Insulated frame and motor

A technology of insulating skeleton and skeleton, which is applied to the shape/style/structure of winding insulation, electrical components, electromechanical devices, etc., can solve the problems of broken insulation slot paper, inconvenient installation, affecting the full rate of copper winding slots, etc. Achieve the effect of reducing installation difficulty, increasing space, and ensuring slot full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The core of the present invention is to provide an insulating framework to reduce the difficulty of installation while ensuring the fullness of the tank;

[0036] Another core of the present invention is to provide a motor with the above insulating frame.

[0037] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

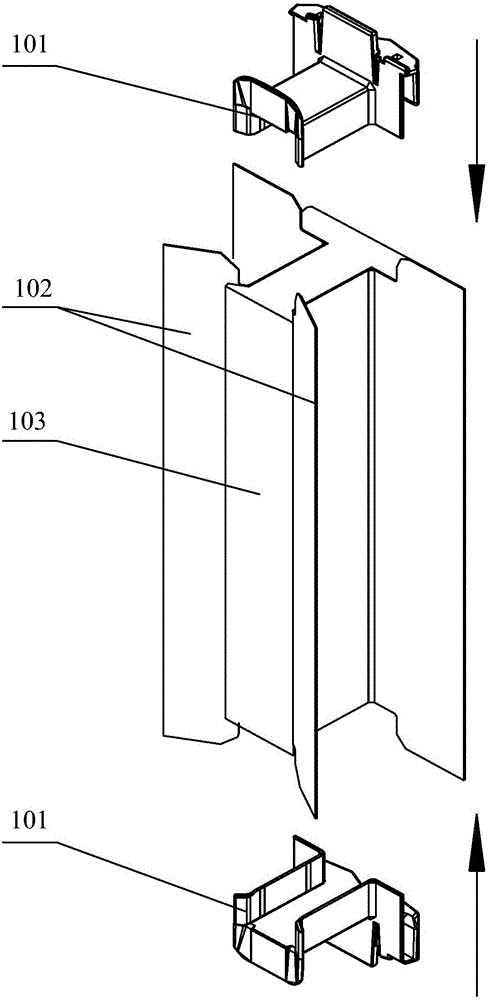

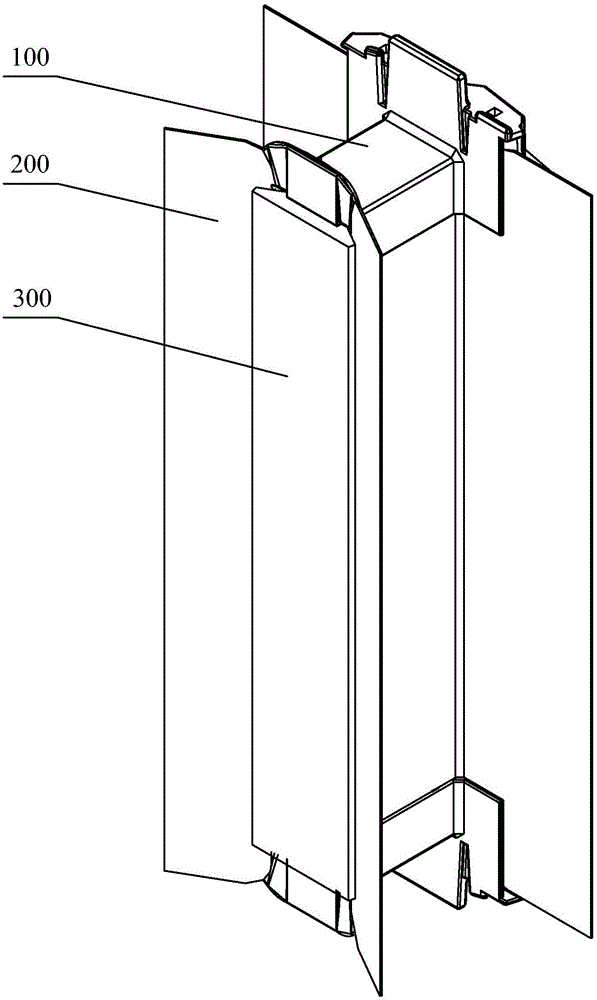

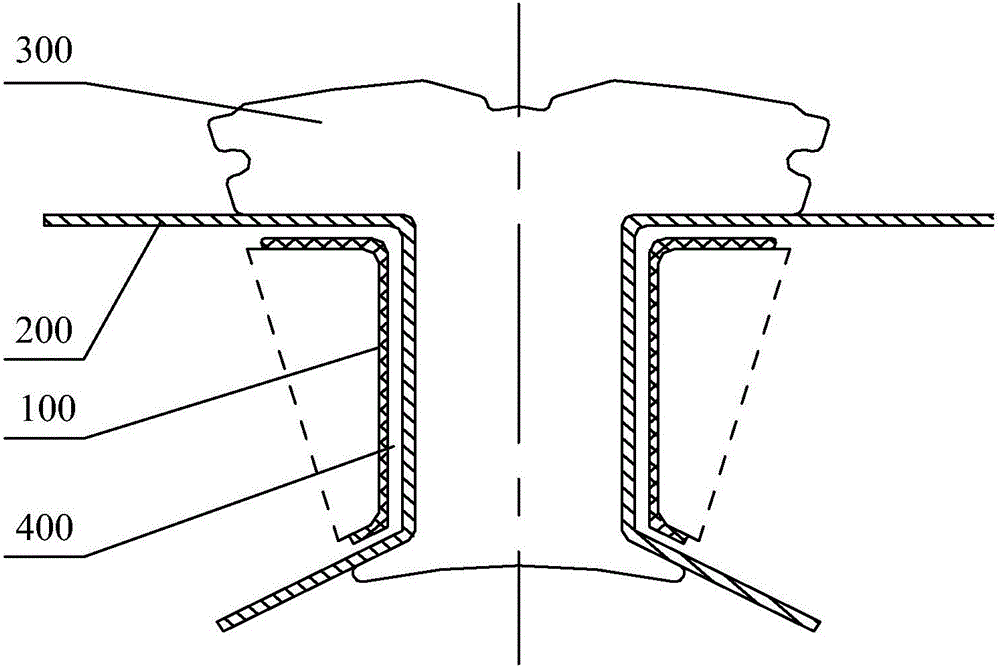

[0038] see Figure 4-Figure 6 , Figure 4 An exploded view of the insulation framework provided by the embodiment of the present invention; Figure 5 An exploded view of an insulating skeleton provided for another embodiment of the present invention; Figure 6 It is a cross-sectional view of the insulating frame provided by the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com