Magnetic assembly and winding frame thereof

A technology of magnetic components and bobbins, applied in electrical components, transformer/inductor cores, transformer/inductor components, etc., can solve the problem of occupying the available space of bobbins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A number of embodiments of the present invention will be disclosed below with the accompanying drawings. For the sake of clarity, many practical details will be described together in the following description. However, those skilled in the art should appreciate that in some embodiments of the present invention, these practical details are not necessary and thus should not be used to limit the present invention. In addition, for the sake of simplifying the drawings, some existing conventional structures and components will be shown in a simple and schematic manner in the drawings.

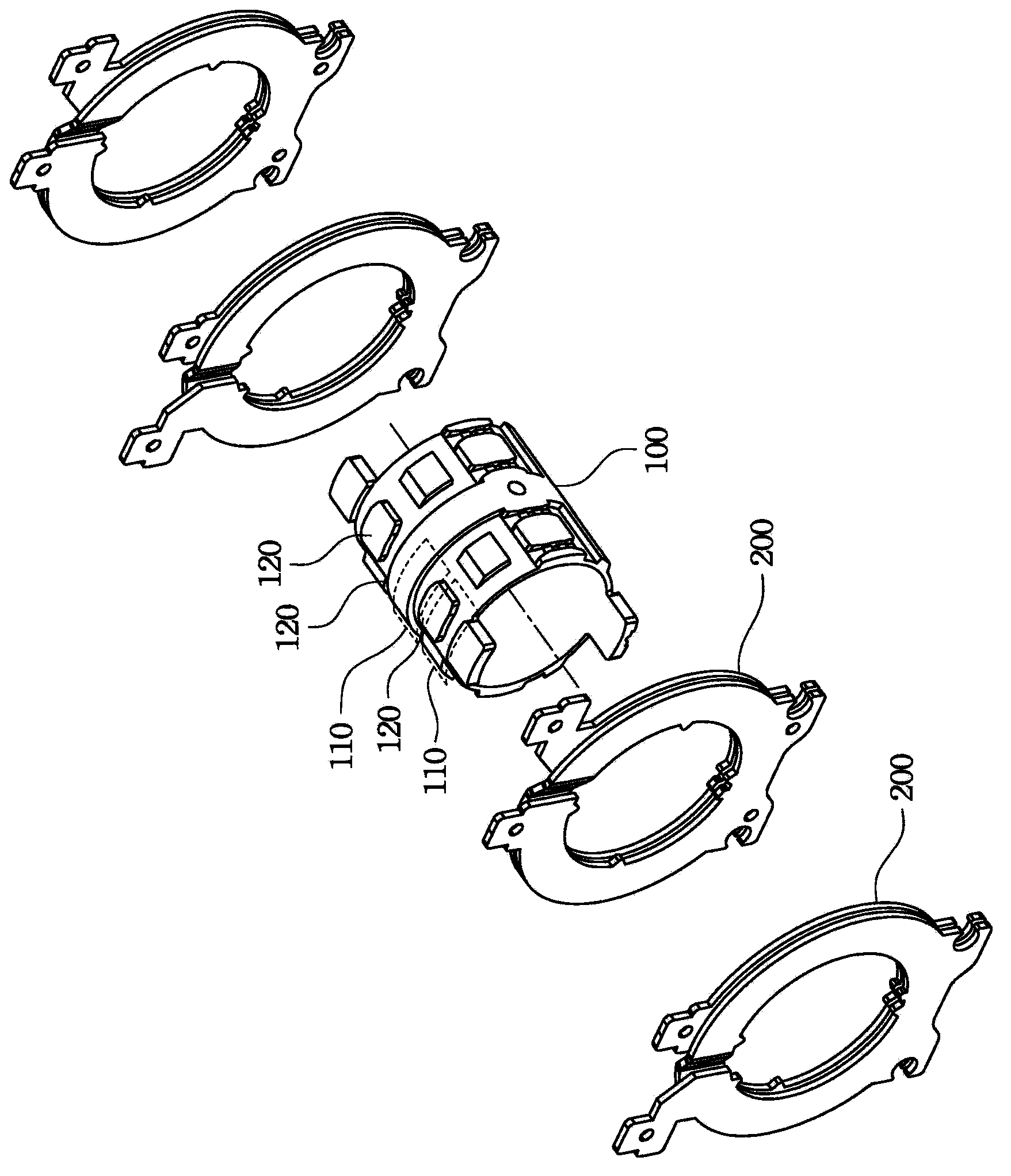

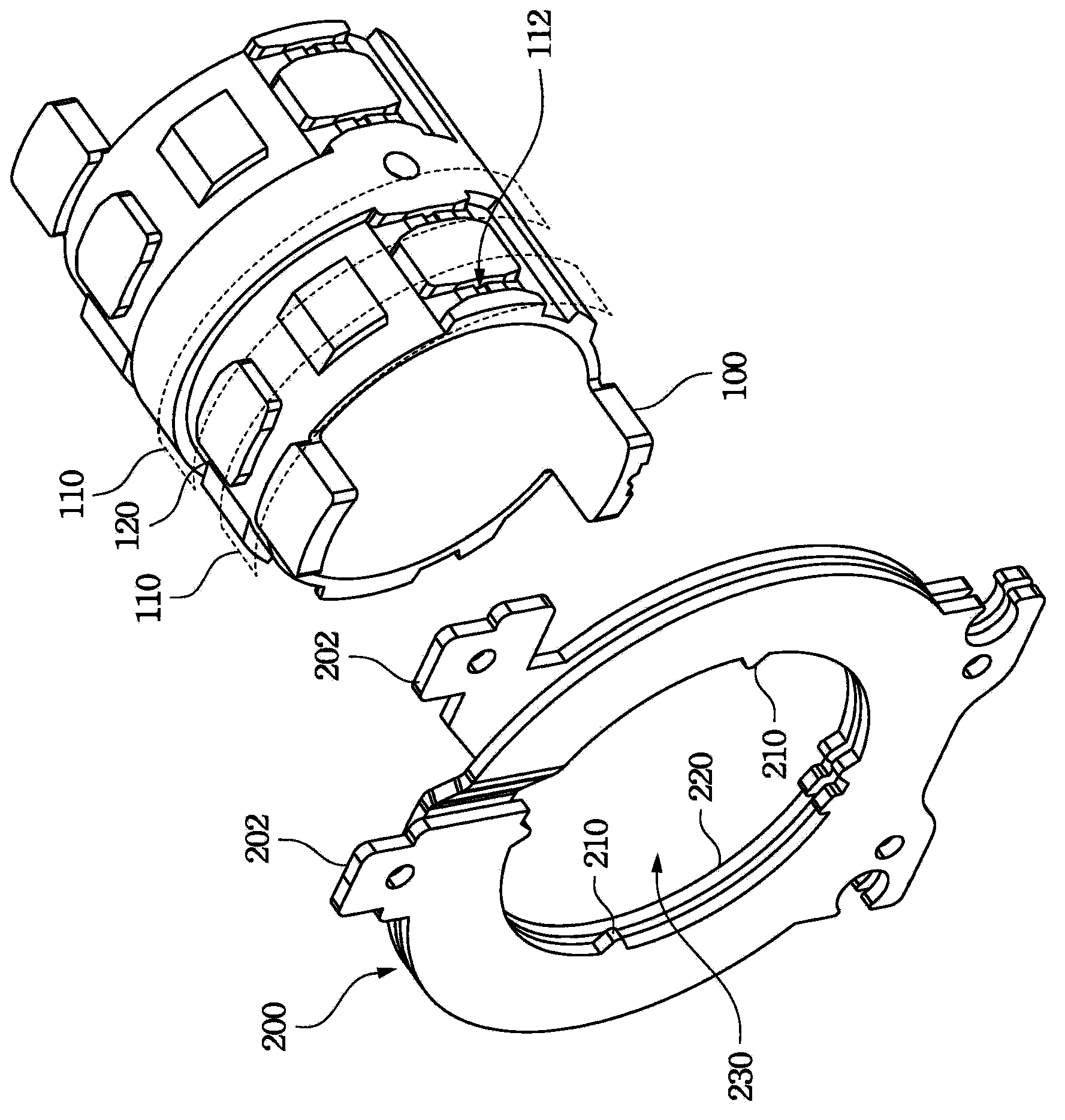

