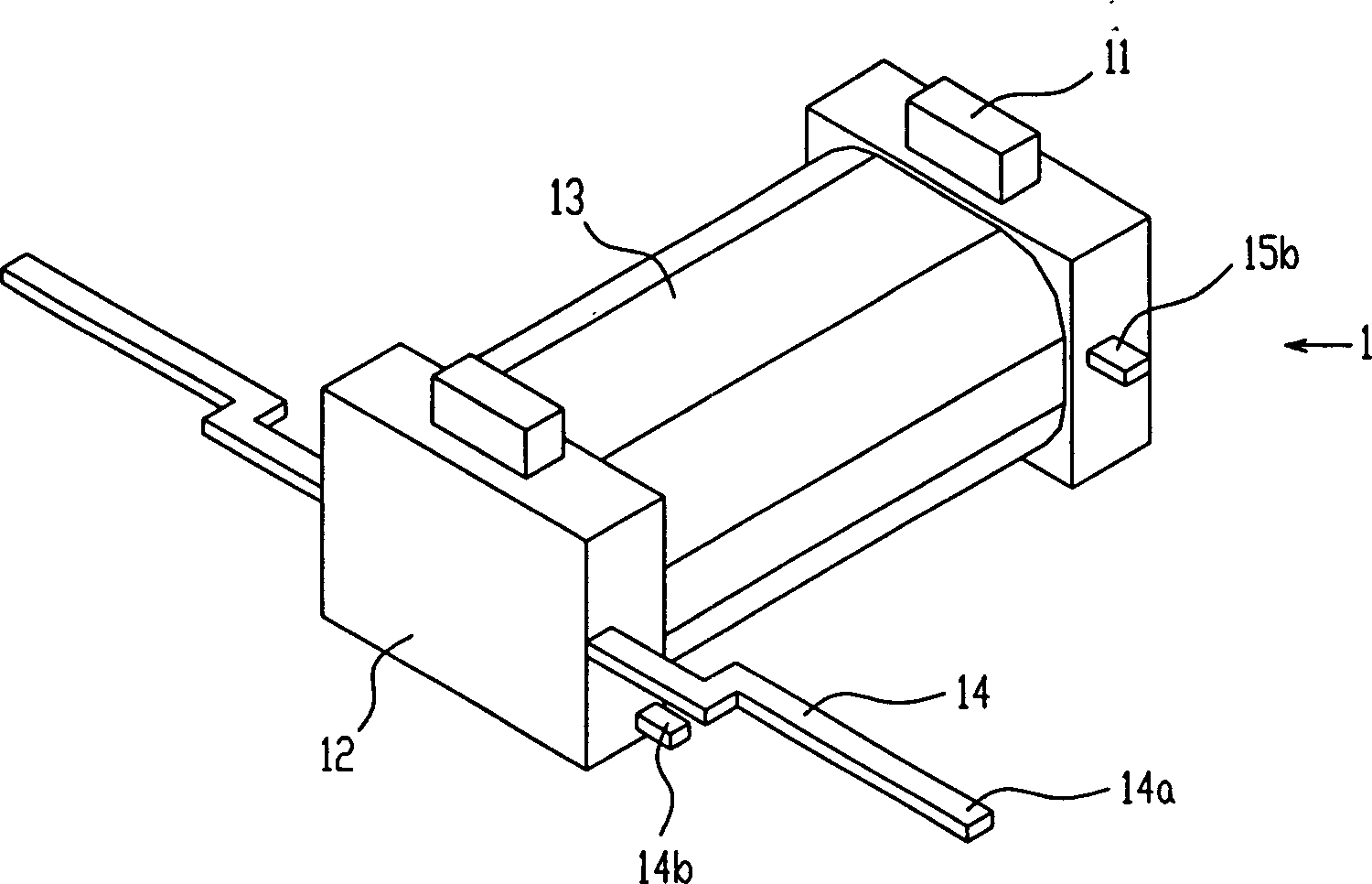

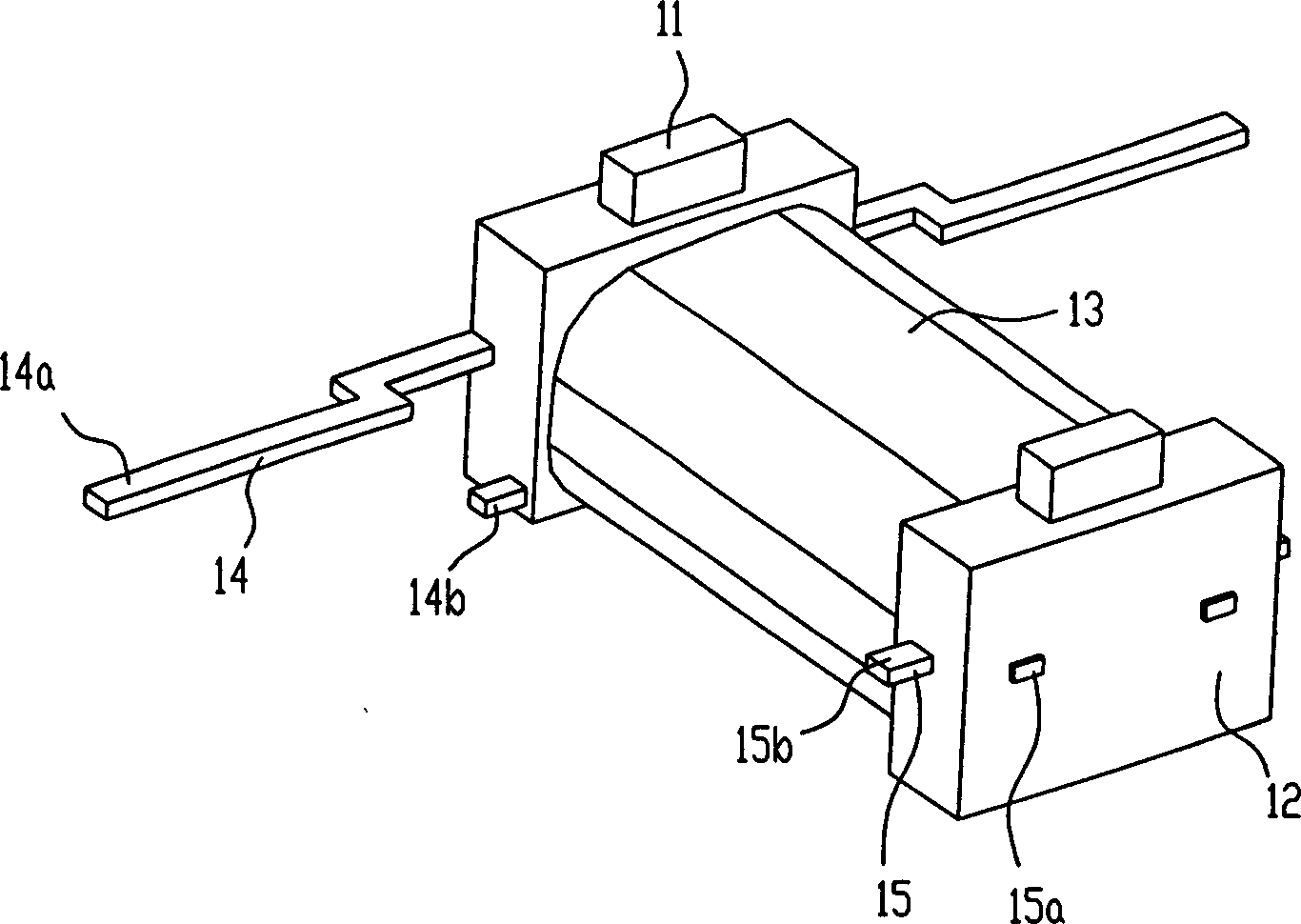

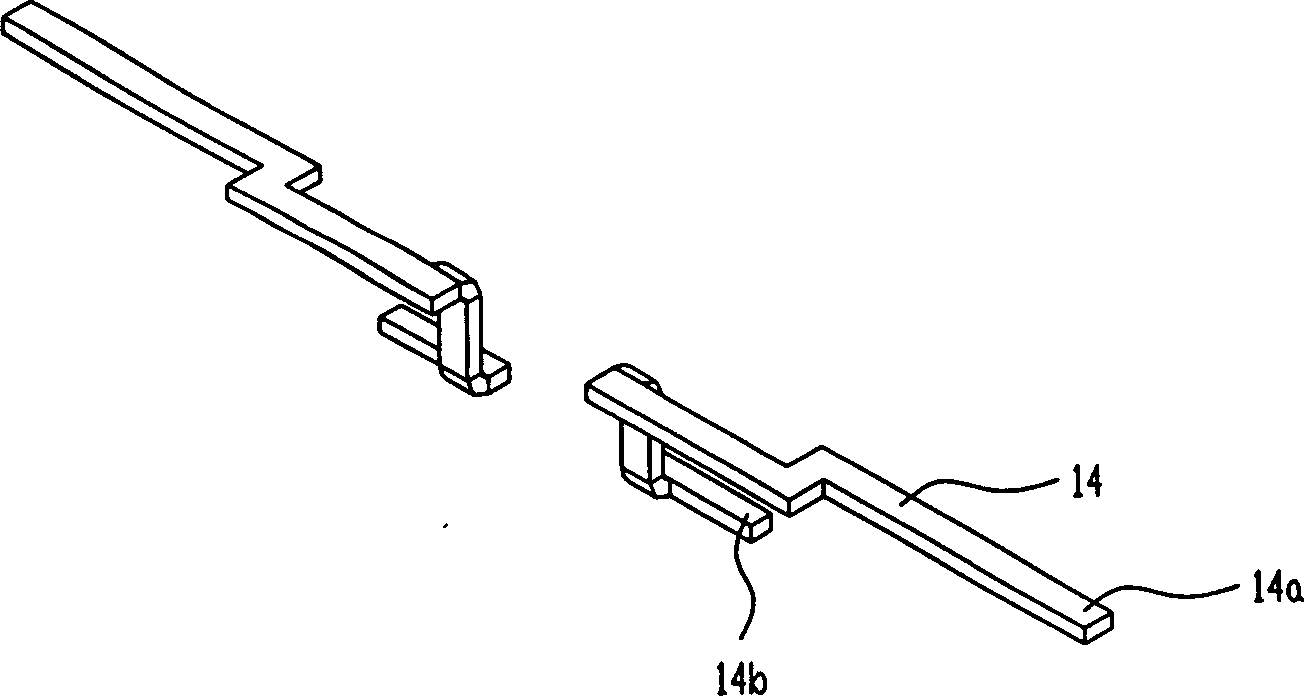

[0025] like Figure 1-3 As shown, the present invention is provided with the C-shaped part 11 that is made of magnetic steel and magnetizer, and coil 13 is wound on the insulating bobbin 12, and lead pin 14,15 and insulating bobbin 12 are injection molded together, and lead pin 14,15 have Two free ends, one free end 14a, 15a is the coil lead-out pin of the relay, and the other free end 14b, 15b is the wrapping end of the coil. When the coil 13 is a single coil, the lead pin 15 only plays the roles of support and positioning in the processing process; when the coil 13 is a double coil, its function is the same as that of the lead pin 14.

[0026] The lead-out mode of the coil 13 is that the two lead-out ends of the coil 13 are respectively wound on the lead-out ends 14b and 15b, or respectively wound on the lead-out ends 14b or 15b, and then they are welded together.

