Radiation fan

A heat dissipation fan and fan frame technology, which is applied in the direction of electromechanical devices, electrical components, magnetic circuits, etc., can solve the problems of affecting the magnetic conduction area of the stator and the winding space, and the inability to reduce the volume of the hub and the air intake of the heat dissipation fan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

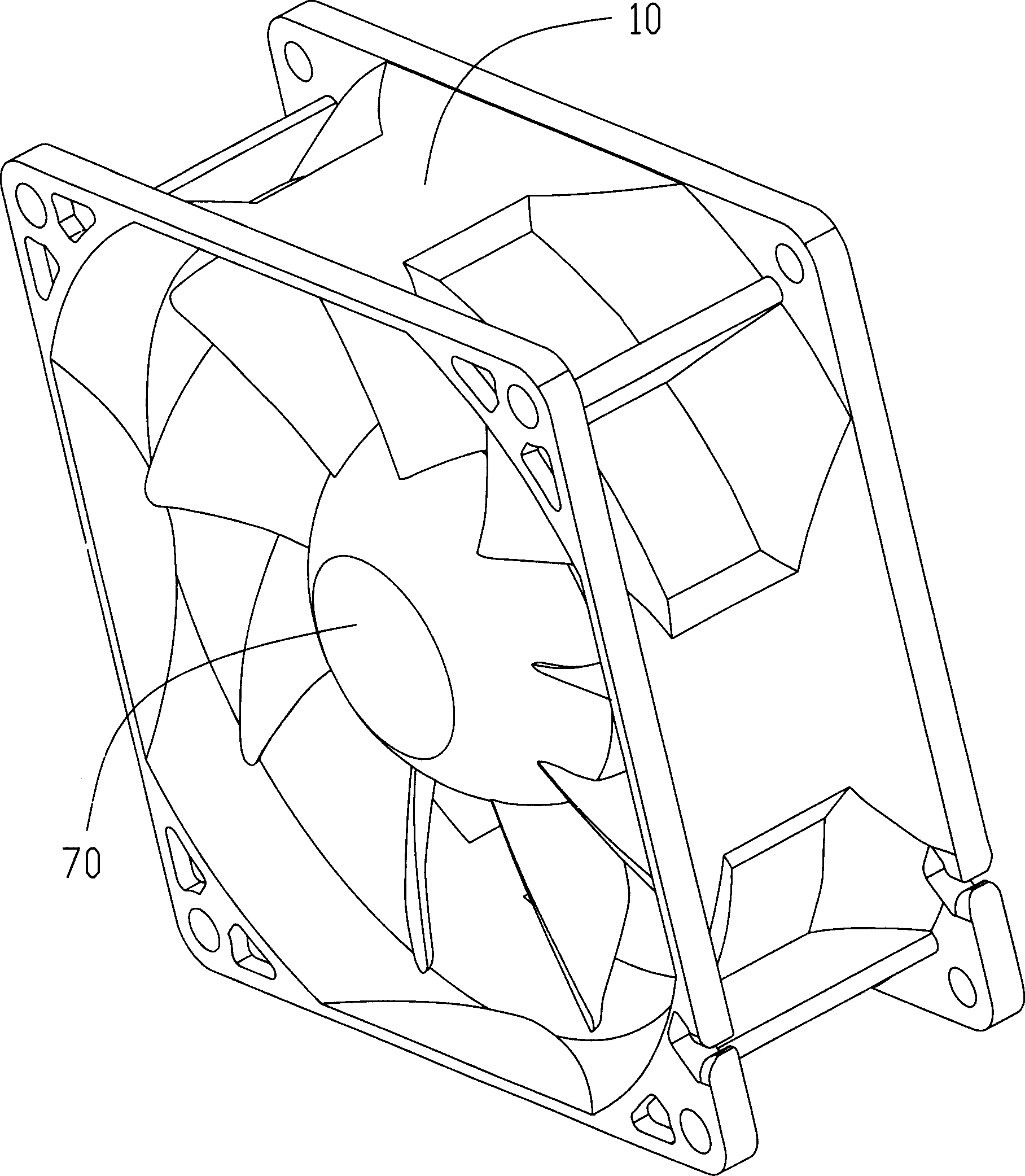

