Motor

A stator and core technology, applied in the shape/pattern/structure of winding insulation, magnetic circuit shape/pattern/structure, magnetic circuit static parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

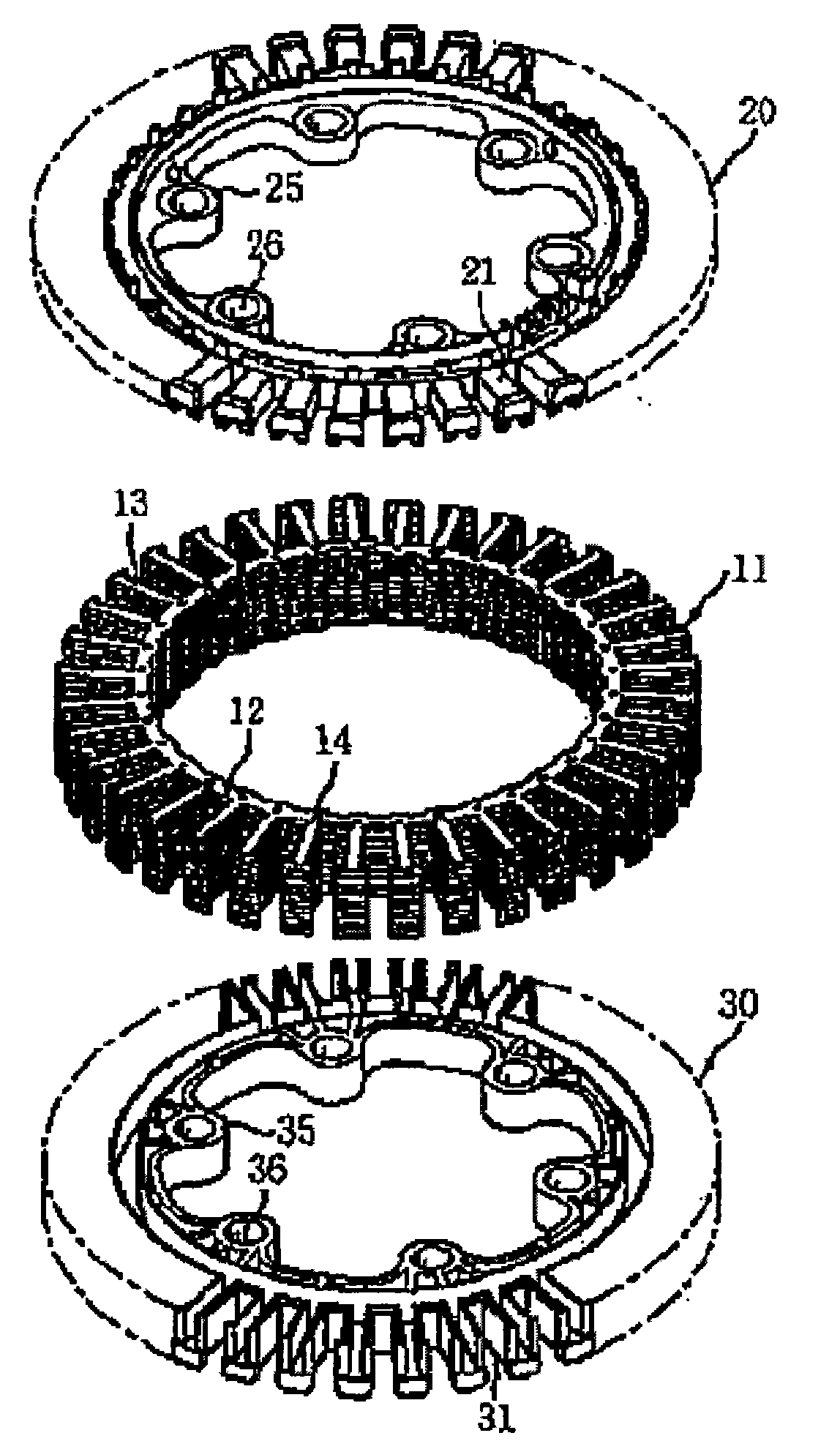

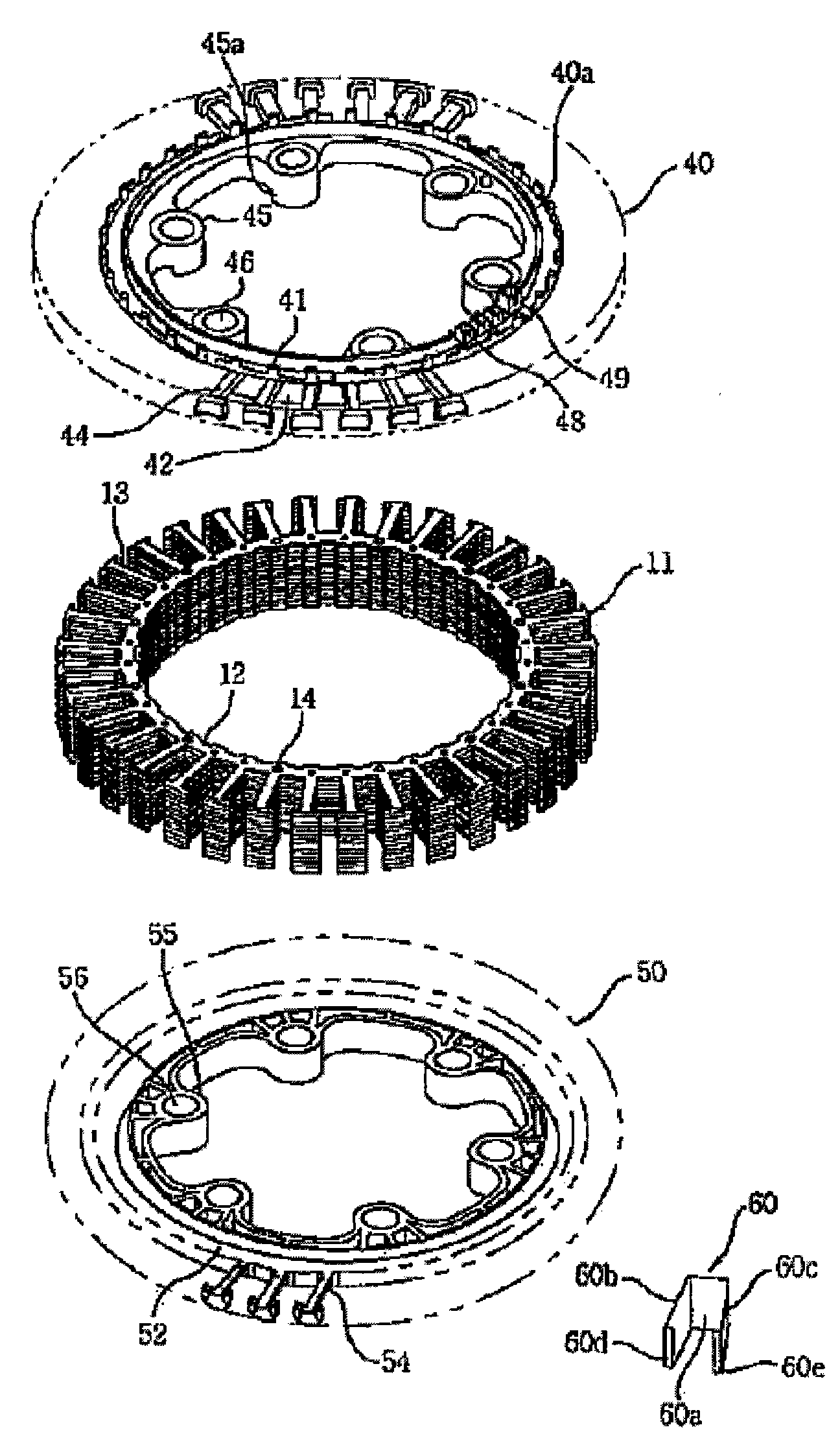

[0043] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

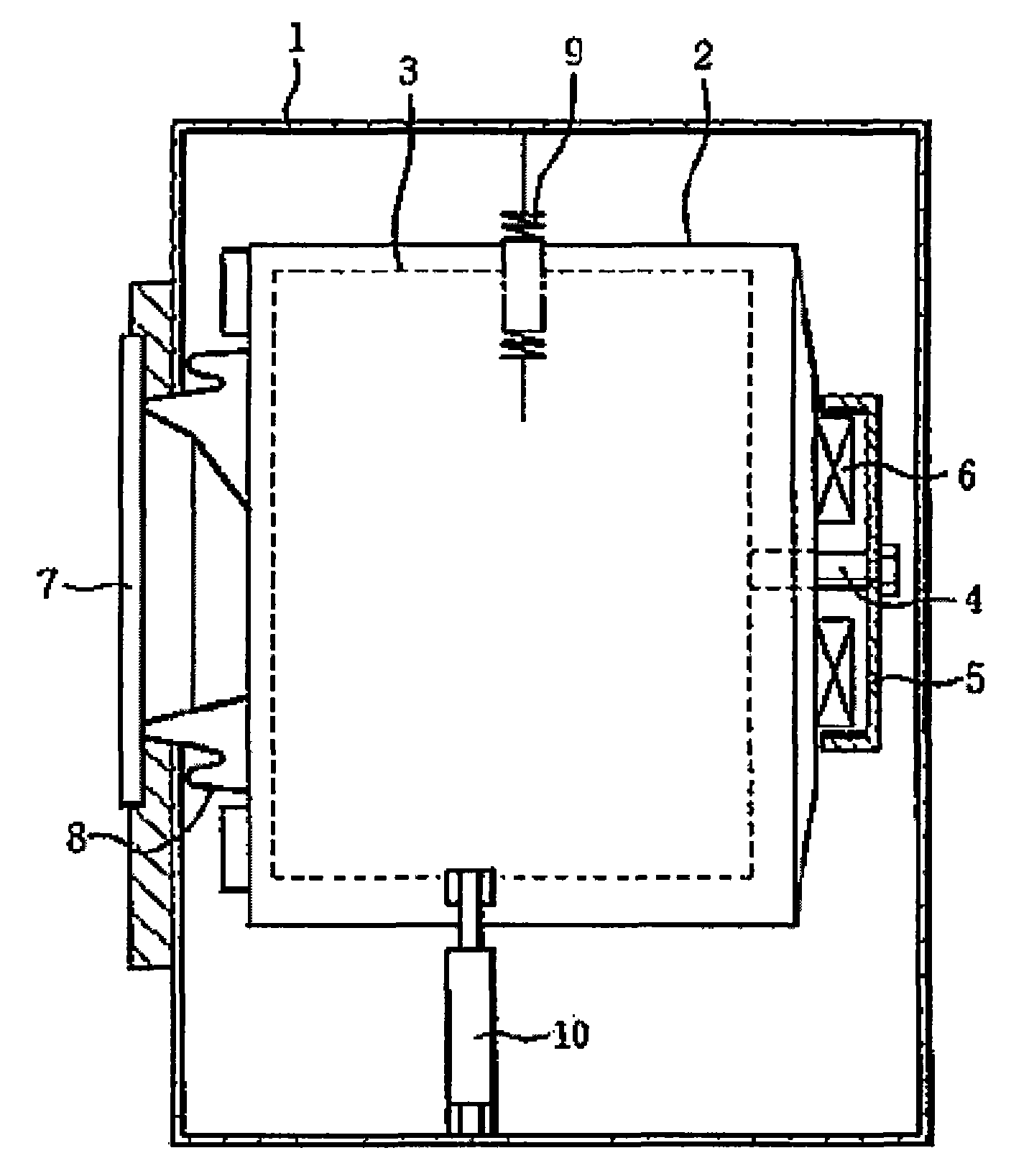

[0044] The drum washing machine is taken as an example for description. In general, the washing method of the drum washing machine is as follows: in a state where detergent, washing water and laundry are put into the drum, the washing operation is performed by using the friction force between the drum rotated by the driving force of the motor and the laundry. The above-mentioned drum washing machine can make the laundry hardly damaged, and the laundry will not be entangled with each other, and at the same time, the washing effect of scrubbing can be obtained. In addition, according to the driving method, the drum washing machine can be divided into: the indirect connection method in which the driving force of the motor is indirectly transmitted to the drum through the belt wound around the pulley of the motor and the drum pulley; the rotor of the motor is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com