[0027] The lead pin 14 of the present invention includes two free ends, one free end 14a is the coil lead-out...

Embodiment 2

[0030] Figure 5 Given another embodiment of the present invention, the insulating bobbin 12 is not integral, but at least includes two parts 12a, 12b, which respectively wrap the parts below the pole faces 11a, 11b of the C-shaped component composed of the magnetic steel and the magnetizer, That is to say, the C-shaped part made of magnetic steel and magnetizer has two pole faces 11a, 11b and the middle part is not wrapped by insulating material, but another insulating material is used in the middle part of the C-shaped part 11 composed of magnetic steel and magnetizer. 16 wraps it up, also can be coated with an insulating layer on the surface of the C-shaped part 11 that magnetic steel and magnetizer constitute. exist Figure 5 Other tags in the figure 2 same.

Embodiment 3

[0032] Image 6 Provided another embodiment of the present invention, the two ends of the insulating bobbin 12 or the center of the coil are left with a magnetic conductor 11c or a magnetic steel 11d seat hole, and the magnetic conductor 11c or the magnetic steel 11d is placed in the subsequent process into the seat hole. It is also possible to replace the C-shaped component 11 formed by the magnetic steel 11d and the magnetic conductor 11c with a C-shaped magnetic conductor 11 composed of several parts. The C-shaped magnetic conductor 11 is divided into several parts similar to the above-mentioned magnetic steel 11d and the magnetic conductor 11c. .

[0033] like Figure 7 As shown, an embodiment of the application of the relay of the present invention is given, see Figure 2-6 , The electromagnetic relay includes a housing 4, an armature part 3, and a contact base part 2 that injects the coil part 1 and the static spring together. The coil part 1 includes a C-shaped part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com