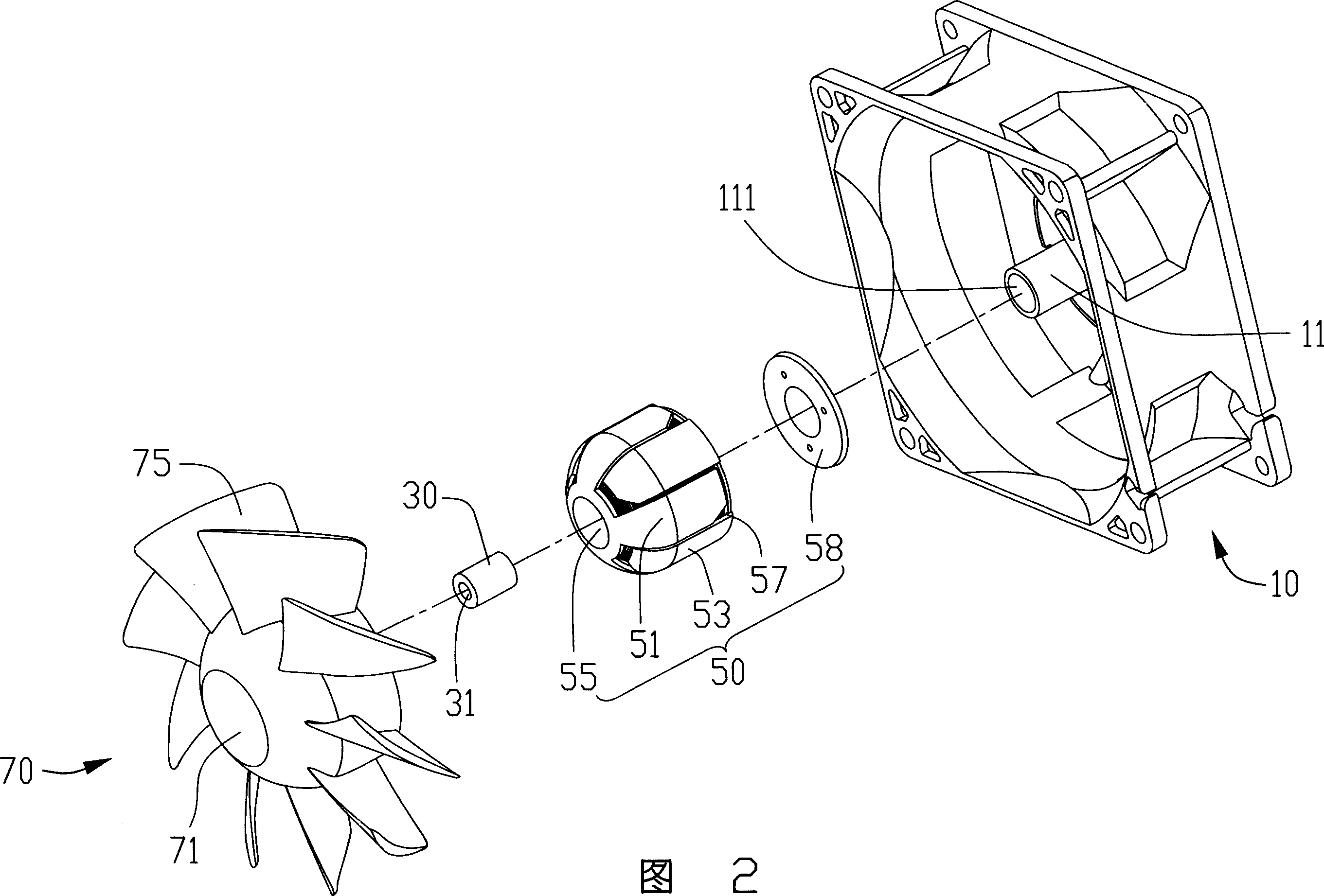

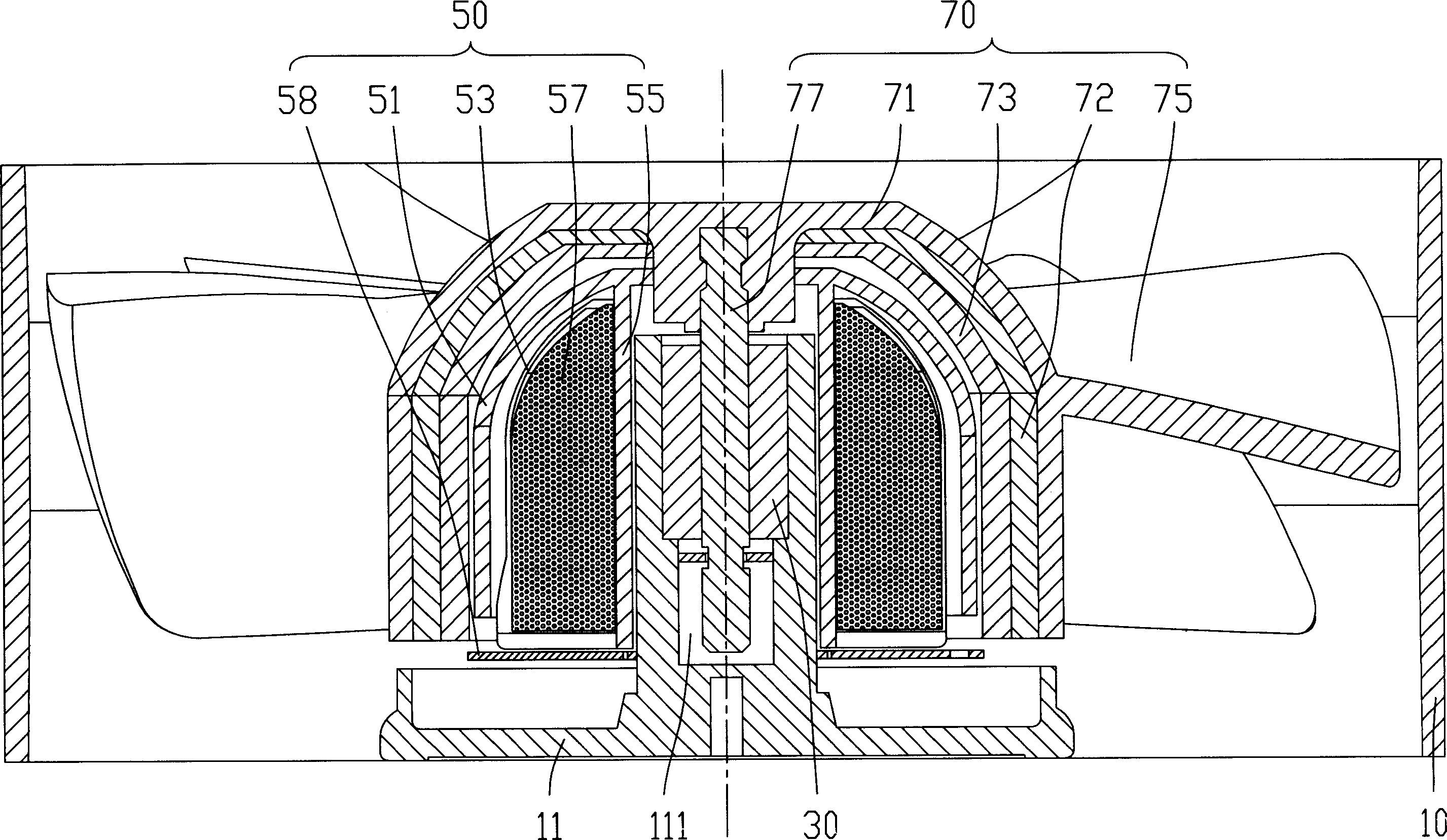

[0023] Such as Figure 1 to Figure 3 As shown, the cooling fan includes a fan frame 10 with a central column 11, a bearing 30 accommodated in the central column 11, a set of stator 50 set on the central column 11 and a rotor rotatably supported by the bearing 30 70.

[0024] A central column 11 protrudes upwards from the center of the fan frame 10 , and a central hole 111 is formed in the central column 11 for accommodating the bearing 30 . The bearing 30 includes a shaft hole 31 through which the rotor 70 passes. The fan frame 10 forms an air outlet corresponding to the bottom of the central column 11, and an air inlet is formed on the other side opposite to the air outlet.

[0025] Please also refer to Figure 4 and Figure 5 , the stator 50 is sleeved on the center column 11 of the fan frame 10, and the stator 50 forms a curved surface structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com