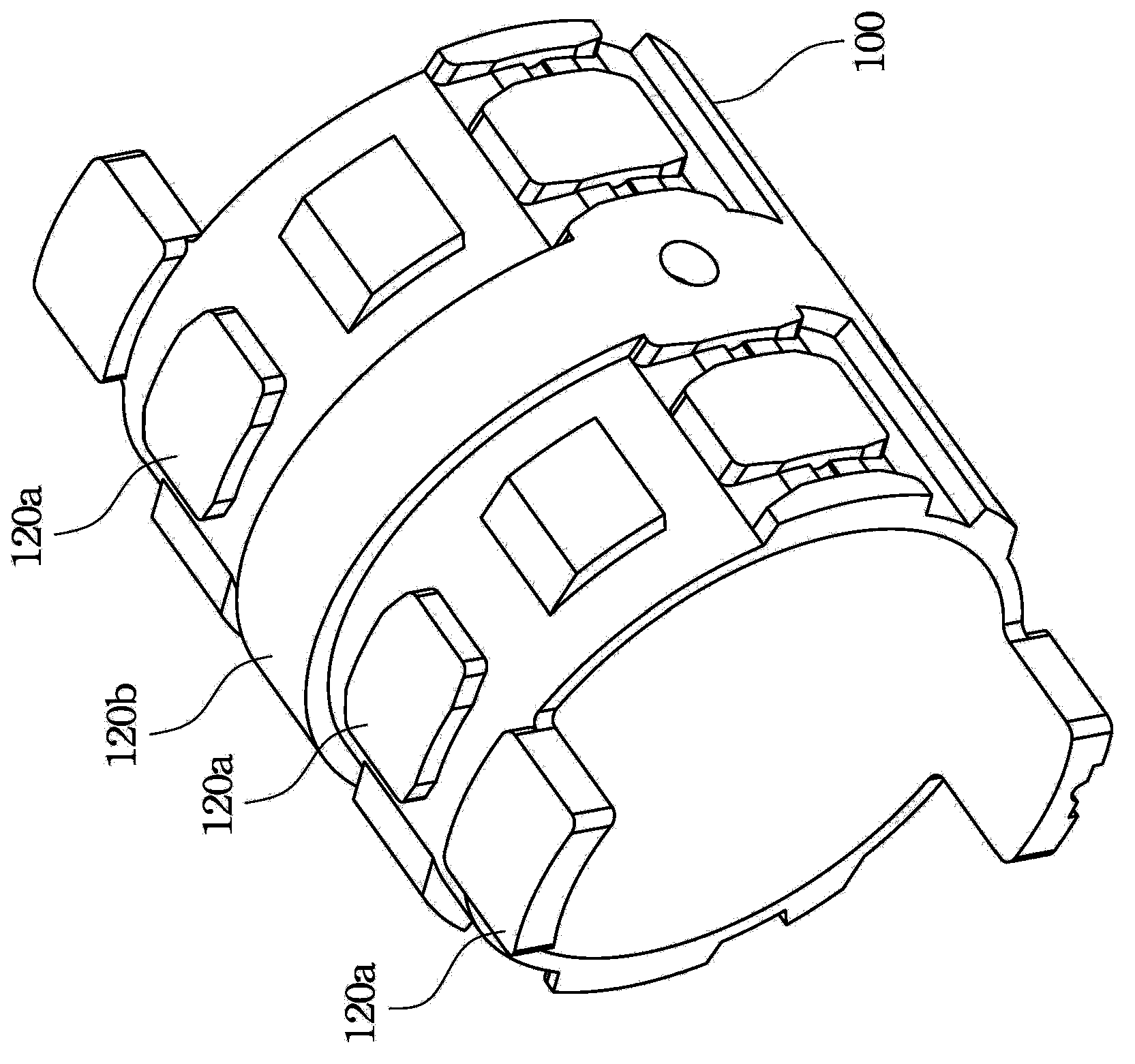

[0039] figure 1 An exploded view showing a bobbin according to an embodiment of the present invention. The winding frame of this embodiment may include a winding sleeve 100 and a plurality of conductive sheet groups 200 . The winding sleeve 100 has a plurality of limiting slots 110 and a plurality of winding bases 120 . The winding bases 120 are generally arranged on the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com