Knitting machine

A knitting machine and warp knitting technology, applied in the field of knitting machines, can solve the problems of reduced productivity, fast running speed, cloth waste, etc., and achieve the effect of increasing winding space, increasing coiling length, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

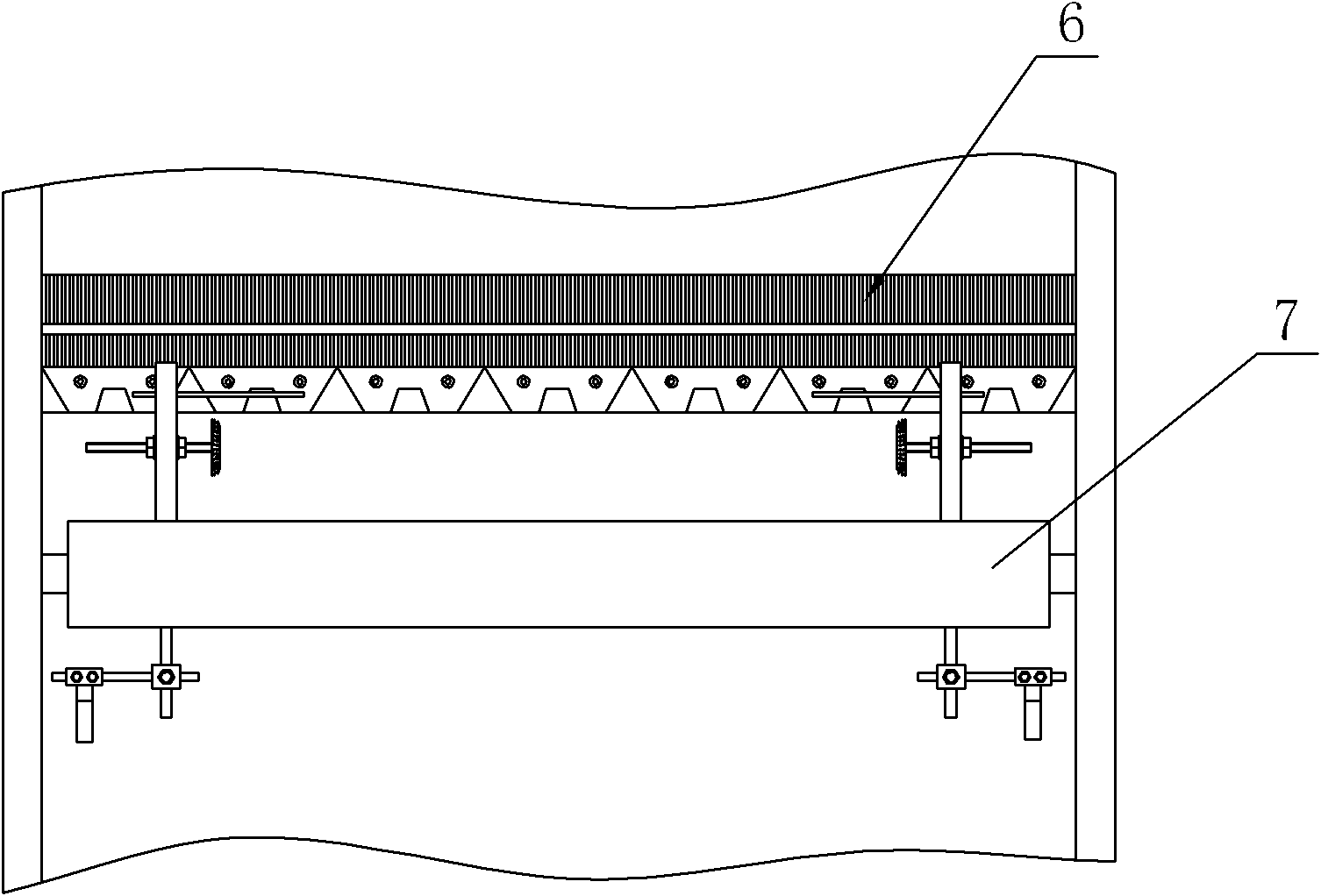

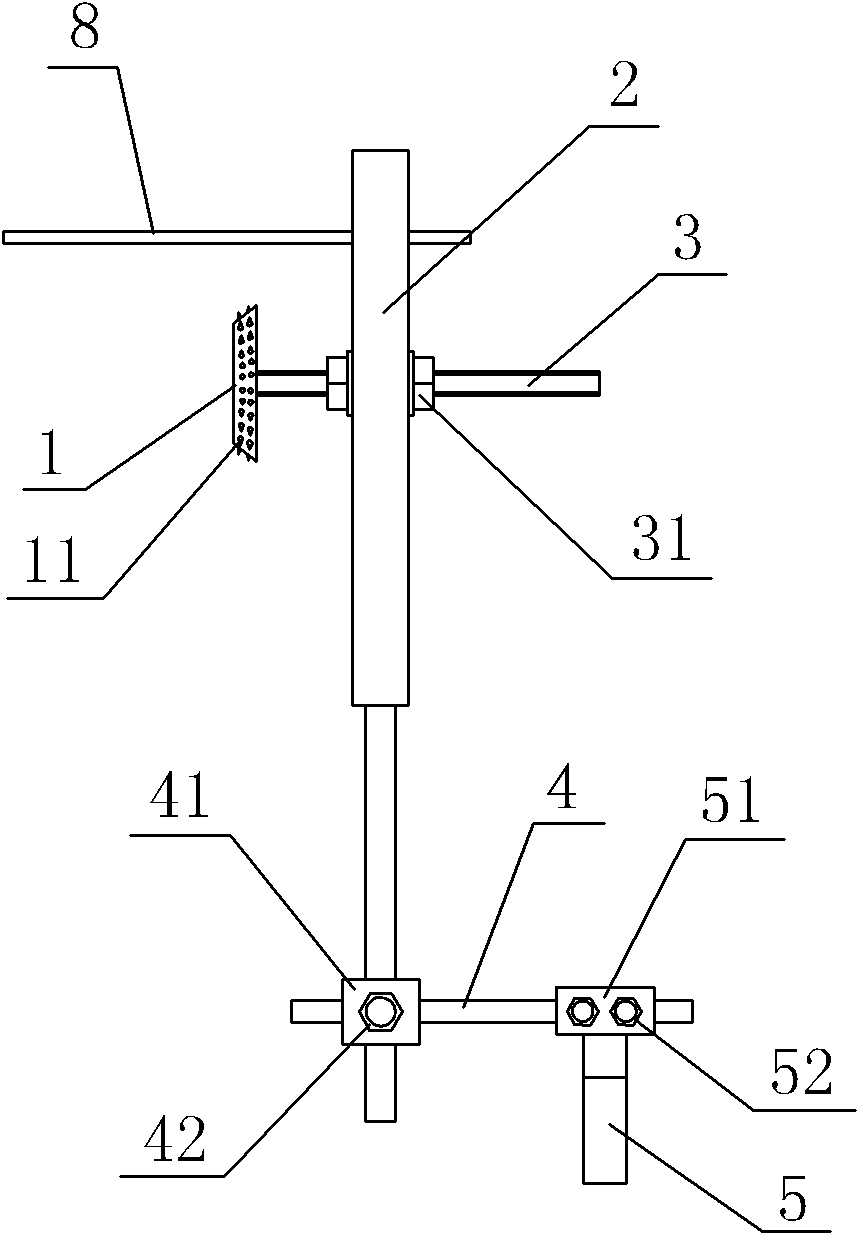

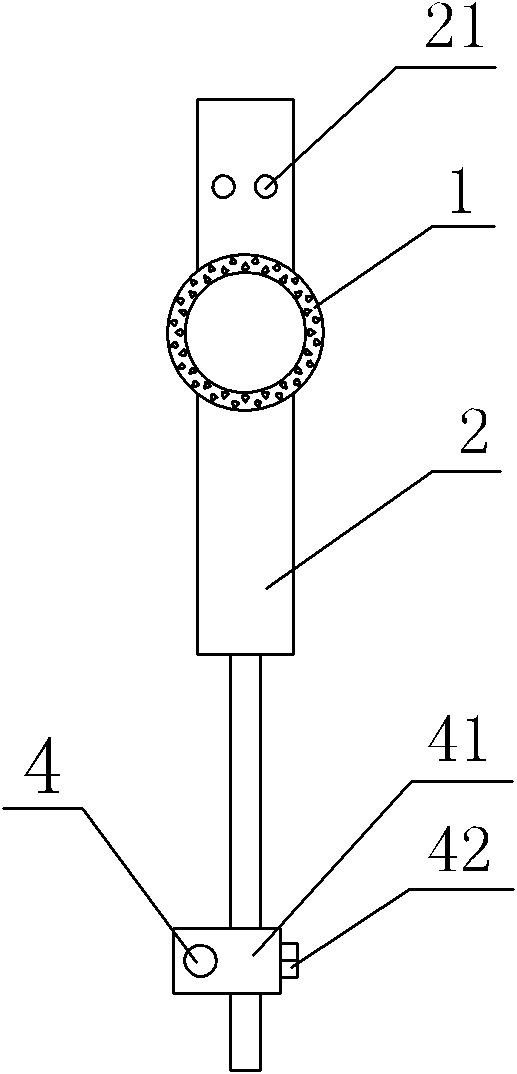

[0022] As shown in the figure, a knitting machine includes a warp knitting assembly 6, a first traction shaft 7, a cloth take-up device, a cloth tension adjustment device and an edge warp breaking self-stopping device, and the cloth tension adjustment device includes a truncated conical pressure wheel 1 , fixed rod 2, support rod 5, the first connecting rod 3, the second connecting rod 4 and the pick bar 8, the pinch roller 1 is positioned between the warp knitting assembly 6 and the first traction shaft 7, the outer circumference of the pinch roller 1 A plurality of evenly distributed protruding points 11 are integrally provided, the pressure wheel 1 is axially connected to the first connecting rod 3, the first connecting rod 3 is a screw rod, the first connecting rod 3 is screw connected to the fixed rod 2, and the first connecting rod 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com